- Home

- Fiberglass Tubes

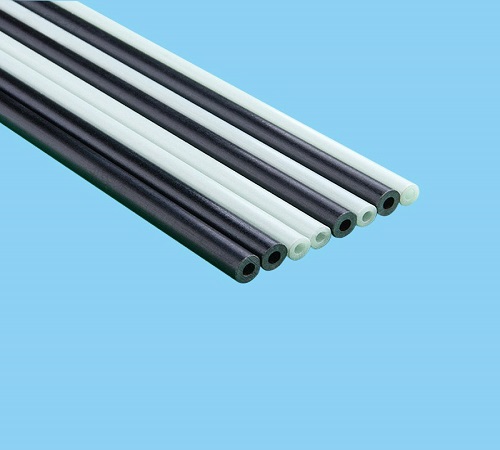

Shop Fiberglass Tubes | Filament Wound Epoxy Tubing

GangLong Fiberglass Tubes are just the ticket for applications that need to balance strength-to-weight and cost or need radio transparency.

Fiberglass Tubes are advanced composite materials renowned for their impressive strength, durability, and lightweight properties. Strong, lightweight Fiberglass Tubes for cost-effective, radio-transparent applications in various styles and sizes. Commonly used as tent poles,Fiberglass is non-conductive, has a high strength-to-weight ratio, and performs well in acidic and corrosive environments. Fiberglass Tubes, available in round and square shapes, are widely used for building equipment stands, tool racks, and support structures.

GangLong Fiberglass is a leading supplier, producing millions of feet of fiberglass tubes annually for various industries, including marine, aeronautical, agriculture, and construction. Made from woven glass fibers and resin, these products, along with fiber glass duct board, offer exceptional resistance to corrosion and are ideal for harsh environments. Their versatility, ease of handling, and reliable performance in extreme conditions make Fiberglass Tubes a preferred choice across industrial and commercial applications.

News

- Exploring the Benefits of Carbon Fiber Apparel

- How to Work with Carbon Fiber Successfully

- Carbon Fiber Suit: The Future of Lightweight Armor

- Is Carbon Fiber Armor the Future of Protection?

- Why White Carbon Fiber is Popular in Automotive Design

- Transparent Carbon Fiber Sheets Two Sided Gloss Twill

- Epoxy-Compatible Chopped Carbon Fiber Mat

- Carbon Fiber EG Hatch: Upgrade Your Civic Today

- The Benefits of Using Structural Carbon Fibre in Engineering

- How Many Layers of Layered Carbon Fiber Are Needed?

Simplifying Your Life: Key Functionalities

| Attribute | Details |

|---|---|

| Place of Origin | Hebei, China (some from Beijing, China) |

| Brand Name | GangLong Fiberglass |

| Material | Fiberglass Reinforced Plastic (FRP), Unsaturated polyester, Epoxy Glass Fabric Laminated Tube |

| Applications | Tent poles, agricultural support poles, electrical equipment, high voltage, industry, and agriculture |

| Techniques | Pultrusion, molding, rolled, and molded processes |

| Surface Treatment | Smooth, UV-resistant, machine-processed |

| Processing Services | Sharpening, drilling, painting, cutting, bending, decoiling, moulding, welding, punching |

| Colors | Customized colors available |

| Shapes | Round tubes, square tubes, section bars |

| Density | 1.7-2.1 g/cm³ |

| Fiberglass Content | 65%-70% |

| Features | Flexible, anti-corrosion, anti-aging, abrasion-resistant, waterproof, heat-insulating, high strength, dielectric properties, anti-corrosion, high mechanical property |

| Certifications | ISO |

| Standards | IEC, NEMA |

| Product Types | FRP poles, hollow rods, rectangular/round tubes, epoxy fiberglass tubes, laminated tubes |

| Supply Ability | 50 Tons per Month |

| OEM Services | Acceptable |

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.

Fiberglass Tubes Standard Dimensions

Fiberglass tubes are composite materials made from glass fibers embedded in a resin matrix, providing a high strength-to-weight ratio and resistance to corrosion and environmental factors. Ideal for various applications due to their non-conductive properties and durability.

Common Dimensions

Diameter:

Standard Sizes: Fiberglass tubes are available in various diameters, commonly ranging from 1 inch to 12 inches.

- Small Diameter: 1″, 1.5″, 2″

- Medium Diameter: 3″, 4″, 5″, 6″

- Large Diameter: 8″, 10″, 12″

Tolerance: Typically, the diameter tolerances can be ±0.05 inches depending on manufacturing processes.

Wall Thickness:

The wall thickness is crucial for determining the strength and flexibility of the tube.

Standard Wall Thicknesses:

- Light Duty: 0.062″ (1/16″)

- Medium Duty: 0.125″ (1/8″)

- Heavy Duty: 0.187″ (3/16″), 0.250″ (1/4″)

Customization: Custom wall thicknesses can be specified based on load requirements and application needs.

Length:

Standard lengths are often available in:

- 10 Feet: Common for shipping and handling.

- 12 Feet: Often used in structural applications.

- Custom Lengths: Available upon request, with lengths exceeding 20 feet possible based on manufacturer capabilities.

- Cutting Services: Many suppliers offer cutting services to achieve specific lengths for projects.

Strength and Load Capacity

- Flexural Strength: Fiberglass tubes exhibit high flexural strength, often measured in psi (pounds per square inch). Typical values range from 40,000 to 70,000 psi, depending on the tube’s design and manufacturing process.

- Load Capacity: Determined by:

- Diameter and wall thickness.

- Length of the span and type of load (axial, lateral, etc.).

- Testing Standards: Load testing may conform to standards like ASTM D198 or similar.

Customization

Many manufacturers provide options for custom sizes and configurations to suit specific applications, including:

- Color and Finish: Gel-coated or painted finishes for aesthetic and protective purposes.

- Reinforcement Options: Additional layers or materials for enhanced strength or specific performance characteristics.

Price Range and Availability

Fiberglass Tubes Price: The cost of Fiberglass Tubes varies based on factors such as diameter, length, and the type of fiberglass used. Prices generally range from around $10 to $200 or more per tube. Larger diameter tubes and those with special requirements or custom specifications tend to be more expensive. Pricing also fluctuates based on market conditions and supplier policies.

Fiberglass Tubes for Sale: GangLong Fiberglass Suppliers sells a wide range of fiberglass tubing. Typical pricing can be found on product pages of GangLong Fiberglass suppliers, where you can compare costs based on size and type. Additionally, bulk purchasing or wholesale options may provide cost savings for larger orders, making it easier to source the necessary quantities for extensive projects.

Standards and Compliance

Compliance with industry standards ensures quality and safety:

- ASTM Standards: For material properties and testing methods.

- ISO Certifications: For manufacturing practices and quality control.

Fiberglass tubes are highly versatile components available in a range of standard dimensions, accommodating various applications across multiple industries. Understanding the specifications regarding diameter, wall thickness, and length is essential for selecting the appropriate tube for your project requirements. Custom options and adherence to industry standards further enhance their usability and reliability.

Key Features of Fiberglass Tubes

Combining exceptional strength, lightweight design, and durability, fiberglass tubes deliver reliable results across diverse applications. Their engineered composition ensures resistance to environmental and mechanical challenges while maintaining cost‑effectiveness and easy installation, making them versatile for industrial and consumer needs.

Non-Corrosive

Fiberglass tubes are inherently non‐corrosive, resisting rust, oxidation, and chemical degradation across harsh environments like marine, industrial, and outdoor applications. Their composition of inert glass fibers and protective resin matrix ensures long‐term performance without protective coatings or frequent maintenance interventions, reducing lifecycle costs while preserving structural integrity and aesthetic appearance even under prolonged exposure to moisture, salts, acids, and alkalis.

Lower Life Cycle Cost

By minimizing maintenance needs, replacement frequency, and downtime, fiberglass tubes deliver a significantly lower lifecycle cost compared to traditional materials. Their remarkable durability, corrosion resistance, and dimensional stability reduce repair expenses and prolong service life, while lightweight handling lowers transportation and installation labor. The result is a cost‐effective solution that optimizes total ownership expenses in industrial, infrastructure, and consumer applications.

Easy to Fabricate and Install

Engineered for simple fabrication and installation, fiberglass tubes can be easily cut, drilled, shaped, or bonded using standard workshop tools and adhesives. Their lightweight construction simplifies handling on‐site, reducing labor requirements and project timelines. Modular joins and mechanical fasteners facilitate rapid assembly without specialized equipment. The result is an efficient installation process that accommodates custom modifications and complex structural configurations.

Lightweight/High Strength

Offering an exceptional strength‐to‐weight ratio, fiberglass tubes provide robust structural support while remaining significantly lighter than steel or aluminum alternatives. This property reduces transportation costs and facilitates handling, crane lifts, and aerial deployment. Engineers leverage this lightweight strength to design slender, efficient frameworks in aerospace, automotive, and civil industries. Performance is maintained under load without sacrificing durability or safety margins.

High Impact Strength

Designed to absorb and dissipate energy, fiberglass tubes exhibit high impact strength, resisting cracks and fractures under loads or collisions. Their composite construction combines flexible glass fibers and resilient resin, allowing deformation without structural failure. This characteristic makes them ideal for applications subject to forces, such as sports equipment, safety barriers, and protective enclosures, where reliability under impact is critical.

Greater Flexural Strength Than Timber

With flexural strength exceeding that of timber, fiberglass tubes endure bending loads without cracking or permanent deformation. Their glass fiber reinforcement and resin bond distribute stress uniformly, preventing localized failure and ensuring consistent performance. This superior bending resistance supports curved components, structures, and load‐bearing frameworks. Architects and engineers prefer fiberglass for applications where timber’s limited flexural capacity would compromise design.

Dimensionally Stable

Fiberglass tubes maintain dimensional stability under wide temperature variation, humidity changes, and load cycles, preventing warping, shrinkage, or expansion. Their composite structure resists thermal deformation, ensuring reliable fit and alignment in assemblies. This stability preserves structural integrity and performance over the long term, reducing the need for realignment or recalibration in critical applications like instrumentation, aerospace components, and architectural installations.

Flame Retardant

Specifically manufactured with fire‐resistant resins and additives, fiberglass tubes exhibit exceptional flame retardant behavior, slowing ignition and self‐extinguishing when exposed to open flames. They meet stringent international safety standards for construction, transportation, and public installations, providing reliable performance in fire‐hazard environments. Their low smoke generation and minimal toxic gas emission enhance safety for occupants and maintenance personnel during emergency situations.

Electrically Non-Conductive

Inherently and completely electrically non‐conductive, fiberglass tubes deliver reliable insulation for power lines, utility poles, antenna masts, and electronic housings. Their high dielectric strength prevents current leakage and reduces electromagnetic interference, ensuring safe operation of high‐voltage and sensitive equipment. The absence of conductive pathways lowers grounding needs and enhances design flexibility in critical electrical infrastructure, modern telecommunications, and high‐frequency applications.

Resists Insect Damage

Unaffected by insects and pests, fiberglass tubes resist termite, beetle, and fungus attacks, ensuring long‐term structural integrity in agricultural, forestry, and demanding outdoor furniture applications. Their inorganic glass fibers and resin matrix provide no nutritional value for biological organisms, eliminating the risk of infestation and decay. This pest resistance reduces maintenance demands and safeguards investments in rural and urban environments.

Low Water Absorption

With low water absorption rates, fiberglass tubes prevent swelling, softening, and microbial growth when exposed to extreme moisture or submerged environments. Their sealed resin matrix limits moisture ingress, preserving mechanical properties and dimensional accuracy. This hydrophobic behavior makes them ideal for marine structures, industrial water treatment systems, and outdoor installations, where efficient moisture resilience ensures long‐term performance and hygiene compliance.

Non-Leeching

Fiberglass tubes are non‐leeching, releasing no harmful substances into surrounding media, making them safe for potable water transport, food processing equipment, and environmental containment systems. Their inert glass fiber and resin components maintain chemical purity, preventing contamination and ensuring regulatory compliance. This characteristic protects product quality and public health in applications requiring strict material safety standards and minimal environmental impact.

Comparison of Fiberglass Tube Types and Features

The table below summarizes three major fiberglass tube variants—round fiberglass tubes, fiberglass square tube, and filament wound epoxy tubing—highlighting their shapes and dimensions, core properties, and common applications. By comparing factors such as strength-to-weight ratio, corrosion resistance, ease of fabrication, and features like radio transparency, you can swiftly determine the ideal tubing type for your specific project requirements.

| Type | Shape & Dimensions | Properties | Applications |

|---|---|---|---|

| Round Fiberglass Tubes | Cylindrical; various diameters & wall thicknesses | High strength-to-weight; corrosion-resistant; lightweight | Piping; wiring conduit; supports |

| Square Fiberglass Tubes | Square cross-section; various side lengths & walls | Stable stacking; versatile; corrosion-resistant | Furniture; shelving; architectural |

| Filament Wound Epoxy Tubing | Glass fiber wound on mandrel; customizable | Superior strength-to-weight; radio-transparent; cost-effective | Antennas; tent poles; hobby |

Pultruded Fiberglass Tubes

Pultruded fiberglass tubes are created through a manufacturing process called pultrusion, where fiberglass fibers are drawn through a resin bath and then cured in a heated die to form continuous lengths of tube. This method results in strong, lightweight structures with uniform cross-sections.

Manufacturing Process

Pultruded fiberglass tubes are made by pulling continuous fiberglass strands through a resin bath into a heated die where they cure, forming a uniform, void‑free profile. This pultrusion process ensures consistent density and strength along the tube’s length and allows for the production of very long, unbroken sections ideal for large‑scale structural or framing applications.

Material Properties

These tubes combine high tensile and compressive strength—capable of supporting heavy loads—with a weight significantly lower than metal alternatives, reducing handling and shipping costs. Their inherent resistance to chemicals, moisture, and corrosion makes them particularly durable in marine, chemical processing, and other harsh environments where maintenance and replacement are challenging.

Economic Benefits

Although pultruded fiberglass tubes may cost more initially than some traditional materials, their exceptional durability and virtually maintenance‑free performance deliver substantial lifecycle savings. Additionally, many formulations are recyclable at end‑of‑life, enabling material recovery and supporting sustainable development initiatives by reducing waste and resource consumption over the product’s lifespan.

Design Flexibility

Pultruded tubes can be tailored in diameter, wall thickness, and color to meet precise engineering, structural, or decorative requirements. This customization capability allows their use not only in industrial frameworks and support structures but also in aesthetic applications—such as furniture, architectural accents, and signage—where both form and function are equally important.

GangLong Fiberglass: Your Reliable Partner for Fiberglass Tubing

GangLong Fiberglass is dedicated to providing premium fiberglass tubing solutions for a wide range of industries. Whether you need lightweight, high‑strength components for aerospace or cost‑effective bulk orders for construction, our end‑to‑end service—from material selection to after‑sales support—ensures seamless integration and reliable performance. Discover why engineers and procurement specialists worldwide choose GangLong Fiberglass as their trusted partner.

Reputation for Quality

With decades of expertise, GangLong Fiberglass ensures each tube meets strict quality benchmarks. We inspect raw materials, monitor the manufacturing process, and verify final dimensions and mechanical properties. Customers value our consistent tolerance accuracy and surface finish, which reduce installation errors and material waste. Our commitment to excellence guarantees that every fiberglass tube performs as expected under real‑world conditions.

Comprehensive Product Range

Our extensive portfolio includes tubes from 6 mm to 200 mm in diameter, 0.5 mm to 10 mm wall thickness, and lengths up to 12 m, available in polyester, vinyl ester, or epoxy resins. We also offer pultruded profiles, custom colors, finishes, and pre‑drilled features. Whether you require tent poles, structural supports, or specialized reinforcements, GangLong Fiberglass delivers the right configuration for any project. Shop our full range online today.

Detailed Specifications

We provide full datasheets for every product, detailing tensile strength, flexural modulus, impact resistance, glass transition temperature, service‑temperature range, chemical‑resistance data, dimensional tolerances, and surface characteristics. All specifications are backed by ISO 9001 and ASTM test reports. This transparency ensures you receive tubing that precisely matches your design requirements and quality standards.

Industry Standards

GangLong Fiberglass adheres to ASTM D578, ISO 9001, and RoHS standards. Our in‑house lab performs chemical exposure tests, heat‑ageing cycles, and fatigue analyses to verify ongoing compliance. Certifications and comprehensive test data are available on request, supporting your internal audits and project approvals. Trust our rigorously certified products for critical applications demanding consistent quality and safety.

Support and Service

Beyond supplying tubing, we offer engineering consultation, rapid prototyping, pilot production runs, and installation training. Our customer service team coordinates logistics, customs documentation, and delivery tracking. Post‑delivery, we remain on call for troubleshooting and maintenance advice. With GangLong Fiberglass as your technical partner, you gain expert guidance throughout your project’s lifespan.

Competitive Pricing

Leveraging efficient manufacturing and global sourcing, GangLong Fiberglass offers transparent quotes breaking down material, labor, and logistics costs. We provide volume discounts, annual contract rates, and flexible payment terms. By eliminating hidden fees and optimizing supply chains, we deliver exceptional value, helping your projects stay on budget without compromising performance. Shop now for exclusive pricing offers.

FAQs about Fiberglass Tubes

What is the strength of a fiberglass tube?

How do you cut a fiberglass tube?

Can You Paint Fiberglass Tubes?

Cleaning: Thoroughly clean the fiberglass surface to remove dirt, grease, and any contaminants.

Sanding: Lightly sand the surface with fine-grit sandpaper to create a rough texture, which helps the paint adhere better.

Priming: Use a primer designed for fiberglass to enhance adhesion and improve the paint's longevity.

Painting: Apply paint suitable for fiberglass, such as marine-grade paint or acrylic paint, in thin, even coats. Make sure to allow adequate drying time between coats.

What Are the Three Types of Fiberglass?

Description: Made from random strands of fiberglass, CSM is bonded together with a resin. It’s commonly used for creating flat surfaces and provides good strength and flexibility.

Applications: Often used in boat building, automotive parts, and general fiberglass applications.

Woven Roving:

Description: Composed of woven fiberglass strands, this type offers greater strength and is less flexible than CSM. It is thicker and provides a higher tensile strength.

Applications: Typically used in applications requiring high strength, such as in the construction of boats, automotive parts, and industrial applications.

Fiberglass Cloth:

Description: Made from tightly woven fiberglass strands, this type provides excellent strength and durability. It can be used with various resins for specific applications.

Applications: Commonly used in high-performance applications like aerospace, automotive, and high-strength structural components.

What are fiberglass tubes used for?

How long do fiberglass mortar tubes last?

What is fiberglass most used for?

Can you reuse fiberglass fireworks tubes?

What are the benefits of fiberglass pipes?

Corrosion Resistance: They are highly resistant to corrosion, making them ideal for transporting corrosive fluids or in corrosive environments.

Lightweight: Fiberglass pipes are much lighter than metal pipes, making them easier to transport and install.

High Strength: Despite their lightweight nature, fiberglass pipes are strong and can withstand significant pressure.

Durability: They have a long lifespan, with excellent resistance to environmental degradation.

Low Maintenance: They require less maintenance compared to metal pipes, reducing long-term operational costs.

Why do people use fiberglass?

Where is fiberglass pipe used?

Who needs fiberglass?

How strong is fiberglass pipe?

How do you cut fiberglass tubing?

Mark the Cut Line: Use a marker or tape to mark the line where you want to cut.

Secure the Tubing: Clamp the tubing securely to prevent it from moving during the cut.

Use the Right Tool: Use a fine-toothed saw or a cutting wheel designed for fiberglass.

Cut Slowly: Apply gentle pressure and cut slowly to avoid splintering or cracking the fiberglass.

Smooth the Edges: After cutting, use sandpaper or a file to smooth the edges to prevent splinters.

What is the best tool to cut fiberglass?

How do you cut fiberglass without cracking it?

Use the Right Blade: Choose a fine-toothed or diamond-grit blade specifically designed for cutting fiberglass.

Secure the Material: Ensure the fiberglass is securely clamped to minimize movement during cutting.

Cut at a Steady Pace: Avoid forcing the tool through the material; instead, cut slowly and steadily to prevent cracking.

Score Before Cutting: For thinner fiberglass, scoring the cut line with a utility knife before cutting can help guide the blade and reduce the risk of cracking.

Cool the Blade: If using a power tool, keep the blade cool by cutting in short bursts or using water to prevent overheating, which can lead to cracking.

How do you cut fiberglass by hand?

Use a Fine-Toothed Saw: A hacksaw with a fine-toothed blade or a handsaw designed for composite materials is suitable.

Mark the Cut Line: Clearly mark the cutting line on the fiberglass.

Secure the Material: Clamp the fiberglass securely to prevent movement.

Saw Gently: Begin sawing gently along the marked line, applying consistent pressure without forcing the blade.

Smooth the Edges: After cutting, use sandpaper or a file to smooth the edges.

What kind of blade to cut fiberglass?

Is it safe to cut up fibreglass?

Wear Protective Gear: Always wear safety goggles, gloves, and a dust mask or respirator to protect against fiberglass dust and particles.

Work in a Well-Ventilated Area: Ensure good ventilation to avoid inhaling fiberglass dust.

Avoid Skin Contact: Cover exposed skin to prevent irritation from fiberglass particles.

Clean Up Thoroughly: After cutting, clean up the area carefully to remove any fiberglass dust.

Can luse a circular saw to cut fiberglass?

Can you cut fiberglass rebar with a hacksaw?

Should you wear a mask when cutting fiberglass?

How strong is fiberglass tubing?

How hard is fiberglass to break?

What is the strongest type of tubing?

Is fiberglass stronger than steel?

What weakens fiberglass?

UV Exposure: Prolonged exposure to sunlight can degrade the resin, leading to brittleness and weakening of the fiberglass structure.

Moisture Ingress: Water penetration can cause delamination or swelling of the resin matrix, reducing the strength of the composite.

Chemical Exposure: Certain chemicals can degrade the resin, leading to reduced structural integrity.

Physical Damage: Cracks, cuts, or impacts can introduce weaknesses that may propagate over time.

Excessive Heat: While fiberglass is heat resistant, excessive temperatures can soften or degrade the resin.

What is the strongest type of fiberglass?

How much weight can Fibreglass hold?

How long does fiberglass pipe last?

Is Fibreglass stronger than PVC?

Is fiberglass stronger than plastic?

Can fiberglass withstand pressure?

What is fiberglass tubing used for?

Structural supports: In construction, electrical, and marine industries.

Protective sleeves: For cables and wires.

Sports equipment: Like tent poles, kite frames, and archery bows.

Industrial components: In chemical processing and water treatment plants.

Aerospace and automotive: For lightweight and durable structural components.

What is fiberglass conduit used for?

What are the disadvantages of fiberglass conduit?

Cost: Fiberglass conduit is more expensive than other types of conduit like PVC or metal.

Brittleness: It can be more brittle than PVC, especially in colder temperatures, which may lead to cracking if not handled properly.

Limited Impact Resistance: Although strong, fiberglass conduit can crack or splinter under severe impact.

Special Handling: Requires specialized tools for cutting and installation.

Is fiberglass conduit cheaper than PVC?

Why use fiberglass pipe?

How do you cut fiberglass conduit?

Mark the Cut Line: Clearly mark where you need to cut.

Secure the Conduit: Clamp the conduit firmly to prevent it from moving during the cut.

Use the Right Tool: Use a fine-toothed saw, such as a hacksaw or a power tool with a diamond-grit blade, to make the cut.

Cut Slowly: Apply steady pressure and cut slowly to avoid splintering or cracking the fiberglass.

Smooth the Edges: Use sandpaper or a file to smooth the cut edges and remove any sharp fibers.

Is PVC the same as fiberglass?

Which is stronger, pVC or conduit?

Is fiberglass conduit fire rated?

What is the NEC code for fiberglass conduit?

What are the uses of fiberglass tubing?

Electrical Insulation: As conduit for wires and cables, especially in corrosive or high-temperature environments.

Structural Supports: In construction, as lightweight, corrosion-resistant beams and frames.

Marine Applications: For masts, booms, and other structural components in boats.

Aerospace: In lightweight, strong components for aircraft.

Recreational Equipment: For poles, tent frames, and sports gear.

What is fiberglass wire used for?

Do you need conduit for fiber?

What is the best conduit to use?

PVC Conduit: Good for general use, especially in residential applications where flexibility and low cost are important.

Fiberglass Conduit: Ideal for industrial environments where corrosion resistance and high strength are needed.

Metal Conduit (EMT, RMC): Suitable for areas where high impact resistance and fire protection are important.

Flexible Conduit: Useful in situations where the conduit needs to bend around obstacles or in tight spaces.