- Home

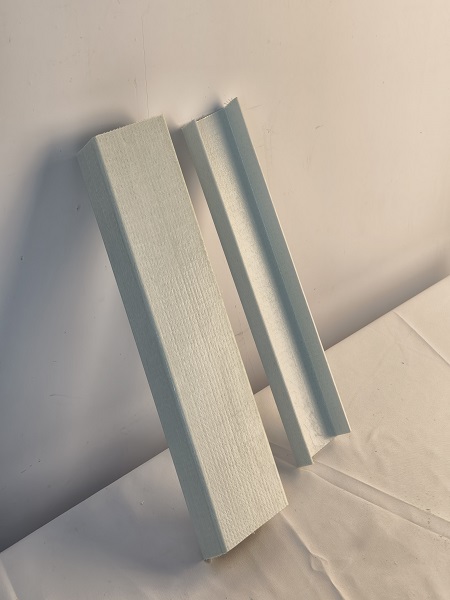

- Fiberglass Channels

Fiberglass Channels-Structural Fiberglass FRP Channel

GangLong Structural Fiberglass Channel: Non-Corrosive, Lower Life Cycle Cost,Easy to Fabricate and Install,Lightweight/High Strength.

Fiberglass Channels offer a robust alternative to traditional materials like steel, which can rust and degrade under environmental stress. Fiberglass Channels are available in different resin types for varying degrees of corrosion resistance and colors, enhancing their adaptability across various industries.Choose from our Fiberglass Channels: lightweight, corrosion-resistant, high strength, easy to install, with fast delivery in various sizes.

Made entirely from corrosion-resistant resins, GangLong Fiberglass‘s Fiberglass Channels are suitable for severe environments, providing a versatile solution for structural supports such as ladder rails, step stringers, and pedestrian bridges. These channels do not rot, decay, or succumb to insect damage, unlike timber. Additionally, they do not require environmentally harmful preservatives, making them a sustainable choice. They are also lighter and stronger than structural timber, non-conductive, and impact-resistant, making them ideal for a wide range of industrial applications.

Simplifying Your Life: Key Functionalities

| Attribute | Details |

|---|---|

| Type | Fiberglass Channels |

| Material | Fiberglass yarn, resin, filler |

| Applications | Pool cover systems, construction, industrial, cooling towers |

| Technique | Pultrusion |

| Fiberglass Content | 65%-70% |

| Density | 1.9-2.1g/cm³ |

| Surface Treatment | Smooth, polished, natural, UV-resistant |

| Processing Services | Cutting, punching, sharpening, bending, welding, decoiling, painting |

| Colors | Customized colors |

| Features | Anti-corrosion, anti-aging, lightweight, high strength, flexible,Higher strength, light weight, flexible, durable |

| Packaging Details | Cartons, plastic woven belt, air bubble paper, pallets, PE foam, pearl cottons, crates, woven bags |

| Certification | ISO9001 |

| OEM Services | Available |

| Service | 24/7 online support |

| Brands | GangLong Fiberglass |

| Place of Origin | Hebei, China |

News

- Exploring the Benefits of Carbon Fiber Apparel

- How to Work with Carbon Fiber Successfully

- Carbon Fiber Suit: The Future of Lightweight Armor

- Is Carbon Fiber Armor the Future of Protection?

- Why White Carbon Fiber is Popular in Automotive Design

- Transparent Carbon Fiber Sheets Two Sided Gloss Twill

- Epoxy-Compatible Chopped Carbon Fiber Mat

- Carbon Fiber EG Hatch: Upgrade Your Civic Today

- The Benefits of Using Structural Carbon Fibre in Engineering

- How Many Layers of Layered Carbon Fiber Are Needed?

Types of Fiberglass Channels

Fiberglass Channels come in various shapes and sizes, each designed for specific applications and offering distinct benefits. Here’s a closer look at the different types:

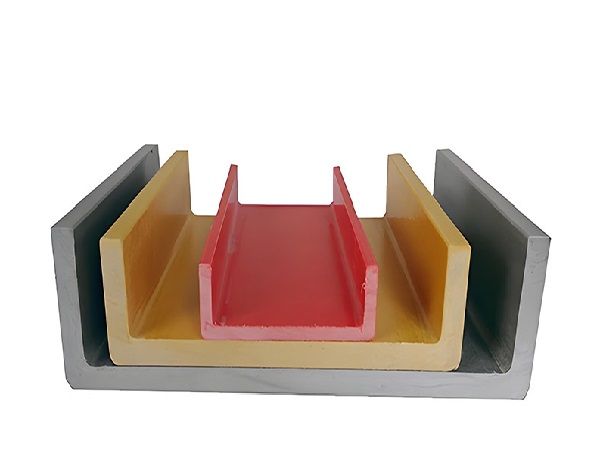

Fiberglass U Channel

Definition and Composition: Fiberglass U Channels are named for their U-shaped cross-section. Made from fiberglass-reinforced plastic, these channels are known for their strength and lightweight properties. They consist of a composite material that combines glass fibers with a resin matrix, providing robust structural support. This makes them an excellent choice for applications such as fiber glass duct board, which is designed to enhance energy efficiency and airflow in HVAC systems.

Common Applications and Benefits: Fiberglass U Channels are commonly used in construction for structural framing, as well as in industrial settings for guiding and supporting equipment. Their main advantages include excellent resistance to corrosion and chemical exposure, making them ideal for use in harsh environments. Additionally, their lightweight nature facilitates easy handling and installation.

Fiberglass C Channel

Definition and Characteristics: Fiberglass C Channels have a C-shaped cross-section, which offers strength and rigidity while being relatively lightweight. These channels are constructed from fiberglass-reinforced composites, providing durability and flexibility in various applications.

Typical Uses and Advantages: Fiberglass C Channels are frequently employed in support structures, brackets, and framework applications. They are well-suited for environments where resistance to corrosion and weathering is crucial. Their non-conductive properties also make them beneficial in electrical and telecommunications applications. The lightweight nature of C Channels reduces the load on supporting structures and simplifies installation processes.

Fiberglass L Channel

Description and Features: Fiberglass L Channels feature an L-shaped cross-section, offering a combination of strength and stability. Made from high-quality fiberglass composites, these channels provide durability and resistance to environmental factors.

Applications and Benefits: Fiberglass L Channels are widely used in various construction and industrial settings. They are commonly found in structural supports, angle reinforcements, and framing applications. The main benefits include resistance to rust, chemical corrosion, and UV degradation. This makes them ideal for outdoor and industrial applications where longevity and minimal maintenance are required.

Structural Fiberglass Channels

Key Characteristics of Structural Fiberglass Channels

Material Composition:

Structural fiberglass channels are typically made from a combination of fiberglass and resin, which together form a composite that is strong, non-corrosive, and resistant to weathering.

The fiberglass provides tensile strength and rigidity, while the resin (usually polyester or vinyl ester) acts as a bonding agent, giving additional resistance to chemicals, moisture, and environmental degradation.

Corrosion Resistance:

Unlike traditional materials like steel or aluminum, FRP channels are highly resistant to corrosion, rust, and chemical exposure.

This feature makes them ideal for environments where metal might degrade, such as in marine, wastewater treatment, chemical processing, and coastal structures.

Lightweight yet Strong:

Fiberglass channels are generally lighter than steel and aluminum, making them easier to handle and install without heavy machinery.

Despite being lightweight, FRP channels have excellent mechanical strength, often comparable to or better than traditional metals, depending on the application.

Electrical Insulation:

Fiberglass is a natural insulator, which makes FRP channels suitable for applications where electrical conductivity is a concern.

This property is beneficial in industries that handle electrical systems or sensitive electronic equipment, as it reduces the risk of electrical hazards.

UV and Weather Resistance:

Many FRP channels are manufactured with UV-resistant additives, allowing them to withstand long-term exposure to sunlight without degrading.

Their resilience to extreme weather conditions makes them useful for outdoor installations.

Non-Magnetic and Non-Conductive:

The non-magnetic properties of fiberglass make these channels suitable for use in electromagnetic-sensitive areas.

Additionally, being non-conductive, they are often used in areas where conductivity might pose safety risks or interfere with nearby equipment.

Common Applications

- Industrial Flooring and Walkways: FRP channels are used to create supportive structures for flooring, walkways, and grating systems in factories, water treatment facilities, and chemical plants.

- Structural Supports: Due to their strength, FRP channels can serve as supports for various structural components, including beams, columns, and cross-bracing.

- Marine Construction: Their corrosion resistance makes them ideal for docks, piers, and other coastal or submerged structures.

- Electrical Infrastructure: Fiberglass channels are used in electrical enclosures, cable trays, and conduits where non-conductivity is essential.

- Transportation: Some vehicles, especially in marine and railway industries, incorporate FRP channels to reduce weight while maintaining structural integrity.

Manufacturing and Sizes

Structural fiberglass channels are manufactured through a pultrusion process, which involves pulling fiberglass rovings through a resin bath and then through a heated die to cure the composite into a solid profile. They are available in various sizes and profiles, typically ranging from small sections suitable for lightweight structures to larger, more robust channels that can handle heavy loads.

Heavy Duty Fiberglass Channels

Heavy Duty Fiberglass Channels are structural components crafted from reinforced fiberglass material, designed specifically to handle high-stress and heavy-load environments. These channels are made using high-strength fiberglass and resin, which create a composite material offering impressive durability, corrosion resistance, and a lightweight profile compared to traditional materials like steel or aluminum.

Heavy Duty Fiberglass Channels are structural components engineered from reinforced fiberglass materials, tailored specifically for high-stress applications that require superior load-bearing capabilities. These channels are produced by combining high-strength fiberglass fibers with a resin matrix, creating a composite that provides a unique balance of strength, lightweight properties, and resistance to environmental challenges. The result is a material that can withstand significant mechanical stress while resisting corrosion and deterioration in harsh environments.

Key Features and Benefits

1.High Strength and Durability:

Heavy Duty Fiberglass Channels are known for their exceptional strength-to-weight ratio, making them ideal for applications where high structural integrity is required without the burden of excess weight.

Despite being lightweight, they offer strong load-bearing capabilities comparable to steel in many applications, which makes them an excellent choice for heavy-duty structural support.

2.Corrosion Resistance:

Fiberglass channels are highly resistant to corrosion, a common challenge in industrial and marine environments.

Unlike metal materials, fiberglass does not rust or corrode, even when exposed to chemicals, saltwater, or harsh environmental conditions, making it suitable for chemical plants, wastewater treatment facilities, and offshore installations.

3.Electrical Insulation:

Fiberglass is a non-conductive material, which provides inherent electrical insulation. This feature makes these channels particularly useful in environments where electrical conductivity could pose a safety risk, such as around electrical equipment and wiring.

4.Thermal Stability:

Heavy Duty Fiberglass Channels offer reliable thermal stability, withstanding both high and low temperature extremes. This makes them suitable for applications with fluctuating or extreme temperatures, such as outdoor or industrial settings.

They do not warp, expand, or contract with temperature changes as much as metals or plastics might, ensuring structural integrity over time.

5.Ease of Installation:

Fiberglass channels are lightweight, which simplifies transportation and handling during installation. They are also relatively easy to cut, drill, and fit on-site, reducing labor and installation costs.

Minimal maintenance is required, making these channels cost-effective over their lifespan. This is especially beneficial in hard-to-access installations where regular upkeep may be impractical.

6.Versatile Shapes and Sizes:

Heavy Duty Fiberglass Channels are available in various standard profiles, such as “C” and “U” shapes, allowing them to accommodate a range of structural needs.

The channels can be customized to specific length, width, and thickness requirements, providing versatility across diverse applications.

Common Applications:

- Industrial Infrastructure: Used for structural supports, beams, and framework in facilities like chemical processing plants, pulp and paper mills, and food processing centers.

- Marine and Offshore Structures: Ideal for docks, bridges, and offshore rigs where corrosion resistance is essential.

- Electrical Environments: Suitable for cable trays, electrical enclosures, and supports where electrical insulation is beneficial.

- Public Works and Infrastructure: Frequently used in walkways, handrails, ladders, and other public installations where strength, durability, and weather resistance are crucial.

- Construction: Provides support in building structures, especially in locations exposed to harsh weather or corrosive agents.

In summary, Heavy Duty Fiberglass Channels are an effective, long-lasting solution for structural applications in both industrial and commercial settings, offering unparalleled resilience to harsh environments. They combine the advantages of strength, durability, and environmental resistance with ease of handling and minimal maintenance requirements, providing a sustainable and cost-effective choice for demanding projects.

Fiberglass Channels Sizes

Overview of Standard Sizes and Dimensions Available

Fiberglass Channels are offered in a range of standard sizes to suit various applications. Typically, these channels come in lengths ranging from 10 feet to 20 feet, though longer or shorter lengths may be available depending on the supplier. Standard cross-sectional dimensions for U, C, and L Channels vary, with common widths ranging from 1 inch to 6 inches and heights from 1 inch to 6 inches. Thicknesses also vary, typically from 0.125 inches to 0.5 inches, depending on the strength and load-bearing requirements.

Information on Custom Sizing Options and How to Determine the Right Size for Your Needs

If standard sizes do not meet your requirements, custom sizing options are often available. Custom dimensions can be tailored to specific project needs, including non-standard lengths, widths, and thicknesses. To determine the right size for your needs, consider the following factors:

Load Requirements: Evaluate the load-bearing capacity required for your application. Heavier loads will necessitate thicker and wider channels.

Application Environment: Consider the environment where the Fiberglass Channels will be used. For instance, larger channels might be needed for structural support in industrial settings, while smaller sizes could be suitable for lighter-duty applications.

Fit and Integration: Ensure that the size of the channels fits with other components of your project. Custom sizing may be necessary to achieve a precise fit or to accommodate specific design constraints.

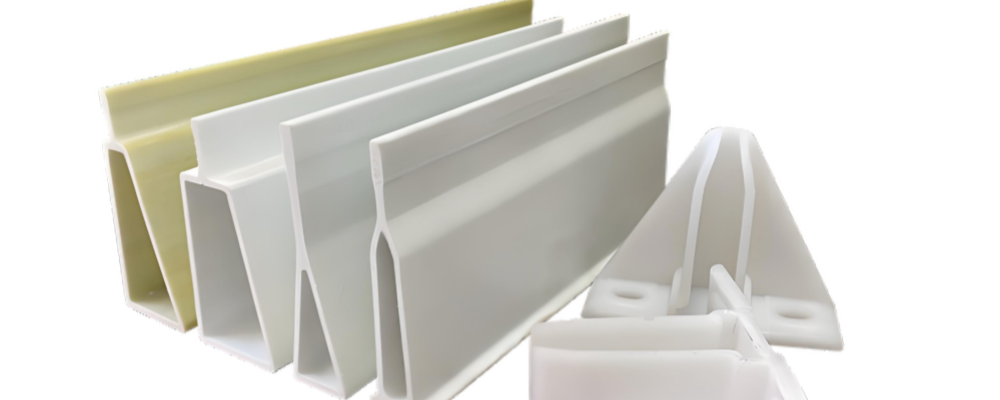

Pultruded Fiberglass Channels

Pultruded Fiberglass Channels are structural components made from fiberglass-reinforced plastic (FRP) that are formed through a pultrusion process. Pultrusion is a continuous molding process where fiberglass rovings (fibers) are pulled through a resin bath and then through a heated die to cure the resin and shape the material into the desired form. This method results in high-strength, lightweight, and corrosion-resistant components with consistent cross-sectional profiles.

Here’s a detailed breakdown of Pultruded Fiberglass Channels:

Materials and Composition

- Fiberglass Reinforcement: Pultruded fiberglass channels typically use a combination of glass fibers (such as E-glass or S-glass) for reinforcement, which provides high tensile strength and durability.

- Resin Matrix: The fiberglass fibers are impregnated with a resin matrix, which can be polyester, vinyl ester, or epoxy. The resin provides structural integrity and chemical resistance.

- Additives: Various additives may be incorporated into the resin to enhance the material’s properties, such as UV resistance, fire retardancy, or conductivity.

Manufacturing Process

- Pultrusion Process: The raw fiberglass rovings are drawn through a resin bath, where the fibers become saturated with the resin. The saturated fibers are then pulled through a heated die that shapes them into the channel profile, curing the resin in the process. This method is known for producing consistent, high-quality, and uniform profiles.

- Profiles and Shapes: Pultruded fiberglass channels come in a variety of shapes, including U-channels, I-beams, Z-channels, and custom profiles, depending on the specific requirements of the application.

Key Properties

- Strength and Durability: Pultruded fiberglass channels are known for their high strength-to-weight ratio, making them strong and lightweight. They also offer excellent resistance to bending, flexing, and stretching.

- Corrosion Resistance: Unlike metal channels, fiberglass channels are highly resistant to corrosion from environmental factors like water, chemicals, and salt, making them ideal for use in harsh environments such as marine, industrial, and outdoor applications.

- Electrical Insulation: Fiberglass is a non-conductive material, which makes pultruded fiberglass channels ideal for electrical insulation in certain applications.

- Thermal Stability: These channels offer good resistance to temperature extremes, making them suitable for applications in a wide range of temperatures, from very low to very high.

- Lightweight: Pultruded fiberglass channels are much lighter than their steel counterparts, making them easier to handle, transport, and install.

Advantages

- Low Maintenance: The corrosion-resistant properties of pultruded fiberglass channels result in minimal maintenance costs over time, especially in demanding environments.

- Customization: Pultrusion allows for a wide range of customizable profiles and sizes, providing flexibility for specific design requirements.

- Sustainability: Fiberglass is a more environmentally friendly option than some metals because it has a longer lifespan and requires less maintenance.

Limitations

- Brittleness: While strong, fiberglass can be brittle and may crack under certain types of stress (e.g., sharp impact).

- Limited High-Temperature Resistance: While it performs well under moderate temperature conditions, fiberglass is not ideal for extremely high-temperature environments (e.g., above 250°C).

- Cost: Fiberglass materials, while cost-effective in the long term due to their durability and low maintenance, can have a higher initial cost compared to materials like aluminum or steel.

Pultruded fiberglass channels offer a combination of high strength, corrosion resistance, electrical insulation, and low weight, making them an excellent choice for many industrial, marine, and construction applications where traditional materials like steel may not perform as well.

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.

Fiberglass Channels Cost

Cost Comparison with Other Materials:

Steel Channels: Generally, steel channels are less expensive upfront than fiberglass channels. However, steel requires ongoing maintenance to prevent rust and corrosion, which can add to the overall cost over time. In contrast, Fiberglass Channels do not require painting or rust prevention treatments, making them a more cost-effective choice in the long run.

Aluminum Channels: Aluminum channels are another alternative to fiberglass, often priced similarly or slightly higher than fiberglass channels. They are commonly used as aluminum channel for 1 4 fiberglass applications, providing durability and strength for various construction needs. While aluminum offers good resistance to corrosion, it can be less durable than fiberglass under certain conditions. Fiberglass Channels typically provide better resistance to harsh chemicals and environmental factors, potentially offering greater longevity and value.

Analysis of Long-Term Cost Benefits:

Durability: Fiberglass Channels are highly resistant to corrosion, chemicals, and extreme weather conditions. This durability reduces the need for frequent replacements or repairs, which translates into lower long-term costs. In environments prone to corrosion or exposure to harsh chemicals, Fiberglass Channels often outperform metal alternatives, resulting in fewer maintenance and replacement costs.

Low Maintenance: One of the significant advantages of Fiberglass Channels is their minimal maintenance requirements. Unlike steel, which needs regular repainting and anti-corrosion treatments, fiberglass channels remain stable without additional upkeep. This low-maintenance feature not only saves on labor and materials but also contributes to the overall cost-effectiveness of using fiberglass.

Applications and Benefits of Fiberglass Channels

Fiberglass Channels are versatile and widely used across various industries due to their unique properties. Their corrosion resistance, lightweight nature, and low maintenance needs make them an ideal material for a broad range of structural and non-structural applications. This section explores the common applications and key benefits of Fiberglass Channels, emphasizing their importance in different sectors.

Common Applications of Fiberglass Channels

Construction Industry

In construction, Fiberglass Channels are used as structural components in buildings, bridges, and infrastructure projects. They are particularly beneficial in environments exposed to harsh weather conditions or corrosive elements like coastal areas or chemical plants. Their lightweight nature simplifies transport and installation, helping reduce labor costs and time spent on-site, thus boosting overall project efficiency.

Fiberglass Channels are highly favored in the marine industry because of their outstanding resistance to saltwater corrosion. They are commonly used in boat hulls, docks, and other structures that are exposed to seawater. Unlike metals, which degrade and rust in marine environments, Fiberglass Channels maintain their strength and durability, providing long-lasting performance and reliability even in harsh oceanic conditions. In the electrical industry, fiberglass channels are used as cable trays and conduits because of their non-conductive properties. Similarly, stainless steel cable tray are favored for their durability and strength, making them ideal for environments that require robust support and corrosion resistance alongside effective cable management. They provide safe housing for electrical wiring in various settings, from industrial plants to commercial buildings. The material’s insulating properties reduce the risk of electrical hazards. Fiberglass Channels are extensively used in the transportation industry, particularly in the production of vehicle, train, and aircraft components. Their lightweight design helps reduce the overall weight of vehicles, improving fuel efficiency, and reducing emissions. The durability of these materials ensures that they withstand the rigors of daily transportation use, providing long-lasting, reliable components even under harsh conditions. One of the standout benefits of Fiberglass Channels is their exceptional resistance to corrosion. Unlike metals that are prone to rust or degradation when exposed to moisture, chemicals, or saltwater, fiberglass maintains its integrity over time. This makes it the perfect choice for environments where other materials would quickly degrade, such as in coastal areas, chemical plants, or marine environments. Fiberglass Channels are significantly lighter than traditional metal materials like steel or aluminum, making them much easier to handle and transport. Their reduced weight helps lower shipping costs and facilitates quicker installation. Despite their lightness, these channels offer impressive strength and can support substantial loads, ensuring their reliability in both structural and non-structural applications. Once installed, Fiberglass Channels require minimal maintenance compared to their metal counterparts. They do not need frequent painting or protective coatings and are resistant to mold, mildew, and insect damage. This low-maintenance nature reduces long-term upkeep costs, making fiberglass a cost-effective material choice for projects that need durability without the hassle of frequent repairs or replacements. The non-conductive properties of Fiberglass Channels make them a safe and effective choice for electrical applications. They provide excellent insulation, reducing the risk of electrical hazards in environments where safety is a priority. This characteristic makes them ideal for use in electrical installations, especially in areas where wiring is exposed to moisture or other conductive materials that might pose a risk. Fiberglass Channels are highly versatile and can be easily customized to meet specific project requirements. They can be cut, drilled, and shaped without compromising their structural integrity, allowing for highly adaptable solutions across different industries. Whether used for structural support, cable management, or other applications, fiberglass channels offer flexibility, making them a practical choice for various design needs.Marine Industry

Electrical Industry

Transportation Industry

Key Benefits of Fiberglass Channels

Corrosion Resistance

Lightweight

Low Maintenance

Non-Conductive

Versatility

Fiberglass Channels VS Traditional Steel and Aluminum Angle

| Factors | Fiberglass Channels | Steel Angles | Aluminum Angles |

|---|---|---|---|

| Material Composition & Manufacturing Process | Made from resin-based materials (polyester, vinyl ester, epoxy), produced by pultrusion. Lightweight, corrosion-resistant, and electrically insulating. | Made from carbon or stainless steel, rolled or extruded. Can be heat-treated for higher strength. Prone to rust and corrosion unless treated. | Made from aluminum alloys, typically extruded or rolled. Naturally corrosion-resistant due to an oxide layer but can wear in extreme conditions. |

| Strength-to-Weight Ratio | High strength-to-weight ratio, suitable for applications requiring lightweight and strength like aerospace, marine, or construction. | Very strong and dense, ideal for heavy structural applications, but heavier than fiberglass. | Lighter than steel but heavier than fiberglass. Provides good strength, but not as strong as steel for heavy-duty applications. |

| Corrosion Resistance | Exceptional corrosion resistance, ideal for harsh environments like marine, chemical plants, and areas with high humidity. Longer lifespan and reduced maintenance. | Prone to rust and corrosion unless galvanized or made from stainless steel. Requires regular maintenance in corrosive environments. | Corrosion-resistant due to natural oxide layer, but still susceptible to corrosion in extreme conditions like saltwater or chemicals. |

| Electrical Insulation | Non-conductive, making them ideal for electrical safety applications, such as electrical enclosures or supporting electrical components. | Conductive, poses electrical hazards unless insulated or grounded properly. | Conductive, requiring insulation in electrical applications. |

| Temperature Resistance | Temperature resistant up to 250°C, but not suitable for high-heat applications. | Highly temperature resistant, can withstand high heat. Steel alloys can be heat-treated for higher temperature resistance. | Has a lower melting point compared to steel, limiting its use in high-temperature environments. Suitable for moderate heat exposure. |

| Cost & Availability | Higher initial cost, but long-term savings due to low maintenance and corrosion resistance. | Generally cheaper than fiberglass and aluminum, with widespread availability and standard sizes. | More expensive than steel but cheaper than fiberglass. Easier to obtain than fiberglass but less common than steel. |

| Applications | Ideal for marine, chemical processing, construction, and electrical applications in harsh environments. | Best suited for heavy structural applications such as bridges, buildings, and industrial machinery. Used when high strength and controlled corrosion resistance are needed. | Ideal for aerospace, automotive, and light construction applications, where a balance between strength and corrosion resistance is needed. |

| Environmental Impact | Long lifespan and low maintenance contribute to sustainability, but challenging to recycle and certain resins may have environmental concerns. | Steel is recyclable, but production is energy-intensive and has a larger environmental impact than fiberglass. | Highly recyclable, with less environmental impact than steel. Energy-intensive production, but aluminum recycling rates are higher. |

High-Performance Fiberglass Channels Factory

Ganglong Fiberglass offers durable and versatile fiberglass channels, an essential part of our extensive fiberglass product line, featuring over 100 fiberglass shapes. Each channel is crafted using a proprietary composite material design, ensuring unmatched quality and performance. Known for their reliability and durability, Ganglong Fiberglass products are the preferred choice for various industrial applications.

Key Features of Ganglong Fiberglass Channels

- Corrosion Resistance – Withstands harsh environments without rusting or degrading.

- Low Thermal and Electrical Conductivity – Ideal for electrical and high-temperature applications.

- Non-Magnetic & Electromagnetically Transparent – Suitable for specialized industrial uses.

- Lightweight Yet Strong – Offers excellent strength-to-weight ratio for easy handling and installation.

- Dimensional Stability & Low Maintenance – Ensures long-term durability with minimal upkeep.

Commitment to Quality & Reliability

Our fiberglass channels are manufactured in ISO 9001-certified facilities, meeting the highest industry standards. With a global distribution network and a commitment to fast delivery, we are your trusted partner for industrial plastic solutions.

Wide Range of Fiberglass Channel Options

We offer a variety of fiberglass channel types that comply with international standards. As a direct factory supplier, we control the entire production process, from raw materials to final manufacturing, ensuring superior quality at competitive prices.

- Advanced FRP Channel Production – Manufactured using state-of-the-art equipment.

- Extensive Warehouse Inventory – Large stock available for immediate shipment.

- Custom Sizes Available – Tailored fiberglass channels to fit specific project requirements.

- Fast Shipping – Ready-to-ship inventory ensures quick delivery to your location.

Ganglong Fiberglass is dedicated to providing top-quality fiberglass channels for a wide range of applications. Contact us today to explore our fiberglass solutions and secure the best products for your project.

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.