- Home

- Fiberglass Decking

Fiberglass Decking : Anti-Skid and Fire Rated

Shop Fiberglass Decking at GangLong Fiberglass: anti-skid, polyester-fire rated, ASTM D635 compliant, and available in various options.

Fiberglass Decking is designed to replace traditional materials like wood, aluminum, or steel in settings where corrosion or rot could cause costly maintenance issues or unsafe conditions. This type of decking is particularly suited for environments near electrical lines due to its low conductivity and non-sparking properties. GangLong Fiberglass offers a variety of decking and planking options, tailored for different surface types, installation locations, and purposes, including molded fiberglass decking for docks and gangways. These decking solutions are also ADA compliant and allow for a 62% open area for light passage, with custom colors available.Choosing the right decking system is crucial for ensuring the longevity and safety of your deck, and fiberglass decking provides a reliable, cost-effective solution for any outdoor project. Specifically, fiberglass reinforced plastic decking offers enhanced durability and resistance to weathering, making it an excellent choice for a variety of outdoor applications.

Simplifying Your Life: Key Functionalities

| Attribute | Details |

|---|---|

| Product Types | FRP Decking |

| Place of Origin | Hebei, China |

| Brands | GangLong Fiberglass |

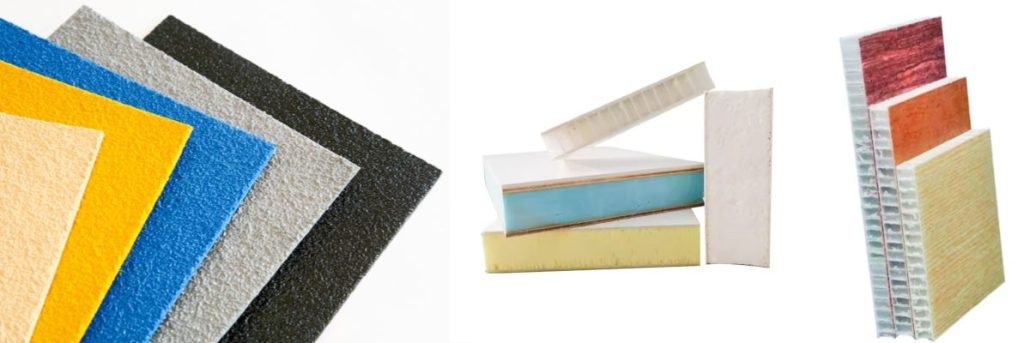

| Primary Materials | Fiberglass, PU, WPC (Wood Plastic Composite), Aluminum |

| Techniques Used | Pultrusion, Moulding, Coextrusion, Smooth Finish, Matt Finish |

| Applications | - Roof Decks |

| - Swimming Pool Decking | |

| - Gardens | |

| - Balconies | |

| - Terraces | |

| - Outdoor Spaces | |

| Surface Treatment | - Concave - Smooth - Gritted - 3D Wood Grain - Sand Paving - Flat Wood Grain |

| Features | - Waterproof - Fire Retardant - Anti-Slip - Crack-Resistant - Eco-Friendly - Durable - Wear Resistant - Sustainable - Moisture Proof - Anti-Termite - Low Maintenance - Real Wood Look - Easy Installation |

| Installation Features | - Interlocking - Click Installation - Dual Lock Tongue-and-Groove System |

| Processing Services | Moulding, Welding, Cutting, Decoiling |

| Warranty | 5-10 Years |

| MOQ (Minimum Order Quantity) | 1-200 Square Meters |

| Packaging | Pallet |

News

- Exploring the Benefits of Carbon Fiber Apparel

- How to Work with Carbon Fiber Successfully

- Carbon Fiber Suit: The Future of Lightweight Armor

- Is Carbon Fiber Armor the Future of Protection?

- Why White Carbon Fiber is Popular in Automotive Design

- Transparent Carbon Fiber Sheets Two Sided Gloss Twill

- Epoxy-Compatible Chopped Carbon Fiber Mat

- Carbon Fiber EG Hatch: Upgrade Your Civic Today

- The Benefits of Using Structural Carbon Fibre in Engineering

- How Many Layers of Layered Carbon Fiber Are Needed?

Waht are Fiberglass Decking Systems?

Fiberglass Decking System

A Fiberglass Decking system is designed to provide a strong, durable, and low-maintenance surface for outdoor spaces. Unlike traditional decking materials like wood or composite, Fiberglass Decking is made from layers of fiberglass cloth embedded in a resin matrix, creating a solid and highly resilient surface. This system works by forming a seamless, waterproof barrier that protects the underlying structure from moisture, UV rays, and physical wear. The installation process typically involves laying down fiberglass sheets, applying resin, and then finishing with a protective gel coat, which adds additional durability and aesthetic appeal.

The advantages of using a Fiberglass Decking system over traditional materials are numerous. Firstly, fiberglass is incredibly resistant to rot, mold, and mildew, making it ideal for wet or humid environments. It also offers superior strength-to-weight ratios, meaning it can support heavy loads without adding excessive weight to the structure. Additionally, Fiberglass Decking requires minimal maintenance; unlike wood, it does not need to be stained, sealed, or treated regularly. Its long lifespan and resistance to environmental damage make it a cost-effective solution in the long run, especially for coastal or marine applications where durability is paramount.

Fiberglass Decking Prices

Factors Influencing Price

The cost of Fiberglass Decking can vary based on several key factors. The quality of the materials used is a primary determinant; higher-grade fiberglass and resins typically result in more durable and long-lasting decking but come at a higher price. The size of the deck also plays a significant role, as larger decks require more materials and labor. Additionally, the complexity of the design—such as custom shapes, integrated features, or intricate layouts—can increase both the material and labor costs. Location and availability of skilled installers can also influence the overall price, with labor costs varying widely depending on the region.

Several factors influence the price of fiberglass decking, making it essential to understand these variables when planning a budget. Here are some key aspects to consider:

1. Deck Size

The size of the deck is one of the most significant factors in determining cost. Larger decks require more materials, including fiberglass matting and resin, as well as increased labor for installation. The per-square-foot cost typically ranges between $20 and $40, so a larger area quickly increases the overall price.

2. Deck Complexity and Design

The design of the deck also affects the cost. Complex designs, such as multi-level decks or those with intricate curves, require more time and skill to install, leading to higher labor costs. Additional features like custom railings, steps, or built-in seating add to the complexity and increase material and labor expenses.

3. Quality of Materials

Fiberglass materials vary in quality, and higher-quality materials tend to cost more. Using premium-grade fiberglass matting, resin, and topcoats with UV protection will increase the upfront expense but improve durability, weather resistance, and lifespan. Cheaper materials may reduce initial costs but could require more frequent maintenance and repairs.

4. Installation Labor

Labor costs vary based on the expertise and rates of the installers. Hiring skilled professionals ensures a quality finish, but it can be costly. Labor prices may also fluctuate depending on regional labor market conditions and the specific requirements of the job, such as preparation work, leveling, or weatherproofing.

5. Weatherproofing and Protective Coatings

To ensure the longevity of a fiberglass deck, protective coatings like UV-resistant gel coats or marine-grade wax are often applied. These coatings protect against fading, cracking, and other forms of weather damage. While this adds to the cost, it’s essential for decks exposed to high sun or harsh climates, as it reduces the need for frequent maintenance.

6. Maintenance and Repair Costs

Although not part of the initial installation cost, future maintenance should be factored in when evaluating the overall investment in a fiberglass deck. Routine cleaning, occasional waxing, and minor repairs for chips or cracks add to the total cost over time. Properly maintaining the deck helps extend its lifespan, which can offset the initial investment in higher-quality materials.

7. Location and Access

The location of the deck and the accessibility of the installation site can also impact costs. Decks on higher floors or those in remote locations may incur additional charges for transportation of materials, equipment rentals, or extra labor. Accessibility challenges like narrow pathways or difficult terrain can lead to higher installation fees.

8. Regional Pricing Variations

Regional differences can affect both material and labor costs. Areas with higher living expenses often have increased labor rates, and shipping costs for fiberglass materials may vary by location. In certain regions, seasonal factors also influence availability and demand, potentially impacting prices.

9. Additional Customizations

Adding custom features like integrated lighting, railings, or decorative finishes can enhance the deck’s appeal but come at an added expense. These features often require specific expertise and materials, increasing both the material and labor costs.

Each of these factors plays a role in the final cost of a fiberglass deck. By understanding and planning for these variables, homeowners can better manage their budget and make informed decisions about materials, design, and maintenance. Proper budgeting can help achieve a durable, attractive deck that meets both functional and aesthetic goals while staying within financial constraints.

Price Range Overview

On average, Fiberglass Decking costs range from $15 to $30 per square foot, depending on the factors mentioned above. This price includes both materials and installation. While this might be higher than the initial cost of wood decking, it’s important to consider the long-term savings. Fiberglass Decking requires far less maintenance, reducing the need for regular sealing, staining, or repairs, which are often necessary with wood decks. Compared to composite decking, Fiberglass Decking offers superior durability and resistance to environmental damage, which can justify the slightly higher upfront investment. When considering the total cost of ownership, Fiberglass Decking proves to be a cost-effective solution over the lifespan of the deck.

Choose the Right Fiberglass Decking for Your Project

At GangLong Fiberglass, we understand the importance of selecting the perfect decking material to enhance your outdoor space. Whether you’re renovating an existing deck, building a new one, or expanding your current outdoor area, fiberglass decking provides a durable, low-maintenance solution. Our fiberglass decking options will transform your outdoor space into a stylish and functional living area.

Why Choose Fiberglass Decking?

Fiberglass decking offers exceptional durability, corrosion resistance, and weatherproof properties. Unlike traditional wood or composite decking, fiberglass decking resists corrosion, rot, and mildew, making it ideal for harsh environments like coastal regions or humid areas. It retains its color and texture over time, eliminating the need for frequent maintenance like staining or sealing.

Anti-Skid and Safety Features

Fiberglass decking is designed with safety in mind. The surface texture provides excellent anti-skid properties, ensuring secure footing even in wet conditions. This makes it perfect for high-moisture areas such as pools, docks, and walkways. The grating also offers added safety with its slip-resistant surfaces, reducing the risk of falls while enhancing the overall safety of your outdoor space.

Fire Rated and Durable

Fiberglass decking is fire-rated, offering superior fire resistance compared to traditional wood decking. This added safety feature is essential for areas near fire hazards like fire pits or chimneys. Additionally, fiberglass decking is incredibly durable, maintaining its integrity in harsh weather conditions, and is resistant to corrosion, chemicals, and extreme temperatures. Unlike metal grating, fiberglass remains structurally sound over time, minimizing the need for repairs and reducing maintenance costs.

Customization Options

We understand that each project is unique, which is why we offer customizable fiberglass decking solutions. Whether you need custom sizes, specific shapes, or material variations for your decking project, we can provide tailored options to suit your requirements. Our fiberglass grating can be molded into different shapes and finished with specific resins, colors, and textures, ensuring it meets your exact needs for both aesthetic appeal and performance.

Low Maintenance and Environmental Benefits

Fiberglass decking is a low-maintenance solution that requires minimal upkeep compared to wood or composite decking. There’s no need for regular sealing, staining, or painting—just occasional cleaning with soap and water. The environmentally friendly nature of fiberglass, combined with its recyclability, makes it an eco-conscious choice. Our manufacturing process minimizes environmental impact, contributing to sustainability while also helping to reduce waste and energy consumption over the product’s lifespan.

Cost-Effective with Competitive Pricing

Although fiberglass decking may have a higher initial cost compared to wood or composite options, its long-term value is undeniable. With reduced maintenance costs and longer lifespan, fiberglass decking proves to be a cost-effective choice in the long run. GangLong Fiberglass offers competitive pricing for all our decking products, ensuring that you receive the best value without compromising on quality or performance.

Reliable Delivery and Expert Customer Support

Timely delivery is essential for any project, and GangLong Fiberglass ensures your fiberglass decking products are delivered on time and in excellent condition. Our efficient production process and reliable logistics help you stay on track with your project timelines. Additionally, our expert customer support team is available to assist you from the initial consultation to post-purchase, offering technical guidance and addressing any concerns to ensure you get the best solution for your project.

How to Purchase Fiberglass Decking Grating

Purchasing fiberglass decking grating from Hebei Ganglong is a straightforward process designed to be efficient and hassle-free. Here’s how it works:

- Contact Us: Reach out to our team via email at [email protected]. Share your project details, including the size, shape, and specifications required for your fiberglass grating.

- Get a Quote: We will provide a detailed quote based on your requirements, including pricing, delivery times, and any customization options you may need.

- Confirm Order: Once you approve the quote, we will begin the production process. Our team will keep you informed about the status of your order, ensuring a smooth and timely delivery.

- Receive Your Grating: Upon delivery, our customer service team will be available to assist you with any installation guidance or technical support you may need.

When it comes to purchasing fiberglass decking grating, Hebei Ganglong Technology Co., Ltd. is the trusted choice for reliable, durable, and customizable products. With our emphasis on quality, safety, environmental sustainability, and customer satisfaction, we ensure that your project will be supported by the best grating solutions available. Reach out to us today to discuss your needs, and let us help you find the perfect fiberglass grating for your application.

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.

Fiberglass Decking Cost Per Square Foot

Average Cost Breakdown

The cost per square foot for Fiberglass Decking typically ranges from $15 to $30, depending on several factors including material quality, design complexity, and installation fees. This price generally covers both the cost of the materials and the labor required for installation. Higher-end Fiberglass Decking systems that use premium-grade resins or offer additional features like textured finishes or custom colors may fall on the higher end of this spectrum. On the other hand, more straightforward installations with standard materials can be found at the lower end of the range. It’s important to consider that these prices can also vary based on your location and the availability of local contractors skilled in installing fiberglass systems.

Long-Term Value

While the upfront cost of Fiberglass Decking may seem higher compared to traditional wood or even composite decking, the long-term value it offers is substantial. Fiberglass Decking is known for its exceptional durability, resistance to weather, and minimal maintenance requirements. Unlike wood, which may need regular sealing, staining, or replacement due to rot or insect damage, Fiberglass Decking can last for decades with very little upkeep. This translates to significant savings over time, as the need for repairs, treatments, and replacements is greatly reduced. Additionally, the strength and resilience of Fiberglass Decking mean that it can withstand heavy use and harsh environmental conditions without warping, cracking, or fading. When you consider these factors, the higher initial investment in Fiberglass Decking can be more cost-effective in the long run, making it an excellent choice for those looking to build a deck that will stand the test of time.

Applications and Advantages of Fiberglass Decking

Applications for Fiberglass Decking

Fiberglass decking serves as a versatile, durable solution in a wide range of outdoor applications. It is used in environments that demand strength, weather resistance, and minimal maintenance, making it suitable for both residential and commercial projects. Below are the specific purposes and areas where fiberglass decking is commonly used.

Residential Outdoor Spaces

Fiberglass decking is commonly used in residential settings for creating long-lasting, low-maintenance outdoor areas. Homeowners use fiberglass decking for patios, decks, pool surrounds, and garden pathways. Its resistance to weather, rot, and corrosion makes it an ideal material for creating functional and aesthetically pleasing outdoor living spaces that require minimal upkeep.

Coastal and Waterfront Areas

Fiberglass decking is widely used in coastal and waterfront environments, such as docks, piers, and boardwalks. The material’s resistance to saltwater, moisture, and UV exposure makes it perfect for high-humidity and corrosive conditions found near oceans, rivers, and lakes. It helps ensure the durability and longevity of decking structures that are frequently exposed to harsh environmental factors.

Commercial and Industrial Applications

Fiberglass decking is also employed in commercial and industrial projects, such as warehouses, factories, and outdoor walkways. Its high strength, lightweight properties, and resistance to chemicals and heavy-duty conditions make it a popular choice for environments that require durable and safe surfaces. Fiberglass decking is often used in industrial platforms, loading docks, and stairways where safety and low maintenance are critical.

Rooftop Decks

Fiberglass decking is a popular choice for rooftop deck installations. Since fiberglass is lightweight yet strong, it is ideal for rooftop applications where load-bearing capacity and weather resistance are essential. The material’s waterproofing and weatherproofing properties make it suitable for decks on top of buildings where water resistance is crucial to prevent leakage into the structure.

Public and Recreational Spaces

Fiberglass decking is used in public parks, recreational areas, and sports facilities due to its low maintenance, safety features, and weather resistance. It’s commonly found in boardwalks, viewing platforms, and bridges in public spaces. The anti-slip surface makes it a safe choice for high-traffic areas, particularly in locations where there is frequent exposure to water or wet conditions.

Marine and Boat Decks

Fiberglass decking is frequently used in the marine industry for boat decks and docks. It is a material of choice for boat manufacturers because it resists moisture, corrosion, and UV damage, ensuring that marine surfaces remain safe and functional over time. The lightweight nature of fiberglass also helps reduce the weight of the boat, improving its performance.

Pool Surrounds and Wet Areas

Fiberglass decking is ideal for pool surrounds, hot tubs, and other wet areas where safety and slip resistance are paramount. Its anti-slip surface prevents accidents around pools and spas, while its resistance to mold, mildew, and water ensures that the decking remains safe and visually appealing over time.

Environmental and Sustainable Projects

Fiberglass decking is often used in sustainable construction projects. Its eco-friendly properties, including recyclability and long lifespan, make it a great choice for projects focused on reducing environmental impact. It is used in green building initiatives, outdoor areas of eco-resorts, and parks, helping to meet sustainability goals while providing durable and functional decking solutions.

Advantages of Fiberglass Decking

Durability and Longevity

Fiberglass decking is incredibly durable, highly resistant to corrosion, rot, and mildew, which makes it perfect for harsh environments. It can withstand extreme weather conditions, such as intense sunlight, rain, and temperature fluctuations, without cracking or warping. Unlike metal or wood, fiberglass does not degrade, ensuring its longevity and reducing the need for frequent replacements or repairs.

Fiberglass also excels in environments exposed to moisture, chemicals, and saltwater, making it ideal for coastal areas, pools, docks, or wet environments. This durability guarantees that fiberglass decking maintains its structural integrity for decades, providing a long-term investment for your outdoor spaces.

Waterproofing and Weather Resistance

Fiberglass decking provides excellent waterproofing capabilities. The material forms a seamless barrier, preventing water infiltration and protecting the deck structure from potential damage. Its resistance to water and weather makes it particularly suitable for areas with high humidity, rainy climates, or installations above living spaces, ensuring no water damage occurs beneath the deck.

Low Maintenance

One of the standout benefits of fiberglass decking is its low-maintenance nature. Unlike wood decks, fiberglass does not require annual sealing, staining, or painting. It resists mold, mildew, and staining, making it easy to clean with just soap and water. This minimal maintenance reduces long-term costs and ensures your decking stays looking great with little effort.

Safety Features

Fiberglass decking is designed with safety in mind. The surface texture of fiberglass decking provides excellent anti-skid properties, which reduces the risk of slips and falls, especially in wet or high-moisture areas. Additionally, its fire-resistant properties add an extra layer of safety, making fiberglass decking suitable for use in wildfire-prone areas and meeting building codes that require fire-rated materials.

Aesthetic Versatility

Fiberglass decking comes in a wide range of colors, textures, and finishes, allowing for customization to match any home design or personal preference. It can mimic the look of wood, stone, or other materials, providing an attractive, low-maintenance alternative to traditional decking options. Its versatility makes fiberglass decking suitable for both modern and traditional styles, enhancing the visual appeal of any outdoor space.

Eco-Friendly and Sustainable

Fiberglass is a non-toxic material that does not release harmful chemicals into the environment. It is fully recyclable, making it an environmentally friendly choice for sustainable building projects. Additionally, fiberglass decking’s long lifespan means fewer replacements and reduced waste over time, contributing to resource conservation.

Lightweight Yet Strong

Fiberglass decking is lighter than many traditional decking materials, making it easier to handle and install. Despite its light weight, fiberglass is incredibly strong, capable of supporting heavy foot traffic and impacts without denting, cracking, or warping. This strength-to-weight ratio makes fiberglass decking ideal for a variety of applications, from residential decks to commercial and industrial installations.

Cost-Effective in the Long Run

Although fiberglass decking may have a higher initial cost compared to wood or composite options, it is a smart long-term investment. With its durability, low maintenance, and longevity, fiberglass decking minimizes the need for repairs and replacements, ultimately saving on costs over time. The ease of installation also reduces labor costs, making fiberglass a cost-effective option in the long run.

Environmental Benefits

Fiberglass is a sustainable material with a significantly lower carbon footprint than materials like steel or concrete. The production process requires less energy, and because fiberglass is fully recyclable, it contributes to a reduction in waste. Additionally, the open-grid structure of fiberglass decking allows sunlight and moisture to reach the underlying vegetation, promoting plant growth and supporting a healthy ecosystem.

Installation Considerations

Fiberglass decking is easy to install, whether you’re a DIY enthusiast or working with a contractor. It can be laid over existing surfaces, such as wood, metal, or concrete, making it a versatile choice for both new constructions and renovations. To ensure proper installation, the underlying surface must be free of damage, level, and structurally sound. Fiberglass grating is lightweight and easy to handle, reducing the complexity and time required for installation.

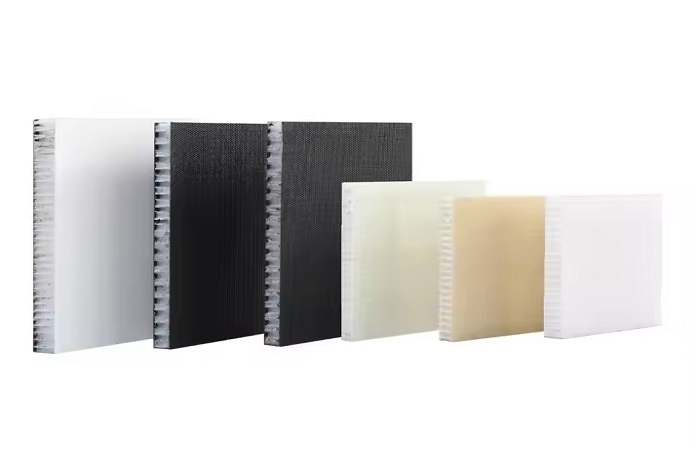

Fiberglass Decking Thickness

Fiberglass decking thickness is a critical factor in determining the deck’s strength, durability, and performance. The ideal thickness varies depending on the deck’s intended use, structural requirements, and environmental conditions. Here’s an in-depth look at considerations surrounding fiberglass decking thickness:

Standard Thickness Ranges

Generally, fiberglass decking is applied in layers, with a common total thickness between 1/8 inch and 3/8 inch. For standard residential decks, a thickness around 1/4 inch is typical, which provides a strong, waterproof surface suitable for moderate foot traffic. Commercial or industrial applications, where durability and load-bearing capabilities are essential, may require thicker fiberglass layers, closer to 3/8 inch or more.

Factors Influencing Required Thickness

Load Requirements

Decks designed to support heavy loads, such as outdoor furniture, hot tubs, or large groups of people, require thicker fiberglass layers for added structural integrity. This ensures that the deck can handle significant weight without cracking or flexing.

Climate and Environmental Conditions

In areas exposed to extreme weather conditions, such as heavy rain, high humidity, or intense sunlight, a thicker fiberglass layer offers better protection. Thicker layers provide enhanced waterproofing, UV resistance, and thermal insulation, helping prevent damage over time.

Foot Traffic

High-traffic areas, such as commercial spaces, public decks, or recreational areas, benefit from a thicker fiberglass application. This prevents wear and tear, ensuring the deck surface remains intact despite frequent use.

Layering and Application Process

Fiberglass decks are typically built up with multiple layers of fiberglass matting and resin. Each layer is applied separately, and additional layers increase the deck’s overall thickness and durability. A base layer forms the initial bond with the deck surface, while additional layers add strength and waterproofing. Each layer is allowed to cure before applying the next, ensuring a smooth, seamless, and durable surface.

Impact on Waterproofing

A thicker fiberglass layer provides superior waterproofing, making it ideal for decks exposed to rain, snow, or moisture. Thicker layers reduce the risk of cracks or pinholes, which can compromise the deck’s ability to repel water. For decks over living spaces, thicker fiberglass applications are often recommended to prevent any moisture infiltration that could damage interior structures.

Cost Considerations

Thicker fiberglass layers generally increase material and labor costs. While a thicker deck offers enhanced durability, it’s essential to balance the benefits with budget constraints. A thicker application may be more costly upfront, but it can also reduce long-term maintenance and repair needs, providing better value over time.

Thermal and UV Resistance

In sunny or warm climates, UV exposure can degrade fiberglass over time, causing fading or surface weakening. A thicker fiberglass layer with a UV-protective topcoat enhances UV resistance, helping the deck maintain its color and integrity. Additionally, thicker layers provide better thermal insulation, reducing heat transfer through the deck surface, which can improve comfort.

Structural Considerations and Substrate Type

The underlying structure and material of the deck substrate play a role in determining the fiberglass thickness needed. Plywood substrates, for instance, typically require a standard fiberglass thickness for adequate waterproofing, while concrete substrates may require additional layers due to their porous nature. Ensuring compatibility between the fiberglass thickness and substrate type optimizes deck performance.

The ideal thickness for fiberglass decking depends on multiple factors, including load requirements, climate, traffic levels, and budget. While standard residential decks typically require around 1/4 inch, heavier-duty applications may need up to 3/8 inch or more. A properly selected thickness ensures durability, waterproofing, and longevity, making fiberglass an effective and resilient choice for a variety of decking needs. Balancing thickness with cost and intended use allows for a custom-tailored deck solution that maximizes performance and lifespan.

Fiberglass Boat Decking

Applications in Marine Environments

Fiberglass decking is widely used in marine environments, particularly in the construction and repair of boat decks. Its exceptional durability and resistance to harsh conditions make fiberglass an ideal material for boat decking. Below are the specific marine applications where fiberglass decking is most commonly used.

Boat Decks and Yachts

Fiberglass decking is commonly used in both recreational boats and commercial yachts. Due to its lightweight yet durable nature, fiberglass provides a strong surface for decks that can withstand constant exposure to water, salt, and sunlight. Fiberglass decking is often chosen for boat construction because it can resist the damaging effects of corrosion, ensuring the deck remains intact over time without the need for frequent repairs.

Docks and Piers

Fiberglass decking is ideal for building docks and piers, as it is resistant to the effects of saltwater and moisture, which can quickly degrade wood or metal structures. The material’s non-corrosive properties ensure that fiberglass decking in these applications maintains its structural integrity, even with constant exposure to water. Fiberglass decking can be used to create safe, durable walkways and platforms for commercial and recreational waterfront areas.

Marina Walkways and Boardwalks

Fiberglass decking is also a common material for marina walkways and public boardwalks. It provides a durable, slip-resistant surface that can handle heavy foot traffic while resisting the wear and tear caused by the marine environment. This makes it ideal for boardwalks in areas with high humidity, salt exposure, or regular contact with water, which can damage traditional materials like wood.

Boat Ramps

Fiberglass decking is used in the construction of boat ramps, which need to withstand water exposure and heavy equipment usage. The material’s strength and resistance to environmental factors make it an excellent choice for these applications. Fiberglass ramps provide a smooth, durable surface for launching boats without the risk of degradation from water or chemicals.

Marine Platforms and Decking Surfaces

Fiberglass decking is used for building marine platforms and various decking surfaces, such as observation decks or commercial marine structures. Its resistance to UV degradation, saltwater corrosion, and temperature changes makes it a reliable material for these outdoor applications. Fiberglass decking is particularly beneficial for ensuring a long lifespan in marine environments where other materials would deteriorate more quickly.

Fishing Docks and Platforms

Fishing docks and platforms benefit from fiberglass decking due to its water-resistant properties and resistance to algae, mold, and mildew. In marine environments where moisture and damp conditions are prevalent, fiberglass decks provide a safer and more reliable surface for fishing activities. These decks are durable, easy to clean, and low-maintenance, making them a popular choice for both private and commercial fishing docks.

Composite Decking vs. Fiberglass Decking

Material Comparison

When comparing Fiberglass Decking to composite decking, several key factors come into play, including strength, durability, and maintenance. Fiberglass Decking is known for its exceptional strength-to-weight ratio, making it an ideal choice for applications requiring a sturdy, lightweight material. It is incredibly durable, with resistance to rot, warping, and insect damage, which often plague composite decking over time. Additionally, Fiberglass Decking can withstand extreme weather conditions, including intense UV exposure and heavy moisture, without deteriorating, whereas composite decking may fade, crack, or swell under similar circumstances.

In terms of maintenance, Fiberglass Decking has a clear advantage. It requires minimal upkeep—typically just occasional cleaning with water and mild soap—compared to composite decking, which may need regular sealing, staining, or specialized cleaners to maintain its appearance and integrity. The non-porous surface of Fiberglass Decking also makes it less susceptible to staining and easier to keep clean, especially in outdoor environments where dirt and debris are common.

When to Choose Fiberglass Over Composite

Choosing Fiberglass Decking over composite decking is particularly advantageous in scenarios where long-term durability and resistance to harsh environments are critical. For example, in coastal or marine applications, Fiberglass Decking is the better choice due to its superior resistance to saltwater corrosion and UV damage. It is also preferable in high-traffic areas or industrial settings, where the decking needs to support heavy loads and resist damage from chemicals or machinery.

If the project involves decking installations in areas with extreme weather fluctuations, Fiberglass Decking offers a more reliable solution, as it does not expand or contract significantly with temperature changes, unlike some composite materials. This stability ensures that the decking remains secure and intact, reducing the likelihood of warping, gaps, or other structural issues.

Fiberglass Decking Materials of Construction

Fiberglass decking is constructed from a combination of materials that work together to create a strong, weatherproof, and durable surface. Each material used in fiberglass decking plays a unique role in the overall performance and longevity of the deck. Here’s a breakdown of the key materials commonly used in fiberglass decking construction:

1. Fiberglass Matting (Reinforcement)

- Types: There are several types of fiberglass matting, including chopped strand mat and woven roving. Chopped strand mat is made from randomly aligned fibers, providing strength and stability to the deck. Woven roving, on the other hand, consists of continuous fibers woven in a pattern, offering additional reinforcement.

- Purpose: Fiberglass matting serves as the primary structural component of the deck. It provides tensile strength and helps distribute loads evenly, preventing cracking or warping. Matting layers also create a seamless, smooth surface, ideal for outdoor environments.

- Variations: The thickness and type of fiberglass matting used depend on the deck’s requirements. For high-traffic or heavy-load areas, multiple layers of matting are used to enhance durability.

2. Resin (Bonding Agent)

- Types: Polyester resin and epoxy resin are commonly used for fiberglass decking. Polyester resin is popular for general-purpose decking applications due to its affordability and ease of use, while epoxy resin provides superior bonding strength, chemical resistance, and waterproofing properties, often preferred in high-performance or marine environments.

- Purpose: Resin acts as the bonding agent that holds the fiberglass matting together, creating a hard, rigid, and seamless surface once cured. It also adds waterproofing properties to the deck, preventing water infiltration and protecting the underlying structure from moisture damage.

- Application: Resin is applied in layers, saturating the fiberglass matting to create a strong bond. Multiple resin layers build up the deck’s thickness, enhance durability, and create a smooth, finished surface.

3. Gel Coat (Surface Finish)

- Types: Gel coats are available in clear, tinted, or pigmented options, providing a variety of aesthetic choices. UV-resistant gel coats are especially valuable for outdoor applications, as they protect the deck from sun damage and fading.

- Purpose: The gel coat is a protective top layer applied over the fiberglass and resin layers. It provides a smooth, glossy, and weather-resistant surface, enhancing the deck’s visual appeal and adding another layer of waterproofing and UV protection.

- Benefits: Gel coats help maintain the deck’s appearance, resist staining, and protect the underlying fiberglass from exposure to environmental elements, reducing maintenance needs and extending the deck’s lifespan.

4. Catalysts and Hardeners

- Types: Most resins require a catalyst (typically methyl ethyl ketone peroxide, or MEKP) to initiate the curing process, turning the resin from a liquid into a solid. Hardeners are often added to resins to control curing speed and improve the strength of the bond.

- Purpose: Catalysts and hardeners ensure that the resin cures properly, creating a hard, durable surface. The right mix and amount of catalyst are essential to achieve optimal curing time, bond strength, and overall durability of the fiberglass deck.

- Considerations: The curing process generates heat, so it’s essential to apply the resin in appropriate temperatures and follow manufacturer recommendations to prevent warping or defects in the final finish.

5. Additives and Fillers

- Types: Additives such as pigments, thickeners, and UV inhibitors are mixed with the resin to enhance its properties. Fillers, like chopped glass fibers or silica, may also be added to increase the deck’s strength, impact resistance, and thickness.

- Purpose: Additives improve the performance of the fiberglass deck by enhancing UV resistance, increasing impact strength, or adding color. Fillers help improve the deck’s structural integrity, providing additional reinforcement without significantly adding weight.

- Benefits: With the right combination of additives and fillers, fiberglass decks can be customized for specific needs, like enhanced UV protection in sunny areas or added strength in high-impact zones.

6. Topcoat or Wax (Optional)

- Types: A marine-grade wax or topcoat with UV inhibitors can be applied as a final layer on top of the gel coat. These coatings are available in clear or tinted varieties.

- Purpose: Topcoats and wax add an extra layer of protection to the fiberglass deck, helping to prevent UV damage, maintain color, and resist staining. They also reduce the frequency of maintenance by providing a durable, easy-to-clean surface.

- Application: Topcoats or wax are generally applied once or twice a year, depending on the deck’s exposure to sunlight and environmental factors. This maintenance step helps keep the deck in excellent condition over the long term.

7. Non-Slip Additives (Optional)

- Types: Non-slip additives, like silica sand or rubber granules, can be mixed into the top layer or gel coat to add texture to the deck surface, making it safer for walking, especially in wet conditions.

- Purpose: These additives increase traction on the fiberglass deck, reducing the risk of slips and falls. This is particularly beneficial for pool decks, boat decks, or other areas where the surface may get wet frequently.

- Benefits: Non-slip additives enhance safety without significantly affecting the deck’s appearance, making it a valuable option for residential and commercial applications alike.

Fiberglass decking is constructed from a combination of fiberglass matting, resin, gel coats, catalysts, and optional additives, each chosen for its unique properties. Together, these materials create a durable, waterproof, and customizable deck that withstands various environmental conditions. Proper selection and application of these materials ensure a strong, weather-resistant, and aesthetically pleasing deck suitable for both residential and commercial use.

Fiberglass Decking Installation Guidelines

Installing fiberglass decking requires careful preparation and the right techniques to ensure a durable, long-lasting, and watertight finish. Here’s a step-by-step guide to proper fiberglass decking installation:

1. Surface Preparation

- Clean the Surface: Ensure the deck substrate is clean, dry, and free from debris, dust, grease, or any contaminants. A clean surface helps the fiberglass adhere properly and prevents imperfections in the final finish.

- Repair and Level: Fix any cracks, holes, or uneven areas on the substrate. For plywood decks, ensure all screws or nails are recessed and fill any gaps with putty or filler. If installing over a concrete surface, ensure it’s free of moisture, smooth, and properly leveled.

- Apply a Primer: Depending on the substrate, a primer may be necessary. This step promotes adhesion between the substrate and the fiberglass, ensuring a strong bond and reducing the risk of peeling or lifting.

2. Gather Materials and Tools

- Materials Needed: Fiberglass matting, resin (polyester or epoxy), catalyst/hardener, gel coat or topcoat, and optional additives like pigments or non-slip granules.

- Tools Required: Paint rollers, brushes, mixing containers, measuring cups, protective gloves, safety goggles, a utility knife, and a sanding block.

- Safety Gear: Resin and fiberglass work can release fumes, so ensure the area is well-ventilated, and wear protective gloves, goggles, and a mask to protect from fumes and potential skin irritation.

3. Measure and Cut Fiberglass Matting

- Fit the Matting: Measure the deck area and cut fiberglass matting to fit, ensuring each piece fits snugly around edges and corners. Pre-cut the matting to allow for smooth and continuous application, with each section slightly overlapping the next by about 1-2 inches.

- Layer Planning: Most decks require 2-3 layers of fiberglass matting for strength and durability. Plan the number of layers based on the traffic level and environmental conditions the deck will face.

4. Mix and Apply the Resin

- Prepare the Resin Mixture: In a mixing container, combine the resin with the appropriate catalyst or hardener according to the manufacturer’s instructions. Be mindful of the pot life (working time) of the resin mixture, as it can harden quickly.

- First Layer Application: Apply a layer of resin over the deck with a roller, creating a smooth, even coating. Immediately place the first layer of fiberglass matting on the wet resin, pressing it down firmly to eliminate air bubbles and wrinkles.

- Saturate the Matting: Use the roller to apply more resin over the fiberglass matting, saturating it completely. Roll firmly to remove air pockets and ensure the matting bonds well with the resin.

- Repeat for Additional Layers: Allow each layer to cure partially before applying the next. Repeat the resin and matting process for each layer, ensuring each one is fully saturated and free from air pockets or bubbles.

5. Curing Process

- Allow Proper Curing Time: Fiberglass decking typically requires 24-48 hours to cure, depending on the resin type and environmental conditions. Avoid disturbing the deck during this time to prevent imperfections.

- Check for Curing Issues: After curing, inspect the surface for tacky or uneven areas. If the resin remains tacky, it may need more curing time, or you may need to lightly sand and apply a thin layer of resin to correct the issue.

6. Apply the Gel Coat or Topcoat

- Prepare the Gel Coat: Once the fiberglass layers have fully cured, mix a gel coat or topcoat according to the manufacturer’s instructions. For outdoor decks, a UV-resistant gel coat is recommended to protect against sun damage.

- Apply the Gel Coat Evenly: Using a clean roller or brush, apply the gel coat evenly over the deck surface. Work in small sections to ensure even application and prevent pooling.

- Optional Non-Slip Additives: If a non-slip surface is desired, mix non-slip additives like silica or rubber granules into the gel coat or sprinkle them on while the coat is wet. This creates a textured surface for added traction.

- Allow Final Curing: The gel coat or topcoat needs time to cure fully, which can take 24-72 hours depending on environmental factors. Protect the deck from moisture and foot traffic during this period to ensure a smooth, durable finish.

7. Final Inspection and Cleanup

- Inspect for Defects: After curing, inspect the deck for any imperfections, bubbles, or missed spots. Lightly sand any rough or uneven areas and apply a thin topcoat if necessary to achieve a smooth finish.

- Edge and Trim Finishing: Trim any excess fiberglass matting around the edges with a utility knife, and apply resin to any exposed edges to ensure a waterproof seal.

- Clean Up: Dispose of resin containers, brushes, and rollers according to local regulations, as they can be hazardous.

8. Regular Maintenance Tips

- Routine Cleaning: Keep the deck clean by sweeping off debris and washing it periodically with mild soap and water. Avoid abrasive cleaners that can damage the gel coat.

- UV Protection: If the deck is exposed to significant sunlight, consider applying a UV-protective wax every six months to maintain the deck’s appearance and durability.

- Inspect for Cracks or Damage: Check periodically for any cracks, chips, or worn areas. Promptly repair any damage with a fiberglass repair kit to prevent moisture infiltration.

Installing fiberglass decking requires careful preparation, layering, and curing to ensure a strong, seamless, and durable surface. Proper application of the fiberglass matting and resin, followed by a UV-resistant gel coat or topcoat, creates a weatherproof deck that can withstand heavy traffic and environmental exposure. With attention to detail during installation and regular maintenance, fiberglass decking can provide a long-lasting and attractive outdoor surface.

FAQs about Fiberglass Decking

How long does a fiberglass deck last?

What is the best long-lasting decking material?

How many layers of fiberglass do I need for a deck?

How many layers of fiberglass do I need for a deck?

Does fiberglass rot over time?

How do you recoat a fiberglass deck?

Are fiberglass decks good?

How long does Fibreglass deck last?

Do fiberglass decks get hot?

What is the hardest wearing decking?

Composite Decking: Known for its durability, resistance to rot, insects, and fading, it requires minimal maintenance.

PVC Decking: Made from 100% plastic, offering excellent resistance to moisture, UV rays, and wear.

Hardwood Decking (such as Ipe or Teak): Naturally resistant to wear, rot, and insects, though it requires regular maintenance to maintain its appearance.

Fiberglass Decking: Extremely durable, resistant to moisture, weathering, and heavy foot traffic.

How do you maintain a fiberglass deck?

Regular Cleaning: Clean the deck with water and mild detergent to remove dirt, debris, and stains. Avoid harsh chemicals that could damage the surface.

Inspect for Damage: Periodically check for cracks, chips, or signs of wear, particularly in areas with heavy use or where furniture is placed.

Re-Coating: Every 5 to 10 years, apply a new coat to maintain the deck's protective surface, preserve its color, and prevent UV damage.

Prevent Scratches: Use furniture pads to prevent scratching and be mindful of heavy objects that could cause dents or damage.

Is fiberglass deck slippery?

What is the most economical deck material?

Pressure-Treated Wood: Low initial cost but requires regular maintenance to prevent rot and decay.

Softwood Decking (like Pine or Cedar): Affordable and readily available, though they require more maintenance than other materials.

Composite Decking: Higher upfront cost but offers long-term savings due to its low maintenance requirements.

Vinyl Decking: Offers good value over time due to its durability and minimal maintenance needs.

What is the most durable type of decking?

Composite Decking: Resistant to rot, insects, and UV damage, with minimal maintenance required.

PVC or Vinyl Decking: Extremely durable and resistant to moisture, UV rays, and wear.

Hardwood Decking (such as Ipe or Teak): Naturally strong and resistant to decay, though it requires maintenance to maintain its appearance.

Fiberglass Decking: Highly durable, weather-resistant, and low-maintenance, making it ideal for long-term use.

What is the best form of decking?

Composite Decking: Best for low maintenance and durability.

Fiberglass Decking: Ideal for moisture-prone environments and long-term durability.

Hardwood Decking: Offers a natural, luxurious look with great durability, though it requires regular maintenance.

PVC Decking: Excellent for areas exposed to harsh weather conditions due to its high resistance to moisture and UV damage.

What is the best coating for a fiberglass deck?

Can you put a rug on a fiberglass deck?

How much does a fiberglass deck cost?

How much should a 20x20 deck cost?

Pressure-Treated Wood: $8,000 to $12,000

Composite Decking: $12,000 to $18,000

Fiberglass Decking: $15,000 to $24,000

High-End Hardwood (like Ipe): $15,000 to $30,000

These estimates include both materials and labor. The specific cost will vary based on the material choice, design complexity, and local labor rates.

How much will a 12x12 deck cost?

Pressure-Treated Wood: $4,320 to $6,480

Composite Decking: $5,760 to $8,640

Fiberglass Decking: $6,480 to $10,800

High-End Hardwood (like Ipe): $7,200 to $12,960

The final price depends on the material, design, and any additional features like railings or stairs.

Does fiberglass deteriorate over time?

How much does a 10x10 deck cost?

Pressure-Treated Wood: $3,000 to $4,500

Composite Decking: $3,800 to $5,600

Fiberglass Decking: $4,500 to $7,500

High-End Hardwood (like Ipe): $4,800 to $8,500

These costs include materials and labor, and prices can vary based on your location and deck specifications.

How much should l budget for a new deck?

Pressure-Treated Wood: $15 to $30 per square foot

Composite Decking: $30 to $60 per square foot

Fiberglass Decking: $30 to $75 per square foot

High-End Hardwoods: $40 to $75 per square foot

For a standard 200-square-foot deck, this would translate to a budget of $3,000 to $15,000 or more, depending on the materials and features.

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.