China CPVC FRP pipe is a composite piping solution that combines the chemical resistance of CPVC (Chlorinated Polyvinyl Chloride) with the mechanical strength of FRP (Fiberglass Reinforced Plastic). This combination results in a pipe that can withstand corrosive environments and high-pressure conditions, making it ideal for use in industries like chemical processing, wastewater treatment, and oil and gas. The CPVC inner layer offers excellent resistance to harsh chemicals, while the outer FRP layer provides structural integrity and durability. China’s expertise in manufacturing these pipes ensures a reliable and cost-effective solution for demanding industrial applications. Wholesale China CPVC FRP pipes from certified manufacturers, offering high-quality, corrosion-resistant solutions at the best price.

Comprehensive Guide of China CPVC FRP Pipe

China CPVC FRP pipe refers to a composite piping solution that combines chlorinated polyvinyl chloride (CPVC) with fiberglass-reinforced plastic (FRP). This combination results in a pipe that offers excellent chemical resistance, mechanical strength, and thermal stability. China CPVC FRP pipe is widely used in industries such as chemical processing, water treatment, oil and gas, and power generation due to its ability to withstand harsh operating conditions. GangLong Fiberglass specializes in manufacturing high-quality CPVC FRP pipes tailored to meet the demands of various applications.

Composition of China CPVC FRP Pipe

The pipe is structured with a CPVC inner layer and an FRP outer layer. The CPVC provides excellent chemical resistance and a smooth interior for fluid transport, while the FRP adds mechanical strength and protection against external factors.

Inner Layer (CPVC)

The CPVC inner layer offers outstanding chemical resistance to acids, bases, and solvents, making it ideal for aggressive industrial fluids. Its smooth surface reduces friction, improving flow efficiency and reducing the chances of blockage. Additionally, it performs well under higher temperatures than standard PVC pipes.

Outer Layer (FRP)

The outer layer consists of fiberglass-reinforced plastic, which provides enhanced structural strength. This layer ensures the pipe can withstand high mechanical stress, impact, and environmental factors such as UV radiation, making the pipe highly durable even in outdoor or exposed environments.

Manufacturing Process of China CPVC FRP Pipe

The manufacturing process of China CPVC FRP pipes involves extrusion for the CPVC inner layer and filament winding for the fiberglass-reinforced outer layer. This combination ensures that the pipe has superior strength and resistance to corrosion.

CPVC Extrusion

The CPVC material is extruded to form the pipe’s inner layer. This extrusion process allows for precise control over the pipe’s diameter and thickness, ensuring a smooth and consistent inner surface. The CPVC layer offers excellent chemical resistance and reduces friction during fluid transport.

Filament Winding for FRP Reinforcement

Once the CPVC core is formed, continuous fiberglass filaments are wound around it, and resin is applied to bond the fibers together. The winding process enhances the pipe’s mechanical strength, making it resistant to pressure, impact, and UV degradation, ensuring that it can perform under harsh conditions.

Curing and Hardening

After the resin is applied, the pipe undergoes a curing process, where heat is used to harden the resin and bond the fiberglass layers together. This step ensures that the pipe is rigid, durable, and resistant to deformation, making it suitable for high-pressure applications.

Quality Control and Testing

Following the curing process, each pipe undergoes rigorous quality checks, including dimensional accuracy tests and pressure resistance tests. These measures ensure that the pipe meets industry standards and can withstand the required internal pressures without leakage.

Cutting and Finishing

After manufacturing, the CPVC FRP pipes are cut to the required lengths for the specific application. The pipe ends are then carefully finished to ensure smooth, clean cuts, which are essential for secure joint connections. This process eliminates rough edges or burrs, ensuring the pipes are ready for installation with minimal risk of leaks or installation issues.

Key Features of China CPVC FRP Pipe

Chemical Resistance

The CPVC inner layer provides excellent chemical resistance, allowing China CPVC FRP pipes to withstand a wide range of aggressive chemicals, including acids, bases, and solvents. This makes them ideal for industries like chemical processing, water treatment, and pharmaceuticals, where safe fluid transport is critical. The smooth inner surface helps prevent chemical buildup, ensuring reliable performance.

High-Temperature Performance

CPVC pipes perform well under high temperatures, making them suitable for applications involving hot water or high-temperature fluid transport. The combination of CPVC’s thermal resistance and fiberglass reinforcement allows the pipe to maintain its structural integrity in environments that would typically cause damage to PVC or metal pipes, ensuring longevity in thermal settings.

Corrosion Resistance

The fiberglass-reinforced outer layer protects the pipe from external corrosion caused by UV radiation, moisture, and environmental chemicals. This robust protection reduces maintenance needs and extends the pipe’s service life, making China CPVC FRP pipes highly reliable, even in outdoor or exposed applications, where traditional metal pipes would degrade quickly.

Mechanical Strength

Fiberglass reinforcement provides China CPVC FRP pipes with superior mechanical strength. These pipes can handle high-pressure systems, external impacts, and mechanical stress without failure. This makes them perfect for demanding industrial environments like oil and gas, where pipes must endure constant pressure and stress while maintaining reliability.

Lightweight and Easy to Install

China CPVC FRP pipes are much lighter than traditional metal pipes, making transportation and installation quicker and more cost-effective. The lightweight nature reduces the need for heavy equipment, simplifies handling, and cuts installation time, offering significant savings in large-scale industrial projects.

The Key Benefits of China CPVC FRP Pipe

China CPVC FRP pipe offers several advantages that make it a preferred choice for various industrial applications. These benefits include superior chemical resistance, high-temperature performance, mechanical strength, and ease of installation.

Superior Chemical Resistance

Corrosion Resistance: One of the primary advantages of China CPVC FRP pipe is its superior resistance to corrosion. The CPVC inner layer provides excellent resistance to a wide range of corrosive chemicals, including acids, bases, salts, and organic solvents. This makes the pipe ideal for use in chemical processing plants, where the transport of aggressive chemicals is a common requirement. The FRP outer layer adds an additional layer of protection, enhancing the pipe’s durability and ensuring long-term performance in corrosive environments.

Chemical Compatibility: China CPVC FRP pipe is compatible with a broad spectrum of chemicals, making it suitable for diverse applications. The smooth inner surface of the CPVC liner minimizes the risk of chemical reactions with the transported fluids, reducing the potential for contamination and ensuring the purity of the transported medium.

High-Temperature Performance

Temperature Tolerance: China CPVC FRP pipe exhibits excellent thermal stability, allowing it to handle high-temperature fluids without compromising its structural integrity. The CPVC layer can withstand temperatures up to 200°F (93°C), making it suitable for applications involving hot fluids, steam, or thermal cycling. The FRP reinforcement provides additional thermal resistance, ensuring that the pipe maintains its performance even in fluctuating temperature conditions.

Thermal Insulation: The multi-layer construction of China CPVC FRP pipe provides thermal insulation properties that help maintain the temperature of the transported fluid. The low thermal conductivity of CPVC reduces heat loss or gain, making the pipe an energy-efficient choice for applications where temperature control is critical.

Mechanical Strength and Durability

High Strength-to-Weight Ratio: China CPVC FRP pipe offers a high strength-to-weight ratio, providing mechanical strength comparable to traditional piping materials like steel, while being significantly lighter. This lightweight nature simplifies handling, transportation, and installation, reducing labor costs and installation time. Despite its lightweight design, the pipe can withstand high internal pressures, mechanical loads, and external impacts, ensuring long-term reliability.

Impact and Abrasion Resistance: The fiberglass-reinforced plastic outer layer of the pipe provides excellent resistance to impact and abrasion, protecting the pipe from mechanical damage during installation and operation. This durability is particularly valuable in applications where the pipe is exposed to physical stresses, such as in underground installations, industrial settings, or areas with heavy traffic.

Ease of Installation and Maintenance

Simplified Installation: China CPVC FRP pipe is designed for easy installation, with options for various jointing methods, including FRP pipe adhesive bonding, mechanical joints, and flanged connections. The lightweight nature of the pipe reduces the need for heavy lifting equipment, making it easier to install in confined spaces or challenging environments. This ease of installation helps reduce project timelines and labor costs.

Low Maintenance: The corrosion-resistant properties of China CPVC FRP pipe result in low maintenance requirements. The pipe does not rust, corrode, or scale, reducing the need for frequent inspections, cleaning, or repairs. Its smooth inner surface minimizes fouling and buildup, ensuring consistent fluid flow and reducing the risk of clogging or blockages.

China CPVC FRP Pipe Fittings and Specifications

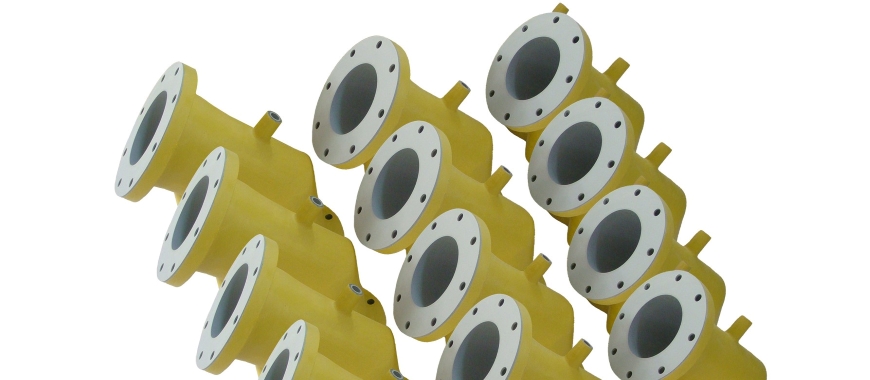

China CPVC FRP pipes are complemented by a wide range of fittings designed to facilitate complex piping layouts and ensure secure connections. These fittings are tailored to meet the specific needs of various industrial applications, providing versatility and reliability.

Types of Fittings

Flanged Elbows:

Flanged elbows are commonly used to change the direction of the piping system while maintaining a secure connection. These fittings are designed with flanged ends that can be bolted together, providing a leak-proof seal. Flanged elbows are available in various angles, including 45° and 90°, allowing for flexible installation in different piping configurations.

Full-Face Flanges:

Full-face flanges are used to connect CPVC FRP pipes to other piping components, such as valves, pumps, or equipment. These flanges provide a robust and leak-tight connection, ensuring the integrity of the piping system. Full-face flanges are available in different sizes and pressure ratings to accommodate various operational requirements.

Couplings:

Couplings are used to join two lengths of CPVC FRP pipe, providing a secure and flexible connection. They are typically designed with a bell-and-spigot configuration, allowing for easy assembly and disassembly. Couplings can be sealed using adhesives, gaskets, or mechanical restraints, depending on the application’s demands.

Reducers:

Reducers are used to connect pipes of different diameters, allowing for a smooth transition between sections of the piping system. This fitting is essential in applications where the flow rate or pressure needs to be adjusted.

Specifications

Size Range: China CPVC FRP pipes are available in a wide range of sizes to accommodate different flow requirements. Common sizes range from 25mm (1 inch) to 1200mm (48 inches) in diameter, with custom sizes available upon request.

Pressure Rating: The pressure rating of China CPVC FRP pipe depends on the pipe’s design, wall thickness, and the type of resin used in its construction. Standard pressure ratings range from 150 psi to 300 psi, making the pipe suitable for a variety of low-pressure and high-pressure applications.

Temperature Tolerance: China CPVC FRP pipe is designed to operate effectively at elevated temperatures. The CPVC layer provides thermal resistance, allowing the pipe to handle fluids with temperatures up to 200°F (93°C). This temperature tolerance makes the pipe suitable for hot water transport, steam lines, and other high-temperature applications.

Applications of China CPVC FRP Pipe

China CPVC FRP pipe is used in a wide range of industries due to its exceptional properties, including chemical resistance, mechanical strength, and thermal stability.

Chemical Processing

In chemical processing plants, China CPVC FRP pipe is used to transport aggressive chemicals, acids, and solvents. Its superior chemical resistance ensures that it can safely handle corrosive substances without degrading or leaching contaminants. The pipe’s smooth inner surface minimizes the risk of chemical reactions, preserving the purity of the transported fluids and ensuring the safety and efficiency of the processing system.

Water and Wastewater Treatment

China CPVC FRP pipe is widely used in water and wastewater treatment facilities for transporting potable water, sewage, and wastewater. The pipe’s corrosion-resistant properties make it ideal for use in environments where exposure to chemicals, chlorides, and other corrosive agents is common. Its smooth inner surface reduces the buildup of scale and biofilm, ensuring consistent flow and reducing maintenance requirements.

Oil and Gas

In the oil and gas industry, China CPVC FRP pipe is used for transporting hydrocarbons, produced water, and chemical additives. Its resistance to hydrocarbons, acids, and brine makes it suitable for use in harsh environments, including offshore platforms, refineries, and petrochemical plants. Additionally, GRP shelter are often employed alongside these pipes to protect critical equipment and infrastructure from harsh environmental conditions. The pipe’s high strength-to-weight ratio and thermal stability ensure reliable performance under high-pressure and high-temperature conditions.

The oil and gas industry presents some of the most challenging environments for piping systems, including exposure to hydrocarbons, high temperatures, and abrasive materials. China CPVC FRP pipe and China FRP sand pipe are both well-suited for use in this industry due to their superior resistance to hydrocarbons and aggressive chemicals. The CPVC lining protects the pipe from the corrosive effects of crude oil, natural gas, and other petroleum products, while the FRP reinforcement provides the necessary strength to handle high pressures and temperatures. Additionally, the lightweight nature of CPVC FRP pipes makes them easier to transport and install in remote or offshore locations, reducing installation costs and time. This combination of durability, chemical resistance, and ease of installation makes CPVC FRP pipes a preferred choice for oil and gas applications.

Applications of FRP Pipe Wet Layup in Industrial Rehabilitation

China CPVC FRP Pipe Manufacturing Process

China CPVC FRP pipe is a versatile and durable piping solution that integrates the chemical resistance of CPVC (Chlorinated Polyvinyl Chloride) with the mechanical strength of FRP (Fiberglass Reinforced Plastic). This dual-layer construction makes it ideal for use in demanding industrial environments, such as chemical processing, wastewater treatment, and oil and gas sectors. With advanced manufacturing processes, Chinese producers like GangLong Fiberglass have perfected the art of creating high-quality CPVC FRP pipes that offer superior performance, longevity, and cost-effectiveness. The combination of CPVC and FRP in these pipes provides enhanced resistance to corrosion, pressure, and temperature variations, making them suitable for a wide range of applications.

Manufacturing Process of CPVC FRP Pipe in China

The manufacturing process of China CPVC FRP pipe is a complex and precise procedure that involves combining CPVC with layers of fiberglass-reinforced plastic to produce a pipe that excels in both chemical resistance and mechanical strength. Chinese manufacturers employ advanced techniques and strict quality control measures to ensure that each pipe meets the required standards and performs reliably in its intended application.

CPVC Lining Preparation

The process begins with the preparation of the CPVC lining, which serves as the inner layer of the pipe. This lining is crucial as it provides the primary barrier against corrosive fluids and chemicals. The CPVC material is carefully selected based on its chemical compatibility with the fluids to be transported and its ability to withstand high temperatures. In some cases, additives are mixed with the CPVC to enhance its performance characteristics, such as increasing its resistance to UV radiation or improving its impact strength. The CPVC is then extruded or molded into the desired pipe shape, often utilizing FRP Pipe Mold to achieve precision and durability. This process ensures a smooth and uniform internal surface that minimizes friction and resists chemical attack.

Fiberglass Reinforcement Layer

Once the CPVC lining is prepared, the next step is to apply the fiberglass reinforcement layer. This layer is constructed using glass fibers that are impregnated with a thermosetting resin, such as polyester, vinyl ester, or epoxy. The choice of resin depends on the specific requirements of the application, including the level of chemical resistance, mechanical strength, and temperature tolerance needed. The fiberglass reinforcement process can involve various techniques, such as filament winding, fiberglass hand lay-up, or spray-up methods. In filament winding, continuous glass fibers are wound around the CPVC lining in a specific pattern to achieve the desired strength and structural integrity. This process allows for precise control over the thickness and orientation of the fiberglass layer, ensuring optimal performance of the finished pipe.

Curing and Hardening

After the fiberglass layer is applied, the pipe undergoes a curing process to harden the resin and bond the layers together. Curing is typically carried out using heat, UV light, or a chemical catalyst, depending on the type of resin used. During this process, the resin undergoes a chemical reaction that transforms it from a liquid or gel state into a solid, durable matrix that encapsulates the glass fibers and bonds them to the CPVC lining. The curing process is carefully controlled to ensure that the pipe achieves the desired mechanical properties, such as high tensile strength, impact resistance, and flexibility. Proper curing is essential to prevent defects like voids, cracks, or weak spots in the pipe structure, which could compromise its performance and longevity.

Quality Control and Inspection

Quality control is a critical aspect of the manufacturing process for China CPVC FRP pipe. Manufacturers like GangLong Fiberglass implement rigorous inspection and testing procedures at various stages of production to ensure that each pipe meets the required standards and specifications. Tests may include visual inspections for surface defects, dimensional checks to verify the pipe’s size and wall thickness, and mechanical tests to assess properties such as tensile strength, flexural strength, and impact resistance. Additionally, chemical resistance tests are conducted to ensure that the CPVC lining provides adequate protection against the intended fluids. By adhering to strict quality control measures, Chinese manufacturers ensure that their CPVC FRP pipes deliver reliable performance in the most demanding environments.

How Resin Types Impact FRP Pipe Tensile Strength

Specifications for Different Applications

China CPVC FRP pipes are manufactured to meet a wide variety of specifications to cater to the unique demands of various industrial applications. These pipes are designed with different sizes, pressure ratings, and temperature tolerances, allowing them to handle a diverse range of fluids and operating conditions. The ability to customize the specifications ensures that the pipes deliver optimal performance and reliability in each application.

High-Pressure Chemical Transport

For high-pressure chemical transport, pipes like a DN200 flanged elbow with a design pressure of 290 psi and a design temperature of 200°F are ideal. This configuration is engineered to withstand the rigorous demands of transporting aggressive chemicals at high pressures while maintaining safe operation at elevated temperatures. The DN200 size provides the necessary flow capacity, while the FRP outer layer ensures that the pipe can handle mechanical stresses, external impacts, and environmental conditions that are common in chemical processing industries.

Lower-Pressure Applications

On the other hand, for applications such as wastewater transport, a DN50 full-face flange with a design pressure of 100 psi and a temperature rating of 170°F is suitable. These pipes are designed for lower-pressure systems, offering excellent performance in transporting non-corrosive or less aggressive fluids like wastewater. The temperature tolerance ensures that the pipe can handle typical environmental conditions without risk of damage or failure. The DN50 size is perfect for more localized or small-scale systems, providing flexibility and efficiency.

Customization and Versatility

By offering a range of sizes, pressure ratings, and temperature tolerances, manufacturers like GangLong Fiberglass are able to provide customized solutions that ensure the pipes perform effectively in their respective applications. Whether it is high-pressure systems that require durable, corrosion-resistant materials or lower-pressure systems that need efficient and reliable fluid transport, CPVC FRP pipes offer a versatile, durable solution for a wide variety of industrial environments.

Top Challenges Contractors Face in Securing FRP Pipes Tenders

How to Choose a Reliable China CPVC FRP Pipe Manufacturer

Key Factors

Product Quality

It is essential to ensure that the manufacturer adheres to international quality standards. Look for certifications that indicate the company uses high-grade CPVC and FRP materials, which are necessary to ensure the pipes’ durability, strength, and resistance to corrosion. High-quality materials will guarantee the pipes perform reliably in harsh conditions, offering long-lasting service in industrial environments.

Experience and Reputation

Choose a manufacturer with years of experience in the production of CPVC FRP pipes. A company with a solid reputation for delivering high-quality products is more likely to be trustworthy. You should also consider customer reviews and testimonials, as positive feedback is a good indicator of consistent performance and reliability. An experienced manufacturer will be more capable of addressing challenges and providing solutions that meet specific industry needs.

Customization and Variety

A reliable manufacturer should offer a wide range of CPVC FRP pipes, fittings, and accessories. Customization options are crucial to meet the diverse requirements of different industries, such as chemical processing, water treatment, or oil and gas. A manufacturer that can provide tailored solutions based on your specific needs is more likely to deliver products that fit your application perfectly and ensure system efficiency.

Technical Support and Certification

Verify the manufacturer’s certifications, such as ISO or other industry-specific standards, which indicate that they meet internationally recognized quality benchmarks. It’s also important that the manufacturer offers comprehensive technical support throughout the product’s lifecycle. Support should include assistance with installation, maintenance, and troubleshooting to ensure the product’s optimal performance. A strong technical support team is invaluable in addressing any issues that arise during the use of the CPVC FRP pipes.

Advantages of GangLong Fiberglass as a China CPVC FRP Pipe Manufacturer

Innovative Manufacturing Techniques

GangLong Fiberglass blends traditional craftsmanship with the latest manufacturing technologies. By utilizing advanced extrusion and filament winding techniques, we ensure that our CPVC FRP pipes offer superior durability, strength, and resistance to environmental factors. This integration of modern innovation with time-tested techniques allows us to produce high-quality, reliable products that meet the highest performance standards.

Comprehensive After-Sales Support

We prioritize customer satisfaction by offering comprehensive after-sales support. Our technical team is available for assistance with installation, troubleshooting, and ongoing maintenance, ensuring that our clients have the resources they need to get the most out of our products. This commitment to support provides peace of mind and helps optimize system efficiency over time.

Efficient Production and Timely Delivery

With robust production capacity, we can handle large orders and deliver products within the required timeframes. Our streamlined manufacturing process ensures that we meet delivery deadlines without compromising quality. Whether you have bulk orders or custom requests, we manage all aspects of production efficiently, enabling timely project completion.

Established Trust with Global Clients

GangLong Fiberglass has earned the trust of both domestic and international clients by consistently delivering high-quality CPVC FRP pipes. Our reputation for reliability, technical excellence, and customer-centric service has positioned us as a preferred partner in industries worldwide, from chemical processing to oil and gas. Our products have helped clients improve their operational efficiency and reduce maintenance costs over the long term.

FAQs about China CPVC FRP Pipe

CPVC (Chlorinated Polyvinyl Chloride) and FRP (Fiberglass Reinforced Plastic) are both used in piping systems, but they differ significantly in terms of composition, properties, and applications. CPVC is a thermoplastic material made by chlorinating PVC resin, which enhances its temperature resistance and chemical durability. It is known for its ease of installation, resistance to corrosion, and ability to handle hot and cold fluids. CPVC is commonly used in residential plumbing, hot water distribution, and certain industrial applications where moderate chemical resistance is required.

FRP, on the other hand, is a composite material made by reinforcing a plastic matrix (usually polyester, vinyl ester, or epoxy resin) with glass fibers. This structure gives FRP pipes high strength, excellent chemical resistance, and the ability to withstand extreme conditions, including high pressures and corrosive environments. FRP pipes are often used in industries like chemical processing, wastewater treatment, and oil and gas, where harsh chemical exposure and mechanical stresses are common. Unlike CPVC, FRP pipes can be custom-engineered for specific applications, providing greater flexibility in terms of design, diameter, and wall thickness.

CPVC is still in use, but its popularity has declined in some areas due to certain limitations and the availability of more advanced piping materials like FRP. One reason CPVC is less favored in some industrial settings is its limited temperature and chemical resistance compared to materials like FRP. While CPVC can handle hot water and certain chemicals, it may degrade or become brittle when exposed to more aggressive chemicals, high temperatures, or UV radiation over time. This makes CPVC less suitable for environments with harsh chemical exposure or where long-term durability is critical.

In addition, CPVC can be prone to issues such as cracking and stress corrosion, especially if installed improperly or exposed to mechanical stress and vibration. These factors can lead to leaks and pipe failures, requiring frequent maintenance or replacement. For industries that demand high performance and reliability, materials like FRP offer a more robust solution. FRP pipes, with their superior strength, corrosion resistance, and customizability, are often chosen for applications where CPVC may fall short. However, CPVC remains a practical choice for certain residential and light industrial applications where its properties meet the system’s requirements.

FRP (Fiberglass Reinforced Plastic) pipe and PVC (Polyvinyl Chloride) pipe differ significantly in their composition, properties, and applications. PVC is a thermoplastic made from polyvinyl chloride, known for its lightweight, chemical resistance, and ease of installation. PVC pipes are commonly used in plumbing, irrigation, drainage, and low-pressure water transport due to their affordability and resistance to corrosion from water and certain chemicals. However, PVC has limitations in terms of temperature resistance and mechanical strength. It can become brittle in cold temperatures and may soften or deform when exposed to high temperatures.

FRP pipe, on the other hand, is a composite material consisting of a plastic matrix reinforced with glass fibers. This construction gives FRP pipes exceptional strength, durability, and resistance to a wide range of chemicals, including acids, alkalis, and solvents. FRP pipes can withstand high pressures and temperatures, making them suitable for demanding industrial applications such as chemical processing, wastewater treatment, and oil and gas transport. Unlike PVC, FRP pipes can be custom-engineered to meet specific requirements, including varying diameters, wall thicknesses, and reinforcement patterns. This flexibility, combined with their superior performance characteristics, makes FRP pipes the preferred choice for applications where PVC would not be sufficient.

CPVC (Chlorinated Polyvinyl Chloride) has some notable disadvantages despite its strength and versatility. One primary concern is its susceptibility to cracking under high physical stress or impact, especially in cold weather conditions. While CPVC FRP pipes (Fiber-Reinforced Plastic) enhance durability, CPVC itself remains more rigid and less flexible than alternatives like PEX, making it prone to stress failures over time. Additionally, CPVC pipes can deteriorate when exposed to certain chemicals, including strong solvents, which may limit their applications. Installation is another challenge—CPVC requires solvent welding, which demands skilled labor to ensure proper sealing and prevent leaks. Moreover, CPVC pipes have a lower tolerance for high-temperature spikes compared to metals, making them unsuitable for extremely high-temperature systems. While CPVC FRP pipes are robust and long-lasting, their brittleness in adverse conditions remains a notable limitation, particularly in heavy-duty or industrial environments.

Yes, CPVC is widely regarded as safe for drinking water applications. CPVC pipes, including CPVC FRP pipes, are specifically designed to meet stringent health and safety standards for potable water. They are non-toxic and resistant to leaching, ensuring water quality remains uncontaminated. CPVC does not corrode or scale like metal pipes, which means harmful contaminants such as rust or heavy metals cannot enter the water supply. Furthermore, CPVC has excellent resistance to biofilm formation, reducing the risk of bacterial growth within pipes. In China and globally, CPVC pipes are tested and approved by regulatory bodies, ensuring compliance with safety certifications like NSF/ANSI for drinking water systems. However, it is essential to install CPVC pipes correctly and avoid exposure to harsh chemicals that may compromise the material’s integrity. As a durable and hygienic solution, CPVC FRP pipes remain a safe and reliable choice for residential and commercial water supply systems.

The best plastic pipe for plumbing largely depends on the specific requirements of the project, but CPVC FRP pipes are among the top contenders for durability and performance. CPVC pipes are ideal for both hot and cold water systems due to their excellent heat resistance, chemical stability, and low maintenance. When reinforced with FRP (Fiber-Reinforced Plastic), they gain enhanced strength and durability, making them suitable for high-pressure and heavy-duty applications. CPVC FRP pipes are corrosion-resistant and long-lasting, outperforming traditional metal pipes in many environments. Other alternatives, like PEX pipes, offer flexibility but lack CPVC’s resistance to extreme temperatures and chemical exposure. In commercial and industrial plumbing systems, where reliability and lifespan are critical, CPVC FRP pipes are preferred for their superior performance. Their lightweight nature, ease of installation, and cost-effectiveness make them one of the best plastic pipe options for plumbing projects, particularly in demanding environments.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.