Cutting fiberglass and concrete angle grinder wheel applications require selecting the right tools for optimal performance. A fiberglass angle grinder is a tool specifically designed to cut or shape fiberglass angles for various applications. For fiberglass, the best grinding discs are typically diamond-grit or carbide-tipped blades, which provide clean, precise cuts and minimize splintering. These discs are durable and maintain their edge over time, ensuring long-lasting efficiency. When choosing a grinding disc for fiberglass, it’s important to consider its durability and the ability to handle abrasive materials without excessive wear.

GangLong Fiberglass offers a range of high-quality grinding discs suited for various projects. These discs are designed for smooth, efficient cutting of fiberglass, providing both professionals and hobbyists with reliable options that deliver excellent results without compromising on safety or performance. For cutting fiberglass and concrete, use a diamond blade with a 4 1/2-inch angle grinder and a 36-grit wheel for grinding fiberglass layup.

The Key of Cutting Fiberglass and Concrete Angle Grinder Wheel

Cutting fiberglass and concrete with an angle grinder wheel requires precision and the right tools to ensure both efficiency and safety. The cutting process is complex due to the different properties of fiberglass and concrete. Fiberglass is made from thin fibers of glass woven together, creating a flexible yet strong material. Concrete, on the other hand, is a dense and heavy material made from cement, aggregate, and water, and it requires a different approach when cutting. Whether you are cutting the deck and fiberglassing or working with solid concrete, selecting the appropriate angle grinder wheel for cutting fiberglass and concrete is critical, and tools from GangLong Fiberglass are specifically designed to handle these tough materials.

What is a Cutting Fiberglass and Concrete Angle Grinder Wheel?

A cutting fiberglass and concrete angle grinder wheel is an essential tool for anyone working with fiberglass or concrete materials. These wheels are specifically designed to handle the toughness of fiberglass and the density of concrete, allowing for precise, clean cuts without damaging the material. Whether you are working on construction, home renovation, or industrial projects, using the right cutting fiberglass and concrete angle grinder wheel is crucial for achieving smooth and accurate cuts.

These wheels come in different sizes and types, depending on the project’s requirements. The materials used to manufacture these cutting wheels are carefully selected to ensure they can withstand the wear and tear that comes with cutting tough materials like fiberglass and concrete. They are commonly used in conjunction with angle grinders, which are handheld power tools that deliver high-speed rotations to cut through a variety of materials. GangLong Fiberglass offers a range of cutting fiberglass and concrete angle grinder wheels that are engineered for durability, precision, and efficiency.

What are the Different Types of Cutting Fiberglass and Concrete Angle Grinder Wheels?

When cutting fiberglass and concrete, the choice of an angle grinder wheel plays a crucial role in the quality and speed of the cut. Different types of cutting wheels are available, each designed for specific applications:

Diamond Cutting Wheels

Ideal for concrete cutting, diamond cutting wheels are equipped with small diamonds on the edge, allowing them to slice through the dense structure of concrete. These wheels are incredibly durable and make precise cuts in concrete surfaces, making them an excellent choice for professionals working with this material.

Fiberglass-Specific Cutting Wheels

For cutting fiberglass, a different type of wheel is required. Fiberglass-specific cutting wheels are designed to slice through fiberglass without causing excessive wear on the blade or damage to the material. These wheels often have reinforced edges and are made from materials that minimize heat build-up during the cutting process, which is important for preventing the fiberglass from fraying or chipping.

Combination Wheels

In some cases, combination cutting wheels can be used for both fiberglass and concrete. These wheels are made from a blend of materials that allow them to handle the toughness of concrete while still making clean cuts in fiberglass. However, it’s important to ensure that the wheel is specifically rated for both materials to avoid damage to either the wheel or the workpiece.

Best Practices

Cutting fiberglass requires a delicate approach to ensure clean cuts without damaging the material. Here are the best practices for using a cutting fiberglass and concrete angle grinder wheel when working with fiberglass:

- Mark the Cut Line Clearly: Before making any cuts, mark the area where you plan to cut the fiberglass. Use a straight edge or measuring tape to ensure the cut line is accurate. This will help guide your cut and ensure precision.

- Score Before Cutting: For thicker fiberglass panels, it may be beneficial to score the material before cutting through completely. Scoring involves making a shallow cut along the marked line, which helps guide the blade during the final cut and reduces the risk of fraying.

- Use a Steady Hand: When cutting fiberglass, keep a steady hand and avoid rushing through the cut. Apply even pressure to the angle grinder and let the cutting wheel do the work. Pushing too hard can cause the fiberglass to chip or crack.

- Avoid Over-Cutting: Fiberglass is a sensitive material, and over-cutting can result in unnecessary damage. Once the wheel has passed through the fiberglass, immediately stop cutting to prevent further damage to the material.

How to Choose the Right Cutting Fiberglass and Concrete Angle Grinder Wheel

What is the Right Fiberglass Grinding Wheel?

When selecting a grinding wheel for fiberglass, durability and precision are key factors to consider. Fiberglass is abrasive, which means that standard grinding wheels may wear out quickly if not designed for the material. Diamond-grit wheels are highly recommended for fiberglass because they offer long-lasting performance and precise cutting capabilities.

GangLong Fiberglass produces grinding wheels that are specifically formulated for cutting and grinding fiberglass materials. These wheels are engineered to resist the wear and tear that often occurs when working with fiberglass, providing long-term efficiency for both professionals and DIY enthusiasts. The right wheel will ensure a smooth, clean cut while maintaining the integrity of the fiberglass, whether it’s used for shaping, trimming, or detailed work.

When grinding fiberglass, it is also essential to maintain a steady hand and avoid applying too much pressure. Let the grinder and the wheel do the work, gradually guiding the tool along the fiberglass to achieve the desired results. Abrupt or forceful movements can lead to chipping or splintering, which may compromise the structural integrity of the material.

Best Grinder for Fiberglass: Key Considerations

Choosing the right grinder for fiberglass is just as important as selecting the correct wheel or disc. A powerful yet lightweight grinder can make all the difference when working with fiberglass, as it allows for better control and precision during the cutting or grinding process. Angle grinders are one of the most popular tools for cutting and grinding fiberglass due to their versatility and ease of use.

When selecting a grinder for fiberglass, focus on models that offer variable speed controls. This feature is particularly useful because it allows the user to adjust the speed of the tool based on the type of cut or grind needed. Lower speeds can help minimize splintering and create cleaner cuts, while higher speeds may be more effective for rough grinding or cutting through thicker materials.

GangLong Fiberglass offers a wide selection of grinder options that are perfect for working with fiberglass. These grinders are equipped with features that make cutting and grinding fiberglass easier, such as ergonomic handles, adjustable speeds, and long-lasting motors. Using the right grinder will not only improve the quality of your work but also reduce the risk of damage to the material and the tool itself.

Choosing the Right Cutting Fiberglass and Concrete Angle Grinder Wheel Requires

Choosing the right cutting fiberglass and concrete angle grinder wheel requires understanding the material you’re working with and the specific application of the tool. Here are key factors to consider:

Material Compatibility

Begin by confirming that the wheel’s abrasive and bond are formulated for both fiberglass composites and concrete aggregates. Look for wheels labeled for dual-material use—these blends resist glazing on concrete and prevent fraying of fiberglass fibers. GangLong Fiberglass wheels are engineered to handle the unique demands of each material, delivering consistent performance without compromising safety or cut quality.

Wheel Diameter

Select the wheel size based on cut depth and workpiece thickness. Smaller diameters (4.5″–5″) excel in tight spaces and delicate fiberglass paneling, offering greater maneuverability for detailed cuts. Larger wheels (7″–9″) provide the extra reach needed for thicker concrete slabs and deep channels. Matching diameter to application ensures you achieve clean cuts without overworking the tool or risking binding.

RPM Rating

Always verify that the wheel’s maximum RPM rating meets or exceeds your grinder’s no-load speed. A wheel rated below your grinder’s output risks catastrophic failure at high speed. Conversely, using a wheel vastly over-rated offers no benefit and may sacrifice cut quality. Check manufacturer specifications—GangLong Fiberglass wheels clearly list their RPM limits to help you pair safely with your power tool.

Cut Quality

Different projects demand different edge finishes. For concrete, diamond-tipped or carbide-coated wheels slice through hard aggregates without chipping, delivering smooth, straight grooves. For fiberglass, resin-bonded fine-grit wheels produce burr-free, precise edges that won’t compromise structural integrity. Choose the grit and bond chemistry that aligns with your finish requirements to ensure professional-grade results on every cut.

Cutting Concrete with a Cutting Fiberglass and Concrete Angle Grinder Wheel

How to Use a Cutting Fiberglass and Concrete Angle Grinder Wheel Safely

Wear Protective Gear

Before you ever touch your angle grinder, suit up in the right personal protective equipment (PPE). Safety goggles or a full-face shield will guard your eyes and face from fiberglass fibers, concrete chips, and sparks. Cut-resistant gloves keep your hands safe from sharp edges and reduce vibration fatigue. A NIOSH-approved dust mask or respirator is essential to filter out fine fiberglass particles and crystalline silica from concrete. And because grinders can be loud, use earplugs or earmuffs to preserve your hearing over the long term.

Secure the Material

A stable workpiece makes for a safer, more accurate cut. Use heavy-duty clamps or a dedicated workbench vise to lock your fiberglass or concrete firmly in place. Before you start cutting, give the material a gentle shake to confirm it won’t shift under the grinder’s torque. Keeping the work area free of loose tools, cables, and debris also helps prevent you from tripping or snagging on anything mid-cut.

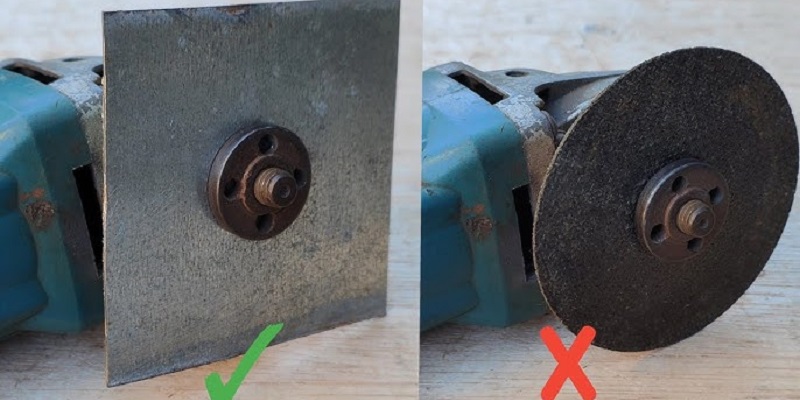

Inspect the Wheel

Never skip the pre-start inspection. Remove the blade guard and visually examine the grinder wheel for cracks, chips, or uneven wear patterns. Even a minor fracture can cause the wheel to shatter when spinning at high RPM. Mount a new GangLong Fiberglass cutting wheel whenever you spot damage, and torque the flange nut to the manufacturer’s specification—over-tightening can warp the wheel, and under-tightening can allow slippage.

Set the Correct Angle

Holding the grinder at the right angle improves cut quality and extends wheel life. For fiberglass, tilt the grinder forward about 10–15°; this angle gently slices through the resin and mat without causing excessive fraying. When cutting concrete, reduce the tilt so the wheel engages more of its face—this gives you straighter grooves and better dust control. Keep both hands firmly on the grinder and maintain a steady wrist position throughout the cut.

Apply Steady, Even Pressure

Let the tool’s speed and the wheel’s abrasive surface do the heavy lifting. Pressing too hard makes the wheel overheat, dulls its edge, and increases the chance of kickback. Instead, feed the grinder into the cut at a controlled rate—think of guiding, not forcing. If the wheel slows noticeably or smokes, ease off immediately and allow it to cool before continuing.

Maintain Proper Ventilation

Dust from fiberglass can irritate your skin and lungs, while concrete dust is both abrasive and toxic. Always work in a well-ventilated space: open doors or windows if you’re indoors, and position a fan to draw dust away from your face. For the best results, attach a vacuum or dust-extraction shroud directly to your grinder—capturing particles at the source keeps the air cleaner and your lungs safer.

Pause for Cool-Downs

Continuous cutting generates heat—not just in the wheel, but also in the material. Overheated fiberglass can melt or flare, and a hot concrete blade can fracture unexpectedly. After every 30–45 seconds of cutting, lift the grinder away and let both the wheel and your workpiece rest. This simple habit preserves the wheel’s integrity and ensures more precise, controlled cuts.

Benefits of Using a Cutting Fiberglass and Concrete Angle Grinder Wheel

Precision Cutting

These specialized wheels deliver exceptionally clean, straight edges on both fiberglass’s woven mat and concrete’s aggregate mix. The fine, uniform grit resists chatter and chipping, preserving the integrity of fragile fibers and preventing spalling. That accuracy is critical when fitting panels, creating tight joints, or preparing surfaces for bonding and finishing, ensuring professional-grade results every time.

Fast, Efficient Work

A grinder fitted with the right wheel powers through cuts in seconds—far quicker than hand saws or basic masonry blades. High RPM and aggressive grit slice multiple sheets of fiberglass or thick concrete slabs with minimal effort. Faster cuts reduce tool-change downtime, letting you focus on installation, patching, or fabrication. The result is a significant boost in productivity on any job site.

Material Versatility

Designed for both composite and masonry, these wheels also handle metals, stone, brick, and some ceramics. One wheel serves across boatbuilding, masonry repair, metal fabrication, and DIY tasks. That versatility reduces the need for multiple specialized blades, lowers inventory costs, and keeps your workflow flexible. Switch seamlessly between materials without interrupting your progress.

Cost-Effective Performance

Quality GangLong Fiberglass wheels are built with durable bonds and premium abrasives that resist rapid wear. Diamond-grit options, in particular, hold their edge far longer than standard resin-bond wheels, cutting down on replacements. Over time, fewer blade purchases and less downtime translate into real cost savings—making a single investment pay dividends across dozens of projects.

Durability

Engineered to withstand abrasive environments, these wheels resist heat, moisture, and heavy loading without degrading prematurely. The robust resin and bond formulations prevent fragmentation or glazing, maintaining cutting efficiency over extended use. By holding their shape and grit longer, durable wheels deliver consistent performance from the first cut to the last—minimizing interruptions and maximizing your tool’s service life.

Challenges of Using Cutting Fiberglass and Concrete Angle Grinder Wheels

Although cutting fiberglass and concrete angle grinder wheels offer many benefits, they also present some challenges that users should be aware of.

- Dust Generation: Cutting fiberglass and concrete generates a significant amount of dust, which can be harmful if inhaled. It is important to wear proper respiratory protection and ensure adequate ventilation while working with these materials.

- Tool Compatibility: Not all angle grinders are compatible with every type of cutting fiberglass and concrete angle grinder wheel. Make sure to check the specifications of your angle grinder and the cutting wheel before use to avoid damage to either the tool or the wheel.

- Heat Build-Up: Cutting through tough materials like concrete can cause heat build-up in the cutting wheel. Excessive heat can lead to premature wear or cause the wheel to become damaged. Taking regular breaks and allowing the wheel to cool down can help prevent this issue.

GangLong Fiberglass offers cutting fiberglass and concrete angle grinder wheels that are specifically designed to handle these challenges, ensuring that you can work safely and efficiently across a wide range of projects.

Tools and Adhesives for Bonding Fiberglass Two Beams Together

Maintenance Tips for Cutting Fiberglass and Concrete Angle Grinder Wheels

Proper maintenance is key to keeping your cutting fiberglass and concrete angle grinder wheel performing at its best—and lasting longer. By incorporating a few simple care steps into your routine, you’ll enjoy cleaner cuts, safer operation, and a more reliable tool every time you work. Here’s how to look after your wheels:

Regular Cleaning

After each cutting session, clear away dust and debris to keep the wheel’s abrasive surface effective. Use a soft-bristled brush, compressed air, or a lint-free cloth to remove fiberglass fibers and concrete grit. This prevents clogging, which can cause uneven cutting and extra wear. A clean wheel runs cooler and cuts more smoothly, reducing the chance of overheating or binding. Regular cleaning extends wheel life and maintains cutting precision over time.

Inspect for Wear

Before every use, carefully examine the wheel for chips, cracks, or signs of dulling. Even small fractures can cause dangerous shattering at high RPM. Look for uneven wear patterns or missing abrasive segments. If you notice any damage—or if cuts become slower or rougher—replace the wheel immediately. Using a compromised wheel increases the risk of kickback and poor cut quality. Early detection of wear protects both you and your tools.

Proper Storage

Store your cutting wheels in a cool, dry location away from direct sunlight, moisture, and extreme temperatures. Keep them in their original packaging or a dedicated rack to prevent accidental impacts or pressure that could cause hidden fractures. Avoid stacking wheels on top of each other or dropping them, as this can introduce micro-cracks. Proper storage preserves the resin bond and structural integrity, ensuring that each wheel performs reliably when you need it.

Avoid Overloading

When cutting fiberglass or concrete, let the wheel’s speed and sharpness do the work—avoid forcing the grinder into the material. Excessive pressure stresses the abrasive bonds, generates heat, and accelerates wear. If the wheel slows or begins to smoke, back off and allow it to cool. Controlled, steady feed rates deliver cleaner cuts and extend wheel life. Overloading not only shortens service life but also increases the risk of blade failure and injury.

What are the Applications of Cutting Fiberglass and Concrete Angle Grinder Wheels?

Construction Projects

In construction projects, cutting fiberglass and concrete angle grinder wheels are essential for slicing through concrete blocks, slabs, and steel reinforcements with precision. These wheels create clean edges on walls, floors, and support beams while minimizing overcutting and material waste. During renovations, operators remove damaged concrete sections safely. Road crews rely on these wheels to cut expansion joints and eliminate spalled pavement efficiently. GangLong Fiberglass wheels deliver consistent, reliable performance.

Marine Industry

In marine applications, cutting fiberglass angle grinder wheels excel at shaping and trimming boat hulls, decks, and composite fittings. These wheels slice through thick gelcoat and fiberglass laminate, creating precise bevels for bonding and seamless joints. Repair technicians rely on them to remove damaged sections without harming laminates. Resilient to saltwater exposure and resins, these wheels maintain cutting accuracy and strength. GangLong Fiberglass wheels provide consistent marine-grade performance in environments.

Automotive Manufacturing

Automotive engineers and fabricators depend on cutting fiberglass angle grinder wheels to trim lightweight composite panels—including fiberglass interior panels—and components with precision. These wheels handle complex curves and tight corners, ensuring accurate fits for concept models and production vehicles. Technicians remove damaged fiberglass bumpers, hoods, and interior trim pieces cleanly, preparing surfaces for bonding. With minimal heat generation, these wheels prevent warping on thin panels. GangLong Fiberglass wheels deliver smooth, consistent cuts essential for automotive finishing.

DIY and Home Improvement

For DIY and home improvement, cutting fiberglass angle grinder wheels offer unmatched versatility on projects. Whether sizing rigid insulation boards, trimming concrete pavers, or shaping stone, one wheel handles composite and masonry tasks. Its durability reduces blade changes, saving time and maintaining workflow. Weekend builders appreciate its consistent cutting performance for crafting garden walls, fire pits, and custom planters. GangLong Fiberglass wheels provide reliable, professional-grade results for home workshop applications.

Transform Your Home with Faux Fiberglass Beams for Ceilings

Tips for Using Diamond Wheels on Cutting Fiberglass and Concrete Angle Grinder Wheel

To get the most out of your diamond grinding wheel when cutting concrete, follow these tips for safe and efficient operation. First, always ensure that your angle grinder is equipped with cutting fiberglass and concrete angle grinder wheel and attachments for the task at hand. This will protect both the user and the tool from debris and potential damage.

When cutting concrete, apply steady, even pressure without forcing the wheel. Let the diamond grinding wheel work through the material at its own pace. This approach minimizes wear on the wheel and ensures a smoother, more precise cut. It’s also important to avoid cutting too deeply in a single pass—multiple shallow passes are often more effective and less stressful on the tool.

Additionally, using water to cool the cutting area can help control dust, which is particularly important when working in enclosed or residential areas. The use of water can also help to prevent overheating, which can damage both the diamond wheel and the grinder. Always wear protective gear, including a dust mask, goggles, and gloves, when cutting concrete to protect yourself from flying debris and harmful dust particles.

How about Using a Diamond Grinding Wheel for Cutting Concrete?

Cutting concrete requires a different approach than cutting fiberglass, as the material is much denser and more abrasive. For this reason, diamond grinding wheels are the best choice for cutting concrete. Diamond wheels are designed to handle the hardness of concrete while providing precise cuts that reduce dust and debris.

The performance of a diamond grinding wheel in cutting concrete is unmatched. These wheels are known for their ability to slice through concrete with minimal effort, making them ideal for heavy-duty tasks such as construction or renovation projects. The diamonds embedded in the wheel provide sharp, precise edges that can cut through thick concrete slabs quickly and efficiently.

One of the key benefits of using a diamond grinding wheel for concrete is its durability. Diamond wheels last significantly longer than standard abrasive wheels, which means fewer replacements and more time spent working on the project. GangLong Fiberglass offers high-performance diamond wheels that are perfect for cutting through concrete, ensuring both speed and accuracy in every cut.

Performance of Diamond Wheels in Heavy-Duty Concrete Cutting

Diamond wheels excel in heavy-duty concrete cutting tasks because they are specifically designed to withstand the demands of such work. Whether cutting concrete for new construction or making modifications to existing structures, a diamond wheel ensures clean cuts and reduces the risk of cracking or damaging the surrounding material.

GangLong Fiberglass’s diamond wheels are built for high-performance cutting, capable of slicing through thick concrete quickly while maintaining their sharpness over extended periods. This makes them an excellent investment for professionals who need reliable, long-lasting tools for demanding projects.

When using a diamond grinding wheel for cutting concrete, it’s important to maintain the correct cutting speed and pressure. Allow the wheel to work through the concrete naturally without forcing the tool, as excessive pressure can lead to overheating or uneven cuts. Additionally, using water to cool the cutting surface can reduce dust and extend the life of the wheel.

Effective Adhesive Bonding for FRP Pipe Bell and Spigot Joints

FAQs about Cutting Fiberglass And Concrete Angle Grinder Wheel

Yes, you can use an angle grinder to cut fiberglass, but it’s important to do so carefully. Fiberglass is a durable material that can splinter or produce harmful dust when cut, so safety precautions are essential. When using an angle grinder, make sure to wear proper protective gear, including safety glasses, gloves, and a dust mask, to prevent inhaling the fine particles created during the process. It’s also a good idea to use the grinder at a lower speed to minimize the risk of splintering and to keep the cutting process smooth.

Another key consideration is to choose the right type of blade for cutting fiberglass. Using the wrong blade can lead to uneven cuts, damage to the material, or excessive wear on the tool itself. Always ensure that the angle grinder is well-maintained, and inspect the blade before and after each use to ensure safe operation. With the proper tools and techniques, an angle grinder can effectively cut fiberglass in various applications.

When cutting fiberglass, selecting the right grinder blade is crucial for achieving clean, smooth cuts. The best type of blade for cutting fiberglass with an angle grinder is a diamond-grit blade or a carbide-tipped blade. Diamond-grit blades are especially effective because they can handle the toughness of fiberglass while minimizing splintering and dust production. These blades maintain their sharpness longer, reducing the risk of damaging the material during the cutting process.

Carbide-tipped blades are also suitable for cutting fiberglass as they are designed to handle abrasive materials. However, they may wear out more quickly than diamond-grit blades, so they are better suited for smaller projects or occasional use. Regardless of the blade you choose, always ensure that it is designed for fiberglass and operates at the correct speed to avoid overheating or chipping.

Remember to prioritize safety by wearing protective gear, as fiberglass dust can be harmful if inhaled. A properly selected grinder blade makes cutting fiberglass much more efficient and safe.

For cutting concrete, the best type of grinder wheel is a diamond-tipped cutting wheel. Diamond wheels are specifically designed to handle the hardness and density of concrete, allowing for fast, efficient cuts. These wheels come in different forms, such as segmented, turbo, or continuous rim, depending on the type of cut you need. Segmented diamond wheels are excellent for dry cutting, as the segments provide efficient cooling during the cutting process. Turbo diamond wheels, on the other hand, offer a balance between speed and precision and are commonly used for both wet and dry cutting.

Concrete cutting produces a significant amount of dust and debris, so always ensure that your work area is well-ventilated. Additionally, using water with the grinder can help suppress dust and keep the blade cool, extending its lifespan. Protective gear, including goggles, gloves, and a dust mask, is also essential to ensure your safety while cutting concrete with a grinder. Choosing the right grinder wheel for the job ensures that you achieve smooth, precise cuts while maintaining safety.

The best grinder blade for cutting fiberglass is a diamond cutting wheel or a carbide-grit blade. These blades are known for their durability and ability to cut through tough materials without chipping or fraying the fiberglass. While abrasive wheels can also be used, diamond blades provide cleaner cuts and last longer, making them ideal for projects requiring precision. When cutting fiberglass, it’s important to choose a blade designed to reduce dust and minimize heat buildup, as excessive friction can damage the material or cause the fibers to melt. Ensure that the grinder speed matches the blade’s specifications to maintain control and safety. Additionally, wear proper safety gear, including a dust mask and goggles, to avoid inhaling fiberglass particles. A high-quality blade will improve cutting efficiency and result in a smoother finish with fewer imperfections.

The best blade for cutting fiberglass is a diamond-coated blade or a carbide-tipped blade. Diamond blades excel in durability and precision, providing clean, smooth cuts without shredding or splintering the fiberglass material. Carbide-tipped blades are also effective due to their toughness and resistance to wear. Both blades can be attached to angle grinders, circular saws, or oscillating tools, depending on your project needs. Avoid regular abrasive blades as they tend to fray the fiberglass edges and wear out quickly due to the material’s abrasive nature. For optimal results, use blades designed specifically for composites or multi-material cutting. Always cut at controlled speeds and ensure proper ventilation to reduce dust exposure. Wearing protective equipment like gloves, goggles, and a respirator is essential when working with fiberglass to protect against airborne particles and sharp fibers.

The best cutting disc for fiberglass is a reinforced diamond cutting disc or a carbide-grit cutting disc. Diamond discs offer excellent performance because they are durable, heat-resistant, and can provide a precise, smooth cut with minimal fraying of the fiberglass. For smaller or more delicate applications, thinner cutting discs may be preferred as they reduce material waste and allow for greater control. Fiber-reinforced abrasive discs can also work, but they tend to wear out faster when cutting through fiberglass, especially over large areas. When choosing a disc, ensure it is rated for fiberglass or composite materials. To minimize dust and splintering, use a lower speed and let the blade do the work rather than applying excessive pressure. Always wear safety gear, including a dust mask, gloves, and safety goggles, to protect yourself from hazardous fiberglass particles and sharp edges.

Yes, you can use a Dremel to cut fiberglass, but you need to equip it with the right accessory, such as a cutting wheel or carbide-grit bit. The Dremel EZ Lock Fiberglass Reinforced Cutting Wheels (such as EZ456) are specifically designed for tough materials like fiberglass. Dremel tools work well for precision cutting, detailed work, and smaller projects due to their compact size and maneuverability. However, cutting fiberglass with a Dremel requires caution. Use lower speeds to avoid overheating and fraying the material. Additionally, frequent stops during cutting will help manage heat buildup. Since fiberglass produces fine dust and sharp fibers during cutting, wear protective equipment, including a dust mask, safety goggles, and gloves. For thicker or larger fiberglass sections, an angle grinder with a proper blade may be more efficient, but for small tasks, a Dremel is highly effective.

An angle grinder can cut a wide range of materials depending on the blade or disc attached. With a diamond cutting wheel, angle grinders can cut hard materials like concrete, tile, and stone. Metal cutting discs are ideal for steel, aluminum, and other metals. For fiberglass, a diamond-coated or carbide-grit blade works best to prevent fraying and achieve a clean cut. Angle grinders can also cut through plastic, wood, composites, and masonry with specialized discs. However, using the correct blade is critical; for example, never use a woodcutting blade on metal or vice versa. Additionally, grinders are powerful tools, so always work at the correct speed, apply consistent pressure, and ensure safety gear is worn. The versatility of an angle grinder makes it one of the most valuable tools for DIYers, fabricators, and construction professionals working with diverse materials.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.