Fibreglass roof profiles offer a superior solution for modern roofing needs, combining durability with cost-effectiveness. Known for their strength and lightweight characteristics, these profiles provide excellent resistance to corrosion and weather impact, making them ideal for both commercial and residential structures. For example, a fibreglass bay window roof utilizes these profiles to achieve both functional and aesthetic benefits, offering durability while complementing the overall design of a home. The energy-efficient nature of fibreglass also enhances insulation properties, reducing heating and cooling costs. Selecting the appropriate fibreglass roof profiles is crucial, as the right profile meets specific architectural aesthetics and functional requirements, ensuring optimal performance and longevity of the roofing system. GangLong Fiberglass offers fibreglass roof profiles, including corrugated, rib, and custom profiles, in all three-resin series. Whether for a simple home renovation or a complex industrial project, the right choice significantly impacts the overall success and maintenance ease of the roof structure.

What Are Fibreglass Roof Profiles

Fibreglass roof profiles are integral components in the design and functionality of modern roofing systems. These profiles consist of a woven material embedded with glass fibers, which is then coated with a resin to create a strong, durable and flexible finish. Understanding these profiles is crucial for anyone considering a roofing project or involved in construction design.

Definition of Fibreglass Roof Profiles

Fibreglass roof profiles are composite materials made of fine glass fibers and resin, offering a range of benefits. They are highly durable, resistant to corrosion, rust, and UV radiation, which ensures a long lifespan with minimal maintenance. Despite being lightweight, these profiles have an impressive strength-to-weight ratio, enabling long spans without compromising stability. Available in various shapes and sizes, fibreglass roof profiles can be tailored to meet specific architectural and aesthetic needs. They are water-resistant, insulating, and fire-resistant, enhancing energy efficiency and safety. Additionally, they are an environmentally friendly choice due to their longevity and ability to reduce the need for frequent replacements.

How Profiles Impact the Structural Integrity and Water Drainage of a Roof

Here are at least eight points on the impact of fibreglass roof profiles on structural integrity and water drainage:

- Load Distribution: The shape and design of fibreglass profiles contribute to the equal distribution of load across the roofing structure, reducing pressure points and potential damage.

- Wind Uplift: Properly engineered profiles can minimize wind uplift forces on the roof, critical in storm-prone regions.

- Water Shedding: The contours in profiled roofing help direct water flow toward gutters and drains, preventing water accumulation.

- Thermal Expansion: Profiles are designed to accommodate thermal expansion and contraction, a key factor in preserving the roof’s integrity over temperature fluctuations.

- Leak Prevention: The continuous nature of profiled sheets reduces the number of seams and joints where leaks could develop.

- Aesthetic Integration: A well-chosen profile complements the building’s design and contributes to its overall visual appeal.

- Installation Efficiency: Certain profiles are engineered for quick and efficient installation, contributing to the structural integrity through uniform placement and secure fittings.

- Compatibility with Accessories: Roofing profiles are often designed to work seamlessly with other roofing components like flashings, gutters, and skylights, ensuring an integrated system that performs well in all conditions.

Selecting the correct fibreglass roof profiles is imperative for a roof’s performance. These profiles not only define the building’s skyline but also ensure that it remains secure, efficiently drains water, and stands the test of time.

Maximize Energy Savings with Best Fiberglass Insulation Solutions

Types of Fibreglass Roof Profiles by GangLong Fiberglass

Fibreglass, with its hallmark strength, durability, and adaptability, serves as an outstanding material for roofing. The term “fibreglass roof profiles” encapsulates the array of shapes and constructions available for roofing sheets or panels. These profiles are tailored to meet the distinct requirements of the architectures they intend to cover. Let’s explore the diverse GangLong Fiberglass roofing profiles and their designated utilities.

Applications of Standard Profiles of GangLong Fiberglass Roof Profiles

Smooth Strength Profile

This profile is crafted to deliver exceptional strength while maintaining a sleek, smooth appearance. It is particularly well-suited for commercial buildings, warehouses, and public amenities, where durability is crucial. Its smooth surface allows for efficient water runoff, minimizing the potential for debris accumulation and ensuring the roof remains functional and easy to maintain over time.

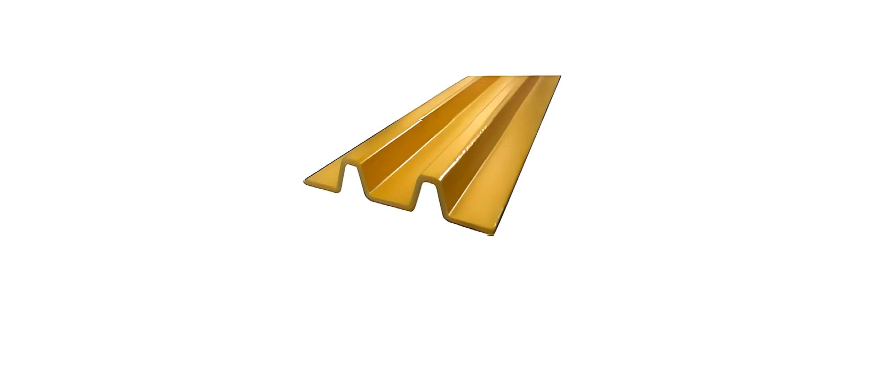

Enhanced Rib Profile

Featuring a double rib construction, this profile is engineered for maximum resilience, making it ideal for areas exposed to harsh weather conditions. The ribbed design provides additional structural support, ensuring the roof can withstand extreme elements such as heavy rainfall, strong winds, and snow accumulation. This profile is predominantly used in industrial and agricultural environments, where durability and weather resistance are essential.

UV Guard Roofing Sheet

Designed with a UV-resistant gel coating, this profile offers enhanced protection against ultraviolet rays and chemical erosion. The UV Guard Roofing Sheet is particularly well-suited for environments like chemical plants, factories, or other industrial facilities where roofs are frequently exposed to harsh chemicals or extreme sunlight. The coating ensures long-term protection, maintaining the roof’s integrity while reducing the effects of UV degradation.

Light Filter Profile

This innovative profile allows natural light to filter through, significantly reducing the need for artificial lighting during the day. It is an excellent solution for greenhouses, allowing plants to benefit from maximum sunlight while minimizing energy consumption. Additionally, it is widely used in commercial spaces such as shopping centers and office buildings, where skylights can enhance the overall ambiance and reduce energy costs by harnessing natural light.

Custom Fit Profile

For clients with specific architectural requirements or unique design needs, we offer made-to-order fibreglass roof profiles. Whether it’s a custom shape, size, or performance characteristic, our team works closely with clients to create bespoke solutions that seamlessly integrate into their projects. This flexibility ensures that even the most complex architectural designs can be realized without compromising on performance or aesthetics.

Wave Guard Profile

The wave-shaped design of this profile is perfect for areas prone to severe weather conditions, as it adds extra rigidity to the roof structure. The unique wave design helps the roof withstand high winds and heavy snow, making it an ideal choice for both residential and commercial buildings in locations that experience extreme weather. Its strength and durability ensure that it can protect buildings from the most challenging environmental conditions.

Comparing Flat and Corrugated Fibreglass Roofing Sheets

| Feature | Flat Fibreglass Sheets | Corrugated Fibreglass Roof Profiles |

|---|---|---|

| Design Flexibility | Limited to flat surfaces and pitches | Highly versatile, fitting various architectural designs |

| Structural Strength | Generally less rigid | Corrugation provides added strength and durability |

| Light Transmission | Can be clear or opaque | Typically translucent but can vary |

| Installation | Can be straightforward on suitable structures | Requires careful alignment of corrugation for effectiveness |

| Aesthetic Appeal | Offers a modern, sleek look | Corrugated profiles may provide a traditional or industrial aesthetic |

| Water Runoff | Effective on a gradient | Corrugated design enhances water runoff capabilities |

Fibreglass roof profiles, both flat and corrugated, offer their unique advantages. The selection of an appropriate profile must consider the factors outlined in the table above, to ensure the roofing material meets the architectural, functional, and aesthetic needs of the building project.

Selecting the Best Fibreglass Roof Profiles

Choosing the right fibreglass roof profiles for a building is a crucial decision that can substantially impact both the functionality and the aesthetics of the structure. Fibreglass, known for its durability and versatility, offers a range of profiles to suit various applications and design preferences. Below, we explore the factors to consider when selecting a fibreglass roof profile and also delve into the advantages of some of the most popular options available on the market.

Fibreglass Roof Profile Types for Various Applications

Corrugated Fibreglass Panels

Corrugated fibreglass panels are a robust and reliable choice for industrial, agricultural, and commercial applications. Known for their exceptional strength and resistance to environmental stressors, these panels are ideal for harsh climates, capable of withstanding high winds, heavy rainfall, and snow. Their distinctive corrugated design ensures long-term durability, making them a popular solution for warehouses, farms, and factory buildings where both performance and protection are critical.

Flat Sheets

Flat fibreglass sheets offer a modern and clean aesthetic, commonly used for residential and commercial roofs. These sheets are easy to install and maintain, making them a cost-effective option for many projects. The smooth surface of flat sheets contributes to a sleek and contemporary design, and their lightweight nature simplifies installation. Ideal for projects that demand simplicity and elegance, flat sheets are a top choice for those looking for practical yet visually appealing roofing solutions.

Trapezoidal Profiles

Trapezoidal fibreglass profiles are designed for areas subject to heavy snow or high winds, offering superior strength and stability. Their unique trapezoidal shape allows them to bear significant weight while maintaining structural integrity, making them ideal for colder climates. These profiles excel in managing snow accumulation and withstanding the stresses associated with extreme weather. For buildings in regions prone to severe weather conditions, trapezoidal profiles provide reliable and long-lasting protection.

Multiwall Sheets

Multiwall fibreglass sheets are known for their superior insulation properties, which help regulate indoor temperatures by reducing heat transfer. With multiple layers of fibreglass, these profiles are highly energy-efficient, making them ideal for eco-friendly construction projects. Multiwall sheets help reduce heating and cooling costs by maintaining comfortable temperatures year-round, providing an excellent solution for buildings aiming to improve energy efficiency and sustainability.

R-HD Profiles

R-HD (High-Durability) fibreglass profiles are engineered to resist chemical degradation and extreme environmental conditions. These profiles are highly resistant to corrosion and can withstand exposure to harsh chemicals, making them perfect for industries like chemical processing or environments with high salt air. Their high endurance ensures that they maintain their structural integrity and long-lasting performance, even in the most demanding conditions, offering a reliable roofing solution for industrial applications.

Translucent Panels

Translucent fibreglass panels allow natural light to filter through the roof, reducing the need for artificial lighting during the day. These panels are ideal for buildings where maximizing natural light is essential, such as in offices, workshops, or greenhouses. Translucent panels provide a bright and airy interior while still maintaining privacy, offering an energy-efficient solution that lowers electricity consumption. Their ability to diffuse light also contributes to a more pleasant indoor environment.

Flexible Rolls

Flexible fibreglass rolls are perfect for roofs with irregular or custom shapes. These rolls can easily conform to curved or non-standard roofing structures, offering both functional coverage and aesthetic appeal. Flexible rolls are particularly suited for buildings with unique architectural features that require a tailored roofing solution. Their adaptability ensures they can meet a wide range of design needs while providing a visually striking result.

Anti-Corrosive Sheets

Anti-corrosive fibreglass sheets are specifically treated to resist corrosion, making them an excellent choice for buildings in coastal areas or environments with exposure to chemicals. These profiles offer long-lasting protection by preventing the breakdown associated with rust and corrosion. Ideal for industrial and marine applications, anti-corrosive fibreglass sheets maintain their strength and durability in harsh environments, ensuring that the roof remains intact and effective over time.

Factors to Consider When Choosing a Roof Profile

Selecting the appropriate roof profile is an essential decision that goes beyond personal preferences; it involves evaluating how different profiles will interact with the building’s requirements and environmental factors. The correct choice can result in a roofing system that is not only aesthetically pleasing but also functional, energy-efficient, and durable. Here are the key factors to consider when making an informed selection:

Climate

The regional climate plays a critical role in determining the most suitable roof profile. For instance, areas that experience heavy rainfall, strong winds, or snow may require a roof profile designed to handle these conditions. Some profiles, such as trapezoidal or corrugated fibreglass, are specifically engineered for high-impact resistance, ensuring they can withstand severe weather events. In contrast, other profiles might be better suited for temperate climates with mild weather patterns. Selecting the correct profile based on the climate ensures that the roof will provide optimal protection for the building over the long term.

Building Use

The intended use of the building will heavily influence the type of roof profile required. Industrial buildings often need profiles that are highly durable and capable of bearing significant loads, such as heavy machinery or large quantities of stored goods. Commercial buildings, like office complexes, may prioritize aesthetic appeal and insulation properties. Residential buildings typically require profiles that offer both durability and comfort. For example, fibreglass roof profiles that provide excellent insulation and energy efficiency are often chosen for residential projects to help manage heating and cooling costs.

Aesthetic Preference

A roof profile must not only meet functional requirements but also complement the architectural style of the building. The choice of profile can significantly influence the overall appearance of a structure. Whether a classic or modern design is preferred, there are a variety of profiles available to suit different aesthetics. Fibreglass profiles come in a range of designs, such as flat sheets, corrugated patterns, and trapezoidal shapes, allowing the profile to seamlessly integrate with the building’s exterior. The visual impact of the roof should enhance the building’s look, ensuring it aligns with the desired architectural theme.

Durability

Durability is a vital consideration in selecting a roof profile. The profile’s lifespan should align with the expected longevity of the building itself. A durable roofing system minimizes the need for frequent repairs and replacements, which can be costly over time. Materials like fibreglass and FRP (Fibreglass Reinforced Plastic) are known for their strength and resilience, offering long-term performance in even the harshest conditions. Similar to the frp pipe life expectancy, the durability of a roof profile can ensure that the building remains protected for decades without significant degradation. Consider profiles that are resistant to corrosion, UV damage, and physical wear.

Maintenance Requirements

Some roof profiles require more maintenance than others. For example, materials that collect debris or are prone to algae growth might need regular cleaning to maintain their appearance and functionality. Conversely, fibreglass profiles often require less maintenance due to their inherent resistance to dirt and moisture. Choosing a low-maintenance profile can save both time and money in the long term. This factor is particularly important for buildings in hard-to-reach locations, where roof cleaning or repairs might be more challenging and costly.

Cost

When selecting a roof profile, it is essential to consider both the initial cost and the long-term expenses associated with the profile. While some profiles may have a lower upfront cost, they may require more frequent repairs or higher energy costs due to poor insulation properties. On the other hand, more durable profiles may come with a higher initial price tag but result in savings over time due to their longevity, minimal maintenance, and energy efficiency. Balancing initial investment with future savings is crucial in making a cost-effective decision.

Energy Efficiency

Energy efficiency is an increasingly important factor in modern building designs. Some roof profiles, such as multiwall fibreglass panels, offer superior insulation capabilities that can significantly reduce heating and cooling costs by preventing heat loss or gain. Additionally, translucent profiles can optimize natural lighting inside a building, reducing the need for artificial lighting during the day. This contributes to energy savings while enhancing the building’s sustainability. For environmentally-conscious projects, selecting an energy-efficient roof profile can also improve the building’s overall green credentials, helping to achieve certifications like LEED (Leadership in Energy and Environmental Design).

Installation Complexity

The complexity of installing a roof profile can affect both the project timeline and the overall budget. More intricate profiles may require specialized tools or professional expertise, which could extend the installation period and increase labor costs. On the other hand, profiles that are easier to handle and install can help keep costs down and speed up the project. If you have a strict timeline or budget, selecting a profile with simpler installation requirements can ensure that the roofing system is completed on schedule and within financial constraints.

Building Codes and Restrictions

It is essential to ensure that the chosen roof profile complies with local building codes and regulations. Each region may have specific requirements regarding factors like fire resistance, weight load capacity, insulation, and material composition. Before proceeding with the selection, it’s important to verify that the profile meets these legal standards to avoid any compliance issues that could lead to delays, fines, or costly changes. Consulting with local authorities or a professional roofing contractor can help confirm that the profile you choose adheres to all necessary guidelines.

Key Benefits of Fibreglass Roof Profiles

Wide Range of Profiles

Fibreglass roof profiles are available in a broad range of shapes and configurations to suit various building needs. From traditional corrugated and rib profiles to more advanced options like V-beam, R-panel, and flat sheets, each profile is designed to serve a specific structural function. This variety ensures that whether you need a lightweight option, one that can support heavy loads, or a profile that can withstand extreme weather, there’s a fibreglass roof profile that meets the requirements of your project. Additionally, custom profiles can be manufactured to address unique design specifications, providing further flexibility.

UL-Listed and FM-Approved

Many fibreglass roof profiles meet stringent safety standards, with UL-listing and FM-approval offering a guarantee of their performance in both interior and exterior applications. These certifications are crucial for projects where safety and regulatory compliance are a top priority, such as in commercial buildings, factories, and warehouses. UL-listing ensures that the products meet fire safety standards, while FM-approval attests to their resilience in adverse conditions, including wind, fire, and impact resistance. This makes fibreglass roofing a reliable and trusted choice for critical infrastructure and industrial applications.

Opaque and Translucent Options

Fibreglass roof profiles are available in both opaque and translucent versions, providing options for controlling natural light within a building. Opaque profiles offer complete privacy and effective coverage, making them ideal for areas that need to block light while still benefiting from the strength and durability of fibreglass. Translucent profiles, on the other hand, allow natural light to filter through, creating a bright and airy interior. This can reduce the need for artificial lighting during the day, contributing to energy savings and a more sustainable building. Additionally, translucent fibreglass profiles can enhance the aesthetic quality of a space by creating a softer, natural lighting effect.

Multiple Color Options

Fibreglass roof profiles come in a wide array of color choices, which can be tailored to complement the aesthetics of your building or project. These colors not only enhance the visual appeal but also offer functional benefits, such as heat reflection or absorption depending on the specific needs of the environment. For example, lighter colors can help to reduce heat buildup inside the building, which is especially important in warmer climates. With multiple color options available, fibreglass roofing allows for greater design flexibility and ensures that your building maintains a cohesive and professional appearance.

Two Resin System Options

Fibreglass roof profiles are made from two main resin systems: Vinyl Ester and Iso-Polyester, each offering distinct advantages depending on the environment and application. Vinyl Ester resins provide superior corrosion resistance, making them ideal for use in harsh, chemically aggressive environments such as industrial settings and coastal areas. Iso-Polyester resins, on the other hand, are well-suited for general construction and residential applications, providing a balance of durability and cost-effectiveness. Having these two resin options ensures that you can select the most suitable fibreglass profile for your specific project, taking into account environmental conditions and the desired performance characteristics.

Corrosion-Resistant

One of the key advantages of fibreglass roof profiles is their inherent resistance to corrosion. Unlike traditional materials such as steel or aluminum, fibreglass does not rust, making it an ideal choice for buildings exposed to moisture, chemicals, or coastal environments with high salt content. This corrosion resistance ensures that fibreglass roofing maintains its strength and appearance over time, requiring less maintenance and fewer replacements. In addition, fibreglass profiles are not affected by rust or the typical wear and tear that affects metal roofing, making them a cost-effective and long-lasting solution for both commercial and residential applications.

Superior UV Protection

Fibreglass roof profiles offer excellent UV protection, which prevents degradation from prolonged exposure to sunlight. UV rays can cause many roofing materials to break down over time, resulting in discoloration, brittleness, and reduced strength. However, fibreglass is specifically designed to resist UV damage, ensuring that the roofing retains its integrity and appearance for many years. This UV resistance not only extends the lifespan of the roof but also helps to maintain the thermal efficiency of the building, as fibreglass retains its insulating properties despite exposure to the sun’s rays.

High Strength-to-Weight Ratio

Fibreglass roof profiles are known for their impressive strength-to-weight ratio, making them a durable yet lightweight option for a variety of building projects. The material’s strength allows it to withstand heavy loads, impacts, and adverse weather conditions without compromising its performance. At the same time, its lightweight nature makes installation easier and more cost-effective, as it reduces the need for additional structural support. This combination of strength and lightness makes fibreglass roof profiles an excellent choice for projects where both durability and ease of installation are essential.

Long Service Life

Fibreglass roof profiles offer a long service life, which makes them a smart investment for both residential and commercial buildings. The material’s resistance to environmental factors such as corrosion, UV degradation, and extreme temperatures means that fibreglass roofing can perform reliably for decades without significant maintenance or replacement. This longevity makes fibreglass a cost-effective option over the long term, as it reduces the need for frequent repairs and replacements that can add up over time with other materials. Choosing fibreglass roofing helps ensure that the roof will continue to perform at a high level, year after year.

Excellent Total Cost of Ownership

The total cost of ownership for fibreglass roof profiles is highly competitive due to their low maintenance requirements and long-lasting performance. While the initial cost may be slightly higher than some traditional roofing materials, the durability and low upkeep of fibreglass roofing make it a cost-effective choice in the long run. Fibreglass profiles are resistant to common issues like corrosion, fading, and structural damage, reducing the need for costly repairs. Additionally, their insulation properties can help lower heating and cooling costs, further enhancing their overall value. With fibreglass roofing, you get a high-performance solution that delivers long-term savings.

Fiberglass Roofing & Siding Panel Uses

Structural Daylighting for Industrial and Commercial Buildings

Fiberglass roofing panels, including various fibreglass roof profiles, are widely used for structural daylighting in industrial and commercial buildings. These panels allow natural light to penetrate into the building, reducing the reliance on artificial lighting during the day. This contributes to energy savings and creates a more pleasant working environment. In industries like manufacturing, warehouses, and retail stores, structural daylighting helps improve the quality of indoor lighting, increases productivity, and enhances the overall well-being of employees. Additionally, the use of translucent fibreglass roof profiles can create an open, airy feel within large spaces, further enhancing the building’s appeal and functionality.

Single-Skin or Insulated Systems

Fiberglass panels are available in both single-skin and insulated systems, providing flexibility in design and performance. Single-skin panels are typically used for roofs and walls where insulation is not a primary concern, offering a cost-effective solution for simple applications. On the other hand, insulated fiberglass panels combine a core of rigid insulation material sandwiched between two layers of fiberglass, providing superior thermal performance. These insulated systems are ideal for buildings where energy efficiency is a priority, such as in temperature-controlled warehouses, refrigerated storage facilities, and offices. Insulated panels help maintain consistent indoor temperatures and reduce energy costs by minimizing heat loss or gain.

Walkable Roofs

Fiberglass panels are increasingly being used in the construction of walkable roofs, especially in commercial and industrial buildings. These roofs are designed to withstand foot traffic, making them suitable for applications like rooftop gardens, terraces, or outdoor spaces. Fiberglass roofing systems are durable and strong enough to support the weight of maintenance personnel, equipment, and foot traffic, while also being resistant to weathering, UV degradation, and corrosion. The lightweight nature of fiberglass makes it easy to install and handle, providing both strength and flexibility for rooftop installations. Walkable fiberglass roofs are also low-maintenance and resistant to cracking or damage under regular use.

EMI Test Labs, Microwave Screens and Other Applications Requiring Radio Frequency (RF) Transparency

Fiberglass panels are commonly used in specialized applications such as EMI (Electromagnetic Interference) test labs, microwave screens, and other areas requiring radio frequency (RF) transparency. Fiberglass is inherently non-metallic, which allows it to provide a transparent barrier for RF signals. This makes it an ideal material for use in environments where maintaining electromagnetic compatibility (EMC) is crucial, such as in laboratories, testing facilities, and communications infrastructure. The ability of fiberglass to transmit radio frequencies while blocking unwanted interference ensures that sensitive equipment can operate accurately and without disruption. Furthermore, fiberglass panels used in these applications are designed to meet stringent regulatory standards for RF performance.

Cooling Tower Casing

Fiberglass is a popular material for cooling tower casings, providing strength, corrosion resistance, and long-lasting performance in demanding environments. Cooling towers, which are used in power plants, HVAC systems, and other industrial applications, require durable enclosures to protect internal components from harsh weather, moisture, and chemicals. Fiberglass panels are ideal for this application because of their resistance to corrosion, particularly in areas where water or chemicals are present. The lightweight and easy-to-install nature of fiberglass allows for the construction of cost-effective and efficient cooling tower systems. Additionally, fiberglass is capable of withstanding temperature fluctuations and can maintain its structural integrity even under extreme conditions.

How Old Fiberglass Insulation Impacts Your Energy Efficiency

Technical Insights: Span Tables and Load Capacity for Fibreglass Roof Profiles

Understanding the span tables and load capacity of fibreglass roof profiles is essential for ensuring that the roofing system will perform adequately under various loads and conditions. These technical details not only aid in achieving optimal safety and stability but also guide the selection process ensuring that the most suitable fibreglass roof profiles are chosen for specific project requirements.

Explanation of Span Tables for Fibreglass Roof Profiles

Span tables are critical tools in roof design, providing essential data about how different fibreglass roof profiles can be expected to perform. Here are at least eight key points detailing the role and utility of span tables for these materials:

- Defining Maximum Spans: Span tables specify the maximum distance that fibreglass roof profiles can span between supports without compromising structural integrity.

- Weight Load Considerations: The tables outline the load capacity of each profile, including how much weight the roof can bear, which is crucial for areas with heavy snowfall or frequent intense weather conditions.

- Type of Support: Span tables indicate the type of support required for each profile, whether it be spacing between purlins or the use of specific structural supports.

- Material Thickness: They note the various thicknesses of fibreglass materials and how this affects span distance and load capacity.

- Impact of Profile Shape: Different shapes of fibreglass roof profiles have varying structural qualities, and the span tables show how these shapes influence performance.

- Safety Factors: These tables include safety margins to help prevent structural failures, ensuring that all specified spans have been rigorously tested for safety.

- Adjustments for Slope: The impact of roof slope on the span and load capacities is detailed, helping in planning for roofs with varying pitches.

- Compliance with Standards: Span tables help ensure that the selected fibreglass roof profiles comply with local building codes and industry standards.

How Span Tables Guide the Selection Process for Fibreglass Roof Profiles

The selection of the correct fibreglass roof profiles for any project becomes more precise and informed with the aid of span tables. Here are at least eight ways in which these tables are instrumental:

- Optimization of Material Usage: By referring to the span tables, architects and builders can choose profiles that utilize the minimum material necessary to safely span a given distance.

- Cost-Effectiveness: Effective use of span tables helps in selecting the most economical fibreglass roof profiles that can handle required loads without over-specification, thus saving on costs.

- Enhanced Building Safety: Utilizing span table data ensures that each roof segment supports appropriate loads, significantly reducing the risk of structural failures.

- Improved Aesthetics: Span tables allow for the selection of fibreglass roof profiles that not only meet functional requirements but also contribute to the desired aesthetic outcome by allowing versatile configurations.

- Efficiency in Design: Span tables streamline the design process by providing quick reference points for different configurations and load requirements.

- Confidence in Compliance: By adhering to the limitations and guidelines set by the span tables, builders are assured of compliance with industry norms and local regulatory standards.

- Customization Options: Span tables provide data for a range of options, facilitating customized solutions that are tailored to the specific needs and restrictions of a project.

- Real-World Applicability: They give real-world insights into how fibreglass roof profiles will perform under operational conditions, guiding the selection process based on practical and tested data.

Fibreglass roof profiles offer a sophisticated option for roofing needs when paired with an informed selection process supported by a thorough understanding of span tables and load capacities. This ensures that the project not only meets aesthetic desires but also adheres to practical performance and safety expectations.

Installation and Accessibility of Fibreglass Roofing

Fibreglass roofing, with its durability and aesthetic appeal, has become a popular option for both residential and commercial building projects. However, the successful implementation and long-term performance of fibreglass roof profiles heavily depend on the quality of the installation process and the ease of obtaining the right materials. This is especially true for roof tank fiberglass, which shares similar requirements in terms of precise installation to ensure its structural integrity and optimal performance. Whether it’s for water storage or roofing, ensuring the materials are correctly installed will significantly impact the longevity and reliability of the installation.

Professional Installation or DIY Projects

When it comes to fitting a fibreglass roof profiles, there are typically two routes one can take: hiring professional installers or taking on the challenge as a DIY project. Each option comes with its own set of considerations:

- Expertise: Professional installers possess the necessary skills and experience to handle fibreglass roof profiles, ensuring a correct and safe installation.

- Time Savings: By hiring experts, the amount of time to complete the roofing project is significantly reduced compared to DIY installations, which can be time-consuming for novices.

- Warranty: Many professional services offer warranties for their work, providing homeowners with peace of mind that is not available with DIY projects.

- Safety: Roof installations can be hazardous. Professionals are trained to work at heights and have access to the necessary safety equipment.

- Quality Assurance: Professionals know how to handle fibreglass roof profiles to avoid damage during installation, ensuring the roofing system’s longevity.

- Cost: While hiring professionals is generally more expensive upfront, it may save money in the long run by avoiding costly errors and future repairs.

- Tools and Materials: Professional installers have access to high-quality tools and materials, often at better rates than the general public.

- Inspection and Permits: Professionals are familiar with local building codes and can handle the inspection and permit process on your behalf, eliminating potential headaches.

Sourcing Fibreglass Roof Profiles Near You

Finding and sourcing the right fibreglass roof profiles for your project involves several key steps:

- Local Building Suppliers: Start by checking with local building supply stores. Many carry a range of fibreglass roof profiles or can order specific products upon request.

- Manufacturer Direct: Some manufacturers sell directly to consumers, offering the opportunity to purchase high-quality fibreglass roof profiles at potentially lower prices and fast shipped directly to your location.

- Online Retailers: Online building supply stores and marketplaces can provide access to a wide variety of fibreglass roofing options. Look for retailers with good return policies and customer reviews.

- Specialist Roofing Companies: Companies that specialize in roofing materials often have a comprehensive selection of fibreglass roof profiles and can provide expert advice on the best choices for your project.

- Trade Shows and Expos: Building and construction expos can be a great way to see and learn about new and innovative fibreglass roofing options and connect directly with suppliers and manufacturers.

- Architectural Salvage Yards: For those looking for unique or hard-to-find profiles, architectural salvage yards can sometimes offer unexpected finds.

Whether opting for a professional installation or a DIY approach, understanding the importance of proper installation techniques and where to source high-quality, fast shipped fibreglass roof profiles will significantly impact the success and longevity of your roofing project. Always consider the pros and cons of each approach and choose the one that best suits your individual needs and capabilities.

Certifications and Approvals of Fibreglass Roof Profiles

Florida Building Code Approval

Fibreglass roof profiles with Florida Building Code approval are recognized for their ability to withstand severe weather conditions, such as hurricanes and tropical storms. This approval ensures that the product meets stringent building codes designed to protect structures in hurricane-prone regions. These roof profiles are engineered to handle high winds and heavy rainfall, making them a reliable choice for areas susceptible to extreme weather events.

UL Class 90 Rating

The UL Class 90 rating is a vital certification for fibreglass roof profiles, assessing the product’s resistance to uplift in high-wind conditions. This certification is obtained through UL 580 uplift testing, which requires the roof profile to endure a pressure differential of 105 psf, including both positive and negative pressures. This ensures the fibreglass roof can withstand severe wind pressures without compromising its structural integrity, providing crucial protection for buildings in wind-prone areas.

Texas (TDI) Windstorm Approval

Fibreglass roof profiles approved by the Texas Department of Insurance (TDI) for windstorm resistance are specifically tested to perform reliably in regions prone to high winds, such as coastal areas. This certification guarantees that the roof profiles are capable of withstanding the stresses caused by windstorms, ensuring long-term protection and stability in buildings located in wind-susceptible regions.

CAN/ULCS-134 Full-Scale Exterior Wall Fire Test (Canada)

In Canada, fibreglass roof and wall profiles undergo the CAN/ULCS-134 Full-Scale Exterior Wall Fire Test, which is the equivalent of the NFPA 285 standard. This certification ensures that the fibreglass panels offer adequate fire resistance, making them suitable for use in building exteriors where fire safety is of utmost importance. This testing evaluates the fire performance of the material in real-world conditions, ensuring the safety of the structure.

Section 3.1.5.5. of NBC 2010 Compliance

Fibreglass roof profiles are compliant with Section 3.1.5.5. of the National Building Code (NBC) 2010, which sets out requirements for the structural integrity and energy efficiency of building materials in Canada. This compliance guarantees that fibreglass roofing products meet the essential building safety and sustainability standards, ensuring both performance and environmental responsibility.

FM-Approval for Wall Assemblies

Fibreglass wall profiles can also be FM-approved, a prestigious certification that attests to their performance in areas such as fire resistance, wind resistance, and structural reliability. FM-Approval involves extensive testing to ensure that the fibreglass panels meet the necessary standards for use in commercial and industrial buildings, making them a trusted solution for demanding applications.

Pricing Considerations for Fibreglass Roof Profiles

When it comes to roofing, fibreglass roof profiles offer a compelling blend of durability and aesthetic appeal, making them a popular choice for both residential and commercial properties. However, the cost of fibreglass roofing sheets and profiles can vary widely, influenced by a range of factors. Understanding these can help you budget more accurately for your roofing project.

Overview of Fibreglass Roofing Sheets Price Points

The pricing of fibreglass roof profiles can differ significantly based on several key aspects. Here are six crucial points to consider:

- Quality of Material: Higher-quality fibreglass materials, known for their durability and superior weather resistance, will be more expensive.

- Thickness: The thicker the fibreglass profile, the higher the cost. Thicker profiles offer better insulation and strength but at a premium.

- Finish and Colour Options: Custom finishes and colours can affect the price. Standard finishes are generally more affordable.

- Panel Sizes and Shapes: Larger or custom-sized panels require more material and labor to produce, leading to higher costs.

- Brand: Pricing can also vary significantly between different manufacturers, with premium brands often commanding higher prices.

- Market Demand: Fluctuations in market demand can impact prices. Higher demand can lead to increased prices, and vice versa.

Factors Affecting the Cost of Fibreglass Roof Profiles

Complexity of Installation

The complexity of the roof design plays a significant role in determining the overall cost. Roofs that require intricate cuts, custom fittings, or non-standard shapes will require more time and labor to install. This can substantially increase the cost of labor and materials, especially if specialized skills or tools are needed for the job. For example, roofs with multiple angles, skylights, or unique architectural features may require additional adjustments, thus raising the installation cost.

Geographical Location

The location of your project can influence the price of fibreglass roof profiles. Prices can vary widely depending on the region due to differences in local labor costs, material availability, shipping fees, and regional taxes. For instance, in urban areas where labor costs are higher, the cost of installation might be more expensive compared to rural areas. Additionally, distant or remote locations may face higher shipping costs for transporting materials, adding to the overall expense.

Shipping and Handling

Transporting fibreglass roof profiles to the project site is a key factor in the overall cost. Fibreglass profiles, especially those designed for large commercial or industrial roofs, are often bulky and require specialized handling. This can increase the shipping cost, particularly if the location is far from the supplier’s manufacturing facility. Shipping costs can also rise if you are dealing with large volumes or heavy orders, making it important to consider transportation fees when calculating the total project cost.

Labor Rates

The cost of professional installation is another important factor to account for. Labor rates can vary significantly depending on the region, the complexity of the project, and the experience of the workers involved. For instance, areas with a higher cost of living tend to have higher labor rates. Additionally, the difficulty level of the installation process, such as working at height, on steep roofs, or in challenging weather conditions, can further drive up labor costs. It’s advisable to obtain several quotes from different contractors to ensure competitive pricing.

Scale of the Project

The size of your project can have a substantial impact on the cost. Larger projects, such as the roofing of large commercial buildings or warehouses, may benefit from bulk purchasing discounts for fibreglass profiles. In contrast, smaller residential projects may face higher prices per unit due to minimum order requirements set by suppliers. Additionally, larger projects may have economies of scale, which could reduce the overall per-square-meter cost, while smaller projects may not qualify for such savings.

Existing Roof Removal

If the existing roof needs to be removed before the installation of the fibreglass profiles, this will incur additional costs. Roof removal can be labor-intensive, especially if the old material is difficult to dismantle or hazardous to remove (such as asbestos roofing). The disposal of the old roofing material, along with the labor involved in stripping it away, can significantly add to the total project cost. It’s essential to factor in these expenses when considering the overall budget for the new roof installation.

Additional Materials

In addition to the fibreglass roof profiles, there are often other materials required to complete the installation. These may include fasteners, sealants, insulation, and underlayment, which help to improve the roof’s performance and longevity. Depending on the type and quality of the materials used, these costs can add up quickly. It’s important to account for these extra materials in your overall project budget to avoid unexpected expenses.

Permits and Inspections

Depending on your location, local regulations may require building permits and inspections before installation can begin. These permits can vary in cost depending on the complexity of the project and local zoning laws. In some cases, the installation of fibreglass roof profiles may require a structural inspection or an environmental impact assessment, which could add extra costs. Be sure to check with your local building authority to understand any necessary permits and inspections, so you can factor these expenses into your budget.

Seasonal Factors

The time of year can have an influence on the pricing of roofing materials and installation services. During peak construction seasons, typically in warmer months, there is often a higher demand for roofing services, which can drive up costs. On the other hand, in the off-season, there may be more availability of contractors and potentially lower prices. Weather conditions also play a role—certain roofing projects may be delayed or incur additional costs if the weather is adverse, such as heavy rain or extreme heat, which can affect the installation schedule and productivity.

Why Choose Fiberglass Insulation for Ductwork: Key Advantages

FAQs about Fibreglass Roof Profiles

Fibreglass roofing, while presenting many benefits, also has its share of disadvantages. Its susceptibility to cracking over time due to thermal expansion and contraction is a notable concern, especially in areas with wide temperature fluctuations. Installation also requires precise skills to avoid errors that can lead to leaks or decreased durability. UV exposure can degrade the resin, leading to discoloration and reduced lifespan unless properly coated with UV-resistant materials. Additionally, while being lightweight is often an advantage, it can also mean that fibreglass roofing may not be as resistant to high winds as heavier materials, thus necessitating strict adherence to installation guidelines to ensure stability.

The number of fibreglass layers on a roof typically ranges from two to three, but this can vary based on the specific requirements of the project and the desired durability. A base layer of roofing resin is applied directly onto the roof deck, followed by one or two layers of fibreglass matting. Each layer of matting must be fully saturated with resin to ensure strength and water resistance. After the matting, a final layer of topcoat resin is applied to seal the fibreglass and provide a weatherproof and UV-resistant finish. It’s crucial that these layers are correctly installed to prevent future issues such as water ingress or premature degradation of the material.

Fibreglass roofs have a reasonably long life expectancy, typically lasting between 25 to 30 years, provided they’re installed correctly and maintained regularly. The lifespan can be influenced by several factors, including the quality of materials, the number of layers applied, the professionalism of the installation, and exposure to the elements. A well-installed fibreglass roof with adequate maintenance and occasional re-coating to address wear from UV exposure can even extend beyond three decades. It’s essential for property owners to carry out periodic checks and repairs as needed to ensure the longevity of their fibreglass roofing.

Fibreglass roofs are indeed a good option for many homeowners and builders due to their durability, waterproof nature, and relatively low maintenance requirements. They are also praised for their versatility in terms of design and color options, which make them suitable for a range of architectural styles. Moreover, fibreglass is immune to rust and rot, making it an excellent choice for harsh or coastal environments where salt spray can damage other roofing materials. While the initial installation must be done carefully to avoid potential issues, a properly installed fibreglass roof can provide reliable protection for many years, aligning with the needs of a robust and long-lasting roofing material.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.