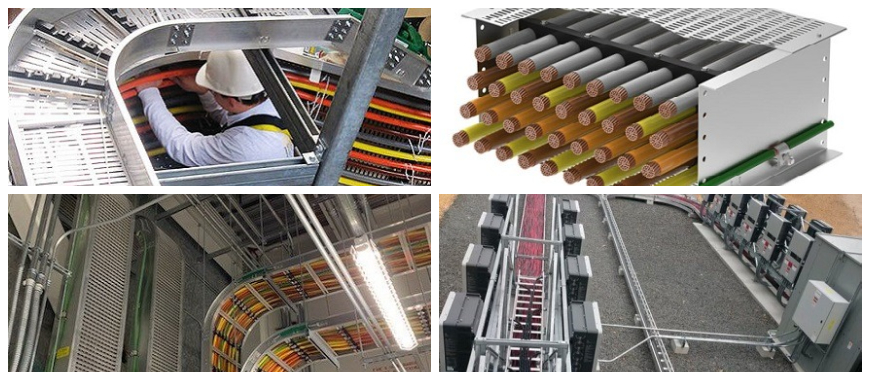

Performance Cable Tray Waterfall – versatile, easy-to-install cable guide that maintains bend radius for drops from wire basket trays. Cable tray systems play a crucial role in modern cable management by organizing and supporting electrical and communication cables. They ensure cables are arranged neatly and are protected from damage during operations. A cable tray waterfall is a key component that facilitates smooth transitions for cables between different tray levels or directions. This prevents cable stress and minimizes wear over time. Proper cable transitions are essential for maintaining system integrity and ensuring long-term performance. By using a cable tray waterfall, cable management becomes more efficient, reducing the risk of tangling or damage. These systems are widely used in data centers, industrial settings, and commercial buildings, where efficient cable routing is critical for operational reliability.

What is a Cable Tray Waterfall?

Definition and Purpose of a Cable Tray Waterfall

A cable tray waterfall is a structural component designed to facilitate smooth cable transitions within a cable tray system. It ensures that cables move seamlessly between tray levels or directions without bending excessively or becoming tangled. The purpose of a waterfall cable tray is to maintain cable integrity, prevent damage, and organize cable pathways effectively. In setups with complex routing, a curved cable tray can complement the waterfall, providing smooth transitions around corners or tight spaces. This combination is vital in scenarios where high-density cabling or sharp directional changes are required, ensuring efficient and reliable system performance.

Key Features of the Cable Tray Waterfall

The cable tray waterfall is engineered to provide smooth and protected transitions for network and electrical cables, especially in high-performance environments where cable integrity is critical. Built with durability, compliance, and cable safety in mind, it incorporates several advanced features that make it an ideal choice for both industrial and commercial cable management systems.

Bundled Cable Support with Tie-Down Openings

To ensure organized cable routing, the waterfall is equipped with strategically placed tie-down openings. These slots allow installers to securely fasten bundled cables, reducing movement, strain, and the risk of signal disruption. This feature is particularly valuable in high-density applications where cable grouping is essential for layout clarity and space optimization.

Durable Protective Powder Coating

The surface of the waterfall is treated with a durable powder coating that protects against physical wear such as scratches, abrasions, or damage during installation and cable movement. This finish extends the lifespan of both the waterfall and the cables, contributing to a more resilient and maintenance-friendly system.

TIA-Compliant Bend Radius Control

Designed with cable integrity in mind, the waterfall maintains a consistent bend radius that conforms to TIA-approved standards for all cable types. This ensures that copper, coaxial, and fiber optic cables are routed without sharp bends that could impair performance or cause long-term damage. By preserving the proper bend radius, the waterfall helps maintain signal quality and system reliability.

Finish Options for Versatility and Aesthetics

Standard finish options include black powder coating for a sleek, modern look, and electro-galvanized (zinc) coating for enhanced corrosion resistance. For projects with specific aesthetic or branding requirements, custom color finishes can be provided upon request. These options offer flexibility for integration into a wide range of environments, from data centers to architectural applications.

High-Performance Cable Support

The design of the cable tray waterfall provides optimal support for high-performance cables, including data, control, and fiber optic lines. Its smooth transition and edge-free surface prevent cable kinks and ensure low-friction guidance, preserving the signal integrity of even the most sensitive cabling systems.

Factors Affecting the Effectiveness of a Cable Tray Waterfall

Material Quality

The durability and load-bearing capacity of a cable tray waterfall depend heavily on the material used. High-quality materials, such as fiberglass, resist environmental stress and heavy usage. At GangLong Fiberglass, we offer robust solutions tailored to diverse needs.

Tray Compatibility

The size and design of the waterfall cable tray must match the cable tray system to ensure smooth transitions. Mismatched components can result in cable misalignment and system inefficiencies.

Installation Practices

Proper installation is critical to achieving optimal performance. Incorrect placement or alignment of the cable tray waterfall can lead to cable tension or insufficient support, compromising system functionality.

Environmental Considerations

Factors like temperature, moisture, and exposure to corrosive elements can impact the longevity of a waterfall cable tray. To minimize these risks, opting for weather-resistant materials is crucial. A stacked cable tray design can also provide added durability, ensuring that cables are protected while maintaining a space-efficient, organized layout.

Disadvantages of a Cable Tray Waterfall

- Higher Initial Cost

High-quality cable tray waterfalls made from durable materials can be more expensive upfront. However, this investment is offset by long-term reliability and reduced maintenance costs. - Space Requirements

A waterfall cable tray may require additional installation space, which can be challenging in compact systems or areas with limited room. - Dependency on Proper Installation

Incorrectly installed cable tray waterfalls can lead to cable misalignment, tension, or inefficiencies, negating their benefits. Professional installation is often necessary to avoid such issues. - Limited Retrofitting Options

In some existing systems, retrofitting a waterfall cable tray may be challenging due to incompatibility with older tray designs or layouts. Custom solutions from GangLong Fiberglass can help overcome these challenges.

Benefits of Installing a Cable Tray Waterfall

Smooth Cable Transitions for Reduced Wear and Tear

One of the primary benefits of a cable tray waterfall is its ability to ensure smooth cable transitions. By providing a controlled pathway for cables, a cable waterfall tray minimizes sharp bends or sudden drops that can damage cables over time. This reduces wear and tear, extending the lifespan of cables and improving system reliability. In environments with high-density cabling, such as data centers or industrial facilities, preventing damage to cables is critical for uninterrupted operations.

At GangLong Fiberglass, we design durable cable tray waterfalls that address these challenges effectively. Our solutions provide superior support and flexibility, making them ideal for protecting cables during directional changes. Whether for horizontal or vertical transitions, a cable tray waterfall ensures cables remain aligned and secure, avoiding unnecessary stress.

Enhanced Cable Organization and Accessibility

A cable tray waterfall helps maintain a neat and organized cable layout. It prevents cables from tangling or overlapping, making it easier to identify specific lines during maintenance. This organization saves time and reduces errors during troubleshooting or upgrades. For instance, in a structured cabling system, using a cable waterfall tray ensures cables are separated by function, improving overall accessibility.

Organized cables also contribute to aesthetic appeal, especially in open installations where trays and cables are visible. GangLong Fiberglass specializes in crafting cable tray waterfalls that align with these needs. Our solutions not only enhance system functionality but also simplify maintenance tasks, reducing downtime and associated costs.

Improved Airflow for Thermal Management in Dense Cable Systems

Efficient airflow is crucial in high-density cabling environments to prevent overheating. A cable tray waterfall enhances airflow by maintaining proper spacing between cables, which helps dissipate heat effectively. This is particularly important in data centers where excessive heat can lead to performance degradation or equipment failure.

A well-designed cable waterfall tray supports thermal management by keeping cables organized and preventing blockages that disrupt airflow. At GangLong Fiberglass, we understand the importance of optimizing thermal performance. Our cable tray waterfalls are engineered to improve airflow, ensuring cables and equipment operate within safe temperature ranges. This feature contributes significantly to the long-term reliability of the entire system.

Compatibility with Various Cable Tray Types

Another significant benefit of a cable tray waterfall is its versatility. It can be used with different cable tray types, including ladder racks, perforated trays, and wire mesh systems. This adaptability ensures that a cable waterfall tray fits seamlessly into existing systems, eliminating the need for extensive modifications. For installations requiring precise connections, cable tray fittings are essential for ensuring secure and stable transitions between sections.

GangLong Fiberglass offers customized solutions to meet unique system requirements. Our cable tray waterfalls are designed to integrate easily with a variety of tray configurations, ensuring smooth installation and reliable performance. This compatibility makes them an excellent choice for both new projects and retrofitting existing setups.

These benefits illustrate the essential role of a cable tray waterfall in efficient cable management. From protecting cables to improving system organization and thermal performance, this component is indispensable for achieving long-term operational success.

Common Uses in Cable Management Systems

In modern cable management systems, especially in large-scale installations, the use of fitting cable tray and specialized components like the Cable Guider plays a crucial role in ensuring a safe, efficient, and well-organized setup. Among these components, cable tray waterfalls stand out for their ability to guide cables smoothly between horizontal and vertical runs. Whether in data centers, industrial plants, or commercial buildings, they help maintain cable integrity, improve accessibility, and support neat transitions across different tray sections, making them an essential part of structured cable routing.

Data Centers

In data centers, cable tray waterfalls are essential for managing the high volume of network and power cables connecting servers, switches, and racks. They allow cables to bend smoothly as they transition from horizontal trays into vertical racks, preventing sharp angles that could damage the cables. This setup also improves airflow and makes maintenance more accessible, which is crucial for system performance and uptime.

Industrial Facilities

Industrial environments often span large areas and involve complex electrical and control systems. Cable tray waterfalls help guide heavy-duty cables across production floors or between machinery with precision and safety. They allow for structured cable transitions, reducing mechanical stress and minimizing risks of cable abrasion or interference, particularly in areas with vibration or heavy equipment movement.

Commercial Buildings

In commercial setups such as office complexes or retail centers, cable tray waterfalls contribute to a clean and organized routing of electrical and communication wiring. They help manage transitions between ceiling-mounted trays and wall conduits or equipment racks. This ensures better cable protection, easier troubleshooting, and a more professional-looking installation, especially in visible or customer-facing areas.

Cable Transition and Alignment

Cable tray waterfalls are also used as transitional fittings to align cable routes between different tray levels or structural sections. They help maintain minimum bend radius requirements, reduce strain on cables, and provide a secure, standardized way to connect sections. These fittings ensure that the entire cable management system remains functional, modular, and scalable for future needs.

Professional Cable Tray Cutter for Large-Scale Projects

Types of Cable Tray Waterfalls

Ladder Rack Waterfall

Designed for ladder rack systems, this type of waterfall supports seamless cable transitions while maintaining proper spacing and airflow. Its open, rung-aligned structure allows high-density cables to be routed without strain. When paired with a reliable cable tray and a Cable Guider, it ensures structural stability and long-term performance, especially in demanding environments. GangLong Fiberglass offers durable FRP versions built to handle heavy cable loads while maintaining flexibility across different configurations. These waterfalls are ideal for data centers and industrial setups, where maintaining performance, cooling, and cable integrity is critical.

Standard Cable Tray Waterfalls

Standard tray waterfalls are compatible with both perforated and non-perforated trays, making them a versatile option for mixed-system installations. Their structure supports organized cable drops and reduces mechanical stress. GangLong Fiberglass produces models with easy mounting features, long-lasting materials, and compatibility with a wide range of tray types. Proper measurement and secure fixing ensure the installation is smooth and the cables remain protected over time.

Performance Cable Tray Waterfalls for Wire Mesh Trays

Commonly used in IT spaces and ceiling-mounted applications, these waterfalls offer a lightweight and cost-effective solution. They attach easily to wire baskets and support gentle cable transitions, especially for low-voltage or data cables. These waterfalls are ideal for office networks and indoor commercial settings, offering quick installation and minimal intrusion while keeping cabling systems neat and efficient.

Vertical Drop-Out Cable Tray Waterfalls

This type allows cables to exit the tray vertically in a controlled and protected manner. Often used near distribution panels, PDUs, or electrical control points, vertical drop-outs reduce bend stress and wear. They are particularly useful in tight spaces where side or bottom transitions are required. Their design ensures that directional changes don’t compromise cable structure or safety.

Modular or Adjustable Cable Tray Waterfalls

Modular cable tray waterfalls are built for flexibility, offering adjustable heights or angles for complex or evolving layouts. These are especially valuable in research facilities or automation systems where frequent reconfiguration occurs. GangLong Fiberglass is developing modular kits that allow seamless adaptation to hybrid trays or custom geometries, improving both installation speed and system adaptability.

Sealed or Covered Cable Tray Waterfalls

In outdoor or harsh industrial environments, sealed waterfalls provide an extra layer of protection against dust, moisture, and corrosive agents. They are often used in chemical processing plants, food-grade areas, and outdoor telecom systems. These waterfalls help extend cable life and ensure consistent function despite environmental exposure. Their covered design also reduces contamination and simplifies maintenance.

Step-by-Step Guide to Cable Tray Waterfall Installation

Pre-Installation Checklist

Proper preparation ensures a smooth and secure cable tray waterfall installation. By checking tools, verifying compatibility, and assessing the site environment, you can avoid delays, reduce errors, and ensure the system performs reliably from day one.

Tools and Materials Needed

Gather essential tools: measuring tape, level, drill, brackets, and screws. Depending on the setup, include cable ties or clamps. Using correct materials ensures proper integration and long-term support. GangLong Fiberglass offers tailored installation kits with all necessary components to help you complete the process efficiently and avoid errors during setup.

Verifying Tray Compatibility and Dimensions

Ensure the waterfall matches your existing tray system by measuring width, height, and thickness. Identify tray types—ladder, perforated, or mesh—and check material compatibility. GangLong Fiberglass designs waterfalls for universal adaptability, ensuring a secure fit with minimal adjustment. Accurate measurements reduce the risk of installation issues and promote long-term system stability.

Assessing Installation Environment and Access

Check the installation environment for space, clearance, and safety. Consider ceiling height, obstacles, and lighting. For harsh environments, account for dust, moisture, or chemicals. Ensure installers have proper PPE if working at height. A quick site review helps prevent delays and supports a safe, efficient installation process.

Installation Process

Measuring and Marking the Installation Area

Begin by identifying the area where the cable tray waterfall will be installed. Measure the space to ensure sufficient room for the waterfall and mark the location on the tray. Use a level to confirm alignment, as improper positioning can affect cable routing and stability. Taking accurate measurements reduces the risk of misalignment and ensures the cable tray waterfall is installed securely.

Securing the Waterfall Component to the Tray

Attach the cable tray waterfall to the tray using the appropriate mounting hardware. Brackets or clamps should be tightly secured to prevent movement or shifting over time. Ensure that the waterfall is firmly connected and can support the expected cable load. At GangLong Fiberglass, our waterfalls come with user-friendly mounting solutions, making this step straightforward and efficient.

Guiding Cables Through the Waterfall for Optimal Layout

Carefully route the cables through the cable tray waterfall. Avoid pulling cables too tightly or overlapping them excessively, as this can cause damage or hinder accessibility. Arrange the cables in a way that maintains proper spacing, which helps with airflow and reduces the risk of overheating. Proper routing enhances both the functionality and safety of the system.

Final Inspections and Adjustments

After installation, inspect the cable tray waterfall and cables to ensure everything is secure and properly aligned. Look for loose brackets, misaligned cables, or potential obstructions. Make any necessary adjustments to optimize cable positioning and maintain system performance. At GangLong Fiberglass, we recommend regular inspections to prolong the life of the system and prevent future issues.

How to Install a Conduit to Cable Tray Connector

Cable Tray Waterfall Dropout

What is a Cable Tray Waterfall Dropout?

A cable tray waterfall dropout is a compact accessory designed to guide cables vertically out of a tray without excessive bending, reducing stress and preventing damage. It ensures organized and secure cable transitions, especially in setups with multiple vertical runs like server racks or telecom rooms. At GangLong Fiberglass, we manufacture durable, precision-engineered dropouts that protect delicate wiring while maintaining accessibility and system functionality.

Unique Design Considerations for Dropout Systems

Compact and Functional Design

A cable tray waterfall dropout is engineered to occupy minimal space while still providing optimal cable support. Its compact design allows it to fit seamlessly into cable tray systems without obstructing other components. This makes it ideal for high-density installations where space is a premium.

Edge Protection for Delicate Cables

One of the key features of a cable tray waterfall dropout is its edge protection. The dropout prevents sharp bends by offering a rounded or padded surface, ensuring cables are not damaged during vertical transitions. This is especially crucial for sensitive cables, such as fiber optics or thin signal wires.

Material and Durability

The material of the cable tray waterfall dropout plays a significant role in its performance. Durable materials, like fiberglass, resist wear and tear while providing long-term support. At GangLong Fiberglass, we design dropouts that meet these criteria, offering robust solutions for a variety of systems.

Benefits for High-Density Cable Systems and Delicate Wiring

Efficient Space Management

A cable tray waterfall dropout helps manage space efficiently by directing cables to their endpoints in a controlled manner. This is particularly beneficial in high-density systems where proper cable organization is essential for performance and accessibility. Dropouts prevent overcrowding and ensure cables remain manageable even in complex setups.

Protection for Delicate Wires

For sensitive wiring, such as fiber optics, a cable tray waterfall dropout provides an added layer of protection. By reducing strain and preventing sharp bends, dropouts maintain the integrity of these delicate cables. This reduces the likelihood of signal loss or damage, ensuring reliable performance.

Improved Maintenance and Access

By guiding cables neatly out of the tray, a cable tray waterfall dropout simplifies maintenance tasks. Technicians can easily identify and access specific cables without disturbing others, saving time and reducing errors. This organized approach improves overall system efficiency and reduces downtime.

Enhanced System Longevity

By preventing damage and maintaining organization, a cable tray waterfall dropout contributes to the longevity of both the cables and the tray system. This reduces repair and replacement costs over time, making it a cost-effective addition to any cable management setup.

Square D Cable Tray Waterfall

What Is a Square D Cable Tray Waterfall?

A square D cable tray waterfall is a specialized component designed to guide cables from a square-shaped cable tray system. It ensures smooth transitions, preventing cable stress and damage during changes in tray direction or level. This type of waterfall is particularly useful in systems where the tray has square dimensions, providing a tailored solution for precise cable management.

Unlike standard waterfalls, the square D cable tray waterfall is designed to fit seamlessly into square tray setups, ensuring compatibility and effective performance. At GangLong Fiberglass, we manufacture cable tray waterfalls, including options that cater to square configurations, ensuring your system operates efficiently and safely.

Key Features of a Square D Cable Tray Waterfall

Custom Fit for Square Tray Systems

The square D cable tray waterfall is engineered to align perfectly with square-shaped trays, offering an exact fit. This ensures that the cables flow smoothly without excessive bending or tension, protecting their integrity over time. The component’s tailored design makes it a preferred choice for applications requiring precise transitions.

Durable and Lightweight Material

The durability of the square D cable tray waterfall is a critical factor in its performance. Materials like fiberglass are ideal for their lightweight yet sturdy nature. At GangLong Fiberglass, we emphasize the use of high-quality materials to create robust components capable of withstanding heavy loads and challenging environments.

Edge Protection for Delicate Cables

One of the standout features of the square D cable tray waterfall is its focus on edge protection. Rounded or padded edges prevent cables from experiencing wear during movement. This feature is particularly advantageous for delicate cables, such as fiber optics, ensuring their performance is maintained.

Benefits of Using a Square D Cable Tray Waterfall

Enhanced Cable Protection

A square D cable tray waterfall minimizes the risk of damage by ensuring that cables are routed smoothly. By reducing sharp bends and preventing kinks, it extends the lifespan of cables, reducing maintenance and replacement costs.

Improved Organization and Accessibility

This type of waterfall organizes cables neatly, simplifying maintenance and troubleshooting. The structured routing makes it easier to identify and access individual cables, reducing downtime in case of repairs or upgrades.

Versatility Across Applications

Square D cable tray waterfalls are suitable for a wide range of applications, from industrial setups to data centers. Their compatibility with square tray systems makes them a reliable choice for complex installations. At GangLong Fiberglass, we offer customized designs to meet diverse operational requirements.

Examples of Applications for a Square D Cable Tray Waterfall

Data Centers

In data centers, where large volumes of data and power cables must be routed between server racks and equipment, a square D cable tray waterfall provides structured, low-stress transitions. It helps maintain bend radius, improves cable airflow, and supports efficient heat dissipation—factors that are critical for maintaining optimal performance and preventing equipment overheating. With clearly defined paths, it also simplifies cable identification and future expansion planning.

Industrial Facilities

In industrial facilities, where cables often pass through complex machinery setups or span long distances, the square D cable tray waterfall ensures safe, controlled drops that protect cables from mechanical stress. Its sturdy construction withstands vibrations, dust, temperature changes, and exposure to chemicals. This makes it a reliable solution for maintaining uninterrupted power or signal flow in production areas, automation systems, or control rooms where durability is essential.

Commercial Buildings

In commercial buildings, a square D cable tray waterfall brings both function and form. It allows for neat organization of electrical and communication cables, which is especially valuable in open ceiling systems or raised floor setups. By guiding cables in an orderly manner, it enhances system clarity, simplifies troubleshooting, and improves the overall appearance of the installation. This makes it ideal for modern office spaces, shopping centers, and public-use buildings.

Cable Tray Waterfalls for Specialized Systems

Overview of Tray Waterfall Configurations

Cable tray waterfalls come in various configurations designed to meet the unique needs of specialized systems. These configurations differ in size, shape, and material to accommodate specific tray types, cable loads, and environmental requirements. Standard designs include ladder rack waterfalls, perforated tray waterfalls, and dropouts, each tailored to optimize cable transitions and organization.

A ladder rack cable tray waterfall features open designs for high-density cabling, while perforated tray waterfalls offer enhanced airflow for heat management. Dropout waterfalls, on the other hand, provide precise vertical cable routing, minimizing strain on delicate wiring. At GangLong Fiberglass, we customize configurations to ensure seamless compatibility with diverse tray systems. Each design prioritizes durability, functionality, and ease of integration, ensuring optimal performance.

Key Applications and Environments for Use

Cable tray waterfalls are widely used across industries where efficient cable management is critical. In data centers, a cable tray waterfall is essential for organizing high-volume cabling, ensuring smooth transitions between racks while maintaining proper airflow for thermal management.

In industrial environments, waterfalls handle heavy power cables, directing them safely between machinery and control systems. Their robust construction supports continuous operation in demanding settings. Commercial buildings also benefit from cable tray waterfalls, which organize communication and electrical cabling for reliable infrastructure.

Specialized systems, such as telecommunications and medical facilities, require customized waterfalls for sensitive wiring like fiber optics. These environments demand precision, protection, and easy accessibility. At GangLong Fiberglass, we create solutions tailored to these applications, delivering reliable performance in any setting.

Tips for Effective Integration into Existing Cable Tray Systems

Assess System Requirements

Before integrating a cable tray waterfall, evaluate the specific needs of your cable system. Identify the tray type—ladder, perforated, or mesh—as well as cable volume and routing complexity. Consider whether your cables carry power, data, or control signals, since each requires different bend radii and organization. With a clear understanding of system demands, you can choose a waterfall that reduces stress, supports efficient routing, and aligns with the tray’s layout.

Choose the Right Material

The material of the cable tray waterfall directly affects its strength, weight, and resistance to harsh conditions. Fiberglass is preferred for its lightweight, corrosion-resistant, and non-conductive properties, ideal for both indoor and outdoor use. At GangLong Fiberglass, we use high-quality FRP to manufacture waterfalls that perform reliably in industrial, marine, and chemical environments, offering long-term protection without excessive maintenance.

Plan the Installation Process

Proper planning ensures a smooth and secure installation. Measure the tray and mark the area for alignment, then select hardware that matches the tray’s material and load needs. Use clamps or brackets to fix the waterfall firmly. Guide cables through with enough spacing to avoid tension or sharp bends. A well-planned setup improves cable protection, simplifies future access, and maintains system organization from the start.

Regular Maintenance Checks

To keep your cable tray waterfall performing well, schedule regular checks. Inspect mounting hardware, look for surface wear or corrosion, and confirm that cables remain neatly aligned and secured. Detecting minor issues early prevents long-term damage. Routine inspections help extend the life of both the waterfall and the cables, avoiding costly replacements and unplanned downtime in the future.

Comprehensive Guide to Choosing an Overhead Cable Tray

Best Practices for Cable Tray Waterfalls

Selecting the Right Waterfall Type for Your System

Choosing the appropriate cable tray waterfall is crucial for maintaining cable integrity and ensuring efficient system performance. The selection process begins with understanding the specific requirements of your cable tray system. Factors to consider include tray type, cable volume, and the environment in which the system operates.

For ladder racks, an open-structured cable tray waterfall is ideal as it accommodates high-density cables and promotes airflow. Perforated trays benefit from waterfalls designed to align with their slots, enhancing cable organization and accessibility. Dropout waterfalls are best for systems with frequent vertical transitions, providing precise cable guidance. At GangLong Fiberglass, we offer customized solutions to meet unique system needs, ensuring compatibility and durability.

The material of the waterfall is another critical factor. Fiberglass is an excellent choice due to its lightweight, corrosion-resistant properties, and durability under heavy loads. Proper material selection ensures the longevity and reliability of the cable tray waterfall, even in harsh environments.

Regular Maintenance and Inspection Guidelines

Maintaining a cable tray waterfall is essential for ensuring its continued performance and preventing long-term system issues. Regular inspections should be conducted to identify signs of wear or misalignment. Focus on checking the stability of mounting hardware and ensuring that cables are properly routed without tension or overlapping.

Cleaning the cable tray waterfall periodically is another best practice, especially in environments prone to dust or debris accumulation. This keeps the system free of obstructions and promotes optimal airflow. At GangLong Fiberglass, we recommend a maintenance schedule tailored to the specific operating conditions of the system.

Additionally, inspect cables for signs of wear or damage. Addressing minor issues early can prevent significant problems, such as cable breakage or system downtime. Proper maintenance extends the life of both the cables and the cable tray waterfall, enhancing overall system reliability.

Troubleshooting Common Installation Issues

Even with careful planning, issues can arise during or after the installation of a cable tray waterfall. One common problem is misalignment, which can cause cables to experience undue strain. This can often be resolved by realigning the waterfall and ensuring it is properly secured to the tray.

Another frequent issue is insufficient cable support due to an undersized waterfall. To avoid this, measure tray dimensions accurately before installation and select a waterfall that matches the system’s needs. GangLong Fiberglass provides detailed sizing guides and customer support to help you make the right choice.

If cables are tangled or overlapping, reroute them carefully to prevent signal interference or damage. Using cable ties or clamps can help maintain proper spacing and organization. Regular checks after installation ensure that adjustments can be made as necessary.

By following these best practices, you can maximize the performance and lifespan of your cable tray waterfall. Proper selection, consistent maintenance, and effective troubleshooting ensure a reliable and efficient cable management system. GangLong Fiberglass is committed to providing high-quality solutions and support for all your cable management needs.

FAQs about Cable Tray Waterfall

A cable tray is a structured system used to support and organize cables above ground. It is often mounted on walls, ceilings, or racks. In contrast, a cable trench is an underground or embedded channel that houses cables, typically providing a higher level of protection from environmental factors. Cable trays are preferred for their accessibility and ease of maintenance, while cable trenches are better suited for applications requiring maximum protection, such as outdoor installations or areas exposed to heavy machinery. Both systems serve the same purpose—efficient cable management—but their applications differ based on environmental and accessibility needs. Cable trays often incorporate features like a cable tray waterfall to manage transitions, while trenches rely on conduits for internal organization.

Pulling a cable through a cable tray requires proper preparation to prevent cable damage and ensure safety. First, determine the pathway and check for obstacles in the tray. Use a cable puller or fish tape to guide the cable through the tray system. For longer runs or directional changes, consider using rollers or guides, such as a cable tray waterfall, to facilitate smoother transitions. Secure the cable loosely with ties or clamps to maintain organization without restricting flexibility. Ensure that cables are not pulled with excessive force, as this can damage their insulation or connectors. Once the cable is laid, perform a final inspection to confirm alignment and stability before securing it permanently.

Holes in cable trays serve multiple purposes, enhancing their functionality and efficiency. Primarily, they allow for improved airflow around cables, helping to dissipate heat generated by electrical currents. This is particularly important in high-density cabling systems where overheating can impact performance and safety. Additionally, the holes reduce the overall weight of the tray, making installation easier and more cost-effective. They also provide multiple points for securing cables, ensuring flexibility in routing and organization. Components like a cable tray waterfall often integrate with perforated trays to enhance cable transitions while maintaining proper ventilation.

The fill factor of a cable tray refers to the percentage of the tray’s capacity occupied by cables. It is a critical parameter in cable management, as exceeding the recommended fill factor can lead to overheating, cable damage, and reduced performance. Industry standards often recommend that the fill factor should not exceed 50% to 60%, depending on the type and application of the tray. This allows space for airflow and future expansions. When using accessories such as a cable tray waterfall, the fill factor should also account for the smooth movement of cables during transitions, ensuring optimal organization and functionality. Proper planning and adherence to fill factor guidelines help maintain system safety and efficiency.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.