Fiberglass lagging cloth is a highly effective material used for thermal insulation in a variety of industries. Its primary role is to provide heat resistance, making it essential in environments where managing high temperatures is crucial. There are various types of fiberglass lagging cloth, each designed to meet specific needs depending on the application and temperature requirements. Fiberglass lagging cloth offers durable insulation fabric, lightweight yet sturdy, ideal for removable blankets and flange covers. This versatile cloth is widely used in industries such as automotive, aerospace, and energy, where components are exposed to extreme heat conditions. Fiberglass lagging cloth serves as an efficient alternative to traditional insulation materials, such as asbestos, offering enhanced safety and performance. Its ability to withstand high temperatures without degrading over time makes it a preferred choice for insulating pipes, machinery, and other equipment in demanding applications. By replacing asbestos, fiberglass lagging cloth not only provides superior insulation but also helps improve overall safety standards in industries that require heat resistance.

What is Fiberglass Lagging Cloth?

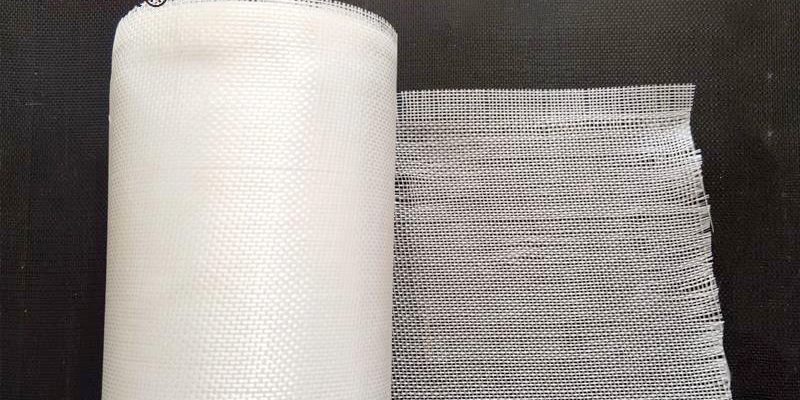

Fiberglass lagging cloth is a high-performance thermal insulation material made from woven glass fibers. It is designed to provide excellent heat resistance and is commonly used in industries where managing high temperatures is critical. The unique properties of fiberglass fibers make this material ideal for use in high-heat environments, where traditional insulation methods may not be effective or safe. The cloth is lightweight yet durable, making it easy to handle and apply in various industrial settings.

Definition and Composition

Fiberglass lagging clothes is composed of tightly woven glass fibers, which are known for their exceptional strength and resistance to heat. The fibers are typically made from E-glass or S-glass, both of which offer high tensile strength and thermal stability. These fibers are woven into a fiberglass fabric that can be used to insulate equipment and machinery that are exposed to extreme heat. The inherent properties of glass fibers—such as their ability to withstand high temperatures, resistance to electrical conductivity, and low moisture absorption—make fiberglass lagging cloth a superior option for many applications.

Heat Resistance

Fiberglass lagging cloth is specifically designed to withstand extreme temperatures. It can maintain its insulating properties even in environments where temperatures reach up to 1000°F (537°C) or higher. This makes it an ideal choice for industries that require insulation materials capable of enduring prolonged exposure to heat. Similar to Rewettable Canvas Fabric, fiberglass lagging cloth does not degrade or lose its effectiveness over time when exposed to high heat. This heat resistance allows for safer and more efficient operation in industries such as automotive, aerospace, and energy production, where temperature control is essential.

Fiberglass Rod Electrical Wiring: A Comprehensive Guide

Fiberglass Lagging Cloth Temperature Rating

Fiberglass lagging cloth is renowned for its exceptional ability to withstand high temperatures, making it an ideal material for thermal insulation in extreme heat environments. Its temperature rating is one of the key factors that contribute to its widespread use in industries requiring reliable heat resistance. Understanding the temperature resistance and the specific applications of fiberglass lagging cloth helps ensure its effective use in protecting equipment and personnel from heat-related hazards.

Standard Temperature Rating (up to 1000°F / 537°C)

Fiberglass lagging cloth is typically rated for continuous use at temperatures up to 1000°F, or 537°C. This level of heat resistance makes it suitable for most industrial insulation tasks, including covering steam pipes, ducts, and machinery surfaces. At this range, the material does not burn or lose its shape, maintaining reliable thermal protection in high-heat environments over long durations.

High-Performance Variants (above 1000°F)

Some fiberglass lagging cloth products are designed for improved performance, with coatings or tighter weaves that allow them to endure temperatures beyond 1000°F. These upgraded materials can handle around 1200°F, depending on the formulation. They are commonly used in high-demand areas like power plant turbines, incinerators, or heavy-duty processing facilities where extreme and constant heat is present.

Short-Term Heat Tolerance (up to 1500°F / 815°C)

Many fiberglass lagging cloth types can withstand short-term or occasional exposure to temperatures as high as 1500°F, or 815°C. This is important in systems that experience heat surges or start-up spikes. While the material can resist these brief peaks without burning, it is not designed for continuous use at these levels and may degrade faster under prolonged exposure.

Glass Fiber Melting Point (over 2000°F / 1100°C)

The base material in fiberglass cloth, woven glass fiber, has a melting point above 2000°F, or roughly 1100°C. While most applications never reach this extreme, knowing the fiber itself won’t melt under normal operating conditions provides added confidence in the cloth’s thermal reliability. It ensures the cloth holds up even when outer coatings begin to break down.

Applications in Extreme Conditions

Fiberglass lagging cloth is widely used in industries where high temperatures are constant, such as power plants, industrial facilities, and heavy-duty machinery operations. Some specific applications include:

Power Plants

In power generation facilities, fiberglass lagging cloth plays a vital role in insulating turbines, reactors, and exhaust systems. These components operate under continuous high temperatures. The cloth helps reduce heat loss, protect sensitive equipment, and maintain operational stability. It supports peak performance while reducing the risk of overheating and thermal fatigue.

Industrial Settings

In industrial environments like chemical plants and manufacturing facilities, fiberglass lagging cloth is commonly used for insulating boilers, furnaces, and chemical reactors. These systems generate extreme heat and require reliable thermal barriers. Fiberglass cloth resists both high temperatures and chemical exposure, providing consistent insulation and preventing dangerous temperature swings.

Heavy-Duty Machinery

In sectors such as automotive, marine, and aerospace, fiberglass lagging cloth is applied to engines, manifolds, and exhaust systems. These components generate intense, localized heat. The cloth insulates key parts, prevents heat damage to surrounding materials, and improves overall system performance by minimizing energy loss through heat escape.

High-Heat Piping and Valves

Fiberglass lagging cloth is widely used to wrap pipes, valves, elbows, and flanges in high-temperature environments. Its flexibility allows it to conform tightly to curved or irregular surfaces, ensuring full insulation coverage. This application is critical in maintaining process temperatures and protecting workers from burns or accidental contact with hot surfaces.

Fire-Prone Environments

Because it is inherently non-flammable, fiberglass lagging cloth is ideal for fire-prone settings like welding zones, refineries, emergency generator rooms, and high-voltage electrical areas. It acts as a protective barrier, helping contain heat, prevent flame spread, and increase the fire resistance of surrounding structures and equipment.

A Step-by-Step Guide to Threading Fiberglass Rod

Fiberglass Lagging Cloth vs. Other Heat-Resistant Materials

When selecting a heat-resistant material for insulation, there are several options to consider, each with its own strengths and weaknesses. Fiberglass fabric cloth, including fiberglass lagging cloth, is a popular choice due to its excellent thermal insulation properties and wide industrial usage. But there are other materials like Teflon high-temperature cloth and high-temp silicone fabric that also offer reliable heat resistance. Comparing these materials can help determine the best choice for specific applications, whether in industrial, automotive, or aerospace settings.

Fiberglass Heat Resistance vs. Teflon High Temperature Cloth

Teflon high-temperature cloth is another well-known material used for heat-resistant applications. While Teflon offers excellent non-stick and chemical resistance properties, fiberglass lagging cloth is better suited for insulation, especially in high-temperature environments. Below is a comparison of both materials:

| Property | Fiberglass Lagging Cloth | Teflon High Temperature Cloth |

|---|---|---|

| Temperature Resistance | Up to 1000°F (537°C) or more | Up to 600°F (316°C) |

| Heat Insulation | Excellent heat insulation | Moderate heat insulation |

| Chemical Resistance | Good | Excellent |

| Flexibility | Rigid | Very flexible |

| Durability | High | Moderate |

Comparison with High Temp Silicone Fabric

High-temperature silicone fabric is another heat-resistant material often compared to fiberglass lagging cloth. Silicone fabrics offer excellent flexibility, making them easier to handle in some situations, but they are generally not as rigid or durable as fiberglass cloth. The table below compares the properties of these two materials:

| Property | Fiberglass Lagging Cloth | High Temp Silicone Fabric |

|---|---|---|

| Temperature Resistance | Up to 1000°F (537°C) or more | Up to 500°F (260°C) |

| Strength and Rigidity | High (rigid) | Moderate (flexible) |

| Flexibility | Low | High |

| Chemical Resistance | Good | Excellent |

| Durability | High | Moderate |

Fiberglass Cloth Insulation vs. Traditional Asbestos Insulation

Fiberglass lagging cloth provides a modern, safe, and sustainable alternative to traditional asbestos insulation. Asbestos was once widely used for its excellent heat resistance properties but has since been phased out due to serious health risks, including cancer and respiratory diseases. Fiberglass cloth insulation offers the following advantages over asbestos-based materials:

- Health and Safety: Fiberglass lagging cloth is non-toxic and does not pose the same health risks associated with asbestos. It provides a safer environment for workers and users.

- Environmental Impact: Unlike asbestos, which is hazardous to dispose of and can contaminate the environment, fiberglass lagging cloth is generally considered safer and easier to dispose of after use.

- Performance: While asbestos offered great thermal insulation, fiberglass lagging cloth performs just as well, if not better, in many applications. It is more versatile, offers higher temperature resistance, and is easier to work with.

Fiberglass lagging cloth stands out as a versatile, safe, and high-performance heat-insulating material when compared to other heat-resistant options like Teflon high-temperature cloth, silicone fabric, and traditional asbestos insulation. The choice of material largely depends on the specific application, temperature requirements, and flexibility needed for installation.

Why Fiberglass Rod with a Bull Nose End Is Essential

Key Benefits of Using Fiberglass Lagging Cloth

Fiberglass lagging cloth is a versatile material widely used in industries that require high heat resistance and thermal insulation. Its exceptional properties, including durability, cost-effectiveness, and safety, make it an ideal choice for numerous applications. Whether in power plants, automotive manufacturing, or aerospace engineering, fiberglass lagging cloth provides lasting benefits that enhance both performance and safety.

Durability and Strength

Fiberglass lagging cloth is extremely strong, especially in its heavier forms. Heavy fiberglass cloth handles heat, friction, and chemical exposure without breaking down. The tightly woven glass fibers give it excellent resistance to wear. This durability ensures it performs well in harsh environments like engine exhausts or pipe systems. It doesn’t degrade easily and lasts long, reducing the need for frequent replacements and improving operational stability.

Cost-Effectiveness

Though the upfront cost can be higher, fiberglass lagging cloth saves money over time. Its durability means fewer repairs or replacements. In cases where damage does occur, fiberglass cloth repair is typically simple and cost-effective. It also maintains its insulation quality even after long use, which prevents equipment damage. Plus, it’s often reusable in multiple projects. These factors lower maintenance costs and reduce downtime, making it a practical and budget-conscious choice for industries focused on long-term efficiency.

Easy Handling and Flexibility

Fiberglass lagging cloth is lightweight and easy to cut, shape, and install. It’s available in multiple fiberglass cloth weights to match different insulation needs. Because it’s flexible, it wraps around pipes, valves, or uneven surfaces with ease. This adaptability helps workers apply it quickly, especially in tight or complex spaces. The material’s easy handling saves time and reduces labor costs during both installation and repairs.

Environmental and Health Safety

Unlike asbestos, fiberglass lagging cloth is non-toxic and safe to use. It doesn’t release harmful fibers or chemicals into the air. This creates a safer environment for workers, especially in enclosed or high-heat spaces. It also poses minimal risk during disposal, reducing environmental hazards. Its safety profile makes it a smart, responsible alternative to outdated insulation materials that carry long-term health risks.

How to Use Fiberglass Lagging Cloth for Insulation

Fiberglass lagging cloth is an essential material for thermal insulation in various industries, from power plants to automotive manufacturing. Its application, maintenance, and durability depend on the right techniques and care. This section will guide you through the process of applying fiberglass lagging cloth and offer tips on how to ensure its longevity and effectiveness.

Application Process

Using fiberglass lagging cloth for insulation requires precision and careful handling to ensure optimal performance. Below is a step-by-step guide on how to apply fiberglass lagging cloth properly:

- Prepare the Surface: Before applying fiberglass lagging cloth, ensure that the surface to be insulated is clean, dry, and free from any dirt or debris. Any contamination can affect the adhesion and performance of the insulation. For pipes or machinery, check that the surface is smooth, and use a wire brush to remove any rust or buildup.

- Measure and Cut the Fiberglass Lagging Cloth: Measure the area you need to insulate carefully, including the length and circumference of pipes or the dimensions of components. Once measured, cut the fiberglass lagging cloth to the appropriate size, allowing extra material for overlap at the seams. Use a sharp utility knife or scissors to cut through the cloth cleanly.

- Wrap the Fiberglass Lagging Cloth: Begin wrapping the fiberglass lagging cloth around the surface. Start at one end and work your way to the other, ensuring that the cloth fits snugly. Overlap each layer of cloth slightly to avoid any gaps, which could reduce insulation efficiency. Be mindful of any bends or curves in the component, as the cloth should conform smoothly to the shape.

- Secure the Cloth in Place: Use metal or stainless steel wire, banding, or heat-resistant tape to secure the edges and seams of the fiberglass lagging cloth. Ensure the cloth is tightly secured to prevent it from shifting or loosening over time. In the case of pipes, you may need to use additional ties or fasteners to ensure the insulation stays in place.

- Seal the Seams: After wrapping and securing the fiberglass lagging cloth, apply a high-temperature sealant to the seams and edges to prevent moisture or debris from getting inside. This step helps maintain the effectiveness of the insulation and prevents degradation over time.

Tips for Best Practices

- Always wear protective gloves, goggles, and a mask when handling fiberglass lagging cloth, as the fibers can irritate the skin and respiratory system.

- If you’re insulating large or complex surfaces, it may be helpful to use pre-formed fiberglass insulation sleeves or jackets, which can simplify the process.

Maintenance and Durability

Fiberglass lagging cloth is a durable and long-lasting material, but like any insulation product, proper maintenance is key to ensuring its effectiveness over time. Follow these guidelines to maintain and prolong the lifespan of your fiberglass lagging cloth:

- Regular Inspections: Periodically inspect the fiberglass lagging cloth for any signs of damage, wear, or compression. Look for visible cracks, tears, or any areas where the cloth has loosened or shifted. Address any issues immediately to avoid reducing the insulation performance.

- Cleaning the Fiberglass Lagging Cloth: To maintain the appearance and functionality of fiberglass lagging cloth, clean it regularly. Use a vacuum cleaner to remove dust and debris from the surface. For more stubborn dirt or contamination, a damp cloth can be used, but ensure that the cloth is completely dry before reapplying it to high-temperature environments. Avoid using harsh chemicals that could damage the fibers.

- Avoid Contact with Moisture: While fiberglass lagging cloth is resistant to moisture, prolonged exposure to water or high humidity can degrade its effectiveness over time. Ensure that insulation is kept dry, and repair any leaks or water damage immediately.

- Re-tightening and Re-securing: Over time, the fastening materials like wire or tape may loosen due to expansion and contraction from temperature changes. Check these fasteners regularly and re-tighten or replace them as necessary to ensure that the fiberglass lagging cloth remains firmly in place.

Tips for Ensuring Durability

- Storage: If fiberglass lagging cloth is not in use, store it in a dry, cool area away from direct sunlight or chemicals.

- Avoid Excessive Stress: When handling the cloth, avoid pulling or stretching it too much, as this can damage the fibers.

Proper application and ongoing maintenance of fiberglass lagging cloth are essential for maintaining its heat-insulating properties and extending its lifespan. By following the recommended steps for application and incorporating regular inspection and care, you can ensure that your insulation performs effectively in high-temperature environments for years to come.

FAQs about Fiberglass Lagging Cloth

The strength of fiberglass mat versus fiberglass cloth largely depends on the specific application and the type of reinforcement needed. Fiberglass cloth is generally stronger than fiberglass mat because it is woven, which provides superior tensile strength and flexibility. The woven structure of fiberglass cloth allows it to resist tearing and breaking under stress, making it ideal for applications that require strength and durability, such as in composite materials and high-performance insulation.

In contrast, fiberglass mat is made from chopped fibers randomly oriented and held together with a resin binder. While it provides good strength for general applications, it does not offer the same level of tensile strength or directional reinforcement as fiberglass cloth. Matting is typically used when flexibility and easier application are more important than ultimate strength.

Key Differences:

Fiberglass cloth offers higher tensile strength and durability.

Fiberglass mat provides more flexibility and is easier to work with but lacks the same strength in stress-resistance.

Ultimately, fiberglass cloth is the stronger option when you need superior performance and durability for demanding applications. For lightweight or less stress-intensive projects, fiberglass mat may be more suitable.

Fiberglass lagging cloth is a specialized fabric used primarily for thermal insulation and heat protection. Made from glass fibers, it is designed to wrap around pipes, turbines, boilers, and other equipment that operate at high temperatures. The cloth works as a barrier, preventing heat loss, and protecting surrounding areas from excessive heat exposure. It also helps to maintain the efficiency of thermal systems by reducing energy consumption.

Lagging cloth is commonly used in industries such as power generation, automotive, aerospace, and oil and gas, where high temperatures are a constant factor. Its unique composition of woven fiberglass fibers allows it to handle extreme heat, typically up to 1000°F (537°C) or more, making it an essential material in environments that require reliable thermal insulation.

Benefits of Fiberglass Lagging Cloth:

Heat Resistance: Can withstand extremely high temperatures without breaking down.

Durability: Resistant to wear and tear, ensuring long-lasting protection.

Non-toxic: Unlike asbestos, it is a safer and more environmentally friendly option for insulation.

Yes, fiberglass cloth does add significant strength to composite materials and structural components. Fiberglass cloth is commonly used in composite manufacturing where it acts as a reinforcement material when combined with resins like epoxy, polyester, or vinyl ester. When impregnated with resin, the cloth forms a solid, durable structure that provides both strength and flexibility.

Fiberglass cloth enhances the strength of materials in several ways:

Increased Tensile Strength: The woven nature of fiberglass fibers allows for directional strength, making it ideal for resisting pulling forces.

Flexibility and Durability: Fiberglass cloth maintains its integrity under stress, and its flexibility allows it to be molded to complex shapes.

Lightweight yet Strong: Despite its high strength, fiberglass cloth remains relatively light compared to metals or other materials with similar strength properties.

For applications requiring both lightweight and strength, such as boat hulls, automotive parts, and aerospace structures, fiberglass cloth is an excellent choice due to its ability to add strength without significantly increasing weight.

There are several types of fiberglass cloth, each designed for specific applications based on the characteristics of the weave and fiber type. The three most common types of fiberglass cloth include:

Plain Weave Fiberglass Cloth: This is the most widely used type of fiberglass cloth, offering a good balance of strength and flexibility. It features a simple over-and-under weaving pattern that is durable and easy to handle. This cloth is ideal for general reinforcement in applications like boat hulls, tanks, and automotive parts.

Twill Weave Fiberglass Cloth: This type of cloth has a distinctive diagonal pattern that provides increased strength and durability compared to plain weave. It’s ideal for applications that require additional strength, such as in vehicle panels and aerospace components. Twill weave cloth offers more flexibility and is easier to mold around curves and complex shapes.

Satin Weave Fiberglass Cloth: Satin weave has a smooth, glossy surface that provides superior flexibility and a smooth finish. While it may not be as strong as twill or plain weave, it is ideal for applications where aesthetic appearance is important, such as in high-end composites or marine structures.

Each of these fiberglass cloth types has unique properties that make them suited to different environments and application needs. When choosing a fiberglass cloth, consider the strength, flexibility, and application requirements to select the best option for your project.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.