Cable tray systems are essential components in modern electrical installations, used to organize, route, and support electrical cables in various environments. They are designed to provide efficient management, ensuring that cables are securely held in place while remaining accessible for future maintenance. A well-structured cable tray system prevents tangling, reduces the risk of damage, and improves the overall safety of the electrical installation.One important aspect of cable tray systems is the use of cable tray box mounts. These mounts are crucial for providing support and securely fastening electrical connections to the tray system, ensuring that cables remain stable and properly routed. Cable tray box mounts are typically used when cables need to be routed into electrical panels, junction boxes, or other equipment. Their role in maintaining the integrity and safety of the system makes them indispensable for effective cable management in both residential and industrial settings.

What is a Cable Tray Box Mount?

A cable tray box mount is a specialized device used to secure electrical boxes to cable tray systems. Its primary purpose is to provide a stable and organized way of routing electrical wiring from the cable tray into electrical panels, junction boxes, or other equipment. By mounting the electrical box securely to the tray system, it ensures that cables are routed without interference or damage, maintaining the integrity and safety of the entire electrical setup.

Purpose and Function of Cable Tray Box Mount

The cable tray box mount plays a critical role in organizing and securing cables within a cable management system. Its primary function is to support electrical boxes, ensuring safe transitions of cables from the tray into connected systems. By holding electrical boxes in place, the mount prevents cables from becoming tangled or misaligned, which is crucial for maintaining the integrity of the entire system. Below are key factors to consider when evaluating the purpose and function of the cable tray box mount:

- Support and Stability: The cable tray box mount provides the necessary support to ensure that electrical boxes remain securely positioned, preventing unwanted movement that could lead to cable damage or disconnections.

- Safe Cable Transitions: By providing a secure method for transitioning cables from the tray into electrical systems, the box mount minimizes the risk of cables becoming twisted, damaged, or disconnected.

- Improved Organization: The mount helps to organize cables neatly as they exit the tray, reducing clutter and making it easier to manage and maintain the system.

- Protection Against Physical Damage: By preventing cables from hanging loosely or being improperly supported, the mount protects cables from physical damage, such as bending or pinching, which can compromise the system’s performance.

Benefits of Cable Tray Box Mount

The cable tray box mount offers several key benefits that contribute to a more efficient and safe cable management system:

- Enhanced Safety: Ensures cables are neatly routed and secured, reducing the risk of accidental disconnections or electrical hazards.

- Increased Durability: By preventing misalignment and strain on cables, the mount helps extend the lifespan of both the cables and the cable tray system.

- Ease of Maintenance: Properly mounted electrical boxes allow for easier access and maintenance, as cables are neatly arranged and clearly identifiable.

Advantages of Using a Cable Tray Box Mount

- Prevents Cable Wear: Reduces friction and wear on cables by holding them securely in place, which is especially important in high-vibration environments.

- Promotes Better Cable Management: Provides a more organized cable management solution, helping to reduce clutter and make troubleshooting and system upgrades easier.

- Compatibility with Various Systems: The mount can be adapted to fit various cable types and tray configurations, making it highly versatile across different industries and applications.

Disadvantages of Cable Tray Box Mount

- Installation Complexity: Depending on the size and configuration, installing a cable tray box mount can be more complex, especially in tight or hard-to-reach areas.

- Cost: While it offers substantial benefits, the added cost of purchasing and installing cable tray box mounts can increase the overall budget for a cable management project.

- Space Limitations: In installations where space is limited, the cable tray box mount may take up valuable room, potentially making the cable routing more difficult.

Case Study / Example

In a chemical processing plant, where cables are exposed to aggressive chemicals, the use of cable tray box mounts can significantly improve the longevity and safety of the entire cable management system. Electrical boxes securely mounted within cable trays help ensure that cables are properly transitioned to machinery without being exposed to hazardous substances. This installation not only enhances the safety and operational efficiency of the plant but also reduces the maintenance costs associated with cable repairs or replacements caused by poor cable management.

By using a cable tray box mount, the plant is able to maintain optimal cable alignment, preventing costly downtime due to cable failures or disconnections. The mount ensures that cables are securely supported while transitioning into specialized equipment, which is especially important in high-risk environments like chemical plants.

Research / Industry Findings

Recent research in industrial cable management systems shows that properly mounted cable trays with well-secured box mounts lead to a 30% reduction in cable-related issues and maintenance costs. Studies in sectors like oil and gas and power plants reveal that integrating cable tray box mounts into the design increases overall system longevity and reduces the risk of electrical accidents caused by improperly routed cables. The consistent application of box mounts can also lead to improved compliance with safety standards, particularly in industries with stringent regulatory requirements for electrical installations.

The cable tray box mount is an essential component for ensuring the safe and efficient management of electrical systems. Its benefits, including enhanced safety, improved organization, and reduced wear on cables, outweigh the challenges it may pose in terms of installation and cost, making it a valuable asset in various industrial applications.

How Box Mounts Help Secure Electrical Boxes

Box mounts are typically fastened directly to the cable tray, with the electrical box then attached to the mount. This configuration ensures that the electrical box is both firmly secured and properly aligned with the tray, preventing unnecessary movement or strain on the cables. With a cable tray box mount, the wiring remains neatly organized and protected, while ensuring easy access for future maintenance and adjustments. This effective method of integration is essential for optimizing cable tray systems in both industrial and commercial electrical installations.

Best Practices for Cable Tray Risk Assessment During Installation

Cable Tray Box Mount and Types of Cable Tray Brackets: A Comprehensive Guide

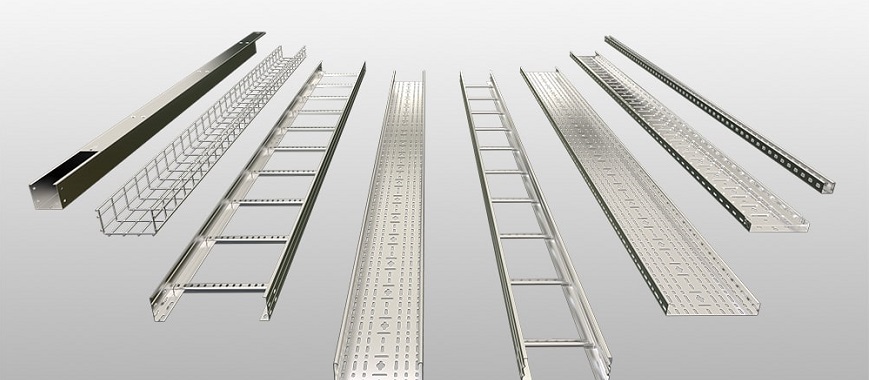

Cable tray brackets are essential components used to support and secure cable trays in various electrical installations. These brackets provide the necessary support to ensure that cable trays remain stable and securely fastened, preventing movement or damage to the cables they house. There are several types of cable tray brackets, each serving a specific function depending on the application, location, and load requirements.

Cable Tray Wall Bracket

A cable tray wall bracket is designed to provide secure mounting for cable trays directly to walls. These brackets are ideal for situations where the tray needs to be fixed vertically against a wall, providing both stability and support for cables. Wall brackets typically come in adjustable designs, allowing for flexibility in positioning the tray at the correct height and angle. By using wall brackets, installers can ensure that the cable tray system remains firmly attached to the wall while also allowing for smooth cable routing.

Cable Tray Brackets for Various Angles

General cable tray brackets are used for mounting and supporting cable trays at various angles or attachment points. These brackets are versatile and can be used to support trays on ceilings, floors, or even across beams. They are available in different designs, such as L-brackets, U-brackets, and custom adjustable versions, allowing for a range of installation configurations. Depending on the installation’s needs, brackets may be used to provide a direct attachment to beams, or they can be used in conjunction with a cable tray box mount to integrate electrical boxes into the cable tray system, ensuring both organization and accessibility.

In both cases, these brackets play an essential role in maintaining the integrity and alignment of the cable tray system, ensuring that the cables are safely routed and supported throughout their installation.

How to Install a Cable Tray Box Mount

Installing a cable tray box mount is an essential part of the cable management process, allowing for the secure attachment of electrical boxes to the cable tray system. This step-by-step guide outlines the installation procedure for ensuring both safety and efficiency in your cable tray setup.

Preparation: Ensure Correct Tools and Equipment

Before beginning the installation, gather all necessary tools and materials. These may include:

- Wrenches or screwdrivers

- Drill and drill bits (if mounting on concrete or other hard surfaces)

- Measuring tape

- Mounting brackets and fasteners (nuts, bolts, screws)

- Safety gear (gloves, goggles, etc.)

Make sure that you have the right cable tray box mount, compatible with the cable tray and electrical box size you plan to use. Verify that all components are intact and ready for installation.

Selecting the Right Mount

Choosing the correct cable tray box mount is crucial for a successful installation. There are various types of box mounts available depending on the size and load of the electrical box. For example:

- Heavy-duty mounts: Suitable for larger electrical boxes or when heavy cables are involved.

- Standard mounts: Ideal for smaller electrical boxes or lighter installations.

The mount should also be compatible with the specific type of cable tray, whether it’s a ladder tray, ventilated tray, or solid-bottom tray. Ensure the box mount is rated to handle the cable load and provides the appropriate support.

Securing the Mount

Once you have selected the right cable tray box mount, position it correctly where you plan to install it. This step involves securing the mount to the cable tray system and the surface (wall, ceiling, or floor).

- For wall installations, use appropriate wall anchors or bolts to secure the mount to the wall. Make sure it is aligned properly with the cable tray.

- For ceiling or floor installations, ensure that the mount is securely fastened to the surface using either screws or bolts, based on the type of tray and material of the surface. Tighten all fasteners to ensure stability.

Double-check the alignment before tightening everything down completely to avoid any misalignment that may affect the final setup.

Installing Electrical Boxes

Once the cable tray box mount is secured in place, the next step is to install the electrical box. Carefully position the electrical box onto the mount, ensuring it aligns properly with the mounting holes.

- Securing the box: Use screws or fasteners to attach the electrical box to the mount. Be sure that the box is tightly fixed to prevent any movement or instability that could affect the wiring.

- Check for proper positioning: Verify that the box is positioned at the correct height and angle for ease of access to connections.

Ensure that no wires are pinched or stressed during the installation, and verify that the electrical box is securely mounted before proceeding with any cable routing.

By following these steps for installing a cable tray box mount, you ensure that both the cable tray system and electrical boxes are securely integrated into the overall cable management layout.

Benefits of Peaked Vented Cable Tray in High-Traffic Cable

Benefits of Using Cable Tray Box Mounts

A cable tray box mount plays a critical role in enhancing the functionality and safety of your cable tray system. These mounts provide numerous benefits, making cable installations more organized, efficient, and secure. Below are the key advantages of using cable tray box mounts in your system.

Space Efficiency: Keeps Cables Organized and Reduces Clutter

One of the most significant benefits of using a cable tray box mount is the improved use of space. By securely mounting electrical boxes onto the cable tray system, you can optimize the layout and reduce the clutter that often results from cables being routed haphazardly. Mounting electrical boxes on the tray keeps the entire cable management system compact and organized, ensuring that cables are routed in a systematic manner. This efficient use of space is especially beneficial in environments with limited room, such as tight electrical rooms or industrial facilities, where proper organization of cables is crucial.

Safety: Ensures Secure Installation to Prevent Damage or Accidents

A cable tray box mount is designed to securely hold electrical boxes in place, which helps prevent potential accidents or damage during installation or over time. By ensuring that boxes are fastened correctly to the cable tray, these mounts eliminate the risk of boxes shifting or falling, which could lead to cable damage or electrical hazards. This secure attachment provides stability, preventing cables from becoming loose or exposed, thereby reducing the chances of accidental contact with live wires. Properly mounted boxes also reduce the likelihood of tripping hazards, a common concern when cables are improperly routed or left unsecured.

Flexibility: Ability to Add or Modify Trays and Boxes Easily

Using cable tray box mounts adds a level of flexibility to your cable management system. These mounts make it easy to add or modify the cable tray system without disrupting the overall setup. If additional cables or boxes need to be installed, new cable tray box mounts can be added without requiring a complete overhaul of the existing system. This flexibility is especially valuable in dynamic environments where cable layouts may need to be updated regularly to accommodate changes in equipment, layout, or electrical needs. Whether you’re expanding a system or reconfiguring it for new installations, cable tray box mounts offer a quick and easy way to modify your setup.

Improved Cable Management: Helps in Routing Cables Neatly, Preventing Tangling and Interference

The use of cable tray box mounts significantly improves cable management by ensuring that cables are neatly routed and properly supported. Electrical boxes that are mounted securely to the tray provide a stable foundation, helping to prevent cables from tangling, kinking, or becoming disorganized. When cables are routed neatly and securely, they are less likely to experience physical damage, interference, or signal degradation. Proper cable management also makes it easier to identify and troubleshoot any issues with the system, as the cables are clearly organized and accessible. By reducing tangling and ensuring that cables are supported, cable tray box mounts contribute to the long-term integrity and efficiency of the installation.

Incorporating a cable tray box mount into your cable tray system provides numerous advantages, including space efficiency, enhanced safety, system flexibility, and improved cable management. These benefits make it an essential component for any modern electrical installation, ensuring that cables are routed securely and effectively.

Why Choose Ventilated Bottom Cable Tray for Outdoor Installations

Choosing the Right Mounting System for Cable Tray Box Mount

Selecting the right cable tray box mount is a crucial step in ensuring the stability, safety, and efficiency of your cable management system. A cable tray box mount plays an essential role in securing electrical boxes to the tray and ensuring smooth cable routing. When choosing the appropriate mounting system, several key factors must be considered to guarantee a successful installation. Below, we discuss the important considerations when selecting a cable tray box mount.

Type of Cable (Low or Medium Voltage)

The type of cable you are working with is one of the most important factors in selecting a cable tray box mount. Cables for low and medium voltage systems often differ in their size, insulation, and weight, which directly influences the type of mounting system required. For instance, medium voltage cables tend to be heavier and bulkier than low voltage cables, which means they require stronger and more robust mounts to ensure secure attachment to the cable tray. It is essential to choose a cable tray box mount that can support the weight and size of the specific cable you are using to prevent any stress or strain on the system, ensuring that cables remain securely positioned.

Tray Material (Steel, Aluminum, or Fiberglass)

The material of the cable tray plays a significant role in the selection of the cable tray box mount. Different materials—such as steel, aluminum, or fiberglass—have varying levels of strength, weight, and resistance to environmental factors. For example, steel trays provide robust support for heavy cables but may require more durable mounting systems, such as galvanized steel box mounts, to handle the weight. On the other hand, aluminum trays, which are lighter and more corrosion-resistant, may require lighter but still durable cable tray box mounts made of aluminum. Fiberglass trays, often used in corrosive environments, require mounts that offer high resistance to chemicals and moisture. Understanding the material of the tray will help you select the appropriate cable tray box mount that will match both the tray’s properties and the cable load.

Environmental Conditions (Indoor/Outdoor, Temperature, Moisture Levels)

Environmental conditions should also be carefully considered when choosing a cable tray box mount. If the cable tray system is installed in an outdoor or industrial setting, the mount must be able to withstand factors such as temperature fluctuations, exposure to moisture, and potential chemical exposure. For instance, cable tray box mounts used in outdoor installations may need to be made of materials with high corrosion resistance, such as stainless steel or coated steel, to ensure longevity in harsh weather conditions. Additionally, trays installed in high-temperature areas or those exposed to extreme heat should be paired with mounts that have heat-resistant properties. It’s also important to consider moisture levels, as a wet or damp environment may require a cable tray box mount made from materials that can resist rust and degradation, such as fiberglass or corrosion-resistant metals.

Load Capacity and Support

Another important factor to consider when selecting a cable tray box mount is the load capacity and support provided by the mount. Different tray systems and cable types require varying levels of support, and the mounting system must be strong enough to bear the load without compromising its stability. It’s important to check the manufacturer’s specifications for both the cable tray box mount and the cable tray to ensure that the mount can support the weight of the electrical boxes and cables over time, preventing the risk of sagging, detachment, or damage. The cable tray box mount should be able to handle dynamic loads, vibrations, and any potential stress caused by temperature variations.

Compliance with Standards and Regulations

It is essential to ensure that the cable tray box mount complies with relevant industry standards and regulations. These standards can vary depending on the location, type of installation, and the cables being used. For example, in many jurisdictions, the National Electrical Code (NEC) provides guidelines on the installation of cable trays and the use of mounts for securing electrical boxes. Compliance with these regulations ensures the safety of the installation and prevents any legal or regulatory issues down the line. Always check the specifications of the cable tray box mount to ensure it meets the required standards for your particular application.

Choosing the right cable tray box mount involves considering various factors, including the type of cable, tray material, environmental conditions, and load capacity. By understanding these key factors and selecting a mount that aligns with the specific needs of your cable tray system, you can ensure a safe, secure, and efficient cable management solution.

FAQs about Cable Tray Box Mount

Yes, you can mount a cable box, and doing so is a common practice in cable management systems. A cable box is typically mounted to a cable tray box mount for easy integration into the cable tray system, ensuring a secure and organized installation of electrical connections. The installation of a cable box involves attaching it to the tray system, using appropriate mounting brackets or clips designed to handle the weight and size of the electrical box. It’s essential to ensure the box is positioned in a way that allows for easy access and doesn’t interfere with the proper routing of cables. Depending on the location and load, cable tray box mounts may be attached to the tray via screws, bolts, or clamps to provide a secure fit. The chosen method of attachment must comply with local codes and regulations, ensuring that the installation is both safe and efficient.

There are specific guidelines regarding which types of cables can and cannot be installed on a cable tray. Generally, cables that do not meet the standards for tray use should not be installed in cable trays. For example, cables that are not suitable for cable tray installation include non-armored cables, low-voltage cables without proper insulation, and cables that are not rated for fire safety. Furthermore, cables such as fiber optic cables and certain high-voltage cables may require alternative containment methods due to their sensitivity to physical damage or electromagnetic interference. Cables with insufficient insulation or those without adequate protection against external factors (such as moisture or chemicals) should also be avoided in tray systems. It’s always essential to consult the manufacturer’s specifications and the National Electrical Code (NEC) or relevant local standards to determine which cables are suitable for cable tray installation.

Attaching a cable tray to a desk is a simple process, but it requires careful planning to ensure safety and functionality. First, you will need to determine the best location for the tray, typically underneath the desk to keep cables out of sight and organized. Use a desk cable tray mount or brackets that are designed for attaching trays to furniture or desks. Mark the points where the tray will be mounted and ensure the desk is sturdy enough to support the weight of the tray and cables. Use screws, anchors, or clamps to securely attach the cable tray to the underside of the desk. When mounting, make sure to leave sufficient space for cables to pass through and avoid sharp bends that could damage them. Additionally, ensure that the tray doesn’t obstruct the desk’s functionality or user access. Finally, confirm that the installation complies with safety standards to avoid any hazards related to weight or electrical load.

Cable trunking and cable trays are both used for organizing and protecting electrical cables, but they differ in design, functionality, and use.

Cable trunking is typically a closed system, offering more protection for cables from external factors like dust, moisture, and physical damage. It is often used in areas where the cables are exposed to harsh environmental conditions or where safety concerns dictate the need for more enclosed protection. Cable trunking can be installed on walls, floors, or ceilings and is suitable for a variety of environments, including residential and commercial buildings.

In contrast, a cable tray is usually an open or ventilated system that allows easy access for installation and maintenance. It’s ideal for larger installations where cables need to be routed in a controlled environment, such as in industrial settings or data centers. Cable trays are often used when there is a need for flexibility, as they allow for easier modifications and expansions.

The main differences come down to the level of protection and the type of installation environment. Cable trays are generally used for heavier, more robust cable installations, while cable trunking is designed for applications where environmental protection is a higher priority.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.