Cable trays are essential components in electrical and communication infrastructure, providing a safe and efficient way to organize and support cables. Whether in commercial buildings, industrial setups, or data centers, they are a key part of managing extensive wiring systems. However, while cable trays themselves offer structural support, they often require additional protection to prevent damage and ensure safety. This is where cable tray cladding comes into play. Cable tray cladding refers to the protective covering or shielding used around the tray to safeguard cables from environmental factors such as moisture, dust, and physical damage. During installation, cable reels streamline cable deployment by feeding wire directly into cable tray runs before cladding is applied. Cable tray cladding supports and routes wire mesh, ladder, and prefab cable trays for organized ceiling and wall cable management. The purpose of this blog is to help readers understand the various cladding options available for different cable tray types and applications, ensuring optimal protection and performance.

What is Cable Tray Cladding?

Cable tray cladding is a protective covering or enclosure that is applied to cable trays to safeguard the cables running through them. This cladding is essential in various industrial, commercial, and residential applications, as it serves multiple key functions that ensure the safety, reliability, and longevity of wiring systems. By providing physical protection and improving performance, cable tray cladding plays a crucial role in cable management solutions.

Primary Functions of Cable Tray Cladding

Shielding Cables from Environmental Damage

Cable tray cladding protects cables from environmental hazards like dust, moisture, UV exposure, and corrosion. In outdoor or high-humidity settings, exposed trays leave wiring vulnerable to degradation over time. Cladding creates a durable barrier that prevents water ingress, blocks harmful rays, and resists chemical corrosion. This protective layer extends cable lifespan, reduces maintenance, and ensures reliable performance in industrial, commercial, or harsh outdoor environments.

Enhancing Fire Resistance and Safety

Fire-resistant cladding materials—such as intumescent coatings, fireproof metals, or fiberglass composites—add a critical layer of protection to cable tray systems. By slowing fire spread and insulating cables, cladding reduces the likelihood of electrical faults escalating into larger emergencies. In high-risk environments like data centers or manufacturing plants, this enhanced fire resistance safeguards personnel and equipment, supports code compliance, and helps maintain uninterrupted operations.

Aesthetic Integration in Exposed Installations

When cable trays are visible—such as under open ceilings or along office walls—cladding delivers both protection and visual appeal. Sleek, customizable covers blend with interior finishes, concealing cables and enhancing decor. This aesthetic integration creates a polished, organized look without compromising function. Architects and facility managers can select cladding colors and styles that match surrounding materials, ensuring the cable management solution complements the overall design.

Improved Cable Organization

Cladding also contributes to organized cable runs by neatly encasing and guiding wires within a structured channel. This reduces the risk of tangling, snagging, or accidental displacement, keeping cables securely in place. A well-organized layout simplifies maintenance, upgrades, and troubleshooting by providing clear access points. As a result, technicians spend less time locating or sorting cables, minimizing downtime and ensuring a clean, efficient installation.

Why Choose Ventilated Bottom Cable Tray for Outdoor Installations

Types of Cable Tray Cladding

Cable tray cladding comes in various materials and designs, each tailored to meet specific environmental and functional needs. The choice of cladding depends on factors like location, the level of protection required, and aesthetic preferences. Below are the common types of cable tray cladding:

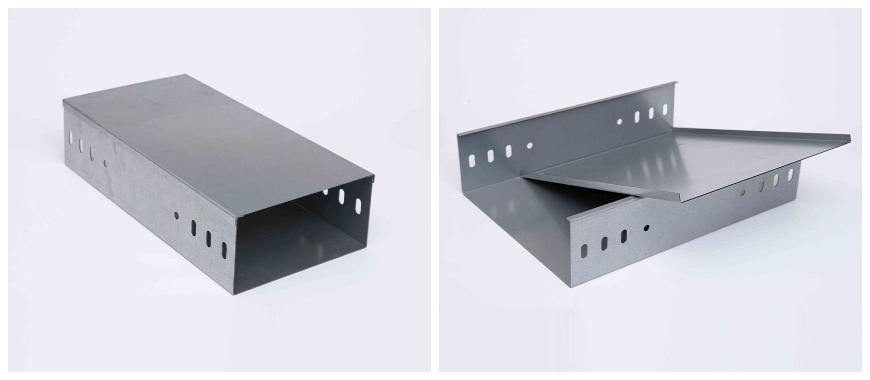

Standard Cladding

Standard cladding for cable trays typically uses galvanized steel, aluminum, or fiberglass-reinforced plastic to provide a robust barrier against everyday hazards. These materials deliver reliable durability, corrosion resistance, and impact protection, ideal for shielding cables from dust, abrasions, and incidental contact. Standard cladding is cost-effective and straightforward to install in indoor environments—such as offices, data centers, and light industrial facilities—where extreme conditions are absent. This essential protection keeps cables neatly contained and ensures long-term system integrity without specialized investment.

Fire-Resistant Cladding

Fire-resistant cable tray cladding incorporates intumescent coatings, stainless steel, or aluminum alloy layers designed to expand under heat, forming a fireproof seal. This protective system reduces flame spread by insulating cables, maintaining circuit integrity, and preventing ignition of adjacent materials. Commonly deployed in power plants, chemical processing facilities, and high-risk industrial zones, fire-resistant cladding supports compliance with stringent safety regulations. By slowing combustion and enhancing fire containment, it safeguards critical infrastructure and personnel during emergency scenarios.

Weatherproof Cladding

Weatherproof cable tray cladding is engineered to withstand harsh outdoor environments through UV-resistant plastics, rubberized barriers, or specially coated metals. Its waterproof seals block moisture ingress, while robust materials endure temperature extremes, precipitation, and solar radiation. Ideal for rooftop installations, outdoor processing plants, and exposed utility corridors, weatherproof cladding extends cable lifespan by preventing corrosion, thermal degradation, and water damage. This all-weather solution ensures reliable performance and minimizes maintenance in settings where cable trays face continuous environmental exposure.

Aesthetic Cladding

Aesthetic cable tray cladding enhances visual integration by offering customizable finishes, colors, and surface treatments that complement interior design themes. Materials range from powder-coated metals to decorative composite panels, allowing trays to blend seamlessly into office ceilings, retail spaces, or residential areas. While maintaining essential protection against dust and minor impacts, aesthetic cladding conceals wiring in a polished, organized fashion. This combination of form and function meets both architectural and operational requirements, delivering a cohesive, professional appearance without sacrificing cable safety.

The Benefits of Using Weatherproof Cable Tray for Projects

Popular Cable Tray Types and Their Cladding Needs

Each type of cable tray has its own specific requirements when it comes to cladding, based on its intended use and the environmental factors it will be exposed to. The right cable tray cladding ensures that the tray meets safety, durability, and aesthetic standards while protecting the cables inside. Below are some of the most popular cable tray types and their cladding needs:

Ladder Cable Trays

- Strength for Heavy-Duty Cables: Ladder cable trays are ideal for supporting large, heavy-duty cables. These trays feature a sturdy design with horizontal rungs that allow for effective cable management, especially in industrial environments where multiple cables are required. They can handle high loads and are typically used for large-scale electrical installations in factories or data centers.

- Ventilated Cladding: One of the key benefits of ladder cable trays is their open design, which allows for proper airflow. This ventilation helps in the dissipation of heat, especially in areas where high-voltage cables or power cables are used. For these types of trays, the cable tray cladding should provide additional protection against environmental elements while allowing sufficient ventilation. Cladding made from perforated materials or mesh is ideal in this case as it supports airflow without sacrificing protection.

Wire Mesh Cable Trays

- Lightweight and Flexible: Wire mesh cable trays are made from interwoven metal wires, making them lightweight and flexible. They are commonly used in commercial or residential settings where the cable management system needs to be easy to install and modify. These trays are ideal for organizing small to medium-sized cables and are commonly used in offices or retail environments.

- Cladding for Protection: While wire mesh trays are generally used in dry, indoor environments, they require cladding to protect the cables from dust, debris, or even corrosion. The cladding used for wire mesh trays should enhance protection while maintaining flexibility. Materials like galvanized steel cladding or plastic-coated cladding can be used to improve the durability of the system in environments where dust or corrosive elements might be present.

Channel Cable Trays

- Compact for Small Cable Bundles: Channel cable trays are ideal for handling smaller cable bundles in confined spaces. These trays offer a compact and closed design, which makes them more suitable for use in tight corners or small areas where space is limited. They are often used in residential and small commercial installations where minimal cable management is required.

- Minimal but Precise Cladding: Channel trays don’t require the same level of protection as larger, open trays, but they still benefit from cable tray cladding to prevent dust, moisture, or accidental damage. Cladding for channel trays is typically more streamlined and may consist of simple sheet metal or plastic cladding to ensure durability without taking up too much space.

Black Cable Trays

- Aesthetic Appeal: Black cable trays are chosen for their sleek appearance and are often used in modern office environments or settings where aesthetics are a priority. These trays are designed to be visually appealing while still providing effective cable management. The black finish offers a professional and clean look, often blending well with contemporary interiors.

- Powder-Coated or Sleek Cladding: When selecting cable tray finishes to maintain their appearance while offering protection, black cable trays are commonly treated with powder-coated cladding. This type of finish is not only durable but also helps maintain a uniform look. It resists scratches and guards against corrosion, ensuring trays blend seamlessly into office settings, conference rooms, or other professional environments.

Each type of cable tray requires specific cable tray cladding based on its design, intended use, and environment. Proper selection of cladding ensures longevity, protection, and aesthetic integration for your cable management system.

Understanding B Line Cable Tray Weight for Installations

Installation Accessories for Cladding in Cable Tray Cladding

When installing cable tray systems with cladding, the right accessories—such as cable reels for smooth wire deployment and modular tray sections for precise layout—play a crucial role in ensuring that the entire system is securely in place and fully protected. These installation accessories are designed to improve the functionality and durability of the system while maintaining safety and aesthetics. Below are key installation accessories needed when dealing with cable tray cladding.

Cable Tray Wall Brackets

Wall brackets securely fasten cladded cable trays to vertical surfaces, ensuring stability and load support in wall-mounted installations. By anchoring trays to walls, these brackets prevent sagging and maintain alignment, even under heavy cable loads. Ideal for environments with limited floor space, wall brackets enable a clean, organized layout and free up valuable room. They complement cladding by keeping the entire assembly firmly in place and visually streamlined.

Cladding Seals

Cladding seals create a watertight and dust-proof barrier around the edges of cable tray cladding, preventing moisture, debris, and contaminants from entering the tray system. These flexible gaskets or strip seals adapt to temperature fluctuations and movement, preserving cladding integrity in harsh conditions. By eliminating gaps, seals enhance weatherproofing and corrosion resistance, ensuring long-term durability and optimal protection for cables in both outdoor and industrial environments.

Support Hardware

Support hardware—including hangers, brackets, and reinforcing rods—provides essential load-bearing capacity and structural reinforcement for cladded cable trays. Designed to withstand the weight of multiple cables and environmental stresses, these components maintain tray alignment and prevent deflection over time. Constructed from durable materials like galvanized steel or stainless steel, support hardware ensures that the combined tray and cladding system remains secure, safe, and capable of handling dynamic loads in demanding applications.

Applications of Cable Tray Cladding

Cable tray cladding serves a critical role in protecting cables across various settings, enhancing both the safety and durability of cable management systems. By offering a protective barrier, cladding helps preserve the integrity of cables in environments that may expose them to physical, environmental, or electrical risks. Below are the key applications of cladded cable trays in different industries and environments:

Industrial Settings

In industrial environments, cable tray cladding shields cables from harsh conditions, ensuring reliable power and control systems. In manufacturing plants, cladding materials like galvanized steel or fiberglass protect against dust, chemicals, heat, and vibration. On offshore oil and gas platforms, corrosion-resistant and fire-resistant cladding defends against saltwater, humidity, and explosion risks. In high-speed production lines, cladding prevents mechanical damage from moving machinery and impacts, minimizing downtime and maintenance costs while preserving operational efficiency.

Commercial Buildings

In commercial spaces, cable tray cladding combines protection with aesthetics. In modern offices, cladding conceals wiring above ceilings or along walls, safeguarding cables from dust and moisture while maintaining a polished look. Retail environments benefit from custom-colored or powder-coated cladding that harmonizes with branding and fixtures, keeping interactive displays and kiosks tidy. In data centers, fire-resistant and weatherproof cladding ensures network stability by protecting critical power and data cables from environmental and safety hazards.

Outdoor Installations

Outdoor cable tray cladding protects systems from environmental and physical threats in exposed settings. Rooftop and yard installations use UV-resistant plastics and waterproof seals to guard against sun, rain, snow, and temperature extremes. Telecommunications and utility corridors rely on cladded trays to shield fiber optics and power lines from moisture, pests, and impact. On construction sites, temporary or permanent cladding prevents abrasion from debris and equipment, maintaining cable integrity and continuous service during building and infrastructure projects.

FAQs about Cable Tray Cladding

Tray cables are typically used in cable tray systems, and whether they need to be in conduit depends on the specific installation requirements and local electrical codes. According to the National Electrical Code (NEC), tray cables do not always need to be placed inside conduit when used in open or accessible installations such as cable trays, provided that the cables are rated for use in such applications.

However, there are certain situations where conduit is necessary. For example, when tray cables are routed through areas where they may be exposed to physical damage, conduit can provide additional protection. The NEC requires conduit in cases where cables pass through walls, floors, or ceilings to prevent mechanical damage. In high-risk environments, such as industrial settings or areas with harsh weather, tray cables may also need to be installed in conduit to provide further protection from environmental hazards, moisture, or corrosive elements.

Ultimately, the need for conduit depends on the application, environmental conditions, and the specifications of the cable being used. Always consult the local electrical code and manufacturer guidelines for specific installation requirements.

Cable trays come in a variety of materials, each suited for specific environments and applications. The most common materials used for cable trays include:

Steel: This is the most widely used material due to its strength and durability. Steel trays are ideal for heavy-duty applications and are typically used in industrial settings where the trays may need to carry large quantities of cables. Steel cable trays can be galvanized or powder-coated to provide resistance to corrosion.

Aluminum: Aluminum is a lightweight and corrosion-resistant material, making it suitable for environments where weight is a concern or where exposure to moisture and chemicals may occur. Aluminum trays are often used in environments such as coastal areas or chemical plants where rust resistance is a priority.

Fiberglass Reinforced Plastic (FRP): FRP cable trays are used in applications where resistance to corrosion, chemicals, and moisture is crucial. They are commonly found in environments with high humidity or exposure to aggressive chemicals, such as wastewater treatment plants or offshore oil rigs.

Plastic: Plastic cable trays are typically used for lightweight applications and are popular in commercial buildings, offices, and homes. They are easy to install, lightweight, and offer some degree of resistance to moisture and corrosion.

The choice of material depends on factors like the type of cables being supported, environmental conditions, load requirements, and budget considerations.

To suspend a cable tray from the ceiling, begin by mapping the tray route, identifying potential obstructions, and marking support points at intervals of 4–6 feet based on load calculations and manufacturer guidelines. Select suitably rated suspension hardware—3/8″ or 1/2″ threaded rods paired with expansion or epoxy anchors for concrete ceilings or beam clamps for steel structures. Securely install anchors or clamps, then thread lock nuts onto each rod to serve as height stops. Insert and tighten the rods into the anchors, using a laser or water level to verify uniform elevation across all support points. Attach U-shaped brackets or clevis hangers to the threaded rods, fastening them with lock nuts above and below each bracket to ensure stability. Lift each tray section onto the supports, join adjacent sections using splice kits, and tighten all hardware to the torque specified by the manufacturer. Finally, lay cables in the tray according to fill capacity and separation codes, secure them with approved ties, ensure proper grounding and bonding, and conduct a thorough inspection to confirm alignment, fastener integrity, and compliance with relevant electrical standards.

Yes—cable tray systems can be installed outdoors successfully when appropriate materials, hardware, and practices are employed. First, select corrosion-resistant tray materials such as hot-dip galvanized steel or 316 stainless steel for areas exposed to moisture, chemicals, or coastal environments; for non-conductive lightweight requirements in moderate climates, consider UV-stabilized FRP or PVC. Equip all joints, covers, and terminations with weatherproof seals or gaskets to prevent water, dust, and debris ingress. Incorporate a slight pitch (1–2°) or drainage holes to avoid standing water, which accelerates corrosion. Choose outdoor-rated support hardware—galvanized or stainless steel brackets, threaded rods, beam clamps, and anchors—ensuring structural integrity under wind or seismic loads. Confirm that plastics, coatings, and sealants carry UV-resistance and temperature tolerance ratings suited to your region. Finally, follow applicable electrical and building codes—for example, NEC Article 392 for grounding, bonding, clearances, and support intervals in the U.S.—to guarantee a durable, safe, low-maintenance outdoor cable tray installation. Routine maintenance extends system lifespan and overall reliability.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.