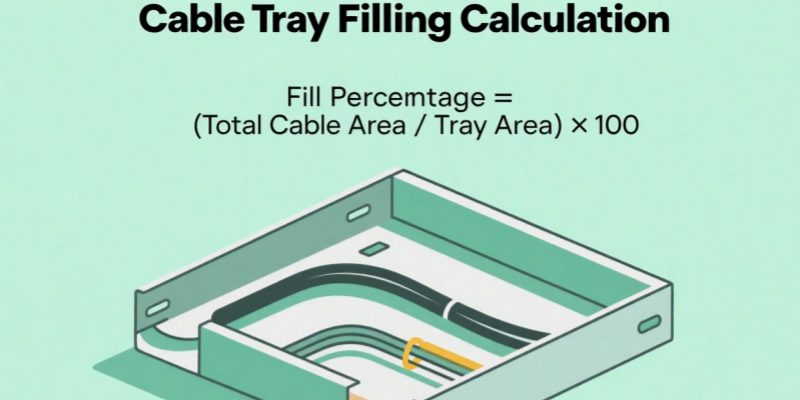

Cable tray filling calculation percentage is found by dividing total cable area by tray area, following 50% fill rules for control wiring. Cable tray filling calculation is crucial for ensuring safety, efficiency, and longevity in electrical installations. Accurate calculation prevents overloading, overheating, and physical damage. Understanding how to calculate area of cable tray helps assess its total usable space and cable capacity. Proper fill maintains airflow, preventing overheating and cable stress. Overfilled trays obstruct airflow, while underfilled ones waste space. Tools like PDF guides, Excel sheets, and fill charts simplify calculations and ensure compliance with safety standards like NEC or IEC, optimizing electrical system design.

What is Cable Tray Filling Calculation?

Cable tray fill calculation is the process of determining how many cables can be safely installed inside a cable tray, without exceeding its maximum load capacity or violating safety regulations. To assist with this process, a cable tray calculator can be used to ensure that the tray has sufficient space for the cables, maintains adequate airflow, and minimizes the risk of overheating, cable damage, and system failures. Accurate cable tray filling calculations are essential for the longevity and safety of electrical installations, helping engineers to make informed decisions about tray sizing, cable management, and regulatory compliance.

Definition and Purpose

The primary purpose of cable tray fill calculation is to prevent overloading, which can lead to significant safety hazards, such as overheating, equipment failure, or even fire. Overfilled trays obstruct airflow, causing cables to overheat, which can damage insulation and potentially result in electrical shorts. Incorporating the NEC cable tray fill requirement into the calculation ensures that the tray is filled within safe limits, determining the maximum number of cables that can be placed without compromising safety or performance. This precise calculation also facilitates optimal cable routing, reducing the risk of damage or interference.

In addition to preventing accidents and ensuring operational efficiency, the calculation is essential for compliance with national and international safety standards, such as those outlined in the National Electrical Code (NEC). By accurately calculating cable tray fill, engineers and electrical contractors can ensure that their installations adhere to these standards, avoiding penalties and enhancing the overall reliability of the system.

What is Cable Tray Filling Ratio

The cable tray filling ratio represents the percentage of the tray’s available space occupied by cables. The goal of the cable tray filling calculation is to balance optimal tray capacity with sufficient space for cable management, airflow, and the proper use of wire mesh for additional support. Overfilling can lead to poor ventilation and overheating, increasing the risk of system failures, while underfilling wastes space and reduces efficiency. Proper information on tray capacity and cable placement is crucial for maintaining airflow and ensuring the system remains cool. A proper filling calculation ensures that airflow remains unobstructed, keeping cables cool, and provides room for future expansions without major modifications.

NEC Guidelines for Cable Tray Filling

The National Electrical Code (NEC) provides strict guidelines regarding cable tray filling to ensure the safety of electrical installations. According to the NEC, the cable tray filling ratio should typically not exceed 50-60% of the tray’s total cross-sectional area. This ensures that there is enough space for the proper ventilation of cables. Adhering to this ratio is crucial for cable tray safety, as overcrowding the tray can lead to overheating, which may damage the cables or, in extreme cases, cause fire hazards.

Adhering to the NEC standards for cable tray filling is vital to avoid overloading the tray, ensuring that electrical systems perform as expected. Following the correct cable tray filling ratio also helps to maintain the integrity of the cable insulation, allowing cables to operate efficiently without excessive heat buildup.

Optimal Cable Tray Filling for Different Applications

Different applications require different cable tray filling ratios for safety and efficiency. In data centers, where high cable densities are common, the ratio may exceed 60%, but wire mesh should be used to maintain airflow and prevent overheating. In industrial environments, a ratio of 40-50% is often recommended to ensure sufficient cooling, especially when cables carry heavy electrical loads. Information on system requirements helps determine the optimal ratio.

Factors Influencing Cable Tray Filling

Cable Types

The type, size, and weight of cables affect the tray’s fill capacity. Power cables are generally larger and heavier, requiring more space, while control or data cables are smaller and lighter. Cables with thicker insulation or coatings need extra space. Heavy-duty industrial cables demand larger trays to prevent overheating, whereas smaller cables for low-power applications allow for higher cable counts in a given space. Each cable type must be factored in to select the appropriate cable tray size.

Tray Dimensions

Tray dimensions, including length, width, and depth, determine the available space for cables. Larger trays can hold more cables but require careful design consideration. For example, trays with solid bottoms may limit airflow, necessitating extra space for cooling. Longer trays may sag, affecting weight distribution, while improper sizing or tray design can lead to inefficient use of space or unsafe overfilling, compromising system performance and safety.

Fill Ratio

The fill ratio refers to the percentage of tray space occupied by cables. The NEC specifies a maximum fill ratio of 50% for most industrial trays, with adjustments based on cable type and temperature. Maintaining the correct ratio is critical for heat dissipation to prevent cable and tray damage. Engineers may adjust this ratio based on environmental factors or future expansion needs. Tools like cable tray fill calculators help determine the optimal fill ratio for specific installations.

Environmental and Safety Considerations

Environmental factors such as temperature, vibration, or exposure to hazardous substances influence cable tray filling calculations. Trays in hot environments may require a lower fill ratio for better cooling. In industrial settings, trays may need additional safety measures to protect cables from external threats. Compliance with standards like the NEC ensures proper installation, reduces the risk of accidents, and promotes long-term system reliability by factoring in environmental challenges.

Complete Guide to Cable Tray Load Calculation

Cable Tray Filling Calculation Formula

Cable tray filling calculations are crucial for ensuring the safe and efficient installation of electrical cables. These calculations determine how many cables a tray can accommodate without exceeding its maximum capacity, preventing issues like overheating, cable damage, and restricted airflow. A well-calculated fill ensures that the tray can carry the cables without compromising safety, durability, or compliance with industry standards. The cable tray formula for calculating the fill percentage is a key tool in this process, helping engineers avoid overfilling or underfilling the tray and promoting optimal cable organization and protection.

Definitions in Cable Tray Fill Calculations

- Conversion Factor: The conversion factor helps convert measurements from one unit to another, such as from square centimeters to square millimeters. This ensures consistency and accuracy in cable tray calculations.

- Cable Area: Cable area refers to the cross-sectional dimensions of the cables measured in square millimeters or square centimeters. It determines the space the cables occupy in the tray, ensuring proper sizing and airflow.

- Fill Percentage: The fill percentage represents the portion of the tray’s space occupied by cables. Standards define acceptable ranges to ensure thermal safety, preventing overheating and ensuring proper ventilation.

- Tray Area: Tray area is the total cross-sectional size of the tray. It ensures there’s enough space for cables without overcrowding or wasting space, balancing performance and cost efficiency.

Mathematical Formula for Calculating Fill Percentage

The cable tray filling calculation determines the fill percentage, which shows how much of the tray’s total cross-sectional area (cable tray area) is occupied by cables. This calculation is essential to avoid overloading or underutilizing the tray, ensuring safe and efficient use of space.

Key Factors for Calculation

- Total Cable Area: The total cross-sectional area of all the cables placed inside the tray.

- For round cables, use the formula for the area of a circle:

Area=π×r2\text{Area} = \pi \times r^2Area=π×r2

where rrr is the radius of the cable. - For non-circular cables, refer to manufacturer-provided dimensions to calculate the area.

- For round cables, use the formula for the area of a circle:

- Tray Area: The cross-sectional area of the cable tray, which can be calculated by multiplying the tray’s width by its height (or depth).

Tray Area=Width×Height\text{Tray Area} = \text{Width} \times \text{Height}Tray Area=Width×Height

Cable Tray Fill Formula

The formula for calculating the fill percentage is: Fill Percentage=(Total Cable AreaTray Area)×100\text{Fill Percentage} = \left( \frac{\text{Total Cable Area}}{\text{Tray Area}} \right) \times 100Fill Percentage=(Tray AreaTotal Cable Area)×100

This formula helps determine what percentage of the tray’s cross-sectional area is occupied by cables.

Example Calculation

Let’s say:

- The total cable area is 20 cm220 \, \text{cm}^220cm2

- The tray area is 100 cm2100 \, \text{cm}^2100cm2

Now, apply the formula: Fill Percentage=(20 cm2100 cm2)×100=20%\text{Fill Percentage} = \left( \frac{20 \, \text{cm}^2}{100 \, \text{cm}^2} \right) \times 100 = 20\%Fill Percentage=(100cm220cm2)×100=20%

This means that 20% of the tray’s available cross-sectional area is filled with cables, leaving sufficient space for proper airflow and cooling.

Steps for Calculation

- Determine Cable Area (A): Calculate the total cross-sectional area of all the cables in the tray.

- Determine Tray Area (T): Calculate the total cross-sectional area of the tray.

- Calculate the Fill Ratio (F): Use the formula:

F=ATF = \frac{A}{T}F=TA - Calculate Fill Percentage: Multiply the result by 100 to get the percentage:

Fill Percentage=F×100\text{Fill Percentage} = F \times 100Fill Percentage=F×100

Cable Tray Fill NEC and Standards

When performing cable tray fill calculations, it’s essential to follow the National Electrical Code (NEC) and industry standards to ensure safe and reliable electrical installations. The NEC sets specific guidelines for maximum fill ratios in cable trays, helping prevent overheating, poor airflow, and other safety hazards.

NEC Recommendations for Cable Tray Fill Ratios

- 50-60% Fill Ratio: The NEC recommends that the maximum fill ratio for most commercial and industrial cable trays should be between 50% and 60%. This ensures enough space for ventilation and cooling, as well as accommodating future expansion.

Specific Fill Guidelines

- Power Cables: These cables often have thicker insulation and generate more heat. Therefore, the NEC suggests a fill ratio closer to 50% for power cables, allowing enough space for air circulation and heat dissipation.

- Communication or Data Cables: These cables are generally smaller in diameter and produce less heat. As a result, they can safely be placed in trays with a higher fill ratio, closer to 60%.

Importance of Adhering to NEC Guidelines

Following these guidelines is crucial for preventing issues like overheating, fires, and system failures. Overfilling a cable tray can obstruct airflow, leading to excessive heat buildup, while underfilling may be inefficient, wasting valuable space. Ensuring the correct fill percentage allows for proper cooling, smooth maintenance, and effective system expansion.

Tools for Cable Tray Filling Calculation

Accurate cable tray filling calculation is vital for safe and efficient electrical installations. Tools like the Estimator, along with Excel sheets, PDF guides, and fill charts, ensure engineers can optimize cable tray use. These tools help streamline calculations, ensure compliance with standards, and prevent errors during the design process.

| Tool | Description | Key Features |

|---|---|---|

| Excel Sheet | Automates calculations for large projects. | Customizable inputs, multiple cable types, NEC/IEC compliance |

| PDF Guide | Provides step-by-step manual instructions. | Detailed guidance, visuals, portable |

| Fill Chart | Quick reference for max fill capacities of trays. | Visual representation, pre-calculated values |

| Estimator | Tool for fast, efficient tray filling calculations. | User-friendly, customizable, fast calculations |

Benefits of Choosing Metar Cable Tray Systems

Common Cable Tray Sizing Mistakes and How to Avoid Them

Correctly calculating the cable tray fill percentage is essential for ensuring the safety, longevity, and efficiency of electrical systems. Mistakes in this process can lead to a variety of issues, including overheating, inefficiencies, and safety hazards. Understanding common cable tray sizing mistakes and how to avoid them is crucial for designing systems that are both functional and safe.

Overfilling and Its Consequences

Overfilling a cable tray occurs when cables exceed the recommended fill ratio, leading to overcrowding, reduced airflow, and overheating. This compromises heat dissipation, which can damage cables and increase the risk of electrical fires. Overfilling also makes future cable additions difficult and increases maintenance challenges. To avoid this, always follow the cable tray filling calculation formula to ensure the tray isn’t overloaded, maintaining safety and allowing for future expansions.

Underfilling and Inefficient Use of Space

Underfilling a cable tray may seem safer, but it often wastes valuable tray capacity. Empty space in the tray can lead to unnecessary tray installations in the future, raising costs and complicating future cable additions. Misplaced cables may also create inefficiencies in the electrical system. To prevent underfilling, use the correct fill percentage and optimize tray space for both current and future needs.

Failing to Account for Future Expansion

Another common mistake is not planning for future cable installations. When calculating tray fill percentages, engineers might focus only on the current cable load and neglect the possibility of adding more cables in the future. This can lead to trays becoming overcrowded after additional cables are added, causing overheating or inefficient cable management. To avoid this, it’s important to consider future needs and design trays with enough capacity to handle expansion.

Importance of Compliance with IEC Cable Tray Filling Calculation

The IEC cable tray filling calculation ensures safe and efficient cable management, preventing overheating and cable damage. By adhering to IEC standards, it ensures trays are not overfilled, allowing proper airflow. As electrical systems become more complex, especially in industrial and data center environments, accurate calculations are vital for maintaining optimal performance. Proper tray fill provides enough space for cables and reduces heat buildup, ensuring safety and compliance with electrical standards. This is critical for the reliability and longevity of high-performance systems.

Safety and Risk Prevention

Adhering to the IEC cable tray filling calculation ensures that trays are not overfilled, which helps maintain proper airflow around cables. This reduces overheating, prevents cable damage, and lowers the risk of electrical fires. By following these guidelines, engineers can avoid costly repairs, system downtime, and ensure the safety of both the electrical system and workers.

Efficiency and System Longevity

Compliance with IEC standards ensures the proper cable spacing and fill ratios, which reduces mechanical stress on cables and enhances cooling. This helps to prevent overheating, protects cable insulation from damage, and extends the operational lifespan of the cables. As a result, maintenance costs are reduced, and the overall performance and reliability of the system improve.

Compliance with International Standards

IEC standards are globally recognized guidelines that ensure electrical systems are designed safely and reliably. By following these standards, engineers ensure that cable trays are designed to handle electrical loads without overfilling, avoiding risks such as fire or electrical faults. This compliance is especially important in large-scale systems, helping prevent safety violations, costly repairs, and potential legal consequences.

Optimizing Space and Reducing Costs

Correct cable tray fill calculations help engineers maximize tray space, preventing waste and reducing the need for oversized trays. Properly calculated fills ensure that trays are used efficiently, lowering material costs and improving overall system performance. This approach reduces unnecessary expenses, helping engineers design cost-effective systems that operate within budget while maximizing capacity.

Proactive Approach to System Design

Following IEC cable tray fill calculations from the start ensures that systems are designed with future expansion in mind. By planning ahead and maintaining compliance with IEC guidelines, engineers can prevent issues related to improper tray sizing and cable management. This proactive approach enhances system reliability, prevents disruptions, and ensures that installations are optimized for both current and future needs.

CEC Cable Tray Fill Requirements and Installation Guidelines

Cable Tray Filling Calculation and Industry Guidelines

Industry guidelines for cable tray filling calculation provide specific fill percentages based on the type of cables and tray installation conditions. For instance:

- Power cables: 40% fill

- Control cables: 50% fill

- Communication cables: 60% fill

These fill percentages help ensure optimal cable organization, proper airflow, and prevent overheating. Correctly applying these calculations is essential for the safe and efficient operation of the electrical system.

Provision for Expansion

It’s important to plan for future expansions when designing cable tray systems. Engineers should reserve additional space within the tray for potential new cable installations. This extra space helps avoid the need for costly reinstallation or modification when new cables are added, saving time and money in the future. This proactive planning ensures that the system remains adaptable as needs grow.

Proper Cable Routing

Cables should be routed through straight paths, avoiding tight bends or crowded areas. Excessive bending of cables can introduce stress, which may affect their performance and longevity. Proper cable routing helps preserve the stability and efficiency of the system, reducing the risk of damage and ensuring the cables maintain their intended functionality over time.

Adhering to Safety Standards

Following established industry standards such as those from the NEC (National Electrical Code) or IEC (International Electrotechnical Commission) is crucial for the safety and reliability of cable tray systems. Compliance with these standards ensures the installation is performed correctly, protecting both the electrical system and personnel from potential hazards while ensuring long-term performance.

Record Keeping for Future Planning

Maintaining accurate records of cable tray capacities and the current fill levels is vital for ongoing system management. Regularly updating these records allows engineers to effectively plan for future expansions and maintenance. This ensures that new cables won’t exceed the tray’s nominal capacity, avoiding overcrowding and maintaining system safety and efficiency over time.

FAQs about Cable Tray Filling Calculation

Calculating the cable tray filling ratio is essential to ensure the safe and efficient use of the tray system. The filling ratio refers to the percentage of the tray’s total cross-sectional area that is occupied by cables. To calculate it, you need to determine the following:

Step 1: Measure Tray Dimensions

First, measure the internal width, height, and length of the tray. The cross-sectional area is the product of the tray’s width and height.

Step 2: Calculate Cable Cross-Sectional Area

Next, measure the individual cables’ diameter or radius. Use the formula for the area of a circle (πr²) to calculate the cross-sectional area of each cable. If you have multiple cables, calculate the total area by adding the individual areas.

Step 3: Determine the Fill Ratio

Finally, divide the total cable cross-sectional area by the tray’s cross-sectional area and multiply by 100 to get the fill ratio as a percentage.

For example, if the tray’s cross-sectional area is 1000 square inches, and the total cable area is 600 square inches, the fill ratio would be 60%. It’s important not to exceed the maximum fill ratio defined by relevant codes to avoid overheating and ensure optimal performance.

Calculating the load for a cable tray is vital to ensure that the tray can safely support the weight of the cables without sagging or becoming structurally compromised. The load calculation includes the weight of the cables, any other accessories, and the tray itself.

Here’s a step-by-step guide to calculating the load:

Step 1: Determine Cable Weight

Identify the type of cables being used and find their weight per unit length (e.g., pounds per foot or kilograms per meter). For multi-conductor cables, add the weight of each conductor to get the total weight of the cable.

Step 2: Add Tray Weight

The tray itself also contributes to the load. Find the weight per unit length of the tray, and multiply it by the total length of the tray to determine the total tray weight.

Step 3: Calculate Total Load

Add the total weight of the cables and the tray to determine the total load. For example, if the cables weigh 200 lbs and the tray weighs 50 lbs over a 10-foot span, the total load would be 250 lbs.

The load should be compared to the tray’s rated load capacity to ensure safe installation. Overloading the tray can lead to deformation or failure of the tray system.

The National Electrical Code (NEC) sets specific guidelines for cable tray installations to ensure safety and performance. The NEC code for cable tray fill is primarily focused on the maximum fill percentage to avoid overcrowding, which could lead to overheating and potential failure of the electrical system.

According to NEC Section 392.22, the maximum fill percentage of a cable tray depends on the type of cables used and their arrangement within the tray. For instance, the code often recommends that the fill ratio not exceed 50% to 60% of the tray’s total cross-sectional area. This ensures proper airflow and heat dissipation, which are crucial for preventing overheating.

Key Points of the NEC Code for Cable Tray Fill:

Maximum Fill: Generally, the maximum fill ratio should be no more than 50-60% of the tray’s cross-sectional area.

Cable Arrangement: The arrangement and type of cables also affect the maximum fill ratio.

Temperature and Ventilation: Consideration for ventilation and thermal expansion is essential when determining cable tray fill to avoid heat buildup.

Adhering to the NEC code helps ensure compliance with national safety standards and reduces the risk of system failures.

The fill ratio for a NEC cable tray is a critical factor in determining how many cables a tray can safely accommodate without compromising the system’s performance. As per NEC guidelines, the fill ratio is defined as the percentage of the tray’s total cross-sectional area that is occupied by cables.

The recommended fill ratio depends on several factors, such as the cable type, size, and configuration within the tray. For instance:

For power cables, the NEC generally suggests a maximum fill ratio of 50%.

For fiber optic cables and communication cables, the recommended fill ratio can be slightly higher, typically 60%.

It’s important to note that NEC Section 392.22 provides guidance on calculating the fill ratio, factoring in not just the cable size, but also the tray’s internal dimensions and the expected temperature rise within the tray.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.