In solar installations, efficient cable management plays a critical role in maintaining system performance and safety. A cable tray for solar provides a structured and reliable solution to organize and protect cables. Without proper management, solar cables risk damage from weather, wear, and improper routing, leading to reduced efficiency or costly repairs. Solar setups often face challenges like tangled cables, exposure to harsh environmental conditions, and insufficient support for long-term durability. These issues can compromise the system’s operational reliability. Implementing a cable tray for solar helps mitigate these challenges by offering organized pathways, reducing maintenance needs, and enhancing overall system efficiency. By addressing these problems, the integration of a cable tray for solar ensures a more robust and effective solar energy system.

Benefits of Cable Tray for Solar Installations

Cable trays are vital in optimizing solar installations. The use of a cable tray for solar ensures organized wiring, cost efficiency, and long-term reliability. Whether you’re employing a standard system or a Clenergy cable tray, these trays address multiple challenges effectively.

Enhanced Cable Management

Proper cable management is crucial for solar systems. A cable tray for solar ensures secure and organized pathways for cables, preventing tangling and misplacement. With the structured design of a Clenergy cable tray, cables are neatly routed, minimizing the risk of damage during installation or operation.

Solar installations often involve complex wiring across rooftops or uneven terrains. Improperly managed cables are susceptible to wear, leading to inefficiencies or operational failures. Using a cable tray for solar, installers can reduce physical strain on cables and avoid common issues like abrasion. Moreover, the design of a Clenergy cable tray simplifies routing, enabling faster and safer installations.

Additionally, cable trays allow for easier inspection and maintenance. With cables securely positioned, technicians can identify and resolve issues without unnecessary disruptions. This enhances the overall longevity and performance of solar systems.

Cost Efficiency

A cable tray for solar provides significant cost advantages, making it a preferred choice for solar projects. Its design reduces labor and installation expenses by simplifying the routing process. The Clenergy cable tray enhances efficiency further, ensuring minimal material waste during installation.

Solar projects can be resource-intensive, and improper cable management may lead to higher expenses in the long run. By utilizing a cable tray for solar, installation time is significantly reduced, lowering associated labor costs. Additionally, the durable materials used in a Clenergy cable tray minimize repair and replacement expenses over time.

Cable trays also contribute to cost savings by protecting cables from damage caused by environmental factors. This prevention reduces the need for frequent repairs or replacements, ensuring long-term value. With organized systems in place, material usage is optimized, further enhancing cost efficiency.

Durability and Weather Resistance

Outdoor solar installations demand robust solutions to withstand harsh environmental conditions. A cable tray for solar offers excellent durability, shielding cables from UV rays, rain, and wind. The high-quality materials of a Clenergy cable tray ensure reliable performance in challenging weather conditions.

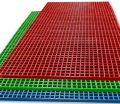

Solar systems are frequently exposed to fluctuating temperatures and moisture, which can degrade unprotected cables. The sturdy design of a cable tray for solar creates a barrier that prevents environmental damage, preserving cable integrity. Materials like aluminum or fiberglass in Clenergy cable trays are corrosion-resistant, ensuring longevity in coastal or humid regions.

Durable cable trays not only extend the life of solar installations but also reduce maintenance needs. With their weatherproof design, Clenergy cable trays minimize the impact of external factors, enabling uninterrupted system performance.

Compliance with Standards

Adhering to regulatory standards is essential for the safety and efficiency of solar systems. A cable tray for solar meets NEC requirements, ensuring compliance in various installations. Similarly, the Clenergy cable tray is designed to align with industry regulations, providing assurance of reliable and safe operations.

Safety standards mandate proper cable management to prevent hazards such as electrical shorts or fire risks. A cable tray for solar simplifies compliance by offering a structured system that reduces these risks. Additionally, the standardized design of a Clenergy cable tray makes it suitable for diverse applications, ensuring universal compatibility.

Compliance also extends to environmental sustainability, as durable and recyclable materials are often used in cable trays. This focus on eco-friendly solutions aligns with the broader goals of renewable energy systems. Employing a Clenergy cable tray guarantees adherence to these principles while maintaining high performance.

By incorporating features like organized pathways, cost efficiency, durability, and compliance, cable trays like the Clenergy cable tray play a pivotal role in optimizing solar installations.

Pultrusion Cable Tray Mold Applications Across Industries

Types of Cable Tray for Solar Installations

Selecting the right cable tray for solar is essential for the efficiency and longevity of any solar energy system. With various options available, each type caters to specific needs, such as rooftop installations, ground-mounted systems, and complex layouts.

Rooftop Cable Trays

Rooftop solar installations require lightweight and compact solutions to support cables without adding unnecessary weight. A cable tray for solar used on rooftops ensures the cables are organized and protected against environmental exposure.

In residential setups, rooftop cable trays provide a streamlined appearance by keeping wires concealed. They are typically made from lightweight materials like aluminum or fiberglass, ensuring minimal impact on structural integrity. GangLong Fiberglass cable trays are particularly effective due to their ease of installation and weather resistance.

Commercial rooftops often involve more extensive wiring systems. Here, a cable tray for solar helps prevent cable tangling and facilitates maintenance. By allowing flexibility in placement, rooftop trays ensure cables are securely routed, reducing the risk of abrasion or disconnection.

Additionally, rooftop trays simplify inspections by providing easy access to cables. This reduces the time and effort needed for routine maintenance while ensuring long-term system reliability.

Ground-Mounted Cable Trays

Ground-mounted systems require a cable tray for solar that can handle large cable volumes and withstand various terrains. These trays are designed to support heavy loads and ensure cables remain organized over long distances.

In large-scale solar farms, ground-mounted trays minimize cable stress by providing ample support. They can be adapted to uneven surfaces, ensuring secure placement in any terrain. GangLong Fiberglass cable trays are highly durable, making them ideal for withstanding environmental challenges such as flooding or high winds.

High-capacity ground-mounted trays reduce maintenance by protecting cables from ground-level wear. Additionally, their robust construction prevents damage caused by rodents or debris, ensuring uninterrupted performance.

The modularity of ground-mounted trays allows for scalability, making them suitable for expanding solar farms. By ensuring cables remain secure and accessible, these trays contribute to cost-effective operations and long-term system reliability.

Modular Cable Trays

For complex layouts, modular trays offer a flexible and scalable cable tray for solar solution. These trays are designed to accommodate varying configurations, making them ideal for expanding systems or challenging layouts.

Modular trays allow for easy customization, enabling installers to create pathways tailored to specific requirements. They are especially useful in projects where solar arrays are spread across irregular surfaces or multiple levels.

By using a modular cable tray for solar, installers can adjust the layout as needed without significant additional costs. This flexibility is particularly valuable for projects that anticipate future upgrades or changes in cable management needs.

These trays are also designed for quick assembly, reducing labor time during installation. Their lightweight yet durable construction ensures long-term reliability without compromising efficiency.

Weatherproof and Corrosion-Resistant Options

Durability is critical in outdoor solar installations. A weatherproof and corrosion-resistant cable tray for solar ensures cables are protected against harsh environmental factors. Materials like aluminum, galvanized steel, and fiberglass are commonly used.

GangLong Fiberglass cable trays are known for their excellent resistance to UV rays, rain, and extreme temperatures. These properties make them ideal for installations in coastal regions or areas with high humidity.

Corrosion-resistant trays extend the lifespan of solar systems by reducing the risk of material degradation. They maintain their structural integrity over time, ensuring cables remain secure and operational.

By investing in a weatherproof cable tray for solar, operators minimize maintenance needs and improve system reliability. This proactive approach saves costs in the long run while ensuring uninterrupted energy production.

Factors to Consider When Choosing Cable Tray for Solar Systems

Selecting the right cable tray for solar requires careful evaluation of several factors to ensure optimal performance. From load capacity to compatibility with solar panels, every aspect plays a role in maximizing system efficiency.

Load Capacity and Size

Load capacity is a critical factor when choosing a cable tray for solar. It ensures the tray can support the volume and weight of cables without sagging or damage.

Solar installations often involve heavy-duty wiring, especially in large-scale projects. A tray must be sized appropriately to accommodate all cables without overcrowding. GangLong Fiberglass cable trays offer excellent load-bearing capabilities while maintaining lightweight construction.

Choosing the correct size prevents strain on cables, reducing wear and tear. Additionally, oversized trays provide room for future expansions, making them a cost-effective choice for scalable systems.

Regular assessments of load capacity ensure the tray remains functional as the system grows. This proactive approach avoids operational disruptions and ensures long-term reliability.

Installation Requirements

Ease of installation is another important consideration for selecting a cable tray for solar. Tools, accessories, and mounting requirements can significantly impact the overall cost and time of setup.

Some trays, like GangLong Fiberglass cable trays, are designed for quick installation with minimal tools. This reduces labor costs and ensures timely project completion. Accessories like mounting brackets and connectors simplify the process further.

By prioritizing easy-to-install trays, operators save time and resources during initial setup. This is especially important in large projects where efficiency is a top priority.

Cost and Budget

Balancing cost with quality is essential when selecting a cable tray for solar. Durable trays may have higher upfront costs but offer significant long-term savings.

GangLong Fiberglass cable trays are cost-effective due to their durability and low maintenance needs. Their extended lifespan offsets the initial investment, making them a smart choice for both small and large projects.

Budgeting should also consider installation expenses and future scalability. Investing in high-quality trays prevents frequent replacements, saving costs over the system’s lifespan.

Compatibility with Solar Panel Systems

A cable tray for solar must integrate seamlessly with the mounting structures of solar panels. Compatibility ensures cables are routed efficiently without hindering panel operation.

For instance, GangLong Fiberglass cable trays are designed to fit various solar panel systems. Their versatile design accommodates different mounting configurations, ensuring proper alignment and secure pathways.

Ensuring compatibility reduces the risk of installation errors and enhances system performance. It also simplifies maintenance, as cables remain easily accessible for inspection and repairs.

By evaluating these factors, operators can select the most suitable cable tray for solar, ensuring efficient and reliable energy generation.

Advantages of Using Cable Tray for Solar

Utilizing a cable tray for solar offers numerous advantages over alternative solutions like conduits. From flexibility in design to reduced maintenance, these trays are essential for efficient solar energy systems.

Flexibility in Design and Installation

A significant advantage of a cable tray for solar is its flexibility in design and installation. Unlike rigid conduits, cable trays can adapt to various layouts, making them suitable for complex solar setups.

For rooftop installations, trays can be customized to fit around obstacles such as vents and chimneys. Ground-mounted systems also benefit from flexible trays that adjust to uneven terrains. GangLong Fiberglass cable trays are particularly effective due to their lightweight yet robust construction, ensuring easy handling and placement.

Flexibility extends to scalability. As solar systems expand, cable trays can accommodate additional cables without requiring major structural changes. This adaptability saves time and costs, especially in large-scale projects.

Additionally, flexible trays reduce the likelihood of installation errors. They allow cables to be routed more easily, ensuring proper alignment and reducing the risk of damage during setup. The versatility of a cable tray for solar ensures it remains a preferred choice for modern solar installations.

Faster Installation Times

A cable tray for solar significantly reduces installation time compared to traditional conduits. Its open design allows cables to be laid out quickly and securely.

With conduits, each cable must be threaded through pipes, a time-consuming process that requires specialized tools. In contrast, GangLong Fiberglass cable trays allow installers to route multiple cables simultaneously, streamlining the process. This efficiency is especially valuable in large-scale projects where time constraints are critical.

Pre-assembled components and modular designs further enhance installation speed. These features minimize the need for cutting or additional assembly, ensuring the project stays on schedule. Faster installation also translates to reduced labor costs, making trays a cost-effective solution.

The simplicity of installing a cable tray for solar benefits both experienced professionals and new installers. By reducing complexity, it ensures consistency in installation quality, contributing to the long-term performance of the solar system.

Reduced Maintenance Needs Compared to Conduits

Maintaining a cable tray for solar is simpler and less costly compared to conduits. The open structure of trays allows easy access to cables, facilitating regular inspections and repairs.

In contrast, conduits require disassembly to access cables, increasing labor and material costs. With GangLong Fiberglass cable trays, technicians can identify and address issues without dismantling the system. This reduces downtime and ensures uninterrupted energy production.

Trays also offer better ventilation, preventing the buildup of heat around cables. This reduces the risk of overheating, a common issue in enclosed conduits. Additionally, trays protect cables from environmental factors, minimizing wear and tear.

By reducing the frequency and complexity of maintenance, a cable tray for solar ensures long-term cost savings. Its durable design further enhances reliability, making it an ideal choice for both small and large solar projects.

The advantages of using a cable tray for solar—flexibility, faster installation, and reduced maintenance—highlight its superiority over alternative solutions. With innovative designs like GangLong Fiberglass cable trays, solar installations can achieve greater efficiency, reliability, and cost-effectiveness.

Ex Proof Cable Tray Installation: Best Practices Explained

Cable Tray for Solar : Installation Tips

Proper installation of a cable tray for solar is crucial for ensuring efficiency and durability in solar systems. Following the correct process helps optimize performance and reduces maintenance needs.

Planning the Layout

Effective planning is the first step when installing a cable tray for solar. Assessing the site and determining cable routing ensures optimal placement.

Before installation, analyze the site conditions, including obstacles, slopes, and weather exposure. This helps in designing a layout that minimizes cable length and reduces material waste. For example, rooftop installations may require routing around vents or chimneys, while ground-mounted systems should avoid waterlogging areas.

Next, determine the exact placement of the cable tray for solar. A detailed plan minimizes errors and ensures efficient use of resources. Using tools like CAD designs can further refine the layout, especially in large-scale projects.

Proper planning also considers future scalability. Ensure the tray layout allows for easy addition of cables if the system expands. This foresight saves time and costs in the long term.

Ensuring Proper Support and Fastening

Securing the cable tray for solar with adequate support is critical for maintaining stability and safety. Improper fastening can lead to operational failures.

Use high-quality hangers and brackets to attach the trays securely to the mounting structure. For rooftop installations, ensure the brackets align with the roof slope and avoid penetrating waterproof layers. Ground-mounted systems may require stakes or concrete bases for added stability.

Fasteners must be compatible with the tray material to prevent corrosion. For instance, stainless steel brackets work well with GangLong Fiberglass cable trays, ensuring long-term reliability. Place supports at regular intervals to distribute weight evenly and prevent sagging.

Test the stability of the tray after installation. A firm tray structure reduces the risk of cable displacement during harsh weather conditions, such as strong winds or heavy rain. Proper support ensures the system operates smoothly for years.

Maintenance and Inspection Guidelines

Regular maintenance of a cable tray for solar ensures its longevity and reliability. Periodic inspections help identify wear or potential issues early.

Inspect the tray and cables at least twice a year, focusing on joints, brackets, and fasteners. Look for signs of rust, corrosion, or physical damage. For GangLong Fiberglass cable trays, check the weatherproof coating to ensure it remains intact.

Clean the tray to remove debris, dirt, or bird droppings that may accumulate. Use non-corrosive cleaning agents to maintain the tray’s protective layer. Regular cleaning prevents clogging and ensures cables remain well-ventilated.

In case of damage, replace the affected section immediately to prevent further deterioration. Modular trays, such as GangLong Fiberglass cable trays, make repairs simple and cost-effective.

By adhering to maintenance guidelines, operators can maximize the efficiency and durability of their cable tray for solar, reducing operational disruptions.

Cable Tray for Solar:Pricing and Budget Considerations

Understanding the costs associated with a cable tray for solar helps in making informed purchasing decisions. Factors like materials, configurations, and installation impact the total expenses.

Overview of Factors Influencing Cable Tray Costs

Several factors determine the cost of a cable tray for solar. These include material type, size, load capacity, and weatherproofing.

Materials such as aluminum and fiberglass are more expensive upfront but offer long-term durability and low maintenance. Steel trays are cost-effective initially but may require more frequent upkeep in corrosive environments.

Additional costs include brackets, hangers, and fasteners. The complexity of the installation site can also influence the overall expense. For instance, trays on sloped rooftops may need specialized mounting hardware.

Investing in quality trays, like GangLong Fiberglass cable trays, reduces long-term costs by minimizing maintenance and replacement needs.

Comparison of Materials and Configurations

| Material | Durability | Maintenance Costs | Weight | Cost Efficiency | Best Applications |

|---|---|---|---|---|---|

| Aluminum | High | Low | Lightweight | Moderate | Coastal areas, rooftop systems |

| Fiberglass (GangLong) | High | Low | Lightweight | High | Harsh weather conditions |

| Galvanized Steel | Moderate | Moderate | Heavy | High | Ground-mounted systems |

Estimating Total Expenses for Rooftop and Ground-Mounted Systems

The total cost of a cable tray for solar depends on the system type and size.

For rooftop systems, expenses include lightweight trays, corrosion-resistant brackets, and labor for careful installation. A 5 kW residential system typically costs $500–$1,000 for cable trays and hardware.

Ground-mounted systems require larger trays with higher load capacities. These trays are paired with robust supports to withstand environmental conditions. A 10 kW system may cost $1,500–$2,500 for trays and installation materials.

By factoring in maintenance and durability, investing in quality trays like GangLong Fiberglass cable trays ensures cost efficiency over time. Comparing these considerations helps optimize the budget for any solar project.

How Much Type Cable Tray is Needed for Installations?

Future Trends in Cable Tray for Solar Management

The evolution of a cable tray for solar continues to shape the efficiency and sustainability of solar energy systems. Innovations like lightweight materials, AI integration, and scalable designs promise to redefine cable management.

Increased Adoption of Lightweight Materials

Lightweight materials are becoming the standard for a cable tray for solar, enhancing efficiency and ease of installation.

Materials like aluminum and fiberglass are increasingly used due to their corrosion resistance and minimal weight. For example, GangLong Fiberglass cable trays combine strength with lightness, making them ideal for both rooftop and ground-mounted systems. These trays reduce stress on structures and simplify transportation, saving labor and costs.

Lightweight materials also contribute to environmental sustainability. Fiberglass, for instance, requires less energy during manufacturing and has a long lifespan. Solar projects benefit from these materials by reducing their carbon footprint while improving durability.

As solar adoption expands to more diverse environments, lightweight cable trays ensure systems can be installed in remote or challenging locations. Their portability and resilience allow projects to scale quickly and efficiently.

Integration with AI for Cable Monitoring

AI is revolutionizing how a cable tray for solar is maintained, offering predictive monitoring and enhanced operational efficiency.

Through sensors embedded in the trays, AI systems can detect potential issues like overheating or cable misalignment. For example, monitoring systems integrated with GangLong Fiberglass cable trays provide real-time updates, ensuring problems are addressed before they escalate.

AI also optimizes maintenance schedules by identifying areas that require immediate attention. This reduces unnecessary inspections and lowers operational costs. Additionally, data collected from AI systems can be analyzed to improve future installations, making them safer and more efficient.

This integration represents a significant leap in solar technology, ensuring the reliability and longevity of energy systems.

Innovative Modular and Scalable Designs

The future of a cable tray for solar lies in modular and scalable designs that adapt to the needs of dynamic solar installations.

Modular trays, such as those offered by GangLong Fiberglass, allow components to be added or replaced without disrupting the entire system. This flexibility is critical for expanding solar farms or integrating new technologies.

Scalable designs also simplify the planning and installation process. Trays can be customized to fit specific project requirements, reducing material waste and saving time. For rooftop systems, modular designs ensure seamless integration with existing structures, while ground-mounted systems benefit from easy adaptability to terrain changes.

As solar energy demand grows, these designs enable systems to evolve without significant additional investment. The combination of modularity and scalability ensures that solar installations remain future-proof.

The Role of Cable Trays in Future Solar Energy Systems

Cable management will remain central to the growth and sustainability of solar power. A cable tray for solar ensures operational reliability and efficiency.

Recap of the Benefits

A cable tray for solar offers a structured and durable solution to manage cables, ensuring organized pathways and protecting against damage. Options like GangLong Fiberglass cable trays provide cost efficiency, easy maintenance, and long-term durability.

The advantages of using cable trays include reduced installation time, lower maintenance costs, and adherence to safety standards. Whether for rooftop or ground-mounted systems, these trays improve system performance and lifespan.

Encouragement to Prioritize Cable Management

Proper cable management is vital for maximizing the efficiency and safety of solar energy systems. Choosing a high-quality cable tray for solar reduces risks, enhances reliability, and simplifies maintenance.

Operators and designers should prioritize investing in durable and adaptable trays, such as GangLong Fiberglass options, to future-proof their systems. By ensuring proper cable management, solar installations can operate at peak efficiency, contributing to a more sustainable energy future.

FAQs about Cable Tray for Solar

The size of the cable depends on the system’s voltage, current, and distance between components. A larger cable size reduces voltage drop and ensures efficient power delivery. For most residential systems, cables between 4 mm² and 6 mm² are commonly used. However, larger systems or those with longer distances may require cables up to 10 mm² or more. Proper sizing is crucial to prevent overheating, inefficiencies, or potential hazards. It’s recommended to consult a professional or refer to the system’s specifications to determine the optimal cable size for your solar setup.

While not always required, placing solar cables in a conduit provides additional protection. Conduits shield cables from physical damage, UV rays, and environmental exposure, especially in outdoor installations. In some regions, building codes may mandate the use of conduits for certain parts of the system. A cable tray for solar can often serve as an alternative to conduits, offering both protection and organization. When deciding, consider the installation environment and compliance with local regulations to ensure safety and durability.

The type of cable used for solar panels must be designed to handle high voltages and outdoor conditions. Solar cables are typically insulated, weatherproof, and UV-resistant. Common types include single-core and double-core cables made from copper or aluminum conductors. These cables are also designed to endure extreme temperatures, making them ideal for both rooftop and ground-mounted systems. When using a cable tray for solar, ensure the cables fit securely and meet the specifications of the system to maximize efficiency and safety.

Yes, earthing is often required for a cable tray for solar to ensure safety and compliance with regulations. Earthing prevents electric shock and reduces the risk of fire by providing a path for fault currents. Metal trays, in particular, require proper earthing as they can conduct electricity. Earthing connections should be inspected regularly to maintain their effectiveness. Non-conductive trays, like those made of fiberglass, may not need earthing but should still be assessed based on system requirements and local codes.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.