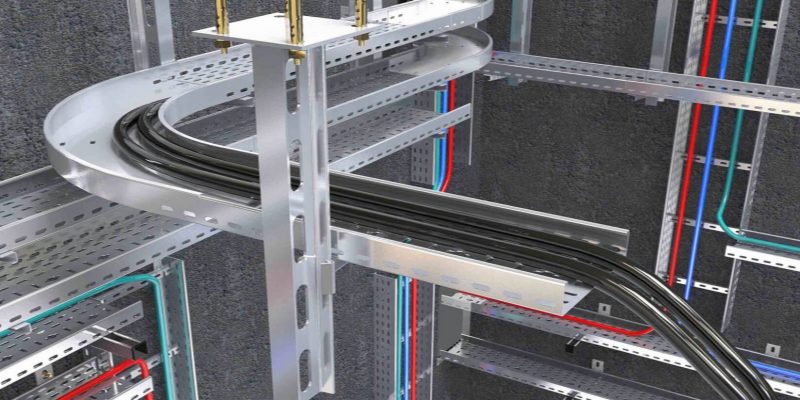

Cable tray to conduit transition requires free air between 1ft-3ft; cables cannot transition through a bushed conduit. Cable trays and conduit systems are essential components in electrical installations, providing organized pathways for electrical cables. Cable trays are typically used for larger or more flexible wiring runs, while conduits are employed to protect cables in more rigid or exposed environments. The use of cable trays is especially advantageous when managing a large number of cables or when flexibility in cable routing is required. A transition from cable tray to conduit is crucial to ensure a smooth connection between these two systems, allowing cables to safely move from a tray to a conduit. Proper transitions are vital for safety, ensuring that the electrical system remains compliant with regulations and operates reliably. The National Electrical Code (NEC) outlines specific requirements for these transitions, emphasizing the importance of secure, reliable connections that uphold the system’s grounding, bonding, and safety standards.

What is the Role of Cable Trays and Conduits in Cable Tray to Conduit Transition

Definition of Cable Trays as Raceways According to NEC

According to the NEC, cable trays are considered raceways that provide a pathway for electrical wiring. They are typically used in industrial, commercial, and residential installations to organize and support cables, especially in environments where flexibility and accessibility are crucial. Equipment for single conduit runs or multi-circuit installations can also be accommodated within these trays, ensuring a secure and organized setup. A cable tray to conduit transition is an essential part of these systems, where the cable tray system seamlessly connects to conduit, ensuring that cables are effectively routed and protected as they move between open and enclosed pathways. The NEC provides guidelines on how to properly install cable trays, ensuring that they meet safety standards and maintain the integrity of the electrical system.

Conduits: Protective Pathways for Wiring, Used Especially in High-Risk Areas

While cable trays are ideal for supporting and organizing wiring, conduits serve a different purpose: they provide additional protection to cables, especially in high-risk or hazardous areas. Conduits are typically used in environments where cables are exposed to potential damage, moisture, chemical exposure, or high temperatures. By enclosing the wiring in a conduit, the cables are shielded from physical damage, and the risk of electrical faults is significantly reduced.

The cable tray to conduit transition ensures that cables move safely from the more open, accessible cable tray system into the more protective, sealed environment of a conduit system. This transition is crucial in environments such as industrial plants, outdoor installations, or areas where cables need to be protected from environmental hazards or mechanical impacts. Properly executed, the cable tray to conduit transition maintains both the safety and functionality of the system, meeting the regulatory requirements set forth by the NEC and providing long-term protection for the electrical system.

Cable trays and conduits both serve vital roles in electrical installations, with trays offering support and organization, and conduits providing additional protection. The conduit transition to cable tray ensures that these two systems work together seamlessly, providing both accessibility and safety while meeting the standards of the NEC.

Key Characteristics of Cable Trays in a Cable Tray to Conduit Transition

Strength and Rigidity: Ensuring Adequate Support for Contained Wiring

One of the defining characteristics of cable trays is their strength and rigidity. The choice of cable tray material—such as steel, aluminum, or fiberglass—plays a crucial role in providing the necessary durability and ability to withstand heavy loads, harsh environments, and physical stresses. These materials ensure that the cable tray supports a wide range of cables, including power, communication, and control wires, while preventing sagging or misalignment. The strength of a cable tray to conduit transition is particularly important, as it must handle the weight of the cables and the transition between the flexible cable tray system and the more rigid conduit system. This ensures that cables are well-supported and protected as they move through different parts of the installation.

Associated Fittings Suitability: Designed for Intended Applications

Cable trays are designed to accommodate a variety of fittings, such as elbows, tees, and transitions, that help guide and protect the cables. The fittings must be suitable for the specific application and meet the NEC standards for safe installation. A conduit to cable tray transition is one of the key fittings that ensures the proper connection between the open cable tray system and the enclosed conduit system. This transition must be secure, well-bonded, and correctly sized to accommodate the specific cables and ensure safe operation. The use of appropriate fittings ensures that the installation remains safe, organized, and compliant with electrical codes, helping to avoid issues such as cable damage or electrical hazards.

Corrosion Resistance: Ensuring Longevity in Harsh Environments

Corrosion resistance is another critical characteristic of cable trays, especially in environments where exposure to moisture, chemicals, or extreme temperatures is common. Materials such as galvanized steel, stainless steel, or fiberglass are often chosen for their ability to resist corrosion and extend the lifespan of the installation. In a cable tray to conduit transition, corrosion resistance is especially important because it helps prevent degradation of the tray or conduit over time, ensuring that the system maintains its structural integrity and performance. This characteristic is essential in industries such as marine, oil and gas, and chemical processing, where corrosive elements are prevalent. The durability provided by corrosion-resistant materials contributes to a safer, more reliable electrical system and reduces the need for frequent maintenance or replacements.

Choosing the Right Grid Cable Tray for Projects

NEC Guidelines for Cable Tray to Conduit Transitions

Cable Tray as a Raceway

The NEC classifies cable trays as raceways, which are pathways designed to protect and support electrical wiring. According to the NEC, a raceway is any enclosed conduit, duct, or other types of channels used to contain cables. Cable trays, as raceways, offer flexibility in organizing, routing, and protecting electrical cables, particularly in large industrial or commercial settings. A cable tray to conduit transition serves as a critical connection when transitioning from an open, accessible cable tray to the more protected, enclosed conduit system. This ensures that cables remain safe as they move through areas where extra protection is needed, such as areas exposed to potential damage or environmental hazards.

In specific installations, cable trays are designed to serve as raceways in situations where cables are not subject to severe environmental conditions or excessive physical damage. For example, in industrial facilities with climate-controlled environments, cable trays are often used for power distribution systems, where cables can be routed safely without the need for additional protection. However, when cables need to be routed outside, through areas exposed to harsh elements, a cable tray to conduit transition ensures that cables are properly enclosed for added protection.

Transition Requirements (NEC 2020 Updates)

The NEC 2020 updates to Section 392.46 provide important guidelines for cable tray to conduit transitions, outlining specific requirements for connecting the cable tray system to conduit or tubing. These updates aim to ensure the system remains safe, organized, and protected against environmental and physical damage.

Through Bushed Conduit or Tubing (392.46(A))

One of the key provisions of NEC 2020 for conduit transition to cable tray transition involves the use of bushed conduit or tubing. According to NEC 392.46(A), when transitioning from a cable tray to a conduit system, it is necessary to secure cables at the transition points to ensure they do not shift or become damaged during installation or in service. Proper securing methods include cable ties, clamps, and other approved devices that hold cables in place.

Additionally, NEC 392.46(A) emphasizes the importance of using nonflexible bushed conduit or tubing for providing physical protection to the cables. These materials protect the cables as they enter the conduit, reducing the risk of wear, friction, and environmental damage, especially in areas with high traffic or external elements like moisture or chemicals.

Finally, the raceway must be sealed at the transition point to prevent debris from entering the system. This is particularly critical in industrial settings where dust, dirt, or other foreign objects can interfere with cable performance or cause potential electrical failures. Sealing the transition ensures that the cable system remains clean and free from obstructions that could pose a hazard.

Flanged Connections (392.46(B))

Another important update in NEC 2020 is the use of flanged connections for cable tray to conduit transitions, as outlined in NEC 392.46(B). This method involves mounting the cable tray directly to the flange of the equipment or conduit, ensuring a stable and secure connection. Flanged connections provide a strong bond between the cable tray and conduit, which is essential for maintaining the integrity of the electrical system.

In these installations, it is critical to ensure that the transition point is protected against abrasion and debris. Flanged connections help minimize wear on the tray and conduit, as well as reduce the risk of cable damage due to friction or contact with other surfaces. Proper sealing at the connection point ensures that the raceway remains clean and undamaged, and prevents any external elements from entering the system and interfering with cable performance.

Compliance with Controlled Receptacles

The 2020 NEC also includes provisions related to controlled receptacles, which play a significant role in managing and ensuring safe connections within cable tray to conduit transitions. Controlled receptacles are electrical outlets that are managed through a centralized control system, which can be used to safely isolate and control electrical systems, particularly in hazardous environments.

Overview of 2020 NEC Requirements for Controlled Receptacles

The NEC 2020 requirements for controlled receptacles emphasize the need for proper protection of circuits connected to cable trays or conduits. When transitioning from a cable tray to a conduit, the cable system may need to connect to receptacles with control features to safely manage electrical loads. These controlled receptacles are designed to prevent overloads, short circuits, and other electrical faults by precisely regulating the flow of electricity through the system. Additionally, conducting a proper cable tray load calculation is crucial to ensure the tray can support the electrical load without exceeding its capacity. This calculation helps determine the maximum number of cables that can safely pass through the tray, preventing potential overheating or overload issues.

Integration of These Provisions During Transitions

The cable tray to conduit transition must include provisions for integrating controlled receptacles into the system, ensuring that the transition point remains compliant with the latest NEC standards. This may involve using receptacles with additional protective measures such as fuses, circuit breakers, or other disconnecting means that can isolate the system in case of faults. By complying with the NEC’s controlled receptacle guidelines during the transition process, installers can ensure that the system remains safe, reliable, and compliant with industry standards.

The NEC guidelines for cable tray to conduit transitions provide essential requirements to ensure that electrical systems remain safe, functional, and compliant. By adhering to these updated provisions, including the use of nonflexible conduit, flanged connections, and controlled receptacles, installers can ensure the integrity of the cable system, minimize the risk of electrical hazards, and maintain a well-organized, efficient installation.

Multi Line Cable Tray Price Comparison for Projects

Best Practices for Transitioning from Cable Trays to Conduits: Cable Tray to Conduit Transition

Ensuring Secure and Safe Installations

A cable tray to conduit transition is a crucial part of any electrical installation, requiring careful attention to ensure safety, reliability, and compliance with the NEC. This transition represents the shift from an open cable tray system, which is flexible and accessible, to a more enclosed and rigid conduit system. Proper handling at this juncture is necessary to ensure that cables remain well-supported and free from damage. Failure to properly secure the cables or transition them smoothly could lead to electrical faults, physical damage, or increased risk of fire hazards.

Selecting Proper Fittings for the Transition

Selecting the correct fittings for the transition from cable tray to conduit is critical to ensuring both safety and compliance with the NEC. Fittings like bushings, adapters, and flanged connections must be chosen carefully to protect the cables and maintain system integrity. These fittings should be properly sized and compliant with the NEC to facilitate a smooth transition that ensures physical protection, electrical grounding, and secure mounting between the tray and conduit.

Providing Strain Relief at Transition Points

Strain relief is essential when transitioning from cable trays to conduits to prevent any undue stress on the cables. Cables moving from the more flexible tray system into the rigid conduit must be adequately supported to avoid tension that could lead to damage. The use of strain relief devices, such as clamps or specialized adapters, ensures that the cables are not subjected to excessive force. This protection helps maintain the integrity of the cables, prevents premature wear, and ensures the longevity of the entire electrical system.

Proper Sealing to Prevent Contaminants

Sealing the transition between cable trays and conduits is a crucial step in ensuring the long-term safety and reliability of the electrical system. Using proper sealants, like duct seal, around the transition points prevents moisture, dust, and other contaminants from entering the conduit. These elements can cause corrosion, short circuits, or damage to the cables over time. Applying a high-quality, NEC-compliant sealant around the transition area ensures that the system remains clean and protected from external hazards, helping to preserve its performance and safety in the long run.

Cable Tray Grounding Lugs for Safe Electrical Systems

Avoiding Common Mistakes in Cable Tray to Conduit Transition

When performing a cable tray to conduit transition, it’s essential to follow the best practices and NEC guidelines to ensure both safety and compliance. Common mistakes can lead to faulty installations, which can compromise the integrity of the electrical system and potentially create safety hazards. Here are some key mistakes to avoid during cable tray to conduit transition installations.

Misinterpretation of NEC Sections (e.g., 312.5C) for Single Conductors

One common mistake is misinterpreting NEC sections, such as NEC 312.5C, which deals with the installation of single conductors within a conduit. According to NEC 312.5C, when using conduit systems, conductors must be securely supported and properly fitted within the raceway. However, the mistake occurs when installers assume that this applies in the same way for a cable tray to conduit transition.

- Key Issue: NEC 312.5C applies to single conductors and does not cover multi-conductor cables or cable tray systems, which often require different handling due to the variety of cables and the larger sizes of the conductors involved. Installing cables in a manner that doesn’t follow NEC cable tray to conduit transition guidelines for multi-conductor cables can lead to improper fitting, strain on conductors, or insufficient protection against external factors like physical damage or moisture.

- Solution: Ensure that all components, including individual conductors and multi-conductor cables, are installed according to the appropriate sections of the NEC. For cable tray to conduit transition, cables should be properly supported and protected using the appropriate fittings and materials. When transitioning from a cable tray to conduit, follow the specific requirements for securing and protecting cables as outlined in NEC 392 and other relevant sections.

Ensuring the Transition Point is Robust and Meets Electrical Safety Standards

Another critical mistake is failing to ensure that the cable tray to conduit transition point is properly secured and robust. The transition point is one of the most vulnerable areas in an electrical system, where cables move from the more flexible and accessible tray into the more enclosed conduit. If this transition is not adequately handled, it can lead to physical damage, loose connections, or exposure to hazardous conditions.

- Key Issue: The cable tray to conduit transition point needs to be sufficiently strong to withstand mechanical stresses and environmental conditions. If the connection between the tray and conduit is not tight, secure, or properly sealed, it may expose the cables to physical damage or allow debris and moisture to enter the system. Additionally, if the transition does not meet NEC standards for electrical continuity, it could cause grounding or bonding issues that create risks for electrical faults.

- Solution: To avoid these issues, the transition point must be fitted with proper connectors and grounding provisions, such as NEC-compliant bushings or flanged connections. The conduit and cable tray must be securely bonded at the transition to ensure a continuous path for fault currents. Additionally, sealing the transition with high-quality duct sealant is crucial to protect cables from moisture, dirt, and other contaminants.

Failing to Account for Cable Bend Radius

Another common mistake is failing to account for the cable bend radius at the transition point from cable tray to conduit. NEC guidelines emphasize the importance of maintaining the proper bend radius for cables to prevent damage to their insulation and conductors. However, installers may overlook this critical requirement, leading to sharp bends that increase the risk of cable failure.

- Key Issue: When cables are bent too sharply during the transition, the insulation may degrade, which could lead to electrical faults, short circuits, or even fires. This issue is particularly common in environments where cables are tightly fitted into the conduit or where space constraints lead to improper routing.

- Solution: To avoid this mistake, ensure that cables are routed smoothly and gradually through the transition, maintaining the manufacturer’s specified bend radius for each type of cable. The use of cable guides or elbows specifically designed for these transitions can help maintain proper bend radii and ensure the longevity of the cables.

Practical Examples of Transitions

Illustrations of Compliant Installations

When performing a cable tray to conduit transition, it is essential to follow best practices to ensure compliance with the NEC standards. Below are two examples of compliant installations that meet the necessary safety and performance requirements.

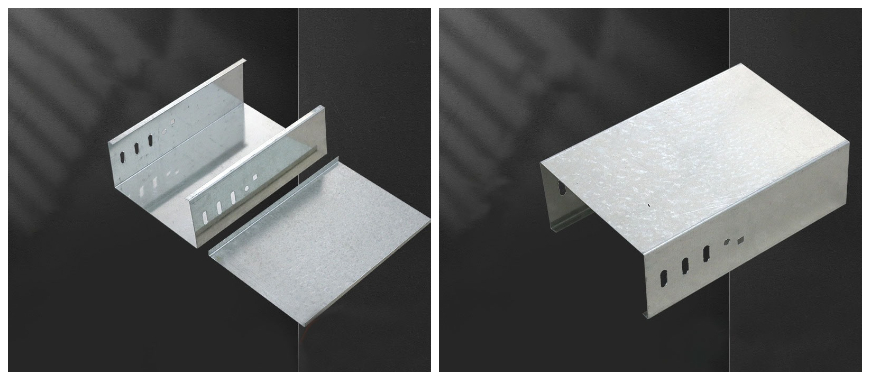

Bushed Conduit Installations with Sealed Ends

A bushed conduit installation with sealed ends is a common and compliant method for making a cable tray to conduit transition. In this setup, the conduit is equipped with bushings, which protect the cables from physical damage as they enter the conduit. The bushings also provide a smooth transition, preventing any sharp edges that could damage the cable insulation. Additionally, sealed ends are used to prevent debris, moisture, or other contaminants from entering the conduit, which could potentially cause system failures or electrical hazards. This type of installation ensures the cables are protected from environmental factors and physical damage while adhering to NEC guidelines for grounding and bonding.

Flanged Connections Directly Mounted to Enclosures

Another compliant installation for a cable tray to conduit transition is the use of flanged connections mounted directly to enclosures. This method involves using flanges to secure the cable tray to the conduit or electrical enclosure, ensuring a tight and secure connection. The flanged connection ensures there are no gaps or loose fittings that could allow debris, moisture, or dirt to enter the system. This setup provides added protection against abrasion and wear and ensures that the transition point remains stable under mechanical stresses. Additionally, this installation method maintains the integrity of the grounding system, which is crucial for safety and compliance with NEC standards.

Comparison of Correct vs. Non-Compliant Setups

To better understand the differences between compliant and non-compliant cable tray to conduit transition setups, the table below highlights key factors and the advantages of adhering to NEC guidelines:

| Aspect | Correct Setup | Non-Compliant Setup |

|---|---|---|

| Description | Proper use of bushings and sealing for a smooth transition, and secure mounting. | Lacking adequate bushings, sealing, or proper mounting, leaving the system exposed. |

| Advantages of Compliance | Prevents physical damage, keeps the system clean, dry, and meets NEC grounding standards. | Risk of cable damage, grounding issues, potential moisture intrusion, and electrical hazards. |

| Bushed Conduit Installations with Sealed Ends | Cables are protected from abrasion, and moisture/debris is kept out, meeting NEC standards. | Exposed cables are at risk of damage from abrasion, moisture, or dirt, leading to system failure. |

| Flanged Connections Directly Mounted to Enclosures | Provides a stable and secure connection with protection against external damage. | Poor connection may lead to instability, potential cable wear, and non-compliance with grounding requirements. |

This comparison helps illustrate why proper cable tray to conduit transition installations are essential for maintaining the safety, reliability, and compliance of electrical systems. By following the NEC guidelines, you can ensure that your system operates efficiently and safely, preventing costly repairs or hazards down the line.

FAQs about Cable Tray To Conduit Transition

Yes, you can run cables from a cable tray into a conduit, but it’s essential to follow specific guidelines outlined in the NEC to ensure safety and compliance. The NEC allows for the transition between cable trays and conduits, especially when cables need to be protected in areas with higher risk, such as exposed environments or areas with physical hazards. When making a cable tray to conduit transition, the conduit should be properly sealed, and the cables should be securely supported to prevent any damage. The NEC specifies that when transitioning from a tray to a conduit, cables should not be subject to sharp bends, tension, or abrasion. Additionally, grounding and bonding are crucial in such transitions to ensure that the entire system remains safe and compliant with electrical standards. Cables running through a conduit from a tray must also be sized according to NEC guidelines to ensure proper electrical load and protection. In summary, while you can run cable tray wire in conduit, it must be done according to the NEC standards for safety, protection, and compliance.

Yes, conduit must be bonded to the cable tray. Proper bonding between the conduit and the cable tray ensures electrical continuity and provides a safe pathway for fault currents. Bonding connects metal parts of the system, ensuring they share the same electrical potential and preventing the buildup of dangerous voltage differences that could lead to electrical shock hazards. The NEC requires that conduits and cable trays be bonded to each other, typically at the point of transition between the tray and conduit. The bonding connection must be secure and provide low-resistance paths for fault currents, ensuring that the system can safely handle electrical faults. Failure to bond conduit and cable trays correctly could result in dangerous electrical conditions, such as unbalanced currents, electrical shock risks, or equipment failure. The NEC also specifies bonding jumpers and grounding conductors’ appropriate sizing and installation methods to ensure a safe, compliant, and reliable connection between the conduit and tray.

Installing a cable tray on a ceiling requires careful planning to ensure safety and compliance with the NEC. The first step in fixing a cable tray to the ceiling is to ensure that the ceiling can support the weight of the tray and cables. The tray should be installed using mounting brackets or supports that are appropriately spaced to prevent sagging or shifting over time. Typically, NEC guidelines recommend supports every 5 feet for lightweight trays and closer intervals for heavier or longer runs. It is essential to use the right hardware, such as ceiling anchors, threaded rods, and braces, to secure the tray firmly. Proper alignment is crucial to ensure that the tray provides stable, safe support for the cables, with enough room for airflow and cable maintenance. Additionally, the cable tray should be grounded and bonded according to the NEC guidelines to prevent electrical hazards. Lastly, the installation should be checked to ensure the tray is level and there are no sharp bends or obstacles that could damage the cables running through it.

When installing cables into conduits or cable trays, several installation parameters must be carefully considered to ensure safety, compliance with the NEC, and optimal performance of the electrical system.

Cable Sizing and Capacity: The NEC provides specific guidelines for calculating the maximum number of cables that can be installed in a conduit or tray. Overloading a tray or conduit can lead to overheating, which could compromise the safety of the electrical system. Proper cable sizing ensures that the system can handle the required electrical load and provides enough space for future expansions.

Bend Radius: Cables should not be bent at sharp angles during installation. The NEC specifies the minimum bend radius for different types of cables to prevent damage to the insulation or conductor, which could lead to failure.

Support and Securing Cables: Both conduits and cable trays must securely support the cables to prevent them from sagging or shifting. This involves using appropriate fasteners, cable ties, and supports to keep the cables in place without putting strain on them.

Grounding and Bonding: Proper grounding and bonding of cable trays and conduits is required by the NEC to ensure electrical safety. All metal components of the cable management system must be grounded and bonded to maintain a safe, low-resistance path for fault currents.

Sealing and Protection: Conduits and cable trays must be sealed at transition points to prevent debris, moisture, or dust from entering the system. Using NEC-approved sealants and fittings is essential to ensure the integrity of the electrical system and prevent the risk of electrical faults.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.