- Home

- Carbon Fiberglass

Carbon Fiberglass Materials and Differences

Carbon Fiberglass is tough and its more flexible nature enables it to withstand stress and physical abuse more easily.

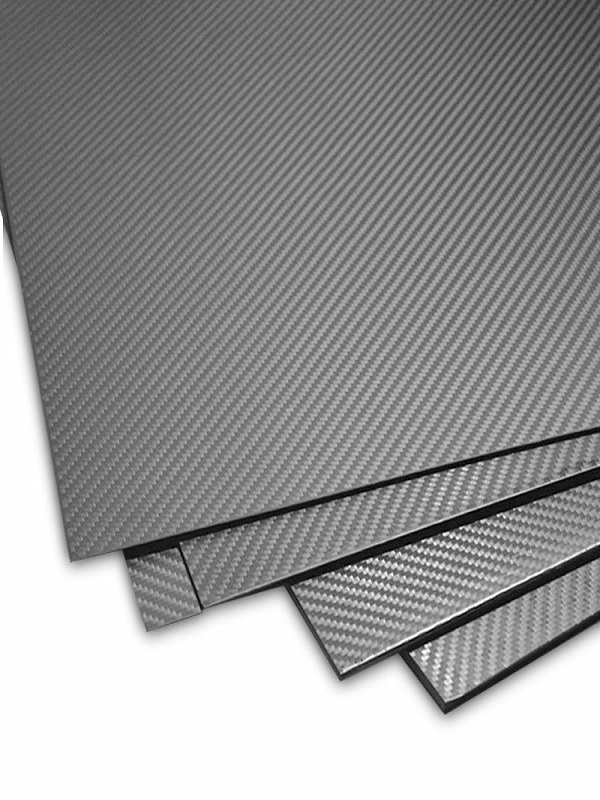

Carbon Fiberglass offers strong, lightweight stiffness of carbon fiber and flexible toughness of fiberglass for commercial applications. This material’s performance is largely driven by the fiber properties, with the fibrous reinforcement carrying most of the load. Known for its superior compressive and flexural strength, Carbon Fiberglass provides the highest strength-to-weight ratio available, surpassing other reinforcements and many traditional building materials.

Its sleek, black appearance adds an aesthetic edge, making it a popular choice in high-performance applications like aerospace, automotive, and sports equipment. However, it’s worth noting that Carbon Fiberglass is generally more expensive and can fail suddenly without warning when it reaches its strength limit.

The unique characteristics of Carbon Fiberglass make it suitable for applications requiring low weight and high stiffness. When compared to other materials like Fiberglass Fabric Cloth or Chopped Strand Mat, which also offer valuable properties for composite construction, Carbon Fiberglass stands out for its high strength and resistance to environmental factors.

Simplifying Your Life: Key Functionalities

| Attribute | Details |

|---|---|

| Product Name | Carbon Fiberglass Fabric |

| Material | 100% Carbon Fiber, Carbon/Fiberglass Hybrid |

| Weave Type | Twill, Plain, Stripe, 3D |

| Weight Range | 200gsm - 300gsm |

| Thickness | Lightweight to Very Lightweight |

| Width | 50cm - 150cm (Customizable) |

| Length | 100m per roll (Customizable) |

| Shape | Roll |

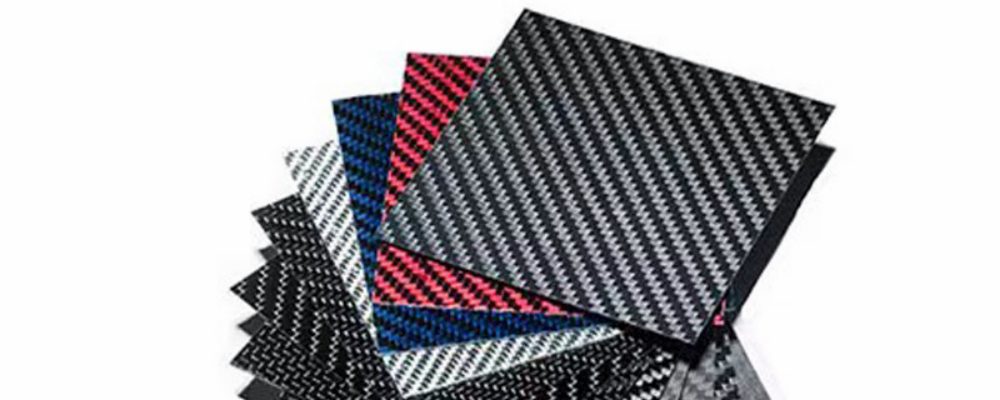

| Color Options | Black, Gold, Custom |

| Surface Treatment | Electroplated, Plating, Special Coating |

| Key Features | Abrasion-Resistant, Waterproof, Anti-static, Heat-Insulation, Flame Retardant, Chemical-Resistant, Radiation-Resistant, Stretchable |

| Usage | Automotive, Sports Equipment, Fishing Tackle, Bags & Luggage, Apparel-Workwear, Outdoor-Tents, Industry, Home Décor, Fashion Accessories, Hospital, Shoes |

| Place of Origin | Hebei, China |

| Brands | GangLong Fiberglass |

| MOQ | 10 meters |

| Packaging | Carton Box, Roll |

| Delivery Time | 3-10 days |

News

- Exploring the Benefits of Carbon Fiber Apparel

- How to Work with Carbon Fiber Successfully

- Carbon Fiber Suit: The Future of Lightweight Armor

- Is Carbon Fiber Armor the Future of Protection?

- Why White Carbon Fiber is Popular in Automotive Design

- Transparent Carbon Fiber Sheets Two Sided Gloss Twill

- Epoxy-Compatible Chopped Carbon Fiber Mat

- Carbon Fiber EG Hatch: Upgrade Your Civic Today

- The Benefits of Using Structural Carbon Fibre in Engineering

- How Many Layers of Layered Carbon Fiber Are Needed?

What is Carbon Fiberglass?

Carbon fiberglass is a specialized composite material that combines the unique properties of carbon fiber and fiberglass. This fusion creates a material that leverages the strengths of both components to achieve a superior balance of strength, durability, and weight.

Definition and Composition

Carbon fiberglass is a composite material that integrates carbon fiber and fiberglass into a single, highly effective material. The primary components of carbon fiberglass are:

- Carbon Fiber: Carbon fibers are thin, strong crystalline filaments of carbon that have remarkable strength-to-weight ratios. They are renowned for their high tensile strength and stiffness, which makes them ideal for applications requiring high strength and low weight.

- Fiberglass: Fiberglass is made from fine fibers of glass and is known for its durability, flexibility, and resistance to corrosion. It is often used to reinforce other materials to improve their mechanical properties.

The production of carbon fiberglass sheets involves several key processes: The manufacturing process begins with sourcing and preparing both carbon fibers and fiberglass. Carbon fibers are created by oxidizing and carbonizing polyacrylonitrile (PAN) fibers at high temperatures in an inert environment. This results in extremely strong, lightweight strands. Fiberglass is produced by melting silica-based glass and drawing it into fine continuous filaments. Both materials must be inspected and classified before integration. Proper fiber quality is essential for mechanical strength and structural performance in the final composite product. After preparation, carbon fibers and fiberglass are woven into fabric using controlled patterns. Common weaves include plain, twill, and satin, each offering unique combinations of flexibility, strength, and surface smoothness. The carbon fiber part of the weave may be used alone or combined with fiberglass, depending on performance requirements. Consistent tension during weaving ensures dimensional stability. The woven fabrics are rolled and stored carefully to prevent distortion or contamination before they are laminated into composite sheets. Woven fabrics are layered according to design specifications and then saturated with a thermosetting resin, typically epoxy. The layering sequence, known as lay-up, determines the final mechanical properties, such as strength, thickness, and stiffness. Resin is applied manually or via infusion to bond the layers together. Air bubbles are removed using rollers or vacuum bagging to prevent voids. The lamination process is critical, as it defines the composite’s structural reliability and environmental resistance under long-term stress. Once laminated, the composite sheet undergoes a curing process to solidify the resin matrix. This typically involves heating in an autoclave or industrial oven under controlled temperature and pressure. The resin crosslinks and hardens, permanently locking the fiber layers together. Time, temperature, and pressure must be precisely managed to avoid under-curing or warping. Proper curing enhances tensile strength, impact resistance, and dimensional stability. Incomplete or uneven curing can result in defects like cracking, delamination, or surface deformation. After curing, the rigid carbon fiberglass sheets are removed, cooled, and processed to meet final product requirements. Trimming removes excess material from edges, while sanding or polishing refines the surface for visual clarity or bonding. Dimensional tolerances are verified through inspection. In some cases, surface coatings are applied for UV protection, chemical resistance, or improved bonding. The finished sheets are then packaged and stored or shipped for use in aerospace, marine, sporting goods, or structural engineering industries.Typical Manufacturing Processes Used to Create Carbon Fiberglass Sheets

Material Preparation

Weaving

Layering and Lamination

Curing

Finishing

Carbon Fiberglass Properties

Carbon fiberglass exhibits a range of properties that make it a highly desirable material for various applications. These properties stem from the unique combination of carbon fiber and fiberglass, which together create a material with exceptional characteristics.

Strength and Durability

Carbon fiberglass offers impressive strength and durability by combining two materials. Carbon fibers provide a high strength-to-weight ratio, while fiberglass enhances toughness and impact resistance. Together, they create a composite that resists deformation and distributes stress evenly. This makes carbon fiberglass ideal for use in demanding environments where both structural integrity and long-term durability are essential, such as marine, automotive, or industrial applications.

Flexibility and Rigidity

Carbon fiberglass maintains a balance between stiffness and controlled flexibility. Carbon fibers contribute to the rigidity needed for structural performance and dimensional stability, while fiberglass allows for limited bending without breaking. This combination enables the material to handle stress while adapting to varying loads. It’s especially useful in aerospace and sporting goods where strength must be combined with slight flexibility and vibration tolerance.

Carbon fiberglass sits between pure carbon fiber and fiberglass in terms of weight. It’s heavier than carbon fiber but lighter than fiberglass, offering an ideal middle ground. This balanced weight-to-strength ratio allows for strong yet relatively lightweight structures. Industries like automotive, aerospace, and high-performance equipment benefit from this balance, as it helps reduce total weight without sacrificing durability or reliability under stress. Carbon fiberglass performs well under extreme temperatures and harsh chemical conditions. The carbon fiber component provides thermal stability, while fiberglass improves resistance to acids, alkalis, and solvents. This combination helps the composite maintain its structure and function in corrosive or high-heat environments. As a result, it’s widely used in heat-exposed or chemically demanding applications like engine bays or industrial settings.Weight and Density

Thermal and Chemical Resistance

Carbon Fiberglass Size

Carbon fiberglass size refers to a special chemical coating or treatment applied to carbon or fiberglass fibers. This coating plays a crucial role in ensuring that the fibers bond properly with resins or other materials during the manufacturing of composite materials. Here’s a more detailed explanation:

What is Carbon Fiberglass Size?

“Size” is a protective and bonding agent that is applied to carbon or fiberglass filaments during their production process. It is typically a resin or chemical solution that helps the fibers maintain their integrity and performance when woven into fabrics or used in composite structures.

Purpose of Carbon Fiberglass Size

Protecting the Fibers

Carbon and fiberglass fibers are extremely delicate and can easily break or become damaged during processing, handling, or when exposed to environmental factors like moisture or UV radiation. The size provides a layer of protection, preventing the fibers from damage.

Enhancing Fiber-Resin Bonding

In the creation of composite materials (e.g., carbon fiber reinforced plastic or fiberglass reinforced plastic), the fibers need to bond effectively with the resin. The size ensures that there is better adhesion between the fiber and the matrix (resin), which is crucial for the mechanical properties of the finished product. Without proper bonding, the composite material may fail under stress.

Improved Processability

The size improves the handling characteristics of the fibers, making them easier to weave, braid, or process into various forms like prepregs, rovings, or fabrics. This ensures that the fibers do not fray or break during the manufacturing process.

Optimizing Mechanical Performance

The right size can also influence the mechanical properties of the final composite, such as strength, flexibility, or heat resistance. This is especially important in high-performance applications like aerospace, automotive, and sporting goods, where the materials must meet strict performance criteria.

Types of Sizes

The composition of the size depends on the intended application and the type of fiber used:

- Epoxy-based Size: Commonly used for carbon fiber composites, as epoxy resins offer strong adhesion to carbon fibers and excellent mechanical properties.

- Polyester or Vinyl Ester-based Size: Typically used for fiberglass fibers, these resins offer good bonding and are cost-effective for applications like boat hulls and certain automotive parts.

- Silane-based Size: Silanes are often used as coupling agents to enhance the bond between fibers and resins, particularly in the case of fiberglass.

Impact of Incorrect Sizing

- Weak Bonding: If the size is inadequate or improperly applied, it can lead to poor bonding between the fibers and the resin, resulting in lower overall strength and durability of the composite.

- Fiber Damage: Improperly sized fibers may become brittle or break during processing, leading to a loss of material integrity and defects in the final product.

- Process Issues: Without the right size, fibers might be difficult to handle, leading to issues like fraying or difficulty in weaving, which complicates production processes.

Carbon fiberglass size is a critical component in the manufacture of composite materials, as it ensures fiber protection, proper bonding with resins, and overall quality in the final product. Different sizes are chosen based on the type of fiber, the desired properties of the composite, and the application in which it will be used.

Carbon Fiberglass Strength

Carbon fiberglass strength refers to the mechanical strength characteristics of composite materials made from carbon fibers and fiberglass. These materials combine the unique properties of carbon fibers and fiberglass to create a high-performance material with superior strength-to-weight ratios, making them ideal for demanding applications in aerospace, automotive, sports, and industrial fields.

Strength of Carbon Fiber

Carbon fiber itself is known for its exceptional strength and stiffness, along with its low weight. The key aspects of carbon fiber strength include:

- Tensile Strength: Carbon fiber has very high tensile strength, meaning it can withstand a significant amount of stretching or pulling force before breaking. Tensile strength values for carbon fibers can range from 2,000 MPa (megapascals) to 6,000 MPa, depending on the type of fiber (standard modulus, intermediate modulus, or high modulus).

- Compressive Strength: Carbon fibers also possess good compressive strength, but they are typically more susceptible to buckling under compression compared to other materials like steel or aluminum.

- Stiffness (Modulus of Elasticity): Carbon fibers are also very stiff (high modulus of elasticity), which means they resist deformation under stress. This is crucial for applications where rigidity is required, such as in aerospace or structural components.

Strength of Carbon Fiberglass Composites

When carbon fiber and fiberglass are combined into a single composite material, they create a hybrid that can offer enhanced properties from both fibers:

Strength-to-Weight Ratio

Carbon fiberglass composites typically have an excellent strength-to-weight ratio, making them ideal for applications that require both strength and reduced weight. This is particularly valuable in industries like aerospace, automotive, and sports equipment, where lightweight but strong materials are crucial.

Balanced Properties

By blending carbon fibers with fiberglass, manufacturers can achieve a balance between the high strength and stiffness of carbon fiber and the flexibility and impact resistance of fiberglass. This results in a composite material that is both strong and tough, making it more versatile than either fiber alone.

Layering for Performance

In composite materials, carbon and fiberglass can be layered to optimize strength. For example, the outer layers might be carbon fiber for strength and stiffness, while the inner layers could be fiberglass for improved impact resistance and cost-effectiveness.

Factors Affecting Strength

The strength of carbon fiberglass composites depends on various factors, including:

- Fiber Content: The ratio of carbon fiber to fiberglass in the composite material influences its overall strength. Higher carbon fiber content typically results in higher strength and stiffness.

- Resin Matrix: The type and quality of the resin (epoxy, polyester, vinyl ester, etc.) used to bind the fibers together also plays a significant role in the material’s strength. Epoxy resins, for example, are known for their strong bonding capabilities and high mechanical properties.

- Manufacturing Process: The way the composite is manufactured (e.g., hand lay-up, filament winding, prepreg, or resin transfer molding) affects the alignment and bonding of the fibers, which can influence the final strength of the material.

- Orientation of Fibers: The orientation of the fibers in the composite affects its strength in different directions. For example, if the fibers are aligned in the direction of the load, the composite will be stronger in that direction. Multi-directional layups can help achieve strength in multiple directions.

Carbon fiberglass composites offer a unique combination of high strength, stiffness, and toughness, making them ideal for applications requiring a lightweight yet durable material. By leveraging the strengths of both carbon fiber and fiberglass, manufacturers can optimize their performance characteristics for specific needs, offering a balance between cost and high-end strength and impact resistance. The result is a versatile material that excels in industries ranging from aerospace to sports equipment.

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.

Carbon Fiberglass Price

Understanding the pricing of carbon fiberglass involves considering various factors that influence its cost. These factors can vary widely depending on the specifics of the material and its intended use.

Pricing Factors

Several key factors influence the price of carbon fiberglass:

Production Complexity

The manufacturing process for carbon fiberglass is more complex than for standard fiberglass. This complexity includes the preparation of carbon fibers, the weaving process, and the curing of the composite. The advanced technology and equipment required for producing high-quality carbon fiberglass contribute to its higher cost.

The quality of the raw materials used in carbon fiberglass affects its price. Higher-grade carbon fibers and resins result in better performance characteristics and durability, which are reflected in the cost. Premium materials typically lead to a higher price point for the final product. Demand for carbon fiberglass in various industries such as aerospace, automotive, and sports equipment can drive up prices. When demand is high and supply is limited, prices tend to increase. Conversely, in periods of lower demand, prices may stabilize or decrease. The price range for carbon fiberglass products can vary based on their type, size, and application. Here are some general price ranges: Comparing the cost of carbon fiberglass with other composite materials provides insight into its value relative to alternatives:Material Quality

Market Demand

Price Range

Cost Comparison

The Differences between Fiberglass and Carbon Fiberglass

The main differences between fiberglass and carbon fiberglass (also known as carbon fiber reinforced fiberglass) stem from the materials themselves—carbon fiber and fiberglass—and their resulting properties. While both are used in composite materials, they offer distinct advantages and are suitable for different applications based on their specific characteristics.

| Category | Fiberglass | Carbon Fiberglass |

|---|---|---|

| Material Structure | Glass fibers + resin | Carbon fiber + fiberglass + resin; combines both strengths |

| Strength & Stiffness | Moderate strength, flexible | Higher strength and stiffness; better load resistance |

| Weight | Lightweight but heavier than carbon fiber (2.5–2.7 g/cm³) | Lighter overall (1.9–2.3 g/cm³); better strength-to-weight ratio |

| Flexibility | More flexible and impact-absorbing | Stiffer, but retains some toughness due to fiberglass |

| Durability & Fatigue | Good fatigue and impact resistance; sensitive to UV and moisture | Better fatigue resistance; more UV, heat, and corrosion resistant |

| Cost | Low-cost; suitable for budget-conscious applications | Higher cost; used in high-performance industries |

| Common Uses | Boats, construction, basic automotive parts | Aerospace, racing, sports gear, advanced automotive parts |

| Environmental Impact | Non-biodegradable; moderate energy use; limited recyclability | Higher energy footprint; recycling is difficult and less developed |

Choosing the Right Carbon Fiberglass

Choosing the right carbon fiberglass composite material for your application depends on various factors, including performance requirements, cost considerations, environmental conditions, and manufacturing capabilities. Here’s a detailed guide to help you select the most appropriate carbon fiberglass based on key factors:

Determine the Application Requirements

When selecting carbon fiberglass, start by identifying your specific project needs. Think about required tensile strength, impact resistance, and flexibility. Will the part be exposed to heat, chemicals, or outdoor elements? Is weight a top priority, like in aerospace or automotive? By clearly defining environmental and performance demands, you can narrow down the options and find the most appropriate composite structure for your intended application.

Balance Between Carbon Fiber and Fiberglass Content

The ratio between carbon fiber and fiberglass significantly impacts the final composite’s performance. High carbon fiber content increases strength and stiffness but comes at a higher cost. A balanced mix offers durability and impact resistance. Lower carbon content helps reduce price but also reduces performance. Your optimal choice depends on the balance you need between cost, rigidity, and flexibility for your project.

Select the Right Resin Matrix

The resin used to bind the fibers plays a vital role in performance and durability. Epoxy resins offer strong bonding and heat resistance but are more expensive. Polyester resins are cheaper and commonly used, though they degrade faster in harsh environments. Vinyl ester resins are a middle ground, providing solid strength and excellent chemical resistance at a moderate price point.

Consider Environmental and Service Conditions

Understanding environmental stress factors is essential when choosing carbon fiberglass. Extreme temperatures, UV exposure, chemicals, and moisture all affect long-term durability. For outdoor or marine applications, select resins that resist degradation. Epoxy and vinyl ester perform better than polyester in harsh conditions. Also consider coatings or additives to enhance UV and chemical resistance.

Manufacturing Process and Design Flexibility

Your production method affects both cost and performance. Hand lay-up is simple and cheap, great for low-volume parts. Prepreg lay-up ensures precision and is used in high-end industries. Resin transfer molding suits consistent, large-scale production. Filament winding works best for cylindrical items, while compression molding is preferred for producing complex shapes in larger volumes.

Performance Criteria to Consider

To ensure your composite meets demands, evaluate tensile strength, impact resistance, and flexural performance. Also assess fatigue resistance for parts that experience repeated loads. High carbon content generally increases tensile and flexural strength, while fiberglass improves impact resistance. Choose a well-balanced composite with a strong resin bond to ensure performance under real-world stress.

Cost Considerations

Material costs vary based on fiber content, resin type, and production method. More carbon fiber means higher cost. Epoxies are pricier but offer better performance. Manufacturing methods like prepreg and autoclave curing also add expense. For non-critical or budget-limited projects, opt for lower carbon content and simpler production techniques to reduce total material costs.

Testing and Certification

For regulated industries, composite materials must meet strict standards. Ensure materials pass ASTM or ISO testing for strength and durability. Use certified products, especially for aerospace or automotive applications. Meeting testing criteria guarantees that the material performs safely and consistently under the intended load and environmental conditions.

Purchase High-Strength, Lightweight Carbon Fiberglass

Carbon fiber is an exceptionally strong, lightweight, and rigid material made from fine, durable carbon crystalline filaments. Produced through a process of heating and stretching carbon strands, these fibers are woven together to create high-performance fabrics. Known for their superior strength-to-weight ratio, carbon fiber materials are widely used in aerospace, marine, automotive, sports equipment, and high-end consumer products where strength and weight reduction are critical.

Versatile Forms of Carbon Fiber Materials

Carbon fiber is available in multiple forms, including:

- Woven Fabrics – Offers excellent strength and flexibility for structural applications.

- Braided Sleeves & Tow – Ideal for reinforcing complex shapes and structures.

- Unidirectional Sheets – Provides high tensile strength in one direction for precision applications.

- Carbon Fiber Tape – Used for targeted reinforcement and repairs.

These materials are commonly combined with resins or metals to create composite materials with enhanced mechanical properties, replacing traditional steel and aluminum components in lightweight structural applications.

Key Benefits of Our Carbon Fiberglass Materials

High Strength-to-Weight Ratio

Our carbon fiberglass materials offer outstanding rigidity while maintaining a lightweight profile. This makes them perfect for applications where strength is critical but added weight is not acceptable. Whether you’re designing aerospace parts, automotive components, or sports equipment, this high strength-to-weight ratio ensures your structure stays durable without compromising speed, agility, or fuel efficiency.

Waterproof & Corrosion-Resistant

Built to perform in harsh environments, our carbon fiberglass composites are both waterproof and highly resistant to corrosion. This makes them a reliable choice for marine vessels, coastal construction, and automotive parts exposed to rain, humidity, or saltwater. They maintain structural integrity over time, even when exposed to challenging outdoor or chemical-rich conditions.

Aerodynamic Properties

Designed with performance in mind, our carbon fiberglass materials offer smooth surfaces and low drag characteristics. This aerodynamic advantage helps improve speed and efficiency in vehicles, aircraft, and sporting equipment. When airflow matters, our composites deliver reduced resistance and increased control, making them ideal for high-speed or high-performance applications.

Thermal & Electrical Conductivity

These materials exhibit excellent thermal and electrical conductivity, making them suitable for use in advanced electronics, energy systems, and heat-sensitive environments. From battery enclosures to heat shields and circuit support structures, carbon fiberglass delivers functionality where both strength and conductivity are essential to system performance.

Structural Reinforcement

Our carbon fiberglass is engineered for superior load-bearing capabilities, making it ideal for reinforcing frames, panels, and other structural components. It’s widely used in aerospace, motorsports, and athletic gear to enhance durability without adding weight. When structural integrity and performance are both required, our composites provide the ultimate solution.

Ideal Applications

- Aerospace & Automotive – Enhances performance while reducing weight.

- Marine Engineering – Provides durability and corrosion resistance.

- Sports Equipment – Used in bicycles, golf clubs, and racing gear.

- Consumer Electronics – Creates sleek, high-tech, and durable designs.

Ganglong Fiberglass ensures that every carbon fiber product is engineered for precision, durability, and peak performance. Whether you need lightweight reinforcements, customized woven patterns, or structural composite solutions, we offer top-tier materials at competitive prices.

Contact us today to explore our carbon fiberglass materials and find the best solution for your project!

FAQs about Carbon Fiberglass

Is carbon fiber stronger than fiberglass?

Can carbon fiber stop a bullet?

What's stronger, Kevlar or carbon fiber?

Is Kevlar carbon fiber bulletproof?

Is fiberglass as strong as Kevlar?

Is carbon fiber actually stronger than steel?

Why does carbon fiber cost so much?

How to tell carbon fiber from fiberglass?

Why is carbon fiber so tough?

What is the strongest composite material?

Is carbon fiber stronger than leather?

Can carbon fiber and fiberglass be used together?

Why can't you touch carbon fiber?

Is Kevlar stronger than fiberglass?

Why is carbon fiber not used more?

What fiberglass looks like carbon fiber?

Is carbon fiber resin the same as fiberglass resin?

Can you use carbon fiber without resin?

How can you tell fiberglass from carbon fiber?

Can you build a house with carbon fiber?

What is carbon fiber fiberglass?

Is carbon fiber cheaper than fiberglass?

What is the best epoxy to use with carbon fiber?

Does carbon fiber do well with heat?

What is carbon fiber used for?

What are the disadvantages of carbon fiber?

Cost: Carbon fiber is expensive to produce and work with, which limits its use to high-end or critical applications.

Brittleness: Carbon fiber composites can be brittle, making them more prone to cracking or shattering under certain types of stress, such as impact or sharp blows.

Complex manufacturing process: Working with carbon fiber requires specialized techniques, equipment, and expertise, which increases the complexity and cost of manufacturing.

Repairability: If a carbon fiber structure is damaged, it is often difficult and costly to repair. In some cases, the entire part may need to be replaced.

Is carbon fiber stronger than steel?

Why is carbon fiber so expensive?

Is carbon fiber safe for humans?

Why do car guys love carbon fiber?

Is carbon fiber waterproof?

Why do people buy carbon fiber?

What is the difference between fiberglass and carbon fiber?

What is the strongest material for a car?

Where is carbon fiber most used?

Is fiberglass or carbon fiber hull better?

What is the longest lasting hull material?

What is the strongest type of fiberglass?

What is the lifespan of a fiberglass hull?

Which type of hull is most efficient?

Is fiberglass stronger than Kevlar?

Is there a better material than carbon fiber?

What are the pros and cons of fiberglass vs carbon fiber?

Cost-Effective: Much cheaper than carbon fiber.

Durability: Good impact resistance and long lifespan.

Easier to Repair: Repairs are less costly and more straightforward.

Widely Available: Easier to source and work with.

Cons of Fiberglass:

Heavier: Heavier than carbon fiber, leading to lower performance in speed and fuel efficiency.

Lower Strength: Not as strong or stiff as carbon fiber.

Pros of Carbon Fiber:

Lightweight: Much lighter than fiberglass, improving speed and efficiency.

High Strength and Stiffness: Superior tensile strength and rigidity.

Aesthetic Appeal: High-tech appearance and often used in luxury or high-performance products.

Cons of Carbon Fiber:

Expensive: Significantly more costly than fiberglass.

Brittle: Can be more prone to cracking under sharp impacts.

Difficult to Repair: Repairs are more complex and expensive.

Is carbon fiber good for boats?

What material is better than fiberglass?

What weakens fiberglass?

UV Exposure: Prolonged exposure to sunlight can degrade the resin, leading to weakening and brittleness.

Moisture Infiltration: Water ingress can cause delamination and degradation of the resin matrix.

Physical Damage: Impact or stress can cause cracks, which may spread and weaken the structure.

Chemical Exposure: Certain chemicals, including some solvents and fuels, can degrade the resin and weaken the fiberglass composite.

Poor Maintenance: Lack of regular maintenance, such as cleaning and inspection, can lead to gradual deterioration.

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.