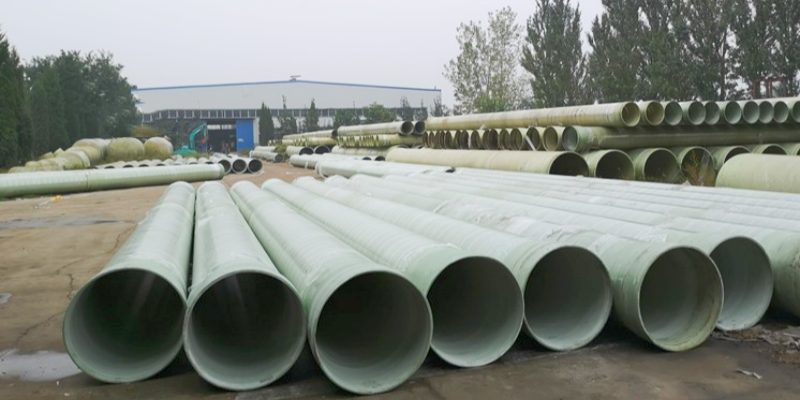

Fibercast FRP pipe is known for its exceptional durability and corrosion resistance, making it a top choice for industries like chemical processing, water treatment, and oil and gas. This fiberglass reinforced pipe is engineered to withstand harsh environments and corrosive substances, ensuring long-lasting performance. Fibercast FRP pipe offers a reliable solution for industries that require high-quality piping systems capable of handling aggressive chemicals and extreme conditions. Its lightweight design also allows for easier installation compared to traditional metal pipes, FRP pipe sleeve reducing labor costs and downtime. With its proven track record in industrial applications, Fibercast FRP pipe continues to be a trusted option for industries demanding both resilience and reliability in their piping infrastructure.

What is Fibercast FRP Pipe?

Fibercast FRP pipe, known for its durability and resistance to corrosion, is commonly used in various industries. This type of pipe is made from fiber-reinforced plastic (FRP), a composite material consisting of a polymer matrix reinforced with fibers, such as glass. Fibercast FRP pipe is especially valued in applications where chemical resistance and mechanical strength are paramount, providing an efficient solution for fluid transportation in both industrial and commercial environments. The unique composition of Fibercast FRP pipe makes it lightweight, strong, and resistant to a wide range of chemicals, making it a preferred choice for many industries, including wastewater treatment, chemical processing, and power generation.

Fibercast FRP pipes are manufactured through advanced processes that ensure the final product is able to withstand harsh conditions. The combination of resin and fiberglass layers creates a robust structure capable of handling high pressures and temperatures. Because of these qualities, Fibercast FRP pipe is often utilized in underground and above-ground installations, as well as in environments where metal pipes may corrode or fail.

The Key of Fibercast FRP Pipe Composition

The composition of Fibercast FRP pipe includes several key elements that contribute to its superior performance. The pipe’s main structure consists of layers of fiberglass, which are bonded together by a resin matrix. The resin matrix, typically made from polyester, vinyl ester, or epoxy, serves as the glue that holds the fiberglass layers together. This combination provides the pipe with excellent mechanical properties, including strength, flexibility, and impact resistance.

The specific type of resin used in the construction of Fibercast FRP pipe can vary depending on the application. This choice of resin is crucial as it directly influences the FRP Pipe tensile strength, impacting the pipe’s overall performance and durability in various environments. By selecting the appropriate resin, manufacturers can optimize the tensile strength and ensure that the FRP pipe meets the demands of its intended use. For example, vinyl ester resin is often used in environments where the pipe will be exposed to highly corrosive chemicals, while epoxy resin is preferred for applications requiring high heat resistance. The choice of resin is crucial to ensuring that the pipe meets the specific demands of the application.

Fibercast FRP pipe also benefits from the use of high-quality fiberglass. The fiberglass used in these pipes is typically woven into mats or chopped into strands, which are then layered within the resin matrix. This layering technique allows the pipe to distribute stress evenly, preventing cracks and other forms of damage from propagating. As a result, Fibercast FRP pipe offers a long service life and requires minimal maintenance, even in challenging environments.

What is Fibercast FRP Pipe Durability?

The durability of Fibercast FRP pipe is one of its most significant advantages, making it a reliable choice for long-term use in demanding industries. The combination of fiberglass and resin creates a pipe that is not only strong but also resistant to wear and tear. This durability is particularly important in industries where the pipe may be exposed to aggressive chemicals, extreme temperatures, or high pressures.

Fibercast FRP pipe’s resistance to corrosion is another factor that contributes to its durability. Unlike metal pipes, which can rust and degrade over time when exposed to moisture and chemicals, Fibercast FRP pipe remains unaffected by such conditions. This makes it an ideal choice for use in environments where corrosion is a concern, such as chemical processing plants, oil refineries, and wastewater treatment facilities.

In addition to its resistance to corrosion, Fibercast FRP pipe is also highly resistant to abrasion. This makes it suitable for transporting abrasive materials, such as slurries or particulate-laden fluids, without the risk of the pipe’s interior surface becoming damaged over time. The smooth inner surface of the pipe also helps to reduce friction, which can improve flow rates and reduce energy costs.

Reinforced Fibercast FRP Pipe Systems

Reinforced Fibercast FRP (Fiberglass Reinforced Plastic) Pipe Systems are advanced piping solutions designed to offer superior performance in a wide range of industrial applications. These systems are engineered using a composite material made of fiberglass reinforcements embedded in a thermosetting resin matrix. This combination provides exceptional mechanical strength, chemical resistance, and durability, making them a preferred choice for demanding environments.

Key Features of Fibercast FRP Pipe Systems

High Strength-to-Weight Ratio

Fibercast FRP (Fiber Reinforced Plastic) pipes are known for their exceptional strength-to-weight ratio. Despite their lightweight design, these pipes deliver impressive mechanical strength, which ensures that they can withstand high pressure and stress without compromising their structural integrity. This feature significantly reduces the challenges associated with transporting and installing heavy pipes, making Fibercast FRP pipes ideal for a range of industrial applications, particularly in environments where ease of handling and installation is crucial.

Corrosion Resistance

One of the standout features of Fibercast FRP pipes is their superior resistance to corrosion. Unlike traditional metal pipes, which are vulnerable to rust and degradation when exposed to chemicals, acids, alkalis, or seawater, FRP pipes remain unaffected in harsh environments. This resistance to corrosion ensures that the pipes maintain their structural integrity over time, leading to longer service life and reduced need for replacement. This makes them highly suitable for industries such as chemical processing, wastewater treatment, and marine applications, where exposure to aggressive substances is common.

Thermal and Electrical Insulation

Fibercast FRP pipes are non-conductive, which makes them an excellent choice for both thermal and electrical insulation. Their insulating properties help in reducing the risk of electrical hazards in high-voltage environments, making them a safe option for applications in power plants, industrial plants, and other electrical infrastructure. Additionally, the thermal insulation properties of FRP pipes help to protect sensitive fluids from temperature fluctuations, ensuring that the temperature within the pipes remains stable, even in extreme conditions.

Customizable Design

Fibercast FRP pipes offer exceptional design flexibility, allowing them to be tailored to meet specific project requirements. Whether it is varying the diameter or length of the pipes or selecting specific pressure ratings to accommodate different pressure levels, the customization options are virtually limitless. The choice of resin types can be further adjusted based on the chemical or environmental conditions of the intended application, such as resistance to certain chemicals or temperature extremes. This level of customization ensures that Fibercast FRP pipes can provide the perfect solution for any project, no matter how demanding.

Ease of Installation

The lightweight nature of Fibercast FRP pipes not only makes them easy to transport but also simplifies the installation process. These pipes are compatible with a variety of joining methods, including adhesive bonding, threaded connections, and flanged joints, all of which allow for quick and efficient installation. As a result, the time and labor costs associated with installation are significantly reduced, making Fibercast FRP pipes a cost-effective solution for a wide range of industries. Their versatility in installation methods further contributes to their popularity in both new construction and maintenance projects.

Low Maintenance Requirements

Thanks to their durability and resistance to issues like fouling, scaling, and corrosion, Fibercast FRP pipes require minimal maintenance over their service life. This significantly lowers long-term maintenance costs, as there is little need for repairs or replacements. The inherent longevity of these pipes also reduces the frequency of inspections and downtime, which is especially beneficial in industries that rely on continuous operations, such as oil and gas, water treatment, and chemical processing.

Applications of Fibercast FRP Pipe Systems

Chemical Processing Plants

Fibercast FRP pipes are widely used in chemical processing plants due to their exceptional resistance to a broad range of corrosive chemicals, acids, and alkalis. These pipes are capable of transporting highly aggressive substances without degradation, ensuring a safe and reliable transport system. The ability to withstand harsh chemical environments makes Fibercast FRP pipes an ideal solution for applications such as chemical reactors, waste management systems, and the transfer of hazardous chemicals. Their longevity and minimal maintenance needs provide a cost-effective and efficient alternative to traditional metal piping systems, which are prone to corrosion and wear.

Water and Wastewater Management

In water and wastewater management, Fibercast FRP pipes are used extensively due to their robust durability and resistance to microbial growth. These pipes are ideal for potable water systems, desalination plants, and sewage pipelines, where contamination and leaks can have severe consequences. Fibercast FRP pipes are non-reactive to most waterborne pathogens, making them an excellent choice for maintaining water quality. Additionally, their resistance to scaling and fouling helps reduce maintenance costs and system downtime. Whether transporting fresh water to urban areas or managing industrial wastewater, these pipes ensure reliability and extend the service life of critical infrastructure.

Oil and Gas Industry

Fibercast FRP pipe systems are indispensable in the oil and gas industry, particularly for applications requiring resistance to high pressure, high temperatures, and corrosive substances. These pipes are commonly used for transporting crude oil, natural gas, and refined products in both onshore and offshore settings. Their ability to withstand extreme conditions makes them suitable for pipelines, offshore platforms, and refineries. The flexibility of FRP systems allows for the creation of custom-designed solutions tailored to specific operational needs, including offshore risers and subsea pipelines. Furthermore, the lightweight nature of FRP pipes reduces the structural load on offshore platforms, contributing to cost savings in installation and operation.

Power Plants

Fibercast FRP pipes are well-suited for use in power plants due to their resistance to thermal expansion, corrosion, and the highly abrasive nature of materials commonly encountered in these environments. In cooling water systems, which require pipes that can handle fluctuating temperatures and harsh chemical treatments, FRP pipes provide a reliable, long-lasting solution. They are also used in flue gas desulfurization systems, where their resistance to acidic gases and high temperatures ensures minimal degradation over time. By reducing maintenance and extending service life, FRP systems offer power plants a cost-effective solution for piping that meets the demands of modern energy production.

Marine and Offshore Applications

The marine and offshore sectors greatly benefit from the unique properties of Fibercast FRP pipes, particularly their resistance to saltwater corrosion. These pipes are essential in applications such as ballast water systems, seawater intake and discharge systems, and offshore oil rigs, where durability in challenging marine environments is a must. The non-corrosive nature of FRP ensures the longevity of piping systems exposed to harsh coastal and offshore conditions. Additionally, the lightweight nature of FRP pipes makes them easier to handle and install in offshore environments, where weight reduction can be crucial. Their ability to withstand the rigors of saltwater environments while maintaining structural integrity makes them an invaluable component of marine infrastructure.

Key Advantages of Fibercast FRP Pipe

Corrosion Resistance

One of the most significant advantages of Fibercast FRP pipes is their outstanding resistance to corrosion. Unlike traditional metal pipes, which are susceptible to rust and degradation when exposed to chemicals, moisture, and other corrosive substances, FRP pipes maintain their structural integrity in aggressive environments. This makes them ideal for industries such as chemical processing, water treatment, marine, and wastewater management, where the pipeline is exposed to harsh substances or corrosive elements.

Lightweight

Fibercast FRP pipes are considerably lighter than metal or concrete pipes, making them easier to transport, handle, and install. This lightweight nature significantly reduces installation time and labor costs, which can be particularly advantageous for large-scale infrastructure projects. Additionally, the ease of handling minimizes the risk of damage during installation, ensuring that the pipes maintain their quality throughout the project.

Durability

Fibercast FRP pipes offer exceptional durability due to the combination of fiberglass and resin. This makes them highly resistant to wear and tear, even in abrasive environments or where exposure to harsh chemicals is common. Their durability ensures a longer lifespan compared to traditional piping materials such as steel and concrete, which are more prone to damage and degradation over time. This long-lasting performance makes FRP pipes a reliable solution for demanding industrial applications, reducing the need for frequent replacements and repairs.

Low Maintenance

Fibercast FRP pipes require minimal maintenance, which significantly lowers long-term operational costs. The resistance of FRP pipes to corrosion, fouling, and scaling means that they do not require regular maintenance interventions or costly repairs. In contrast, metal pipes often need extensive maintenance to prevent rust or degradation. By reducing the need for ongoing maintenance, FRP pipes help extend the lifespan of a fluid transportation system, ultimately lowering lifecycle costs.

Versatility

Fibercast FRP pipe systems are highly versatile and can be customized for a wide range of applications. They are available in various sizes, pressure ratings, and configurations, allowing them to meet the specific requirements of diverse industries such as chemical processing, marine environments, energy production, and water management. Whether transporting corrosive chemicals, seawater, or high-pressure fluids, FRP pipes offer flexibility in design and performance. This adaptability ensures that they can be tailored to suit a variety of operational needs, from industrial piping systems to large-scale infrastructure projects.

Longevity

Fibercast FRP pipes are known for their extended service life, particularly in corrosive and extreme environments. Unlike metal pipes, which are prone to corrosion and can degrade quickly under harsh conditions, FRP pipes maintain their strength and integrity for much longer. This durability reduces the need for frequent replacements and repairs, which is especially important in industries like oil and gas, chemical processing, and wastewater management, where downtime can be costly. The longevity of FRP pipes ensures reliable, uninterrupted service over time, significantly reducing maintenance costs and enhancing overall system reliability.

Sustainability

The sustainability benefits of Fibercast FRP pipes are increasingly important in today’s environmentally-conscious world. Their durability and resistance to corrosion mean that they require fewer replacements, reducing the environmental impact associated with the production, transportation, and disposal of traditional piping materials like steel and concrete. Additionally, the lightweight nature of FRP pipes leads to lower transportation energy consumption and a reduced carbon footprint. The ability of FRP pipes to resist fouling and corrosion also results in fewer maintenance interventions, further contributing to a cleaner environment by minimizing waste and chemical treatments.

Know FRP’s Coefficient of Thermal Expansion

Fibercast FRP Pipe Sizes, Customization, and Standards

Fibercast FRP pipe systems are available in a wide range of sizes to meet the needs of various industrial applications. The sizes typically include variations in diameter, wall thickness, and pressure ratings. Here is a detailed breakdown:

| Category | Details |

|---|---|

| Small-Diameter Pipes | 1–6 inches, for low-flow or compact systems |

| Medium-Diameter Pipes | 8–16 inches, for general industrial systems |

| Large-Diameter Pipes | Up to 72 inches, for large-scale processes or water treatment |

| Wall Thickness | Varies by pressure rating; defined by ASTM D2996 and AWWA C950 |

| Pressure Ratings | Low: 50-150 psi Medium: 150-300 psi High: 300-3000 psi |

| Customization Options | Lengths: 10 ft, 20 ft, 40 ft; Fittings: flanges, threaded, adhesive; Resins: epoxy, vinyl ester, polyester |

| Key Standards Governing Sizes | ASTM D2996 (Filament-wound reinforced thermosetting resin pipe) ASTM D3262 (Gravity sewer systems) AWWA C950 (Fiberglass pressure pipe) ISO 14692 (Petroleum and natural gas industries) |

Fibercast FRP Pipe Manufacturing Process

The manufacturing process of Fibercast FRP (Fiberglass Reinforced Plastic) Pipe Systems is designed to ensure high quality, strength, and durability. The process primarily involves creating a composite material by embedding glass fibers in a thermosetting resin matrix and forming it into pipes through advanced techniques. Below is a detailed overview of the process:

Material Preparation

- Fiberglass Reinforcement:High-strength fiberglass is prepared in the form of continuous strands, chopped fibers, or woven mats. The type of fiberglass used depends on the pipe’s intended application and required strength.

- Thermosetting Resin:Resins like epoxy, polyester, or vinyl ester are selected based on the chemical, thermal, and mechanical properties needed for the application. Additives and curing agents are also included.

- Fillers and Additives (Optional):Materials like silica, pigments, or flame retardants may be added to improve properties like abrasion resistance, color, or thermal performance.

Manufacturing Techniques

There are three main techniques used in manufacturing Fibercast FRP pipes:

Filament Winding

This is the most common process for manufacturing FRP pipes.

- Mandrel Preparation:

A cylindrical mandrel (often steel or rubber) is prepared. It serves as the mold for the pipe. - Resin Application:

Fiberglass filaments are impregnated with resin as they are wound around the rotating mandrel in predetermined patterns (e.g., helical, hoop, or axial winding) to achieve desired strength characteristics. - Layering:

Multiple layers of resin-impregnated fiberglass are applied to build the required wall thickness. The composition of layers can vary to provide strength in specific directions. - Curing:

The pipe is cured under controlled conditions (e.g., room temperature curing or elevated temperature curing in an oven) to harden the resin and solidify the structure. - Demolding:

Once cured, the pipe is removed from the mandrel.

Centrifugal Casting

This method is often used for pipes requiring high chemical resistance.

- Mold Preparation:

A rotating cylindrical mold is prepared and treated with a release agent. - Resin and Fiber Addition:

Resin, fillers, and chopped fibers are poured into the rotating mold. Centrifugal force distributes the materials evenly along the mold’s inner surface. - Curing and Cooling:

The resin cures as the mold rotates, forming a dense, void-free composite pipe. After curing, the pipe is cooled and removed from the mold.

Hand Lay-Up (Used for Custom Applications)

This manual process is less common for large-scale production but is suitable for custom or small-diameter pipes.

- Layers of resin and fiberglass mats are applied by hand over a mandrel.

- The composite is then cured and removed from the mold.

Post-Processing

- Trimming and Cutting:

Pipes are trimmed to the required length and beveled or threaded at the ends as needed. - Surface Treatment:

Pipes may be coated with an additional resin layer for UV protection or chemical resistance. - Fittings Fabrication:

Flanges, elbows, tees, and other fittings are manufactured or bonded to the pipes during assembly.

Quality Control

Strict quality assurance measures are taken at every stage:

- Dimensional Checks: Verifying the diameter, wall thickness, and length.

- Pressure Testing: Ensuring the pipe meets the designed pressure rating.

- Material Testing: Testing for mechanical properties (e.g., tensile strength, flexural strength) and chemical resistance.

- Visual Inspection: Checking for defects like cracks, voids, or uneven surfaces.

Advantages of the Process

- Customization: The layering process allows for pipes tailored to specific mechanical and chemical demands.

- Efficiency: Modern filament winding and centrifugal casting methods are highly automated, ensuring consistent quality.

- Versatility: Compatible with various resin types and reinforcement patterns, making the pipes suitable for a wide range of applications.

By combining advanced materials with precision manufacturing techniques, Fibercast FRP pipes achieve a balance of lightweight design, durability, and high performance.

Applications of FRP Pipe Wet Layup in Industrial Rehabilitation

The Key of Fibercast FRP Pipe in Industrial Applications

GangLong Fiberglass, a leader in FRP piping, supplies durable Fibercast FRP pipe for extreme temps (-70°F to 300°F) with epoxy resin. Fibercast FRP pipe is a durable and corrosion-resistant fiberglass-reinforced piping solution widely used across various industries. Its composition offers a blend of lightweight flexibility and strength, making it ideal for challenging environments such as chemical processing, water treatment, and the oil and gas sector. The unique structure of Fibercast FRP pipe enables it to withstand harsh chemicals and extreme temperatures, which traditional metal pipes often cannot handle. By incorporating advanced composite materials, Fibercast FRP pipe provides an effective alternative to conventional piping systems, ensuring long-lasting reliability while reducing the risk of corrosion, leakage, or deterioration over time.

Fibercast FRP pipe plays a critical role in various industrial applications, particularly in sectors that demand high-performance materials capable of enduring corrosive environments. In chemical processing, for example, pipes are frequently exposed to highly aggressive chemicals that can quickly erode metal piping. Fibercast FRP pipe, with its corrosion-resistant properties, ensures that the integrity of the system remains intact even in the presence of harsh substances. Its resilience extends beyond chemical applications, making it a versatile choice for water treatment plants and oil and gas operations, where pipe longevity and resistance to environmental stressors are essential for maintaining operational efficiency.

The Key of Fibercast FRP Pipe in Chemical Processing

The chemical processing industry faces demanding challenges when it comes to handling and transporting aggressive chemicals. Fibercast FRP pipe offers a robust solution with its corrosion-resistant properties that ensure a reliable and safe flow of chemicals through the piping system. Chemical plants must maintain the integrity of their pipes to avoid leaks, contamination, and potential hazards. Fibercast FRP pipe, designed to resist the corrosive effects of acids, bases, and solvents, is built to meet these needs. This pipe is frequently used in environments where materials are subject to continuous exposure to aggressive substances, which makes it an ideal choice for facilities that handle hazardous or reactive chemicals.

Fibercast FRP Pipe in Water Treatment Facilities

Water treatment plants rely on a variety of piping systems to carry water through different stages of treatment. Given the need to resist both chemical treatments and environmental wear, Fibercast FRP pipe stands out as an efficient solution. The corrosion-resistant properties of Fibercast FRP pipe prevent the buildup of scale and other deposits that can occur in traditional metal pipes, ensuring the smooth flow of water throughout the system. Additionally, the lightweight design of Fibercast FRP pipe simplifies installation, reducing labor costs and time without compromising on performance. This combination of efficiency and durability positions Fibercast FRP pipe as a valuable asset in modern water treatment processes.

Fibercast FRP Pipe in Oil and Gas Applications

In the oil and gas industry, where pipes are subjected to extreme conditions such as high temperatures, pressure, and exposure to corrosive substances, Fibercast FRP pipe offers an effective solution. The advanced composite materials used in Fibercast FRP pipe provide superior resistance to corrosion, reducing the risk of FRP pipe failure modes or leakage. Its lightweight nature also makes transportation and installation easier compared to traditional steel pipes. Additionally, Fibercast FRP pipe’s long service life contributes to reduced maintenance costs and downtime in oil and gas operations. The combination of durability, cost savings, and ease of use makes it an excellent choice for the demanding conditions of oil and gas pipelines.

Fibercast FRP Pipe in Harsh Environments

Fibercast FRP pipe is particularly well-suited for use in harsh environments where other materials would quickly degrade. From extreme temperatures to high levels of chemical exposure, Fibercast FRP pipe is designed to withstand the most challenging conditions. Its composite structure gives it the ability to handle mechanical stress, thermal expansion, and external impacts without compromising performance. Industries that operate in harsh or remote locations, such as offshore oil rigs or chemical plants, can rely on Fibercast FRP pipe to maintain the safety and efficiency of their operations.

Fibercast FRP Pipe as a Cost-Effective Solution

Fibercast FRP pipe offers significant cost savings for industries looking for long-term piping solutions. Its lightweight nature reduces transportation and installation costs, while its corrosion resistance minimizes the need for frequent repairs or replacements. Fibercast FRP pipe’s durability ensures that companies can rely on it for years without the additional costs associated with maintenance and upkeep. By investing in Fibercast FRP pipe, industries can benefit from both immediate and long-term savings, making it an attractive option for those seeking to optimize operational efficiency and reduce overall expenses.

Installation and Maintenance of Fibercast FRP Pipe

Fibercast FRP Pipe Installation

Preparation and Planning

Before beginning the installation of Fibercast FRP pipes, it is essential to plan the entire process carefully. This involves determining the layout of the piping system, evaluating environmental conditions, and ensuring all tools and materials are on hand. Effective planning prevents unnecessary delays and helps avoid mistakes during installation, guaranteeing that the pipes will function correctly from the start.

Cutting and Handling

Fibercast FRP pipes should be carefully handled to avoid damage during the installation process. The pipes are lightweight, but they still require attention to prevent cracks or deformation. Cutting the pipes to the desired length should be done with the proper tools designed for fiberglass. Following the manufacturer’s guidelines is crucial for ensuring the integrity of the pipe after cutting.

Joining Methods

Fibercast FRP pipes can be joined using various methods, such as adhesive bonding, mechanical fittings, or flanged connections. Adhesive bonding is common because it is simple to apply and creates a strong, leak-proof bond without specialized equipment. Mechanical fittings or flanged connections are better suited for high-temperature, high-pressure environments or where disassembly may be needed for future maintenance or repairs. Additionally, FRP pipe bell and spigot joints are often used to create a secure and tight connection between pipe sections, ensuring leak-proof performance in many installations.

Installation Techniques

There are several methods to install Fibercast FRP pipes, each suited for different applications. Butt and strap joints are one option, where the ends of the pipes are secured with a strap, ensuring a secure connection. Bell and spigot joints, another common method, involve one pipe end flaring to fit securely with the next. Threaded joints are used when easy disassembly is required for maintenance or future upgrades.

Securing the Pipes

After the pipes are connected, they need to be secured in place to avoid movement or sagging. This is done using supports and brackets placed at appropriate intervals along the pipes. Proper support prevents the pipes from stress or vibration that could damage the joints over time. This ensures the system remains stable and operational for the long term, reducing the risk of pipe failure.

Testing the System

Once the installation is complete, it is important to test the entire system to ensure it is functioning correctly. This includes checking for leaks and ensuring that the pipes can handle the required pressure. A pressure test, usually conducted by filling the system with air or water, helps to detect any weak points or leaks, confirming the integrity of the installation before the system goes into full operation.

Maintenance of Fibercast FRP Pipe Systems

Inspection

Periodic inspections are essential for identifying potential issues such as cracks, leaks, or discoloration in Fibercast FRP pipes. These inspections help detect early signs of wear or damage, enabling timely repairs. By using adhesive bonding or patching techniques, minor issues can be fixed before they escalate, restoring the pipe to its original condition and avoiding the high cost of full replacements, thus ensuring the system’s long-term reliability and efficiency.

Cleaning

To maintain the optimal performance of Fibercast FRP pipes, regular cleaning is crucial. Over time, sediment and debris can accumulate inside the pipes, leading to reduced flow rates and higher energy costs. Though the smooth inner surface of FRP pipes minimizes material buildup, periodic flushing or cleaning may be necessary in certain applications. This maintenance step helps to maintain the efficiency of the piping system and prevents operational issues caused by blockages or reduced fluid flow.

Leak Detection

Fibercast FRP pipes are designed to be leak-proof, but regular monitoring for any potential leaks or cracks is still important, especially in high-pressure systems. Using advanced leak detection systems or performing manual checks at joints, connections, and valves can ensure the integrity of the system. Additionally, conducting pressure tests and employing diagnostic tools can help identify weaknesses or hidden issues that may not be visible to the naked eye, preventing potential failures and enhancing the safety of the system.

Monitoring System Performance

Regular monitoring of system performance is vital in industrial environments to ensure that Fibercast FRP pipes are operating at their best. Parameters such as pressure, temperature, and flow rates should be closely observed. Any irregular readings may indicate potential issues such as pipe expansion, blockages, or wear on the pipe surfaces. Proactively monitoring these parameters helps to detect problems early, allowing for timely interventions that minimize downtime, prevent costly repairs, and maintain the smooth operation of the entire system.

GangLong Fiberglass & Fibercast FRP Pipes: High-Performance Solutions

At GangLong Fiberglass, we are committed to providing advanced fiberglass solutions that meet the most demanding industrial requirements. Our Fibercast FRP pipes are designed for high-performance applications across various industries, offering superior durability, resistance to corrosion, and a long service life. Through decades of experience and continuous technological innovation, we have built a reputation for delivering reliable and cost-effective products that help our customers achieve their goals.

Expertise and Innovation

With years of experience in the fiberglass manufacturing industry, we take pride in our ability to combine technical know-how with cutting-edge technology. At GangLong Fiberglass, we are constantly exploring new ways to improve our products, ensuring they meet the ever-evolving demands of the industrial sector. Our Fibercast FRP pipes are engineered with the latest advancements in fiberglass technology, ensuring they provide superior performance, even in the most challenging environments.

Our expertise allows us to offer customized solutions tailored to the specific needs of each customer, from design and installation to long-term maintenance. We work closely with our clients to understand their unique requirements, ensuring that every solution is optimized for maximum efficiency and cost-effectiveness.

Comprehensive Services

We offer a range of services designed to support our customers throughout the life cycle of their Fibercast FRP pipe systems. Our services include:

- Certified Laboratory Testing: We conduct thorough testing to ensure the quality and performance of our FRP products, providing peace of mind to our customers that they are receiving the highest standards of reliability.

- Extensive Inventory: Our broad and diverse stock of fiberglass materials and components means that we can deliver the right parts quickly, minimizing downtime and keeping operations running smoothly.

- Repair and Maintenance: At GangLong Fiberglass, we also provide expert repair and maintenance services. We understand the importance of minimizing operational disruptions, and our team ensures that your Fibercast FRP pipes remain in optimal condition throughout their service life.

Commitment to Quality and Reliability

At GangLong Fiberglass, we prioritize quality and reliability in every product we manufacture. Our Fibercast FRP pipes are built to withstand the most demanding environments, offering exceptional strength, corrosion resistance, and longevity. These pipes are perfect for applications such as chemical processing, wastewater treatment, power generation, and marine environments, where reliability is paramount.

We ensure that each product undergoes rigorous quality control processes before it reaches our customers. Our commitment to excellence in both product design and manufacturing guarantees that our Fibercast FRP pipes provide maximum performance and durability, minimizing the need for repairs and replacements over time.

Cost-Effective Solutions

Choosing Fibercast FRP pipes from GangLong Fiberglass ensures cost-effectiveness over the long term. Our lightweight FRP pipes reduce transportation and installation costs, while their durability and low maintenance requirements minimize ongoing expenses. By reducing the need for frequent repairs or replacements, our pipes provide significant long-term savings for industries that rely on high-performance piping systems.

We believe in delivering not just products, but solutions that drive operational efficiency and reduce total cost of ownership. The durability of our Fibercast FRP pipes means less downtime and fewer disruptions, allowing businesses to focus on their core operations with confidence.

Environmental Benefits

In addition to their performance advantages, Fibercast FRP pipes also offer several environmental benefits. Their lightweight composition reduces energy consumption during transportation and installation, lowering overall carbon emissions associated with their use. Furthermore, the durability of our pipes means they need to be replaced less frequently than traditional metal pipes, leading to reduced material waste over time. Their resistance to corrosion also ensures that there are no harmful leaks of chemicals or pollutants, contributing to a cleaner, safer environment.

Top Challenges Contractors Face in Securing FRP Pipes Tenders

FAQs about Fibercast FRP Pipe

FRP (Fiber Reinforced Plastic) pipe and PVC (Polyvinyl Chloride) pipe are different in terms of their material composition, strength, and application. FRP pipe is a composite material made from a combination of resin and fiberglass, which gives it excellent strength, corrosion resistance, and the ability to withstand high temperatures and pressures. This makes FRP pipes ideal for industrial applications, such as chemical processing, oil and gas, and water treatment, where the environment can be harsh and traditional materials may fail.

On the other hand, PVC pipe is a type of plastic pipe commonly used for residential and commercial plumbing, drainage systems, and low-pressure applications. While PVC is lightweight and easy to install, it does not offer the same level of strength or resistance to high temperatures and corrosive chemicals as FRP. PVC pipes are more suitable for applications with less demanding environmental conditions, while FRP pipes are used in more challenging industrial settings. The key difference lies in their ability to handle stress: FRP is designed for high-pressure, high-temperature environments, while PVC is typically used for low-pressure systems.

FRP (Fiber Reinforced Plastic) and GRP (Glass Reinforced Plastic) are often used interchangeably, but they have subtle differences in their composition and application. Both types of pipes are composite materials made using a combination of resin and fiber reinforcements. However, FRP refers to pipes that use various types of fibers for reinforcement, including glass, carbon, and aramid fibers. In contrast, GRP pipes specifically use glass fibers as their primary reinforcement. This means GRP pipes are a subset of FRP pipes. In terms of application, both FRP and GRP pipes are highly resistant to corrosion and chemicals, making them suitable for industries like chemical processing, water treatment, and oil and gas. The choice between FRP and GRP depends on the specific needs of the project. GRP is commonly chosen when glass fibers provide sufficient strength and corrosion resistance, while FRP is selected when a mix of fiber types is required for additional strength or specialized performance characteristics.

FRP, or Fiber Reinforced Plastic, in piping refers to a composite material made from a combination of thermoset resin and fiberglass reinforcement. This type of piping is known for its excellent corrosion resistance, lightweight properties, and high strength, making it a popular choice in industries such as oil and gas, chemical processing, and water treatment. The resin matrix, often made from polyester, vinyl ester, or epoxy, provides the pipe with its resistance to chemicals and environmental degradation, while the fiberglass reinforcement contributes to its strength and durability. FRP piping systems are often used in situations where traditional materials like steel or concrete would fail due to corrosion or chemical exposure. FRP piping offers a long service life with minimal maintenance requirements, which reduces overall operational costs. It is also valued for its ease of installation, as its lightweight nature makes it easier to transport and handle on-site.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.