- Home

- Fiberglass Rebar

GangLong Fiberglass Rebar: A New Reinforcement Standard

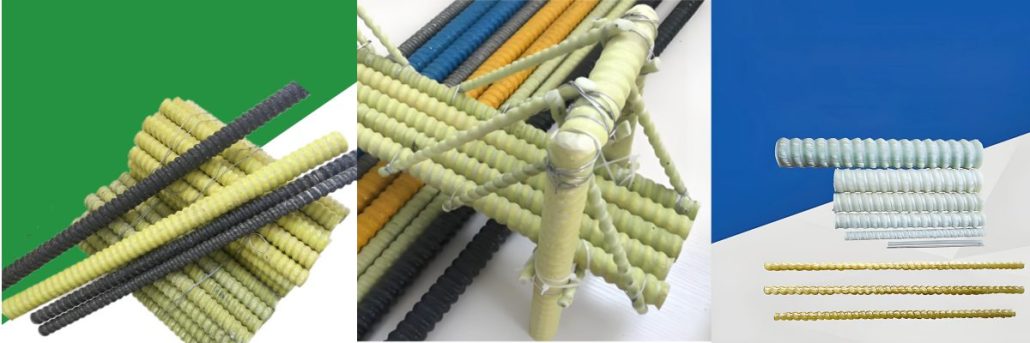

Fiberglass Rebar is revolutionizing concrete reinforcement as a modern alternative to traditional steel. Fiberglass Rebar: Spiral-wrapped fiberglass rovings with resin offering superior tensile reinforcement for concrete and masonry. This innovative composite rod is lightweight, non‑corrosive and non‑conductive, providing foundations, walls, bridge decks and driveways with up to twenty times the lifespan of steel‑reinforced slabs under heavy traffic, while allowing architects and engineers to paint, face with aggregates, color or leave it natural—plus enjoy easier handling, reduced maintenance and long‑term cost savings.

Simplifying Your Life: Key Functionalities

| Attribute | Details |

|---|---|

| Product Name | Fiberglass Rebar (FRP Rebar, GFRP Rebar) |

| Materials Used | Fiberglass Reinforced Polymer (GFRP), Composite Materials, Basalt Fiber |

| Technique | Pultrusion, Moulding |

| Brand | GangLong Fiberglass |

| Place of Origin | Hebei, China |

| Application | - Construction (concrete reinforcement, structural applications) |

| - Suitable for use in environments subject to corrosion, such as seawater | |

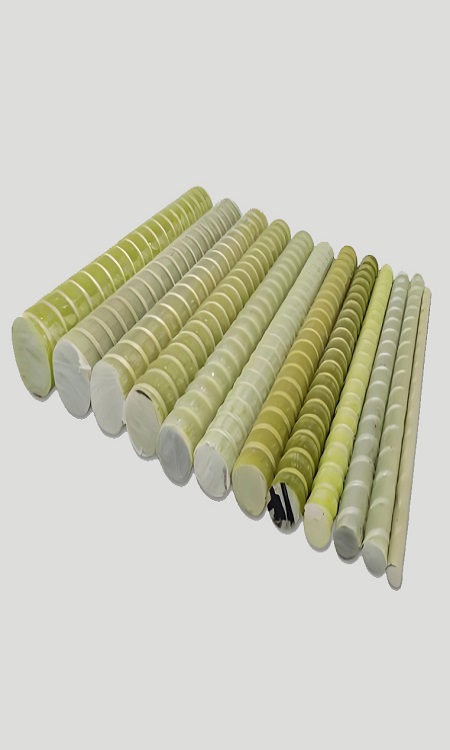

| Diameter Options | 3mm to 40mm (customizable) |

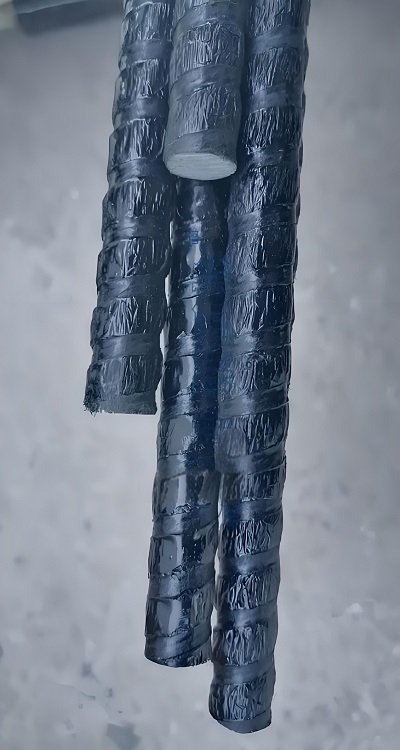

| Surface Treatment | - Full thread, sandblasted, screw thread |

| Tensile Strength | 509MPa to 1900MPa |

| Density | 2.1 to 2.2 g/cm³ |

| Color Options | Customizable (varies by manufacturer) |

| Shape Options | Customizable shapes (e.g., round, ribbed, deformed) |

| Features | - More strength than traditional steel rebar |

| - Water-resistant, never rusts | |

| - Corrosion-resistant to seawater | |

| - Long lifecycle of 100+ years | |

| - High tensile strength and flexibility | |

| - Lightweight yet durable | |

| - Highly suitable for infrastructure projects in harsh environments | |

| Certificates | ISO9001, CE, MTC |

| Processing Services | - Bending, Decoiling, Moulding, Welding, Punching, Cutting |

| Technology | Pultrusion Process |

| Standard Compliance | - Meets international standards (ASTM A615, EN10080, ISO standards) |

| OEM Acceptance | OEM options available (custom orders for specific project requirements) |

| Delivery Time | - 7 to 15 days depending on the size and customization of the order |

News

- Exploring the Benefits of Carbon Fiber Apparel

- How to Work with Carbon Fiber Successfully

- Carbon Fiber Suit: The Future of Lightweight Armor

- Is Carbon Fiber Armor the Future of Protection?

- Why White Carbon Fiber is Popular in Automotive Design

- Transparent Carbon Fiber Sheets Two Sided Gloss Twill

- Epoxy-Compatible Chopped Carbon Fiber Mat

- Carbon Fiber EG Hatch: Upgrade Your Civic Today

- The Benefits of Using Structural Carbon Fibre in Engineering

- How Many Layers of Layered Carbon Fiber Are Needed?

Superior Benefit of Fiberglass Rebar

Fiberglass rebar, also known as GFRP (Glass Fiber Reinforced Polymer) rebar, is an advanced reinforcement material used in concrete structures as a substitute for traditional steel rebar. It is composed of continuous glass fibers embedded in a polymer resin matrix, offering several superior benefits compared to steel rebar. Here’s a detailed description of its key advantages:

Corrosion Immunity

Fiberglass Rebar remains inert when exposed to moisture, de‑icing salts, carbonation, and harsh marine conditions. It never rusts or loses cross‑sectional area, preserving full bond strength and preventing spalling or surface staining. Laboratory and field tests project service lives beyond 100 years, eliminating the extensive repair cycles and structural maintenance often required for steel‑reinforced concrete in aggressive environments.

Lightweight Handling

Weighing only 25 percent of steel, Fiberglass Rebar dramatically simplifies transport and placement. Crews can handle longer bars without mechanical assistance, reducing labor and equipment needs. Increased bar lengths per delivery decrease trucking costs, while lighter loads cut crane and hoist time. This streamlined workflow accelerates schedules, lowers on‑site expenses, and even permits leaner formwork systems in both horizontal and vertical applications.

High Strength‑to‑Weight

Despite its low density, Fiberglass Rebar delivers tensile strengths on par with or exceeding Grade 60 steel. Its superior strength‑to‑weight ratio enables engineers to reduce bar sizes or spacing while maintaining required load capacities. This efficiency trims material quantities, permits slimmer concrete sections, and optimizes structural designs—especially valuable in seismic zones, long‑span decks, and any project where minimizing self‑weight is essential.

Electrical & Thermal Insulation

As a non‑metallic composite, Fiberglass Rebar is completely non‑conductive, preventing stray currents that accelerate steel corrosion and avoiding grounding paths in sensitive installations. Its low thermal conductivity also minimizes thermal bridging in slabs and walls, enhancing building envelope performance. This electrical and thermal insulation makes it ideal for data centers, electrical substations, and energy‑efficient residential or commercial structures seeking improved occupant comfort.

Chemical & Thermal Durability

Fiberglass Rebar withstands acids, alkalis, sulfates, solvents, and oils common in wastewater treatment, chemical plants, and industrial facilities. It also tolerates elevated temperatures and freeze‑thaw cycles without significant loss of mechanical properties. This dual chemical and thermal resistance safeguards concrete structures against aggressive media and thermal shocks, preserving integrity and reducing the risk of cracks, delamination, or bond deterioration over decades.

Low Thermal Expansion

With a coefficient of thermal expansion closely matched to concrete, Fiberglass Rebar minimizes dimensional changes from temperature fluctuations. This compatibility prevents internal stresses that cause microcracking, delamination, or bond loss, ensuring long‑term crack control and structural durability. Buildings and pavements in extreme climates—ranging from desert heat to subzero winters—benefit from stable reinforcement that doesn’t shift or stress the surrounding concrete matrix.

Environmental Sustainability

Producing Fiberglass Rebar consumes significantly less energy than steelmaking and generates no heavy‑metal byproducts. Its non‑toxic, fully recyclable composition aligns with circular‑economy principles and qualifies for green‑building certifications. By extending service life and reducing maintenance, it cuts embodied carbon over a structure’s lifecycle. This eco‑friendly profile supports LEED credits, lowers project carbon footprints, and advances sustainable infrastructure goals.

Cost Efficiency

Although initial material costs for Fiberglass Rebar can exceed steel, its longevity and zero‑maintenance characteristics yield lower life‑cycle expenses. Eliminating corrosion‑related repairs, accelerating placement, and cutting downtime translate into substantial savings over decades. For long‑span bridges, parking decks, and coastal structures, these factors often produce a lower total cost of ownership compared to steel‑reinforced alternatives, making it financially prudent for high‑exposure projects.

Design Versatility

Fiberglass Rebar comes in multiple diameters, tensile grades, and surface textures to match engineering requirements. Its light weight and corrosion immunity allow for reduced concrete cover depths and more slender profiles, enabling architects to explore thinner slabs, cantilevers, and complex shapes. Prefabricated cages or mat assemblies can be produced offsite, enhancing quality control, minimizing onsite labor, and supporting innovative structural and architectural designs.

Aesthetic Durability

Because Fiberglass Rebar never oxidizes, there is no risk of rust streaks or staining on exposed‑aggregate or architectural concrete surfaces. Decorative elements, precast panels, and fair‑faced finishes maintain their intended appearance without sealants or coatings. This long‑term visual stability reduces surface maintenance costs and preserves the clean, uniform aesthetic of both interior and exterior exposed concrete applications.

Electromagnetic Transparency

Fiberglass Rebar’s non‑metallic composition renders it transparent to electromagnetic fields, radar frequencies, and non‑destructive testing methods. This makes it indispensable for installations requiring accurate subsurface scanning—such as airport runways, radar arrays, and secure communication hubs—where steel reinforcement would block or distort signals. Electromagnetic transparency ensures reliable diagnostics and monitoring without invasive inspections.

Direct Steel Replacement

In common horizontal applications—such as slab‑on‑grade, bridge decks, and precast panels—½″ (#4) Fiberglass Rebar can directly substitute for steel without modifying spacing or cover specifications. This one‑for‑one swap streamlines design approvals, leverages existing reinforcement schedules, and avoids bespoke anchorage or splice detailing. Engineers can thus maintain standard construction drawings and detailing, simplifying documentation and reducing design revisions.

The New Reinforcement Standard of Fiberglass Rebar

Fiberglass rebar (GFRP – Glass Fiber Reinforced Polymer) reinforcement is subject to various standards and specifications that ensure its proper performance in concrete structures. These standards address the material properties, quality control, testing methods, and design recommendations for the use of fiberglass rebar in construction.

Key Standards for Fiberglass Rebar Reinforcement

ASTM D7957 – Specification for Fiberglass Rebar

This standard defines the essential material and performance parameters for Fiberglass Rebar used in concrete. Key properties covered include:

- Tensile strength and modulus of elasticity requirements

- Durability: corrosion and chemical resistance thresholds

- Impact and fatigue resistance criteria

- Dimensional tolerances (bar diameter and length allowances)

- Surface roughness specifications for optimal concrete bonding

ASTM D7958 provides field‑ready guidance on handling, storage, cutting, and anchorage of Fiberglass Rebar. It outlines safety measures to protect bar integrity, offers design advice for tension and flexural members, and includes load‑calculation methods with service‑load factors. Best practices cover installation under varied environmental and construction conditions. ACI 440.4R delivers comprehensive design procedures for beams, slabs, columns, and walls reinforced with Fiberglass Rebar. It covers flexural, shear, and torsional analysis tailored to composite properties; bond‑performance criteria; strength reduction and load‑deflection relationships; and durability under moisture, temperature cycling, and chemical exposure, ensuring safe, long‑lasting structures. CSA S806 prescribes the key design and construction criteria for using Fiberglass Rebar in Canadian practice. It defines: ISO 1920‑5’s standardized test procedures—originally intended for steel but broadly adopted for Fiberglass Rebar—cover tensile strength and elongation tests, bending and flexural performance assessments, dimensional accuracy and straightness checks, fatigue and impact resistance evaluations, and specimen preparation with environmental conditioning to ensure consistent quality control. EN 13706 specifies mechanical property thresholds (tensile strength, stiffness, fatigue life) and durability assessments under chemical attack, moisture ingress, and temperature extremes for Fiberglass Rebar. It also mandates bond‑quality evaluations through surface treatment criteria and enforces strict dimensional tolerances to guarantee reliable, high‑performance reinforcement in European infrastructure and building projects. Fiberglass rebar standards ensure that this innovative material performs as expected in concrete reinforcement applications. They set guidelines for material properties, testing, and design to ensure the safety, reliability, and durability of concrete structures. Engineers must follow these standards to properly design and use GFRP rebar, taking into account its unique properties and potential limitations compared to traditional steel reinforcement.ASTM D7958 – Guide to Using Fiberglass Rebar in Concrete

ACI 440.4R – Design & Construction with Fiberglass Rebar

CSA S806 – FRP‑Reinforced Concrete Design

ISO 1920‑5 – Testing Methods for Reinforcement Bars

EN 13706 – European FRP Reinforcement Standard

Design Considerations and Limitations

Fiberglass Rebar Mechanical Properties

Fiberglass rebar, or Glass Fiber Reinforced Polymer (GFRP) rebar, offers a unique set of mechanical properties that differentiate it from traditional steel rebar. These properties are critical in determining how fiberglass rebar behaves under various loading conditions in reinforced concrete structures. Below is a detailed breakdown of the key mechanical properties of fiberglass rebar:

Tensile Strength

- Tensile strength is the maximum stress that a material can withstand while being stretched or pulled before breaking.

- Fiberglass Rebar: The tensile strength of GFRP rebar is typically much higher than that of concrete but lower than steel. It generally ranges from 1,000 MPa to 2,500 MPa depending on the grade of the rebar and its manufacturing process.

- Significance: This high tensile strength allows fiberglass rebar to resist breaking or failure under tension, making it an effective reinforcement for concrete subjected to stretching forces.

Modulus of Elasticity

- Modulus of elasticity (also called Young’s modulus) measures a material’s resistance to deformation under stress. It indicates how much a material will stretch or compress under a given load.

- Fiberglass Rebar: The modulus of elasticity of fiberglass rebar is lower than that of steel. It typically ranges from 40 GPa to 50 GPa (gigapascals).

- Comparison to Steel: Steel has a modulus of elasticity around 200 GPa, so fiberglass rebar is less stiff and will experience more deflection under the same loading conditions than steel. This must be considered in design, as it may lead to larger structural deflections.

Shear Strength

- Shear strength refers to the material’s ability to resist forces that can cause the material to slide or shear along a plane.

- Fiberglass Rebar: The shear strength of fiberglass rebar is generally lower than that of steel rebar. Typical values are in the range of 50 MPa to 100 MPa.

- Significance: Shear strength is important for applications like beams and slabs where transverse (shear) forces are present. The lower shear strength of fiberglass rebar means it is often used in combination with other reinforcement strategies in structures exposed to high shear forces.

Bond Strength

- Bond strength is a measure of how effectively the rebar transfers loads to the surrounding concrete, which is critical for the performance of reinforced concrete structures.

- Fiberglass Rebar: Fiberglass rebar tends to have a lower bond strength to concrete compared to steel, primarily due to its smoother surface. The bond strength typically ranges from 1.5 MPa to 5 MPa.

- Surface Treatment: To enhance bond strength, fiberglass rebar often features surface treatments such as sand coating or ribbing. These treatments help improve mechanical interlocking between the rebar and the surrounding concrete.

Fatigue Resistance

- Fatigue resistance refers to a material’s ability to withstand repeated or fluctuating stresses without failing over time.

- Fiberglass Rebar: GFRP bars have excellent fatigue resistance compared to steel. Due to their resistance to corrosion, fiberglass rebar maintains its mechanical properties even after many loading cycles. However, the fatigue resistance can depend on the specific resin system and the reinforcement configuration (fiber orientation and density).

- Significance: Fatigue resistance is crucial for concrete structures subjected to repeated loading, such as bridges, pavements, and other transportation infrastructure.

Creep Resistance

- Creep is the gradual deformation of a material under a constant load over time.

- Fiberglass Rebar: Fiberglass rebar exhibits low creep behavior, especially when compared to other materials like concrete or steel. However, long-term creep under sustained loading is still a consideration and can lead to some deformation, especially in high-temperature environments.

- Significance: GFRP bars are particularly beneficial in structures that are subject to long-term, sustained loads, such as in bridges and high-rise buildings.

Impact Strength

- Impact strength is the ability of a material to absorb energy when subjected to a sudden force or impact.

- Fiberglass Rebar: GFRP rebar generally has a good resistance to impact compared to traditional materials like concrete, which can be brittle under certain conditions. However, it is more prone to fracture under high-impact forces than steel.

- Significance: Impact strength is an important property for structures that may be exposed to dynamic loads, such as industrial floors or structures in seismic areas.

Coefficient of Thermal Expansion

- Thermal expansion refers to the extent to which a material changes in size or volume in response to changes in temperature.

- Fiberglass Rebar: Fiberglass rebar has a lower coefficient of thermal expansion compared to steel (typically around 5 to 7 × 10⁻⁶/°C). This means it expands and contracts less with temperature fluctuations.

- Significance: The lower thermal expansion of fiberglass rebar reduces the risk of thermal stresses between the reinforcement and the concrete, which can lead to cracking or degradation in structures exposed to extreme temperature variations.

Tensile Elongation (Strain at Break)

- Tensile elongation measures how much the material stretches before breaking.

- Fiberglass Rebar: The elongation at break for fiberglass rebar is typically around 1% to 3%. This is much lower than that of steel, which can elongate up to 15% to 20% before failure.

- Significance: The relatively low elongation means that fiberglass rebar is more brittle than steel and is less capable of absorbing large deformations before failure. This must be accounted for in design, as structures using fiberglass rebar may be less ductile than those using steel.

Density

- Density of fiberglass rebar is lower than that of steel, typically around 2.4 to 2.5 g/cm³.

- Significance: This lower density makes fiberglass rebar significantly lighter than steel, which eases transportation and handling during construction. It also reduces the overall weight of reinforced concrete structures, which can be beneficial for seismic design and load-bearing capacity.

Durability and Environmental Resistance

- Fiberglass Rebar: One of the major advantages of fiberglass rebar is its corrosion resistance, which ensures that the material retains its mechanical properties over time, even when exposed to moisture, salt, and other environmental factors. Unlike steel, fiberglass rebar does not rust, which significantly improves the longevity and durability of the reinforced concrete.

- Chemical Resistance: GFRP rebar is highly resistant to a range of chemicals, including acids, alkalis, and organic solvents, which makes it ideal for use in aggressive environments, such as wastewater treatment plants, marine structures, and industrial facilities.

Fiberglass rebar offers a unique combination of high tensile strength, excellent corrosion resistance, and light weight, making it an attractive option for specific reinforced concrete applications. However, it also has some limitations compared to steel, including lower bond strength, reduced ductility, and lower modulus of elasticity. Engineers must carefully consider these mechanical properties when designing structures with fiberglass rebar, taking into account the specific loading conditions, environmental exposure, and desired service life.

Comparison of Fiberglass Rebar and Steel Rebar

Understanding what is fiberglass rebar made of—continuous glass fibers embedded in a polymer resin matrix—sheds light on its exceptional corrosion resistance and roughly 80 percent lower weight versus steel. This composition keeps it inert in aggressive environments and streamlines handling and installation. The table below contrasts its primary benefits and trade‑offs with traditional steel rebar.

| Aspect | Fiberglass Rebar | Steel Rebar |

|---|---|---|

| Corrosion | Fully corrosion‑proof, ideal for marine and chemical exposure | Prone to rust and spalling in moist/chemical environments |

| Weight | ~80 percent lighter – simplifies handling and logistics | Heavy – increases handling and transport costs |

| Cost & Maintenance | Higher initial cost, minimal upkeep over service life | Lower upfront cost, high lifecycle maintenance |

| Stiffness & Fire | Lower stiffness, more brittle, limited fire tolerance | High stiffness and fire resistance |

GFRP Fiberglass Rebar

GFRP Fiberglass Rebar (Glass Fiber Reinforced Polymer Rebar) is a type of reinforcement bar used in concrete structures, composed of glass fibers embedded in a polymer resin matrix. It is a non-metallic alternative to traditional steel rebar, and is valued for its exceptional properties such as corrosion resistance, light weight, and high tensile strength.

Composition of GFRP Fiberglass Rebar

GFRP rebar is made from:

- Glass Fibers: These are continuous strands of glass that provide the rebar with its strength. The glass fibers are arranged in a longitudinal direction to provide maximum tensile strength.

- Polymer Resin Matrix: The glass fibers are coated with a polymer resin, typically epoxy, vinyl ester, or polyester. The resin binds the fibers together and gives the rebar its form and durability.

- Surface Treatment: Some types of GFRP rebar have a roughened surface (such as sand coating or ribs) to improve the bond between the rebar and the surrounding concrete. The bond strength is essential for effective load transfer.

Applications of GFRP Fiberglass Rebar

GFRP rebar is used in various concrete structures, particularly in situations where corrosion resistance and durability are critical. Some common applications include:

Bridge Construction

GFRP Fiberglass Rebar is increasingly specified for bridge decks, girders, and piers in regions exposed to de‑icing salts or coastal salt spray. Its corrosion immunity prevents rebar oxidation and concrete spalling, reducing maintenance cycles and extending service intervals. Lightweight bars also simplify placement on overhead formwork, accelerating construction schedules and lowering labor and equipment costs for new bridges and deck rehabilitations.

Marine Structures

In seawalls, piers, docks, and offshore platforms, GFRP Fiberglass Rebar delivers unmatched durability against chloride attack. Unlike steel that rapidly corrodes in saltwater, GFRP remains chemically stable, preserving concrete cover and structural capacity. This resilience minimizes repair frequency and prolongs asset life in harsh marine environments, making it the reinforcement of choice for ports, wharves, and coastal protection projects.

Pavements and Roads

Concrete pavements and roadways in cold climates often suffer corrosion from de‑icing salts. By substituting GFRP Fiberglass Rebar for steel, agencies can significantly extend pavement life and defer costly overlays. The non‑corroding bars maintain full cross section and bond under freeze‑thaw cycles, ensuring consistent load transfer and crack control without the need for frequent maintenance in highway, airport apron, or bridge approach slabs.

Wastewater Treatment Plants

Aggressive chemicals and moisture in sewage and industrial wastewater can rapidly degrade steel reinforcement. GFRP Fiberglass Rebar resists acids, alkalis, sulfates, and biological agents present in treatment facilities. Its chemical inertness and mechanical stability safeguard tanks, channels, and process structures, reducing repair disruptions and ensuring reliable performance in clarifiers, digesters, and pipeline linings, where long‑term durability is paramount.

Foundations and Slabs

In slab‑on‑grade and shallow foundation applications—especially in high water table or humid regions—GFRP Fiberglass Rebar prevents the corrosion issues that plague steel reinforcement. Its low weight facilitates placement in tight slab pours and under congested footings, while its non‑metallic nature eliminates the risk of early deterioration, delivering stable load‑bearing capacity and long‑term serviceability in residential, commercial, and industrial foundations.

Underground and Elevated Structures

Subterranean and elevated parking decks, tunnels, and utility vaults are prone to moisture intrusion and condensation, which can corrode steel. GFRP Fiberglass Rebar’s imperviousness to moisture extends the lifespan of these structures, reducing crack propagation and spalling. Its ease of handling improves productivity in confined underground spaces, and its resilience to environmental extremes ensures dependable performance in elevated, exposed applications.

Chemical Plants

Concrete process equipment and containment structures in chemical plants face constant exposure to harsh reagents—acids, alkalis, and solvents. GFRP Fiberglass Rebar resists these aggressive media, avoiding the rapid corrosion that can compromise steel‑reinforced elements. This stability supports safe, uninterrupted plant operation, lowers downtime for maintenance, and enhances the longevity of reactor pads, troughs, and secondary containment walls.

Parking Structures

Parking garages endure constant vehicle traffic, abrasion, and frequent exposure to road salts and hydrocarbons. GFRP Fiberglass Rebar’s corrosion resistance prevents rebar deterioration and spalling of precast and cast‑in‑place elements. Its lightweight nature accelerates deck panel installation and reduces crane time, while its non‑conductive properties eliminate stray current corrosion, enhancing durability and minimizing maintenance in multi‑level parking structures.

Cost Analysis of Fiberglass Rebar

Fiberglass Rebar typically commands a higher upfront price than traditional steel rebar due to its advanced glass‐fiber and polymer manufacturing processes. While steel rebar is cheaper initially, its vulnerability to corrosion leads to ongoing maintenance and repair expenses that accumulate over a structure’s service life. In contrast, the superior durability and chemical resistance of Fiberglass Rebar can substantially reduce lifecycle maintenance costs, often offsetting its higher purchase price.

Cost-Effectiveness in the Long Term

Though fiberglass rebar may have a higher initial price point compared to steel rebar, it offers substantial cost savings over time due to:

- Lower Maintenance Needs: No corrosion, rust, or degradation reduces maintenance efforts and extends the service life of the structure.

- Reduced Installation Costs: Lighter weight means fewer handling and transportation challenges, making installation easier and cheaper.

- Improved Performance in Harsh Environments: Its resistance to corrosion makes it ideal for marine, industrial, and chemical environments, where traditional steel rebar would degrade rapidly.

Factors Influencing the Price of GangLong Fiberglass Custom Fiberglass Rebar

Customization and Specifications

Quantity of Order

Project Complexity

Shipping and Logistics

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.

Fiberglass Rebar Sizes

Fiberglass Rebar is a modern construction material made from reinforced plastic fibers that provide an alternative to traditional steel rebar. Its unique properties, such as high strength-to-weight ratio and corrosion resistance, make it an attractive choice for various construction projects. Understanding the different sizes of Fiberglass Rebar and their applications is crucial for optimizing its use in construction.

Common Sizes and Their Uses

Fiberglass Rebar is available in a range of sizes to meet different construction needs. The sizes generally vary in diameter and length, which can be tailored to specific project requirements. Here is an overview of some common sizes and their typical applications:

Small Diameters (e.g., 6 mm, 8 mm)

Overview: Smaller diameters are often used for lighter load-bearing applications and in situations where space is constrained.

Uses: These sizes are ideal for reinforcement in residential construction, decorative concrete elements, and smaller precast concrete components. They are also suitable for applications where high corrosion resistance is required, such as in coastal or industrial environments.

Overview: Medium diameters offer a balance between strength and flexibility, making them versatile for a variety of structural applications. Overview: Larger diameters provide increased load-bearing capacity and are used in high-stress applications. Fiberglass Rebar 20′ is a versatile option for various construction projects, known for its length and utility. This specific length of Fiberglass Rebar is often utilized in applications that require extended reinforcement spans, such as in large concrete slabs or structural components. The 20-foot length provides significant coverage and reduces the need for frequent splicing or jointing, which can streamline the construction process and enhance the structural integrity of the project. Fiberglass Rebar 20′ is particularly useful in applications where longer, uninterrupted reinforcement is needed. For instance, it is ideal for use in foundations, bridge decks, and large industrial floors where minimizing joints can improve overall strength and stability. Its corrosion resistance makes it suitable for environments exposed to moisture, chemicals, or other corrosive agents, where traditional steel rebar might deteriorate quickly.Medium Diameters (e.g., 10 mm, 12 mm)

Uses: These sizes are commonly used in medium-load structures like driveways, sidewalks, and residential slabs. They are also employed in some commercial and industrial projects where moderate strength and resistance to environmental factors are needed.Large Diameters (e.g., 16 mm, 20 mm)

Uses: Large-diameter Fiberglass Rebar is ideal for heavy-duty structures such as bridge decks, industrial floors, and large-scale foundations. These sizes are selected for their ability to handle significant structural loads and their superior performance in harsh conditions.Fiberglass Rebar 20′

Availability and Specifications

Disadvantages of Fiberglass Rebar

While Fiberglass Rebar offers several benefits, such as corrosion resistance and lightweight handling, it is important to also consider its disadvantages. Understanding these challenges and limitations can help in making informed decisions about when and where to use Fiberglass Rebar.

Challenges and Limitations

Higher Costs and Economic Implications

Cost Comparison: Fiberglass Rebar is generally more expensive than traditional steel rebar. The higher production costs associated with the specialized materials and manufacturing processes contribute to its elevated price. This can impact the overall budget for construction projects, especially on a large scale.

Economic Considerations: While the initial cost of Fiberglass Rebar is higher, its durability and rust resistance may lead to lower maintenance costs over time. However, the upfront investment can be a significant consideration for budget-conscious projects or smaller-scale applications where cost savings are a priority.

Stiffness and Brittleness: Fiberglass Rebar tends to be more brittle compared to traditional steel rebar. This can lead to challenges during installation, as it may be more prone to cracking or breaking under certain conditions. Additionally, its lower stiffness compared to steel might affect its performance in applications requiring high rigidity. Durability Concerns: Although Fiberglass Rebar is highly resistant to corrosion, its long-term performance can be affected by factors such as exposure to UV light and chemical interactions. Over time, these factors may impact its effectiveness and longevity.Issues Related to Stiffness, Brittleness, and Fire Resistance

Fire Resistance: Fiberglass Rebar generally has lower fire resistance compared to steel rebar. In high-temperature scenarios, such as fires, the resin used in Fiberglass Rebar can degrade, potentially compromising the structural integrity of the concrete. This limitation makes it less suitable for applications where fire resistance is a critical factor.Long-Term Performance Considerations

Structural Behavior: The long-term structural behavior of Fiberglass Rebar in various environmental conditions is still under study. Unlike traditional steel rebar, which has a well-documented performance history, Fiberglass Rebar’s long-term performance data is less comprehensive. This can lead to uncertainties regarding its behavior in specific applications or environments.

FAQs about Fiberglass Rebar

What is the lifespan of fiberglass rebar?

Is fiberglass rebar stronger than steel?

Does fiberglass rebar meet code?

Do you have to bond fiberglass rebar?

Where can you use fiberglass rebar?

Is fiberglass rebar any good?

Is fiberglass rebar easy to cut?

Can fiberglass rebar bend?

Does fiberglass rebar rust?

What is the strongest rebar?

Does fiberglass rebar float?

Is fiberglass stronger than steel?

What is the lifespan of GFRP rebar?

Can fiberglass rebar be used in columns?

What are the problems with fiberglass rebar?

Brittleness: Unlike steel, fiberglass rebar is brittle and cannot be bent on-site. This limits its flexibility in construction projects where custom shaping is required.

Lower Compressive Strength: Fiberglass rebar has lower compressive strength compared to steel, which may limit its use in certain load-bearing applications.

Initial Cost: GFRP rebar is often more expensive upfront than traditional steel rebar, although it can be more cost-effective over time in corrosive environments due to its longer lifespan.

Limited Ductility: Fiberglass rebar does not deform plastically under load, which means it can fail suddenly without the warning signs that steel rebar might show, such as bending or yielding.

Specialized Installation: Requires specific knowledge and tools for installation, particularly since it cannot be bent or welded like steel.

Why is fiberglass not good?

Brittleness: It is more prone to cracking or breaking under impact compared to materials like steel.

Temperature Sensitivity: Fiberglass can weaken at high temperatures, which may limit its use in environments with extreme heat.

Incompatibility with On-Site Bending: Fiberglass rebar cannot be bent on-site, requiring precise pre-fabrication or the use of steel in applications that need on-site adjustments.

Higher Initial Cost: The cost of fiberglass materials can be higher than traditional options like steel, which may not be justified in non-corrosive environments.

Can you use fiberglass rebar in a driveway?

Is fiberglass rebar worth it?

Is fiberglass better than rebar in concrete?

When to use fiberglass rebar?

Corrosion Resistance is Crucial: Such as in marine environments, chemical plants, or bridges exposed to de-icing salts.

Lightweight Requirements: In applications where reducing weight is beneficial, such as in certain prefabricated structures or in areas where transportation costs are a concern.

Non-Magnetic Properties: In facilities where magnetic interference must be minimized, such as in MRI rooms or research laboratories.

Electrical Insulation is Needed: In situations where the non-conductive nature of fiberglass rebar is an advantage.

Is GFRP rebar cheaper than steel rebar?

Is fiberglass rebar cheaper than steel?

What is pink fiberglass rebar used for?

Concrete reinforcement in corrosive environments: Such as in bridges, marine structures, and coastal infrastructure.

Driveways and sidewalks: Where exposure to de-icing salts could cause traditional steel rebar to corrode.

Parking structures and garages: To prevent corrosion from road salt.

Retaining walls and foundations: In areas with high moisture content or chemical exposure.

Is fiberglass in concrete as good as rebar?

What is the purpose of fiberglass rebar?

Does fiberglass last longer than steel?

When can you use fiberglass rebar?

Marine environments: For docks, piers, and other structures exposed to saltwater.

Bridges and highways: Especially in areas that use de-icing salts, which can corrode steel rebar.

Chemical plants: Where exposure to corrosive chemicals could degrade steel.

Parking garages: To prevent corrosion from road salt.

Tunnels and retaining walls: Where long-term durability and corrosion resistance are required.

MRI rooms and research facilities: Where non-magnetic and non-conductive properties are essential.

What do you tie fiberglass rebar with?

What cuts fiberglass rebar?

Diamond-bladed saws: Circular saws with diamond blades provide clean cuts without damaging the material.

Carbide-tipped hacksaws: For smaller diameters, a carbide-tipped hacksaw can be used effectively.

Bolt cutters: For quick cuts, though they may not produce as clean an edge as a saw.

Why is epoxy coated rebar being banned?

Can fiberglass rebar be used in footings?

Will fiberglass rebar bend?

Can you use fiberglass rebar vertically?

Can you use fiber instead of rebar in concrete?

What are the downsides of fiberglass rebar?

Brittleness: Fiberglass rebar cannot be bent or reshaped on-site, limiting its versatility.

Lower compressive strength: It is not as strong as steel in terms of compressive load-bearing capacity.

Higher initial cost: Fiberglass rebar can be more expensive upfront compared to steel rebar.

Specialized installation: Requires specific tools and knowledge for proper installation.

Lack of ductility: Fiberglass rebar does not deform plastically under load, meaning it can fail suddenly without warning.

Can you use fiberglass to reinforce concrete?

Is fiberglass rebar as good as steel rebar?

Is fiberglass rebar cheaper?

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.