- Home

- Fiberglass Rods

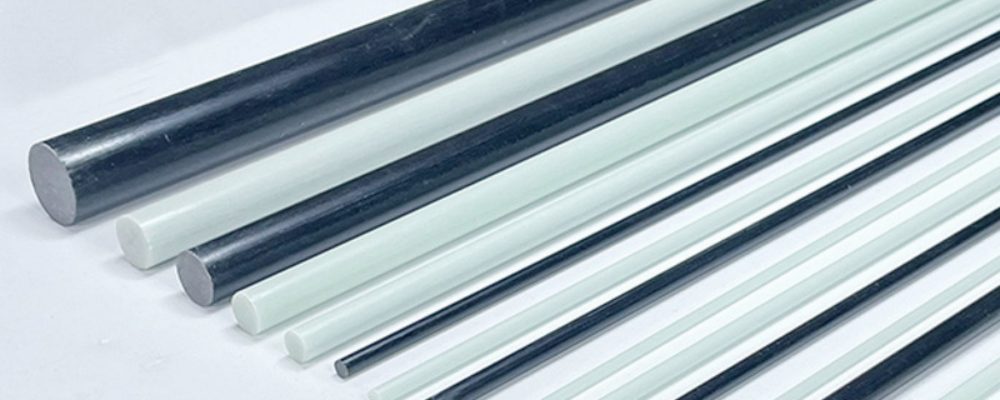

Solid Round Fiberglass Rods – Uncoated, Undrilled

Fiberglass rods, also known as glass fiber rods, are versatile and durable materials used in various applications such as structural support, framing, and fabric reinforcement. Commonly employed in making antennas, flags, tarp containment, and boat covers, these rods, along with fiberglass tubes, are available in 6′ lengths and are composed of 65%-75% glass for maximum strength. Solid, uncoated Fiberglass Rods deliver exceptional strength, durability, and lightweight performance for versatile outdoor applications.

Fiberglass rods are lightweight, non-conductive, and inexpensive, with options available in black or white. They are easily cut with a hacksaw or tile saw, making them convenient for both industrial and DIY projects. With diameters of 1/8″, 3/16″, 1/4″, 5/16″, and 3/8″, these rods are suitable for a range of needs and can be customized in color depending on the diameter.

These rods are used across multiple industries due to their high strength-to-weight ratio, resistance to corrosion, and ability to maintain micro-structural integrity. Fiberglass rods, along with fiberglass rebar, are particularly valuable in structural applications, electrical insulation, and marine environments, where their durability and flexibility make them a preferred choice over traditional materials like wood dowels.

Simplifying Your Life: Key Functionalities

| Attributes | Details |

|---|---|

| Place of Origin | Hebei, China |

| Brand Name | GangLong Fiberglass |

| Product Name | Fiberglass Rods |

| Material | Fiberglass |

| Application | Architecture, Engineering |

| Technology | Pultrusion |

| Surface Treatment | Smooth or Customized |

| Size | Customizable |

| Length | Customizable |

| Thickness | Customizable |

| Color | Customizable |

| Diameter | Customizable |

| Shape | Customizable |

| Quality | High Quality |

| Features | Waterproof, Durable, Anti-corrosion, Fireproof, Lightweight and High Strength |

| Processing Services | Punching, Cutting, Bending, Forming, Welding |

| After-sales Service | Online Technical Support |

News

- Exploring the Benefits of Carbon Fiber Apparel

- How to Work with Carbon Fiber Successfully

- Carbon Fiber Suit: The Future of Lightweight Armor

- Is Carbon Fiber Armor the Future of Protection?

- Why White Carbon Fiber is Popular in Automotive Design

- Transparent Carbon Fiber Sheets Two Sided Gloss Twill

- Epoxy-Compatible Chopped Carbon Fiber Mat

- Carbon Fiber EG Hatch: Upgrade Your Civic Today

- The Benefits of Using Structural Carbon Fibre in Engineering

- How Many Layers of Layered Carbon Fiber Are Needed?

What Are Fiberglass Rods?

Definition and Composition

Fiberglass Rods are engineered from a composite material that combines glass fibers with resin. This combination creates a rod that is both strong and lightweight, making it ideal for various structural and reinforcement applications. The glass fibers provide tensile strength, while the resin binds the fibers together, offering stability and durability. This composition is not only essential for applications like FRP Pipe but also for fiber glass duct board, where similar properties are required to ensure effective performance in various environments. Both materials leverage the strength of glass fibers, making them reliable choices for demanding applications.

Key features of fiberglass rods

High Tensile Strength

Fiberglass rods feature continuous glass fibers oriented along the rod’s length or woven into specialized fabrics. These fibers deliver tensile strengths ranging from two hundred to one thousand two hundred megapascals. The remarkable strength combined with low density makes fiberglass rods ideal for applications like post‑tensioned concrete reinforcement and high‑load guy wires, providing exceptional pull‑out resistance while minimizing weight overall.

Lightweight Construction

With densities between 1.8 and 2.0 grams per cubic centimeter—about one‑quarter to one‑fifth that of steel—fiberglass rods dramatically reduce dead loads. Their low mass simplifies handling, lowers shipping costs, and enables designers to create longer spans or extended reaches in aerospace structures, sporting equipment, and architectural elements, where every kilogram saved contributes to performance without sacrificing structural integrity or safety.

Corrosion and Chemical Resistance

Fiberglass rods resist rust, galvanic corrosion, and degradation from salt spray, acids, alkalis, and most organic solvents. Their chemical resilience makes them invaluable for marine hardware, chemical‑processing pipe supports, and outdoor anchoring systems. By eliminating corrosion concerns, fiberglass rods extend maintenance intervals, reduce lifecycle costs, and ensure reliable operation in harsh industrial environments, saline conditions, or chemically aggressive atmospheres for years.

Electrical and Thermal Insulation

Encapsulated in a non‑conductive polymer matrix, fiberglass rods provide excellent electrical insulation and thermal resistance. They are widely used as supports in high‑voltage equipment, hot‑wire cutting tools, and thermal shielding components. Unlike metal alternatives, fiberglass rods prevent short circuits, eliminate conductive pathways, and minimize heat transfer, ensuring safe operation in electrical assemblies and heat‑sensitive applications without additional insulating layers.

Dimensional Stability

Fiberglass rods exhibit minimal thermal expansion—typically five to ten micrometers per meter per degree Celsius—and excellent fatigue resistance under cyclic loading. This stability preserves precise alignment of structural elements such as antenna masts, concrete reinforcement cages, and precision machine components. By maintaining shape and dimensional accuracy across temperature fluctuations and repeated stresses, fiberglass rods deliver consistent performance throughout their service life.

Affordable

Thanks to efficient pultrusion manufacturing and abundant raw materials—silica sand for glass fibers and widely available thermosetting resins—fiberglass rods remain highly cost‑effective. High production yields and scalable processes drive down unit costs compared to specialty metals and alternative composites. Their economical price point makes fiberglass rods an attractive choice for large‑scale construction, infrastructure projects, and mass‑produced consumer goods without compromising performance.

Durable

The combination of tough glass fibers and a resilient cured resin matrix grants fiberglass rods superior resistance to impact, abrasion, UV radiation, and fatigue cracking. They withstand decades of continuous use without significant degradation, preserving mechanical properties in demanding conditions. This durability reduces replacement frequency, ensures structural integrity, and provides dependable, long‑term performance for industrial machinery, outdoor structures, and high‑load applications.

Multi‑purpose

By varying diameter, fiber orientation, and resin formulation, manufacturers tailor fiberglass rods for diverse end uses. They reinforce FRP pipes, serve as spines in fishing rods and tent poles, and act as masts for antennas and booms for lightweight structures. This versatility enables a single material system to meet performance requirements across construction, telecommunications, recreational equipment, and specialized tooling without multiple proprietary components.

Adaptable

Fiberglass rods can be pultruded into custom cross‑sections—round, square, I‑beam—and undergo secondary machining, bonding, or overmolding. They integrate readily with metals and plastics to form hybrid assemblies, using adhesives, coatings, or mechanical fasteners. Designers exploit this adaptability to create complex structural frameworks, composite panels, and precision fixtures, taking advantage of fiberglass rods’ compatibility with diverse fabrication techniques and finishing processes.

Weather Friendly

Resistant to ultraviolet radiation, moisture ingress, freeze‑thaw cycles, and extreme temperatures, fiberglass rods maintain mechanical integrity and appearance outdoors. They do not warp, crack, or delaminate under prolonged environmental exposure, ensuring reliability in architectural accents, environmental sensors, and outdoor support structures. This weather tolerance translates into low maintenance requirements and extended service life in all climates without protective coatings.

Solid vs. Hollow Fiberglass Rods Comparison

Fiberglass rods are commonly used in various industries for their strength, durability, and versatility. There are two primary types of fiberglass rods: solid and hollow. Both types offer distinct advantages and disadvantages depending on the specific needs of the application. Below is a table summarizing the key differences, advantages, disadvantages, and common uses for solid and hollow fiberglass rods.

| Category | Solid Fiberglass Rods | Hollow Fiberglass Rods |

|---|---|---|

| Structure | Solid fiberglass, strong and rigid. | Central void, lightweight and flexible. |

| Advantages | High strength, durability, corrosion-resistant. | Lightweight, flexible, easier to handle. |

| Disadvantages | Heavier, less portable. | Lower strength, less rigid. |

| Applications | Structural support, construction, outdoor use. | Aerospace, lightweight structures, easy-to-handle components. |

| Weight | Heavier. | Lighter. |

| Strength & Rigidity | Stronger and more rigid. | More flexible but weaker. |

Common Applications of Fiberglass Rods

Fiberglass rods are highly versatile, durable, and lightweight, making them indispensable across a wide range of industries. Below are the most common applications of fiberglass rods, clearly categorized and described:

Structural Support and Framing

Fiberglass rods are widely utilized in the construction industry for reinforcing and supporting structures. Their high strength-to-weight ratio and corrosion resistance make them ideal for both residential and commercial applications. Common uses include reinforcing load-bearing elements such as beams and columns and providing stability in framing systems. Fiberglass rods are especially beneficial in harsh environments where traditional materials might degrade, ensuring long-lasting structural integrity.

Marine Applications

In the marine industry, fiberglass rods are valued for their resistance to water, chemicals, and salt. They are commonly used in boat covers, where their lightweight nature and durability provide effective structural support. Additionally, their corrosion-resistant properties ensure they can withstand prolonged exposure to harsh marine conditions, making them a reliable choice for various watercraft-related applications.

Electrical Insulation

The non-conductive nature of fiberglass rods makes them an excellent choice for electrical applications. They are frequently used in antenna construction to provide electrical isolation and enhance signal transmission. Additionally, fiberglass rods are used in electrical insulation systems to protect against current leakage, contributing to safer and more reliable installations in both industrial and residential settings.

DIY and Home Improvement Projects

For DIY enthusiasts, fiberglass rods offer a flexible and creative material for home improvement projects. These rods can be cut, shaped, and assembled with basic tools, making them ideal for tasks such as creating custom shelving, supporting garden trellises, or reinforcing home structures. Their durability and lightweight properties make them suitable for both practical and decorative purposes, offering endless possibilities for innovative projects.

Industry-Specific Applications

Fiberglass rods serve unique roles in various industries, including:

- Aviation: Used for lightweight structural components.

- Agriculture: Employed in greenhouses and other farming structures for reinforcement.

- Construction: Applied in industrial frameworks and as durable reinforcements.

- Emergency Services: Utilized for safety and rescue tools due to their strength and non-conductive properties.

Other Common Uses

Fiberglass rods are also popular for creating antennas, flags, tarp containment systems, and fabric reinforcements. Their adaptability and ease of fabrication make them a go-to material for designers, builders, and manufacturers who require strong, lightweight components.

Fiberglass rods are an excellent choice for applications that demand strength, durability, and versatility. Whether for marine, electrical, structural, or creative purposes, their unique properties make them a valuable material across countless industries.

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.

Fiberglass Rods: Special Sizes and Custom Options

Fiberglass rods are available in a wide range of sizes, making them versatile and adaptable for various applications. Beyond standard sizes, special options like 10 ft rods and fully customized pultruded fiberglass rods cater to specific needs. Below is a comprehensive guide to common sizes, special sizes, and custom options.

Common Sizes of Fiberglass Rods

Fiberglass rods typically range in diameter from 0.062 inches to 0.750 inches and are available in standard lengths of 6 feet, 8 feet, and 12 feet. These sizes offer unique advantages and are suited for different applications:

Small-Diameter Rods (0.062–0.250 inches)

- Advantages: Lightweight, flexible, and easy to work with.

- Disadvantages: Lower strength and rigidity; unsuitable for heavy-duty tasks.

- Applications: Ideal for DIY projects, crafting, and lightweight support structures.

Medium-Diameter Rods (0.250–0.500 inches)

- Advantages: Balanced strength and flexibility, suitable for a wide range of applications.

- Disadvantages: Heavier than smaller rods but still manageable.

- Applications: Used in framing, antenna construction, and small-scale structural support.

Large-Diameter Rods (0.500–0.750 inches)

- Advantages: High strength, durability, and rigidity.

- Disadvantages: Heavier and less flexible; requires more effort to cut and handle.

- Applications: Perfect for industrial applications, heavy-duty frameworks, and load-bearing structures.

Special Sizes: 10 ft Fiberglass Rods

10 ft fiberglass rods are a popular choice for projects requiring extended reach or fewer joints. They combine the versatility of standard fiberglass rods with the added benefit of longer spans.

Advantages:

- Fewer joints ensure better structural integrity and aesthetics.

- Provides enhanced flexibility for larger frameworks and extended supports.

- Reduces the need for additional connectors or reinforcements.

Disadvantages:

- Longer rods can be more challenging to transport and install.

- Slightly higher cost due to their size and versatility.

Applications:

- Reinforcing large structures like buildings or bridges.

- Creating tall supports for marine, agricultural, or construction purposes.

- DIY projects requiring seamless integration over extended lengths.

Customized Fiberglass Rods

Custom fiberglass rods are manufactured through a precise process called pultrusion, allowing for tailored solutions that meet unique project requirements. With custom options, you can specify various aspects, such as:

- Length: Choose the exact length needed to minimize waste and maximize efficiency.

- Diameter and Thickness: Adjust the rod’s dimensions to achieve the desired balance of strength, rigidity, and weight.

- Color and Finish: Match specific aesthetic or functional requirements.

- Material Properties: Modify rigidity, flexibility, or chemical resistance based on application demands.

Benefits of Customization:

Ensures compatibility with unique designs or specifications.

- Reduces material waste by eliminating unnecessary cutting or modifications.

- Enhances project performance with rods tailored for specific tasks.

- Supports innovative designs for industrial, commercial, and DIY applications.

GangLong Fiberglass specializes in providing customized pultruded fiberglass rods. By discussing your requirements with GangLong, you can ensure that your rods meet exact specifications, whether you need unique dimensions, specific material properties, or tailored colors. Our expertise and customer-focused approach make it easy to bring your project to life.

Fiberglass rods are available in a variety of sizes, each offering distinct advantages for different applications. Special sizes like 10 ft rods and the ability to customize dimensions through GangLong Fiberglass provide flexibility and efficiency for unique project demands. Whether for structural reinforcement, creative designs, or specialized industrial needs, fiberglass rods are a reliable and versatile solution.

Popular Fiberglass Rod Products and Their Features

Fiberglass rods are available in a variety of types—including undrilled solid‑core rods—each designed to meet specific requirements across industries. From structural support to lightweight flexibility, these products are known for their durability, corrosion resistance, and adaptability. Below is an overview of five popular types of fiberglass rods and their key features:

Solid Fiberglass Rods

Solid fiberglass rods are a versatile and robust choice, manufactured using continuous fiberglass filaments impregnated with resin and cured to create a solid, durable product.

Key Features:

- Strength and Durability: High tensile strength and resistance to impact make them ideal for demanding applications.

- Corrosion Resistance: Excellent performance in harsh environments, such as marine, chemical, or outdoor settings.

- Lightweight: Despite their robustness, they are lightweight, making handling and installation easier.

- Customizability: Available in various diameters and lengths to suit diverse projects.

Applications: Widely used for structural reinforcement, framing, and industrial projects requiring high durability. Hollow fiberglass rods are designed with a central void, offering reduced weight and increased flexibility compared to their solid counterparts. Key Features: Applications: Commonly used in aerospace, lightweight construction, and agricultural supports. Pultruded fiberglass rods are manufactured using a pultrusion process, which allows precise control over dimensions and material properties, resulting in a high-performance product. Key Features: Applications: Ideal for antennas, flagpoles, and chemical processing equipment. Flexible fiberglass rods are specifically designed for applications requiring bendability without sacrificing durability. Key Features: Applications: Used in sports equipment (e.g., tent poles, fishing rods) and garden trellises. Colored fiberglass rods offer the same durability and strength as other types but include pigmentation during the manufacturing process for aesthetic or functional purposes. Key Features: Applications: Used in creative designs, safety markers, and projects requiring color-coded components.Hollow Fiberglass Rods

Pultruded Fiberglass Rods

Flexible Fiberglass Rods

Colored Fiberglass Rods

Considerations and Limitations of Fiberglass Rods

When evaluating the use of fiberglass rods, it is essential to weigh both their advantages and challenges to make an informed decision. Fiberglass rods are widely used across various industries due to their unique properties, but they also come with certain limitations that need to be considered.

Advantages

Fiberglass rods offer several key benefits that make them a popular choice in many applications:

Lightweight: One of the most significant advantages of fiberglass rods is their lightweight nature. This property allows for easy handling and installation, reducing labor costs and simplifying transportation.

Corrosion-Resistant: Fiberglass rods are highly resistant to corrosion, which makes them ideal for use in harsh environmental conditions where metal rods might fail. Their resistance to chemical and moisture damage ensures a longer service life in various applications.

Durable Properties: The durability of fiberglass rods is another notable advantage. They are designed to withstand significant stress and strain without deforming, making them suitable for use in structural and support roles where strength and reliability are critical.

Despite their advantages, fiberglass rods also present some challenges that must be addressed: Issues with Brittleness: Fiberglass rods can be prone to brittleness under certain conditions. This means that while they are generally strong, they may not perform well under extreme impact or sudden stress, which can lead to breakage or failure. The long-term performance of fiberglass rods is influenced by several factors that affect their longevity and reliability: Environmental Conditions: The performance of fiberglass rods can be significantly impacted by environmental conditions. Extreme temperatures, UV radiation, and chemical exposure can affect their structural integrity and overall lifespan.Challenges

Fire Resistance: Fiberglass rods do not offer high levels of fire resistance. In applications where fire safety is a concern, their performance may be inadequate compared to other materials that offer better fire resistance.

Cost: The initial cost of fiberglass rods can be relatively high compared to traditional materials like steel. While they may offer long-term savings due to their durability and low maintenance needs, the upfront investment can be a barrier for some projects.Long-Term Performance

Maintenance and Care: Regular maintenance and proper handling are crucial for extending the life of fiberglass rods. Ensuring that they are not subjected to conditions that could cause damage will help maintain their performance over time.

Manufacturing Quality: The quality of the fiberglass rods, including the resin and reinforcing fibers used, plays a critical role in their long-term performance. High-quality materials and manufacturing processes contribute to better durability and reliability.

Manufacturing Process of Fiberglass Rods

Fiberglass rods are produced through a method called pultrusion, ensuring high strength and durability. The manufacturing process involves the following steps:

Preparation of Fiberglass Rovings

The process begins by selecting high–quality fiberglass rovings—bundles of continuous, unidirectional glass filaments that will carry the load in the final product. Each roving is precisely tensioned and aligned to guarantee uniform fiber distribution and optimum tensile performance. Quality control at this stage checks fiber diameter, sizing treatment (to promote resin adhesion), and roving count to match the mechanical requirements of the finished rod. Proper handling minimizes breakage and ensures consistent feed into the pultrusion line.

Resin and Pigment Application

Next, the rovings are drawn through a resin bath containing a carefully formulated mixture of thermosetting resin (often polyester, vinyl ester, or epoxy) and any desired pigments or additives. The resin bath wets each filament thoroughly, infusing the fibers with the polymer matrix that will bind them together. Pigments can be added to provide UV protection or color coding for different rod grades. Controlled bath temperature and resin viscosity ensure a uniform coating without excess resin waste or dry spots.

Pultrusion Process

Once resin‑impregnated, the rovings enter the pultrusion die—a precisely machined, heated steel mold that shapes the material into its final cross‑section (round, square, I‑beam, etc.). A hydraulic or electric puller maintains constant tension, pulling the continuous profile through the die at a regulated speed. Inside the die, heat initiates polymerization of the resin, transforming the tacky mixture into a solid, fiber‑reinforced composite. This continuous process yields high‑quality rods with tight dimensional tolerances and straightness.

Heating and Curing

As the composite profile exits the die, it enters an additional heated curing zone or oven where temperature and dwell time are optimized to complete crosslinking of the resin. Precise control of the cure cycle prevents internal stresses, voids, or incomplete polymerization that could compromise mechanical properties. In some cases, a staged heat profile is employed—gradually ramping temperature to enhance thermal stability and impact resistance. Post‑curing checks measure hardness, fiber–resin ratio, and any residual exotherm to confirm full cure.

Cutting to Length

The fully cured rod, now exhibiting its final mechanical strength and rigidity, is conveyed to a cutting station where automated saws or shears trim it to specified lengths. Standard cut lengths—often ranging from one to six meters—are stocked, while custom orders can be produced on‑demand to suit project requirements. Clean, burr‑free ends facilitate easy handling and insertion into downstream assemblies or connectors. Final inspections check length accuracy, surface finish, and straightness before rods are bundled, labeled, and packaged for shipment.

FAQs about Fiberglass Rods

What are the different types of fiberglass rods?

Solid Fiberglass Rods: These are robust and provide high strength and durability. They are commonly used in structural applications and for reinforcement purposes.

Hollow Fiberglass Rods: These rods are lighter than solid rods and are often used in applications where weight is a critical factor, such as in the construction of lightweight frameworks.

Flexible Fiberglass Rods: Designed to bend and conform to various shapes, these rods are often used in applications where flexibility is needed, such as in fishing rods and certain industrial applications.

Composite Fiberglass Rods: These rods combine fiberglass with other materials to enhance specific properties like impact resistance or thermal stability, making them suitable for specialized applications.

What are fiberglass poles used for?

What can you put on the Fiberglass Rod?

Are Fiberglass Rods Stronger than Graphite?

How Do You Cut Fiberglass Rods?

Measure and mark the desired length.

Secure the rod in a vise or clamp to prevent movement during cutting.

Use a steady and even motion to cut through the rod.

Smooth the edges with sandpaper to prevent splinters. Wear safety goggles, gloves, and a mask to protect yourself from fiberglass dust, which can be irritating to the skin and lungs.

Why Are Some Fly Rods So Expensive?

Which Is Stronger: Carbon Fiber or Fiberglass?

What Is the Best Tool to Cut Fiberglass?

What Do You Cut Fiberglass Rebar With?

What Are Fiberglass Poles Used For?

Construction: For scaffolding, structural supports, and framing.

Marine Industry: As masts, antenna poles, and reinforcement structures.

Electrical Industry: As non-conductive poles for safety applications.

Sports and Recreation: In tent poles, fishing rods, and sports equipment. Fiberglass poles are valued for their lightweight properties, making them easy to transport and handle across diverse industries.

Are Fiberglass Fly Rods Strong?

What are fiberglass rods good for?

What are the pros and cons of Fibreglass?

Lightweight: Fiberglass is much lighter than metals, making it easier to handle and transport.

Corrosion Resistant: It does not rust or corrode, making it ideal for use in harsh environments.

High Strength: Fiberglass has excellent tensile strength, making it durable for various applications.

Electrical Insulation: It is non-conductive, making it safe for electrical and electronic applications.

Design Flexibility: It can be molded into complex shapes, allowing for a wide range of applications.

Cons:

Brittle: While strong, fiberglass can be brittle and may crack under heavy impact or stress.

Expensive: High-quality fiberglass materials can be costly compared to other materials.

Difficult to Repair: Damaged fiberglass can be challenging to repair and often requires specialized techniques.

Health Risks: Dust from cutting or sanding fiberglass can be hazardous if inhaled, requiring proper safety precautions.

How strong are fiberglass poles?

What are the different types offiberglass rods?

Solid Fiberglass Rods: These are dense and strong, often used for structural support, tool handles, and fishing rods.

Hollow Fiberglass Rods: Lighter and more flexible, used in kite frames, tent poles, and lightweight structural applications.

Pultruded Fiberglass Rods: Produced through a pultrusion process, these rods have high strength and are used in electrical insulators, cable trays, and industrial applications.

What are the 3 types of rods?

Fiberglass Rods: Known for their flexibility, corrosion resistance, and non-conductive properties, used in construction, electrical applications, and sporting goods.

Carbon Fiber Rods: Lighter and stronger than fiberglass, these rods are used in high-performance applications like aerospace, automotive, and advanced sports equipment.

Steel Rods: Strong and durable, steel rods are used in heavy construction, infrastructure, and automotive industries due to their high tensile strength.

What is the strongest type of fiberglass?

When can you buy Fiberglass Rod?

What can you attach to the Fiberglass Rod?

Connectors and fittings: Used in construction or tent poles.

Hooks or eyelets: For fishing rods or other sporting goods.

Clamps or brackets: In structural or industrial applications.

Electrical terminals: For non-conductive uses in electrical installations.

How do you connect fiberglass rods?

Threaded connectors: Screwed onto the ends of rods.

Sleeves or couplers: Slid over the ends of two rods and secured with adhesive or mechanical fasteners.

Epoxy or other adhesives: Bonding rods permanently.

Mechanical fasteners: Such as bolts or clamps for removable connections.

Are fiberglass rods stronger?

Why are fiberglass rods shorter?

Are fiberglass fly rods worth it?

Are fiberglass rods slow action?

Do fiberglass rods break?

Which is better bamboo rod or Fiberglass Rod?

Can you use bait on a Fiberglass Rod?

Are fiberglass fishing rods better than graphite?

Why fish a fiberglass fly rod?

Why are fiberglass fly rods shorter?

Do fiberglass rods have a spine?

What are the benefits of fiberglass rods?

Durability: They are more resistant to impact and bending compared to graphite.

Flexibility: Provides a smooth, slow action, ideal for certain fishing styles like fly fishing.

Affordability: Generally less expensive than graphite or bamboo rods.

Versatility: Suitable for various types of fishing, including fly fishing, baitcasting, and trolling.

Forgiveness: Easier to cast accurately at short distances, making them suitable for beginners and small stream fishing.

What is the strongest fishing rod material?

Which is better aluminum or fiberglass fishing rod?

Are fiberglass rods good for streamers?

What is the best tool to cut fiberglass rods?

How do you cut a fiberglass rod without splintering it?

How do you cut fiberglass without cracking it?

What cuts fiberglass best?

Can you cut fiberglass rebar with a hacksaw?

How do you cleanly cut fiberglass?

Can you cut fiberglass rebar with a bolt cutter?

How do you cut fiberglass bars?

What is the best tool for shaping fiberglass?

Will a diamond blade cut fiberglass?

How to cut a fiberglass stake?

How to cut fiberglass with an angle grinder?

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.