Fiberglass is a composite material known for its strength and versatility, making it essential in various applications, from construction to automotive. The fiberglass sheet melting point is crucial for understanding how this material behaves under heat. Typically, fiberglass melts at temperatures ranging from 1000°C to 1200°C, depending on its specific formulation and additives. Knowing the fiberglass sheet melting point allows engineers and manufacturers to select appropriate materials for high-temperature environments, ensuring safety and performance. Additionally, this knowledge helps in processing and shaping fiberglass sheets during manufacturing, enabling efficient production methods while maintaining material integrity. Understanding the fiberglass sheet melting point is vital for optimizing its use in diverse industries. The fiberglass sheet melting point is around 2075°F (1135°C), retaining strength up to 700°F (371°C) with fire resistance and an average of 540°C.

What is Fiberglass Sheet Melting Point

Fiberglass is composed of glass fibers that are woven into a mat and combined with resin to form a strong, lightweight material. The composition can vary, but it typically consists of silica, alumina, and other additives to enhance specific properties. A key component in some fiberglass products is hollow glass fiber, which consists of small glass tubes filled with air. These fibers provide a lightweight structure and improve thermal insulation, making the material ideal for applications requiring reduced weight and enhanced heat resistance. Fiberglass sheet protects for its resistance to high temperatures, which plays a significant role in determining the fiberglass sheet melting point. The fibreglass melting point is influenced by the type of glass used, the resin involved, and any additional materials integrated during manufacturing. Typically, the melting point of fiberglass lies between 1,000 to 1,200°C (1,832 to 2,192°F).

Melting Point of Fiberglass

The fiberglass sheet melting point varies based on the type of fiberglass and its formulation. Generally, fiberglass will begin to soften at temperatures around 1000°C and can fully melt by approximately 1200°C. Different grades of fiberglass, such as E-glass and S-glass, exhibit slightly different melting behaviors due to variations in their chemical compositions. E-glass, known for its electrical insulating properties, tends to have a melting point on the lower end of the scale, while S-glass, which offers higher tensile strength, can withstand greater temperatures.

Factors Affecting the Melting Point

Several factors influence the fiberglass sheet melting point. The composition of fiberglass panel, including the type of glass and the resin used, plays a significant role. Additives like flame retardants or fillers can also impact the thermal properties of the material. The manufacturing process, such as the cooling rate and the conditions under which the fiberglass is produced, further affect the melting characteristics. These variables make it crucial for manufacturers to conduct thorough testing to determine the precise melting point of their specific fiberglass products.

Applications Based on Fiberglass Sheet Melting Point

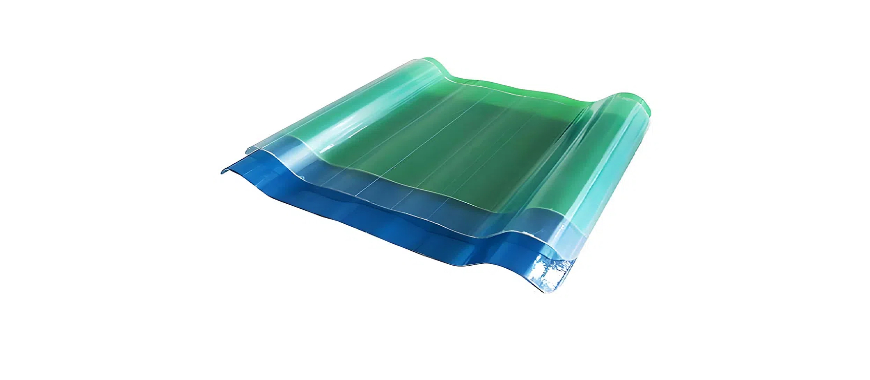

The fiberglass sheet melting point directly influences its applications. In the construction industry, fiberglass is often used for insulation, roofing, and fiberglass wall sheets due to its ability to withstand high temperatures. In automotive manufacturing, components made from fiberglass can endure the thermal stress of engines and exhaust systems. Additionally, fiberglass is commonly utilized in electrical applications, where its high melting point and dielectric properties make it an ideal insulator.

Technical Data and Safety Information Related to Fiberglass Sheet Melting Point

The technical data is essential for safe handling and application of fiberglass materials. Technical data sheets provide detailed information about fiberglass properties, including the melting point. Safety Data Sheets (SDS) are crucial for detailing safe handling procedures and potential hazards associated with fiberglass. Familiarizing oneself with these documents is key to ensuring the effective use of materials, considering the fiberglass sheet melting point.

Installation Tips for Fiberglass Sheets Considering Melting Point

Proper installation techniques are crucial for maximizing the benefits of fiberglass sheets. When working with fiberglass, it’s essential to be aware of its melting point to avoid damaging the material during processing. Users should use suitable cutting tools that do not generate excessive heat, as this can approach the melting point. Additionally, ensuring proper ventilation during installation can help mitigate any fumes that may be released when fiberglass is exposed to high temperatures.

Future Trends in Fiberglass Technology and Melting Point

As industries evolve, so do the technologies associated with fiberglass manufacturing. Ongoing research aims to enhance the properties of fiberglass, including its melting point, to improve performance in extreme conditions. Innovations in formulations and processing techniques may lead to fiberglass sheets that can withstand even higher temperatures, broadening their applications in fields such as aerospace and advanced automotive design. Keeping abreast of these developments can help manufacturers adapt to changing market demands.

Tips on How to Remove Gummy Tape from Fiberglass Rod

The Key of Fiberglass Sheet Melting Point

Fiberglass is a composite material made from glass fibers and resin, and the fiberglass sheet melting point is crucial for determining how this material behaves under heat. This melting point influences its effectiveness in various applications, making it essential for engineers and manufacturers to understand. Knowing the fiberglass sheet melting point helps ensure proper material selection and processing methods for different environments.

Composition of Fiberglass

The primary components of fiberglass include silica, alumina, and various additives. Silica forms the backbone of the glass fibers, providing strength, while alumina enhances thermal resistance. These elements directly contribute to the fiberglass sheet melting point, which typically ranges from 1000°C to 1200°C. Recognizing the composition of fiberglass helps in understanding how these materials can withstand high temperatures.

History and Development of Fiberglass Materials

The history of fiberglass is marked by innovative developments that have expanded its applications. Early fiberglass materials focused on insulation and decorative purposes. As technology advanced, so did the understanding of fiberglass sheet melting points, leading to stronger and more versatile fiberglass sheets. Companies like GangLong Fiberglass have played a significant role in making these materials widely available for various industries.

Melting Point of Fiberglass

The fiberglass sheet melting point is a critical characteristic, generally falling between 1000°C and 1200°C. This melting point can vary based on the type of fiberglass, such as E-glass or S-glass, which exhibit different thermal behaviors. Awareness of the fiberglass sheet melting point is essential for ensuring that products can withstand the thermal demands of their applications.

Factors Influencing Fiberglass Sheet Melting Point

Several factors impact the fiberglass sheet melting point. The chemical composition is vital, as different types of fiberglass include various additives and resins that affect thermal performance. Additionally, the manufacturing process, including cooling rates and techniques, influences the melting point. Understanding these factors allows manufacturers to tailor fiberglass products to specific temperature requirements.

Applications of Fiberglass Based on Melting Point

The fiberglass sheet melting point significantly affects its applications. In construction, fiberglass sheets are utilized for roofing and insulation due to their ability to endure high temperatures. In the automotive sector, components made from fiberglass are suited for areas that experience thermal stress, such as engine covers. Furthermore, fiberglass is widely used in electrical applications where its high melting point makes it an excellent insulator.

How Well Does Fiberglass Rod Hold Thread Successfully

Applications of Fiberglass Sheet Due to Its Melting Point

The fiberglass sheet melting point is a key factor in determining its suitability for various applications. With a melting point of around 2075°F (1135°C) and the ability to retain strength at temperatures up to 700°F (371°C), fiberglass sheets are widely used in environments requiring heat resistance. Their non-combustible nature and thermal stability make them essential in industries where exposure to high temperatures is a concern. Below are specific areas where the fiberglass sheet melting point plays a crucial role in its application.

Industrial Insulation and Fire Protection

Fiberglass sheets are commonly used in insulation due to their high-temperature resistance. They act as thermal barriers in industrial equipment, preventing heat loss and protecting surrounding materials. Their fire-resistant properties make them ideal for fireproofing applications, such as wall panels and protective gear, ensuring safety in extreme conditions.

Aerospace and Automotive Applications

The high fiberglass sheet melting point makes it a preferred material in aerospace and automotive industries. It is used in aircraft interiors, heat shields, and exhaust systems, where exposure to high temperatures is frequent. In automobiles, fiberglass components enhance durability and resistance to engine heat, improving performance and longevity.

Construction and Roofing

Fiberglass sheets serve as durable, fire-resistant roofing and structural materials. Their ability to withstand high temperatures ensures longevity in extreme climates. Fiberglass panels in buildings help enhance fire safety, reducing the risk of fire spread in case of accidents.

Foundry and Metal Processing

Fiberglass sheets are used in metal foundries for high-temperature shielding and mold-making. Their ability to resist melting under extreme heat conditions makes them suitable for handling molten metals, ensuring structural integrity and worker safety.

Electrical and Electronics Industry

With excellent thermal and electrical insulation properties, fiberglass sheets are widely used in electrical components. They are found in circuit boards, transformers, and heat-resistant enclosures, preventing overheating and ensuring the safe operation of electrical devices.

The fiberglass sheet melting point significantly influences its applications, making it a valuable material in industries requiring heat resistance, fire safety, and durability.

Does the Melting Point of Fiberglass Sheets of Different Colors Differ?

The melting point of fiberglass sheets can be influenced by several factors, such as the type of resin used, the glass composition, and the additives incorporated into the material. One of the common questions that arise regarding fiberglass is whether the color of the sheet affects its melting point. While color itself is not a direct factor influencing the melting point of fiberglass sheets, other aspects such as the resin used for coloring or the manufacturing process might have an impact. This answer will explore this concept from various angles, including the role of color, resin, and the impact of manufacturing processes on the melting point of fiberglass sheets.

Influence of Color on Fiberglass Sheet Melting Point

When it comes to color, the pigment used in the fiberglass sheet’s resin could potentially play a role in how the material behaves at high temperatures. However, color itself is not a direct factor in determining the melting point. The pigments or dyes that are used to color fiberglass typically do not significantly change the material’s thermal properties. The main component of fiberglass, the glass fibers themselves, have a relatively consistent melting point, around 1,200°F to 1,400°F (649°C to 760°C), regardless of color. However, some resins used for different colors may have varying chemical compositions or thermal stability. A fiberglass sheet with a darker color may absorb more heat compared to a lighter-colored one, which could cause slight variations in the material’s temperature during exposure to heat. Nevertheless, these changes are unlikely to affect the material’s actual melting point in any significant way.

Resin Impact on Melting Point

The resin used to bond the glass fibers in fiberglass sheets has a more significant impact on the material’s thermal resistance than the color of the sheet. Resin types vary, with some being more heat-resistant than others. Epoxy resins, for example, offer higher heat resistance compared to polyester or vinyl ester resins. Darker-colored fiberglass sheets, which may contain more complex resin formulations for coloring purposes, could have slightly different thermal properties than their lighter counterparts. However, even with such variations, the fiberglass itself will not melt until temperatures approach the glass’s intrinsic melting point. The resin will start to degrade and lose its strength at much lower temperatures, typically between 300°F to 500°F (149°C to 260°C), before the glass fibers themselves reach their melting threshold. Therefore, the resin formulation has a more pronounced influence on the behavior of fiberglass under high heat than the color of the sheet.

Manufacturing Process and Melting Point

The manufacturing process of fiberglass sheets can also influence their melting point. Different processes, such as hand lay-up or pultrusion, can affect the density and overall structure of the fiberglass. A more densely packed or reinforced fiberglass sheet may have slightly different thermal properties due to the overall strength and integrity of the fibers. However, the glass fibers themselves, which have a high melting point, will remain the limiting factor in the fiberglass sheet’s overall resistance to heat. Color-related manufacturing processes do not typically alter the inherent melting point of the fiberglass; instead, variations in manufacturing will be related to the quality, strength, and thermal stability of the resin used.

While the color of fiberglass sheets might have an indirect effect on how they handle heat due to the influence of pigments and resins used in the coloring process, the overall melting point of fiberglass sheets is primarily determined by the glass fibers themselves. The color does not drastically change the melting point, but variations in resin composition or manufacturing processes might slightly affect the material’s thermal behavior. The primary factors influencing the melting point are the type of glass and resin, not the color of the fiberglass sheet. Generally, fiberglass sheets can withstand high temperatures, with the glass fibers themselves having a melting point between 1,200°F and 1,400°F (649°C to 760°C), regardless of color.

Advantages and Disadvantages of Fiberglass Sheet Melting Point

The fiberglass sheet melting point plays a crucial role in determining its suitability for various applications. With a high melting point of around 2075°F (1135°C), fiberglass sheets offer excellent heat resistance, making them ideal for fireproofing, insulation, and industrial applications. However, while this characteristic provides significant advantages, it also comes with certain drawbacks that must be considered in specific use cases. Below, we explore both the benefits and limitations of the fiberglass sheet melting point in different contexts.

Advantages of Fiberglass Sheet Melting Point

Because of its high melting point, fiberglass sheet offers several benefits in heat-intensive environments. These advantages make it a preferred material for industries that require thermal stability and fire resistance.

- Excellent Heat Resistance – Fiberglass sheets can withstand high temperatures without deforming, making them suitable for insulation, fireproofing, and high-heat industrial applications.

- Fireproof Properties – Since fiberglass does not burn easily and retains its structure under heat, it enhances fire safety in buildings, vehicles, and industrial settings.

- Durability in Harsh Conditions – The high fiberglass sheet melting point ensures that the material remains stable in extreme environments, contributing to its long lifespan and reduced maintenance needs.

- Wide Industrial Applications – Due to its ability to resist melting and degradation under heat, fiberglass sheets are used in aerospace, automotive, foundry, and electronic industries.

Disadvantages of Fiberglass Sheet Melting Point

Despite its advantages, the high fiberglass sheet melting point also presents certain challenges that affect its usability and manufacturing processes.

- Difficult to Process at High Temperatures – While fiberglass withstands heat well, its high melting point makes reshaping and manufacturing complex without specialized equipment.

- Potential for Resin Degradation – While the glass fibers in fiberglass sheets are highly heat-resistant, the resin matrix binding them may degrade or char at lower temperatures, affecting overall performance.

- Brittleness Under Thermal Stress – Although fiberglass is strong, extreme temperature fluctuations can lead to thermal expansion and contraction, causing stress fractures or cracks over time.

- Higher Production Costs – Manufacturing fiberglass sheets with high heat resistance requires specialized resins and processing techniques, which can increase production costs compared to lower-melting-point alternatives.

The fiberglass sheet melting point provides significant advantages in terms of heat resistance, fireproofing, and durability, making it essential for industrial and safety applications. However, its limitations, such as brittleness under stress and challenges in processing, must be considered when selecting it for specific uses.

Why the Best Fiberglass Rods Are Essential for Anglers

FAQs about Fiberglass Sheet Melting Point

Fiberglass itself is non-combustible; however, the resin used in the fiberglass composite can be flammable. Typically, the resin can ignite at temperatures around 400°F (204°C) to 600°F (316°C). This means while the fiberglass material can withstand considerable heat, care should be taken in environments where ignition sources may be present. It’s important to use fiberglass in accordance with safety standards and guidelines to minimize fire risks, particularly in applications involving high temperatures or open flames. Always ensure proper ventilation and follow safety protocols when working with fiberglass materials.

The temperature rating of fiberglass sheets varies based on their composition and intended use. Generally, standard fiberglass sheets can withstand temperatures up to 200°F (93°C) without losing structural integrity. However, certain high-performance fiberglass sheets are designed to handle temperatures up to 500°F (260°C) or higher. It’s crucial for users to consult the manufacturer’s specifications to determine the exact temperature rating for their specific fiberglass sheet, especially when the material will be exposed to extreme conditions.

Fiberglass is known for its excellent heat resistance. Depending on the specific resin used in the fiberglass composite, it can typically withstand temperatures ranging from 150°F (65°C) to over 300°F (149°C) without significant degradation. However, specialized formulations, such as high-temperature fiberglass, can endure even higher temperatures, up to 500°F (260°C) or more, making them suitable for industrial applications. This thermal stability is one of the reasons fiberglass is widely used in industries like aerospace, automotive, and construction.

Fiberglass can withstand high temperatures, making it a popular material for insulation and industrial applications. Its resistance to heat depends on the type of fiberglass and the resin used. Standard fiberglass can typically endure temperatures up to 300-500°F (150-260°C) without significant degradation. Specialized high-temperature fiberglass, reinforced with heat-resistant resins, can tolerate temperatures exceeding 1000°F (540°C). However, prolonged exposure to extreme heat can weaken its structural integrity, especially if it surpasses its melting point, which is around 2,000°F (1,093°C). While fiberglass itself is non-combustible, the resin components may deteriorate or burn under extreme heat, affecting its performance. Therefore, while fiberglass is heat resistant, its long-term durability depends on the specific formulation and application conditions.

Fiberglass is highly resistant to water and does not easily break down when exposed to moisture. It is commonly used in marine, roofing, and piping applications due to its excellent waterproofing properties. The fiberglass itself is made from fine glass fibers, which do not dissolve or degrade in water. However, the resin that binds the fibers can be affected by prolonged water exposure, especially in cases of poor-quality resin or improper curing. Over time, water infiltration can lead to issues such as osmosis, which may weaken the structure and cause blistering. High-performance fiberglass with proper sealing and coatings can prevent water damage and extend its lifespan. While fiberglass does not decompose in water, mechanical stress combined with water exposure can cause minor surface degradation over many years.

Fiberglass is a durable material with a long lifespan, but it does degrade over time due to environmental exposure. Factors such as UV radiation, extreme temperatures, moisture, and chemical exposure can cause gradual weakening. While the glass fibers themselves are highly resistant to degradation, the resin matrix that holds them together may break down, leading to brittleness and microcracking. UV exposure, in particular, can cause yellowing and surface chalking, reducing its aesthetic and mechanical properties. In harsh conditions, fiberglass can last anywhere from 20 to 50 years or more, depending on its formulation and maintenance. Proper sealing, coatings, and periodic inspections can significantly prolong its lifespan. Although it does not rot or decompose like organic materials, long-term exposure to environmental stressors can lead to eventual weakening and surface wear.

Fiberglass itself does not burn because it is composed of glass fibers, which are inherently non-combustible. However, the resin used in fiberglass products may burn or char at high temperatures, producing smoke and fumes. The melting point of fiberglass is around 2,000°F (1,093°C), meaning it can withstand most industrial and household heat exposures without melting. However, direct exposure to flames or extreme temperatures above this point can cause the material to soften, deform, or lose structural integrity. Fire-retardant resins can enhance its resistance to combustion, making it suitable for fireproofing applications. While fiberglass does not contribute to fire spread in the same way as organic materials, it is important to use fire-resistant coatings or additives if the material is intended for high-temperature environments.

Fiberglass is a poor conductor of heat, making it an excellent insulating material. Its low thermal conductivity allows it to retain heat or block external temperatures effectively, which is why it is widely used in building insulation, industrial applications, and heat-resistant panels. The composition of fine glass fibers and air pockets within the material further reduces heat transfer, improving its performance in extreme temperatures. Compared to metals, which have high thermal conductivity, fiberglass significantly slows down heat transfer, making it an energy-efficient choice. This property is particularly beneficial in applications requiring thermal resistance, such as furnace insulation, pipes, and fire-resistant barriers. However, while fiberglass itself resists heat conduction, its resin matrix may degrade if exposed to extreme or prolonged heat conditions, necessitating the use of specialized high-temperature resins for demanding applications.

Fiberglass can withstand cold temperatures quite well, but extreme cold can make it more brittle and prone to cracking under mechanical stress. The glass fibers themselves remain stable at low temperatures, but the resin matrix that binds them can contract and lose flexibility, increasing the likelihood of cracking if the material is subjected to impact or heavy loads. Some fiberglass formulations include additives that enhance cold resistance, preventing brittleness and ensuring durability in freezing conditions. In general, fiberglass used in outdoor or cold-climate applications is engineered to withstand temperature fluctuations without significant damage. However, sudden mechanical shocks in extremely cold environments may cause surface cracks or stress fractures, especially in aged or poorly maintained fiberglass. Proper resin selection and protective coatings can help improve cold-weather performance and longevity.

Fiberglass is heat-resistant, but prolonged exposure to high temperatures can weaken its structure and cause surface cracking, especially if the resin matrix becomes brittle over time. Standard fiberglass can typically withstand temperatures up to 300-500°F (150-260°C) without noticeable damage. However, repeated heating and cooling cycles can cause thermal expansion and contraction, leading to stress fractures or surface degradation. Specialized high-temperature fiberglass formulations, reinforced with heat-resistant resins, can prevent such issues and extend its durability in extreme heat conditions. If fiberglass is exposed to temperatures close to its melting point (around 2,000°F or 1,093°C), it may begin to soften, warp, or degrade. To prevent heat-related cracking, it is essential to use high-quality, heat-resistant resins and coatings tailored to the specific operating environment.

Yes, fiberglass expands when exposed to heat, but its thermal expansion rate is relatively low compared to metals and plastics. The expansion occurs due to the resin matrix, which reacts more to temperature changes than the glass fibers themselves. This controlled expansion makes fiberglass a stable material for applications requiring dimensional stability. However, repeated heating and cooling cycles can lead to minor expansion and contraction, which may contribute to surface stress and microcracking over time. Properly formulated fiberglass composites, designed for high-temperature resistance, minimize expansion-related issues. When used in structural applications, engineers account for thermal expansion by incorporating design allowances to prevent warping or cracking. Overall, fiberglass remains dimensionally stable across a wide temperature range, making it a reliable material for both hot and cold environments.

Fiberglass can absorb heat from the sun, especially if it has a dark-colored surface. While the material itself has low thermal conductivity, the resin matrix can heat up when exposed to direct sunlight for prolonged periods. The temperature of fiberglass in the sun depends on factors such as color, thickness, and ambient temperature. Dark-colored fiberglass absorbs more heat, reaching surface temperatures significantly higher than the surrounding air. In contrast, light-colored or reflective coatings help reduce heat absorption. Prolonged sun exposure can also lead to UV degradation, causing surface chalking, yellowing, and reduced mechanical strength. To minimize heat retention, fiberglass products used in outdoor applications often include UV-resistant coatings or heat-reflective additives.

Yes, excessive heat can damage fiberglass, particularly if it surpasses the material’s thermal tolerance. Standard fiberglass can withstand temperatures between 300-500°F (150-260°C) without immediate damage, but prolonged exposure to high heat can weaken the resin, causing softening, charring, or structural degradation. If temperatures exceed its melting point of approximately 2,000°F (1,093°C), the fiberglass may begin to deform or break down. The glass fibers themselves are heat-resistant, but the resin is more vulnerable to heat-related damage. In high-temperature environments, specialized resins with heat-resistant properties are used to enhance fiberglass durability. Regular inspections and protective coatings can help prevent heat-induced wear and extend the material’s lifespan in extreme conditions.

Fiberglass itself is not highly flammable. It is a composite material made of glass fibers, which are typically coated with a resin. The glass fibers are non-combustible and do not catch fire easily. However, the resin that binds the fibers together can burn under certain conditions. The resin used in fiberglass may vary, with some formulations being more prone to combustion than others. The flame resistance of fiberglass is enhanced when the fibers are reinforced with fire-resistant additives. While fiberglass doesn’t ignite easily, it can still contribute to fire hazards if exposed to high temperatures long enough for the resin to break down and catch fire. Therefore, fiberglass is considered fire-resistant but not completely fireproof. For applications requiring high heat resistance, fireproof coatings can be applied to fiberglass to enhance its properties.

When fiberglass is curing, the temperature can vary depending on the specific resin used. Typically, fiberglass curing involves a chemical reaction in the resin that produces heat, a process called exothermic curing. The curing temperature of fiberglass resin usually ranges from 140°F (60°C) to 250°F (120°C), though certain specialty resins can exceed this. During curing, the temperature of the resin can rise significantly, but it will generally remain below the threshold where the glass fibers themselves could be damaged. It’s important to monitor the curing process to prevent overheating, as excessive heat can weaken the final product, cause the resin to degrade, or even lead to fires. Most fiberglass manufacturers provide guidelines for optimal curing temperatures, ensuring the material reaches full hardness without exceeding damaging temperatures.

Fiberglass, when properly installed and maintained, can last for many years. The longevity of fiberglass depends on its exposure to the elements, UV radiation, moisture, and physical wear. In construction and insulation applications, fiberglass typically lasts 20-30 years or more. Fiberglass in marine or automotive applications may last less time due to harsher environmental conditions. Fiberglass is resistant to rot and decay, unlike some organic materials, but it can degrade if exposed to certain chemicals or excessive moisture over time. Additionally, UV rays can break down the resin used in fiberglass, leading to brittleness and potential cracking. Regular inspection and maintenance can help fiberglass products last longer. For insulation, fiberglass does not compress or settle significantly, which helps it maintain its efficiency over the years, making it a long-lasting choice for many construction projects.

Fiberglass mesh is known for its heat resistance, but it is not completely heatproof. The mesh itself is made of woven fiberglass fibers, which are naturally resistant to high temperatures. The heat resistance of fiberglass mesh can typically withstand temperatures up to 1,000°F (538°C) or higher, depending on the specific type and resin coating used. In applications like heat-resistant fabrics, industrial insulation, or reinforcing materials in composites, fiberglass mesh is often chosen for its ability to handle high heat without degrading. However, it’s important to note that fiberglass mesh can still be affected by excessive heat, especially if exposed to direct flames or extremely high temperatures over prolonged periods. In these cases, the resin or coating used to bind the fibers together may degrade or burn, reducing the effectiveness of the mesh.

Pink fiberglass insulation, a popular brand of fiberglass insulation, is fire-resistant but not completely fireproof. The glass fibers themselves do not burn, but the resin used to hold the fibers together can combust when exposed to high temperatures. Fiberglass insulation is designed to help slow the spread of fire and provide thermal protection. It generally has a fire-resistance rating that allows it to withstand temperatures up to 1,000°F (538°C), though this can vary depending on the manufacturer and product specifications. In the event of a fire, pink fiberglass insulation will not catch fire easily and can help delay the spread of flames. However, it is not a fireproof material and should not be relied upon as the sole fire barrier in areas of high fire risk. It’s essential to consider fireproofing measures and materials for enhanced fire protection.

The three main types of fiberglass are E-glass, S-glass, and C-glass, each differing in their composition and properties:

E-glass (Electrical glass): This is the most commonly used type of fiberglass and is known for its excellent electrical insulating properties, as well as its affordability and versatility. It is used in a wide range of applications, including electrical insulation, construction, and automotive industries.

S-glass (Strength glass): S-glass is designed for high-strength applications and has superior tensile strength compared to E-glass. It is often used in aerospace, military, and high-performance sporting equipment due to its ability to withstand greater stresses.

C-glass (Chemical glass): C-glass is used primarily for applications where resistance to chemicals is necessary. It is highly resistant to corrosion and is typically used in environments where fiberglass is exposed to acids, alkalis, or other corrosive substances, such as in chemical tanks or industrial pipes.

Each type of fiberglass has its unique properties, making them suited to different applications based on strength, electrical insulation, or chemical resistance.

When exposed to fire, fiberglass behaves in a particular way depending on the temperature and duration of the exposure. The glass fibers themselves are non-combustible and will not catch fire, but the resin used to bond the fibers together can burn. At temperatures above 300°F (150°C), the resin in fiberglass materials may begin to break down, releasing smoke and potentially contributing to fire spread. The glass fibers will remain intact, but the structural integrity of the material may be compromised due to the loss of the resin. In some cases, fiberglass can help prevent or slow the spread of fire due to its heat resistance. However, if exposed to intense or prolonged heat, fiberglass may lose its strength and insulation properties. The material will typically not ignite or support combustion but can degrade under extreme conditions.

The fire rating of fiberglass depends on its resin content and the specific application in which it’s used. Fiberglass materials are generally fire-resistant and have a fire rating that can withstand temperatures ranging from 300°F to 1,000°F (150°C to 538°C). In building codes, fiberglass insulation often has a Class 1 or Class A fire rating, meaning it has limited flame spread and can help slow the spread of fire. However, the resin used to bond the glass fibers can influence the fire rating significantly. Some fiberglass materials are specifically treated with fire retardants to improve their fire resistance, while others may have a lower fire rating if exposed to high temperatures for extended periods. It’s important to refer to manufacturer specifications to determine the exact fire rating of a particular fiberglass product, especially in fire-sensitive environments.

The most flammable insulation materials are those made from organic materials such as cellulose, which is made from recycled paper products. While fiberglass insulation is highly fire-resistant and does not catch fire easily, cellulose insulation can catch fire more quickly because it is made from paper. When exposed to high heat or flames, cellulose insulation can ignite and burn, which is why it is often treated with fire retardants to improve its fire resistance. Other flammable insulation materials include polystyrene and polyurethane foam, which are commonly used for thermal insulation but can also be highly flammable. These materials, while effective at insulating, may require additional fire-retardant treatments to meet safety standards. Fiberglass insulation, by contrast, has a much higher resistance to fire and is generally a safer choice for fire-prone areas.

Fiberglass is resistant to most chemicals, but certain substances can dissolve or degrade it over time. Strong acids such as hydrofluoric acid can break down fiberglass by attacking the silica in the glass fibers. Some alkalis, like sodium hydroxide, can also weaken fiberglass, although it is generally more resistant to alkaline substances than acids. Organic solvents, including acetone and methylene chloride, may dissolve or damage the resin used to bond the fiberglass fibers, potentially weakening the material. Additionally, prolonged exposure to UV light or moisture can degrade the resin over time, leading to brittleness or loss of structural integrity. It’s essential to avoid contact with aggressive chemicals if the fiberglass is exposed to environments where such substances are present, as they can compromise the material’s strength and longevity.

Touching fiberglass can be harmful due to the tiny, sharp glass fibers that can break off from the material. These microscopic fibers can irritate the skin, eyes, and respiratory system. When fiberglass is disturbed, the fibers become airborne and can cause irritation when inhaled, potentially leading to respiratory issues, including coughing, wheezing, and lung discomfort. When fiberglass touches the skin, the fibers can cause itching, rashes, and irritation, especially if they become embedded in the skin. For safety, it’s recommended to wear protective gear such as gloves, long sleeves, and a dust mask when handling fiberglass. If fiberglass fibers do get on the skin, it’s important to wash the area thoroughly with soap and water to avoid irritation or injury. The irritation is usually temporary, but it’s important to minimize exposure to avoid long-term health risks.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.