High-quality filament wound FRP pipe, offering superior corrosion resistance, temperature stability, and optimal strength-to-weight ratio. Filament wound FRP pipe is a type of fiberglass-reinforced plastic pipe created through a process of winding glass fibers soaked in resin around a rotating mandrel. This method produces pipes with exceptional strength, chemical resistance, and durability. Filament wound FRP pipe is significant in industries like chemical processing, water treatment, and oil and gas, where corrosion resistance and high-pressure tolerance are crucial. Its manufacturing process allows precise control over the pipe’s wall thickness and structural integrity, making it suitable for a wide range of applications. This type of pipe offers a lightweight yet robust solution, outperforming traditional materials like metal and PVC in harsh environments.

What is Filament Wound FRP Pipe?

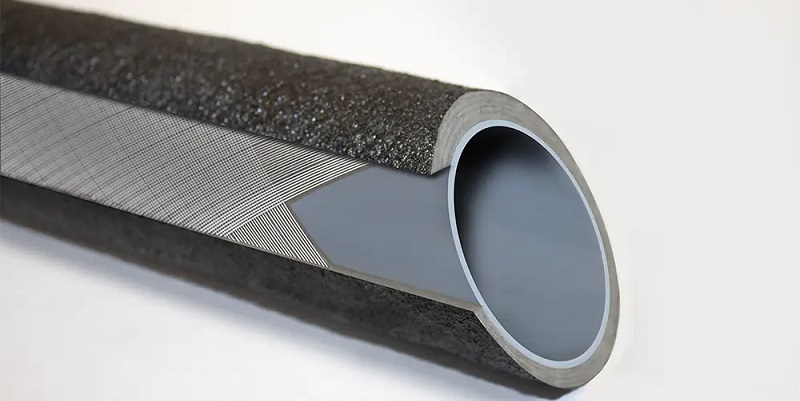

Filament wound FRP pipe is a type of fiberglass-reinforced plastic pipe crafted using a specialized process known as filament winding. This method involves winding continuous strands of glass fiber, impregnated with resin, around a rotating mandrel to form a composite structure. The filament winding process allows for the precise control of fiber placement and resin content, resulting in a high-strength, lightweight pipe that is tailored to meet specific performance requirements. Filament wound FRP pipe is highly valued in industries where durability, corrosion resistance, and strength are essential. Its ability to withstand harsh chemical environments, high pressures, and temperature variations makes it an ideal choice for applications in chemical processing, water treatment, and oil and gas.

Filament wound FRP pipe is a specialized type of fiberglass-reinforced plastic pipe manufactured using the filament winding process. This process involves winding continuous strands of glass fiber impregnated with resin around a rotating mandrel in a controlled pattern. The result is a strong, durable, and lightweight pipe designed to withstand the demands of various industrial applications. Filament wound FRP pipe is renowned for its high strength-to-weight ratio, corrosion resistance, and versatility, making it a preferred choice in industries such as water treatment, chemical processing, and oil and gas. GangLong Fiberglass specializes in producing high-quality filament wound FRP pipes that meet the stringent requirements of these industries.

The Key of Filament Wound FRP Pipe

Filament wound FRP pipe is a type of fiberglass-reinforced plastic pipe manufactured using a process known as filament winding. This process involves winding continuous strands of glass fiber, which are impregnated with a resin, around a rotating mandrel in a precise pattern. The result is a strong, lightweight, and corrosion-resistant pipe suitable for various applications in industries such as water treatment, chemical processing, and oil and gas. Filament wound FRP pipe is known for its exceptional strength-to-weight ratio, durability, and resistance to harsh environmental conditions. GangLong Fiberglass specializes in producing high-quality filament wound FRP pipes and filament wound fiberglass tubing designed to meet the demands of a wide range of industrial applications. Our commitment to quality ensures that our products provide exceptional performance, durability, and reliability in various environments.

The Filament Winding Process in FRP Pipe Production

The filament winding process used in the production of FRP pipes involves several critical steps, typically carried out using a GRP FRP Pipe Filament Winding Machine to ensure precision and consistency. First, the glass fibers are impregnated with a resin mixture, typically consisting of polyester, vinyl ester, or epoxy resins. This impregnation ensures that the fibers are fully saturated, which is vital for achieving optimal mechanical properties. The resin-coated fibers are then wound onto a rotating mandrel, following a predetermined pattern. The winding pattern can vary, with common angles including helical, hoop, and polar windings, each providing different mechanical characteristics to the finished pipe.

During the winding process, tension is carefully controlled to ensure that the fibers are laid down uniformly and without gaps. The wound pipe is then cured, either at room temperature or using heat, to solidify the resin matrix and lock the fibers into place. This curing step is crucial for developing the pipe’s final strength and chemical resistance. After curing, the pipe is removed from the mandrel and cut to the desired length. The result is a seamless, homogenous structure that offers superior performance compared to traditional piping materials.

Filament Wound FRP Pipe Manufacturing Process

The filament winding process is a critical aspect of manufacturing filament wound FRP pipes. This technique ensures that the final product is not only robust but also tailored to meet specific operational requirements. The following is an overview of the filament winding process used by GangLong Fiberglass to produce high-quality FRP pipes:

- Mandrel Preparation: The process begins with the preparation of a mandrel, which serves as the form around which the glass fibers are wound. The mandrel is coated with a release agent to facilitate easy removal of the finished pipe.

- Fiber Winding: Continuous glass fibers are impregnated with resin and wound onto the mandrel in a specific pattern. The winding pattern, angle, and fiber tension are controlled to achieve the desired mechanical properties. Multiple layers of fibers are applied to build up the wall thickness of the pipe, with each layer oriented to provide strength in different directions.

- Curing: After the fibers are wound onto the mandrel, the pipe is cured to harden the resin and create a solid composite structure. The curing process may involve heating the pipe to accelerate the chemical reaction between the resin and the hardener. The result is a strong, rigid pipe with a smooth inner and outer surface.

- Mandrel Removal: Once the pipe is fully cured, it is removed from the mandrel. The release agent applied to the mandrel ensures that the pipe can be removed without damaging its surface.

- Finishing and Inspection: The finished pipe undergoes inspection and finishing processes to ensure it meets the required specifications. This may include trimming the ends, applying protective coatings, and conducting quality control tests to verify the pipe’s dimensions, strength, and performance.

This manufacturing process results in a filament wound FRP pipe that offers excellent strength, corrosion resistance, and durability, making it suitable for demanding industrial applications.

Design Considerations for Filament Wound FRP Pipe

When designing a filament wound FRP pipe system, several factors must be taken into account to ensure optimal performance and reliability:

- Pressure Rating: The pressure rating of the pipe must be matched to the operating conditions of the system. The filament winding process allows for customization of the pipe’s wall thickness and fiber orientation to achieve the desired pressure rating.

- Chemical Compatibility: The resin used in the filament wound FRP pipe must be compatible with the fluids it will transport. GangLong Fiberglass offers a range of resins that provide resistance to various chemicals, ensuring the pipe’s long-term performance in corrosive environments.

- Temperature Range: The pipe’s design must account for the temperature range it will be exposed to. Filament wound FRP pipes can be engineered to handle a wide range of temperatures, making them suitable for applications involving both hot and cold fluids.

- Support and Anchoring: Proper support and anchoring are essential for maintaining the integrity of the piping system. Filament wound FRP pipes should be supported at regular intervals to prevent sagging and movement, especially in large diameter installations.

- Jointing and Fittings: The design of the piping system should include appropriate joints and fittings to accommodate changes in direction, expansion, and contraction. GangLong Fiberglass provides a variety of fittings designed to work seamlessl.

Advantages of Filament Wound FRP Pipe

Exceptional Strength-to-Weight Ratio

Filament-wound FRP pipe delivers high mechanical strength while remaining lightweight, making it much easier to transport, lift, and install compared to steel or concrete pipes. This strength-to-weight advantage reduces structural load and installation costs while maintaining excellent pressure performance. The precision of the winding process ensures consistent quality and load distribution, making it suitable for high-pressure applications in water, chemical, and industrial systems.

Outstanding Corrosion & Chemical Resistance

Filament-wound FRP pipe offers excellent resistance to a wide range of corrosive substances, including acids, alkalis, and industrial solvents. The fiberglass-reinforced composite structure creates a protective barrier that prevents chemical attack, even in highly aggressive environments. This makes it especially valuable in chemical processing, desalination, wastewater treatment, and marine applications where metal or concrete would degrade quickly under similar conditions.

Tailored Mechanical Properties

One of the major advantages of filament winding is the ability to fully customize the pipe’s mechanical properties. Fiber orientation, laminate thickness, and resin type can all be adjusted to meet specific operational demands, such as pressure ratings, temperature tolerance, or flexibility. This versatility ensures that the pipe is optimized for both performance and durability, making it adaptable across a wide range of industries and environments.

Thermal & Electrical Insulation

Filament-wound FRP pipe naturally offers low thermal conductivity and non-conductivity, making it ideal for applications where temperature stability or electrical insulation is required. This includes chemical facilities, power plants, and underground systems near electrical infrastructure. The material helps prevent heat loss, protects nearby components, and enhances overall safety by eliminating risks associated with metal piping in conductive or high-temperature environments.

Superior Abrasion Resistance

Thanks to its dense laminate structure, filament-wound FRP pipe is highly resistant to wear from abrasive media such as slurries, sand, and sediment-laden fluids. This makes it well-suited for demanding industries like mining, pulp and paper, and industrial drainage, where internal erosion is a constant threat. The abrasion resistance helps extend service life, reduce maintenance needs, and ensure reliable operation under harsh flow conditions.

Long Service Life & Low Maintenance

Filament-wound FRP pipe is built for durability, offering decades of reliable performance with minimal upkeep. Its resistance to corrosion, UV rays, chemicals, and abrasion ensures long-term structural integrity, even in harsh outdoor or industrial environments. Unlike traditional materials that may require frequent painting, coating, or replacement, FRP offers a low-maintenance, cost-effective alternative that reduces lifecycle costs while maximizing operational uptime.

Large Diameter Filament Wound FRP Pipe

Why Filament Wound Technology is Essential for Producing Large Diameter Pipes

Filament wound technology is essential for producing large diameter FRP pipes due to its ability to create a strong, structurally sound product that can withstand the stresses associated with large-scale fluid transport. The filament winding process involves winding continuous glass fibers onto a rotating mandrel in a predetermined pattern, ensuring uniform distribution of stress throughout the pipe wall. Here are some reasons why this technology is crucial for large diameter fiberglass pipes:

- Controlled Fiber Placement: Filament winding allows for precise control over the placement and orientation of the glass fibers within the pipe. This control ensures that the fibers are optimally aligned to handle the stresses imposed by internal pressure, external loads, and environmental conditions. By varying the winding angle and pattern, manufacturers can tailor the mechanical properties of the pipe to suit specific requirements.

- High Structural Integrity: The filament winding process produces a composite structure with high structural integrity, making it capable of withstanding high pressures and mechanical loads. This is especially important for large diameter pipes, which must maintain their shape and performance under the weight of the fluid they carry and the external forces they encounter.

- Consistent Quality: Filament winding is a highly automated process that ensures consistent quality and uniformity in the finished product. This consistency is vital for large diameter pipes, where variations in wall thickness or material properties can lead to weaknesses and potential failure points.

- Efficient Production: The filament winding process is well-suited for producing large diameter pipes efficiently. It allows for the continuous production of long pipe sections, reducing the number of joints and connections required in the piping system. Fewer joints mean reduced installation time and lower risk of leaks, contributing to the overall reliability of the system.

These aspects make filament wound technology the preferred method for producing large diameter FRP pipes, ensuring that they meet the performance and safety standards required in critical industrial applications.

The Key of FRP Pipe Specifications

FRP pipe specifications are vital to ensure that the piping system meets the demands of its intended application. These specifications typically include dimensions, pressure ratings, temperature resistance, and chemical compatibility. Properly defining these parameters is essential for selecting the right filament wound FRP pipe and ensuring its long-term performance in the field.

Dimensions and Sizing of Filament Wound FRP Pipe

The dimensions of filament wound FRP pipe are an important consideration in the design of any piping system. Standard dimensions include the nominal diameter, wall thickness, and length of the pipe. For example, pipes with a nominal diameter of 8 inches, such as the GangLong Fiberglass 8″ FRP pipe, are commonly used in various industrial applications due to their balance of size and flow capacity. Wall thickness is determined based on the required pressure rating and the application’s environmental conditions. Filament winding allows for the precise control of wall thickness, enabling the production of pipes with uniform and consistent dimensions.

Length is another key dimension, with filament wound FRP pipes typically produced in standard lengths to facilitate transportation and installation. However, custom lengths can also be manufactured to suit specific project requirements. The flexibility in sizing offered by filament winding makes it possible to produce both small and large diameter pipes, with sizes ranging from a few inches to several feet in diameter.

Pressure Ratings of Filament Wound FRP Pipe

Filament wound FRP pipes are engineered to handle a wide range of internal pressures, making them suitable for both low-pressure drainage applications and high-pressure industrial systems. The pressure rating of a filament wound FRP pipe depends on several key factors: fiber orientation, wall thickness, type of resin, diameter, and the specific service conditions for which the pipe is designed. In addition to pressure, FRP pipe temperature limits must also be considered—FRP pipes typically operate reliably within a temperature range of -40°C to 120°C, depending on the resin system used. Exposure to higher temperatures may reduce pressure capacity and long-term durability, which is why thermal conditions must be factored into all design calculations.

| Parameter | Description |

|---|---|

| Standard Pressure Classes | PN 6, PN 10, PN 16, PN 20, PN 25 (custom ratings available on request) |

| Pressure Range | ~6 bar (87 psi) to ~25 bar (362 psi) and above |

| Fiber Orientation | Optimized hoop winding for high internal pressure resistance |

| Wall Thickness | Increased thickness improves pressure capacity and stiffness |

| Resin Type | Vinyl ester, epoxy, or polyester resins selected based on pressure & chemical exposure |

| Diameter Range | Can be manufactured from small-bore (<50 mm) to large-diameter (>2000 mm) |

| Safety Factor | Typically 2.0 to 4.0 times the operating pressure |

| Surge Pressure Resistance | Excellent ability to absorb pressure spikes and cyclic loads |

PPR FRP Pipe: Advanced Solution for Industrial Water Supply

Applications of Filament Wound FRP Pipe

Chemical Processing

Filament wound FRP pipes are extensively used in chemical plants for conveying acids, alkalis, solvents, and corrosive gases. Their exceptional chemical resistance, combined with high pressure tolerance, ensures safe and reliable transport of aggressive fluids. Customizable designs allow engineers to tailor pipe specifications to specific chemical exposures, making these pipes ideal for environments where traditional materials would corrode or degrade rapidly.

Water and Wastewater Treatment

In water and wastewater treatment facilities, filament wound FRP pipes are used to transport clean water, sewage, and chemical additives. Their resistance to corrosion, biological fouling, and varying pH levels ensures long service life. The smooth interior surface reduces friction, improving flow efficiency and lowering energy consumption. These qualities make FRP pipes an effective and sustainable solution for municipal and industrial water management systems.

Oil and Gas

Filament wound FRP pipes are widely used in the oil and gas industry for transporting crude oil, natural gas, brine, and process fluids. Their lightweight structure reduces transportation and installation costs, while their resistance to seawater and hydrocarbons makes them suitable for offshore platforms and onshore pipelines. They offer a durable, low-maintenance solution for long-distance and corrosive fluid transfer in energy operations.

Cooling Water Systems

In power plants and industrial cooling systems, filament wound FRP pipes are used to circulate cooling water under high temperature and pressure conditions. Their resistance to scaling, corrosion, and biofouling ensures consistent performance and long-term reliability. Non-conductive and thermally stable, these pipes are well suited for use around sensitive equipment, helping maintain safe, efficient cooling operations in demanding environments.

Industrial Waste Management

Filament wound FRP pipes are ideal for transporting corrosive and hazardous waste in industrial facilities. Their chemical resistance and non-permeable structure prevent leaks and environmental contamination. These pipes are often used in chemical containment, landfill drainage, and waste processing systems where durability and compliance with safety standards are critical. Their long service life and minimal maintenance further reduce overall disposal system costs.

Power Generation

Power generation facilities use filament wound FRP pipes in processes such as flue gas desulfurization, chemical feed systems, and cooling water transport. These pipes withstand high temperatures, aggressive chemicals, and mechanical stress without degrading. Their low maintenance needs and corrosion resistance contribute to the safe, efficient operation of thermal and nuclear power plants over extended service periods.

Infrastructure and Utility Systems

Filament wound FRP pipes are used in public infrastructure for applications like stormwater drainage, trenchless rehabilitation, and irrigation systems. Their lightweight construction simplifies installation in urban or remote areas, and their corrosion resistance ensures durability in buried or exposed environments. These pipes offer a cost-effective and long-lasting solution for modern utility networks requiring minimal disruption and high performance.

Pre insulated FRP pipe: Energy Efficiency for Heating Systems

Filament Wound FRP Pipe O.D. Chart and Its Importance

The outer diameter (O.D.) chart of filament wound FRP pipe is a vital tool for engineers and designers when planning and selecting the appropriate pipe size for various applications. The O.D. chart provides detailed information about the pipe’s external dimensions, which is crucial for ensuring compatibility with fittings, joints, and other components in the piping system.

- Role in Pipe Selection: The filament wound FRP pipe O.D. chart helps engineers select the right pipe size based on the flow requirements, pressure ratings, and installation constraints of a project. By knowing the pipe’s outer diameter, they can determine the appropriate fittings, flanges, and supports needed for the system.

- Ensuring Proper Fit and Installation: The O.D. chart is essential for ensuring that the selected pipes and fittings fit together correctly during installation. Proper fitment is crucial for achieving leak-free joints and maintaining the integrity of the piping system.

- Assisting in System Design: The O.D. chart provides valuable data for designing the piping system layout. It allows designers to calculate the space needed for pipe routing, including considerations for thermal expansion, support spacing, and clearances around the pipes.

- Standardization and Quality Control: The O.D. chart serves as a reference for standardizing pipe sizes, ensuring consistency and quality control in the manufacturing process. It helps GangLong Fiberglass produce pipes that meet industry standards and customer specifications.

Utilizing the filament wound FRP pipe O.D. chart ensures that the piping system is designed and installed correctly, minimizing the risk of errors and enhancing the system’s overall performance and reliability.

Delamination in FRP Pipe Failure Modes: Causes and Solutions

Comprehensive Parameters of Filament Wound FRP Pipe

Pipe Diameter

- Nominal Diameter: 1″ to 144″ (25 mm to 3650 mm)

- Inside Diameter (ID): 1″ to 140″ (25 mm to 3550 mm)

- Outside Diameter (OD): 1.5″ to 144″ (38 mm to 3650 mm)

Wall Thickness

- Minimum Thickness: 1/8″ (3 mm)

- Maximum Thickness: 2″ (51 mm)

- Typical Range: 1/4″ to 1″ (6 mm to 25 mm)

Length

- Standard Lengths: 20 ft (6.1 m) to 40 ft (12.2 m)

- Custom Lengths: Up to 60 ft (18.3 m) or longer

Material Properties

- Tensile Strength: 10,000 to 50,000 psi (69 to 345 bar)

- Flexural Strength: 10,000 to 30,000 psi (69 to 207 bar)

- Compressive Strength: 5,000 to 20,000 psi (34 to 138 bar)

- Modulus of Elasticity: 100,000 to 500,000 psi (689 to 3,448 bar)

Fiber Orientation

- Spiral Winding: ±30° to ±70°

- Circumferential Winding: 0° to 20°

- Combination Winding: Spiral and circumferential techniques

Fiber and Resin Content

- Glass Fiber: 30% to 70% by weight

- Resin Content: 30% to 70% by weight

Resin Systems

- Thermosetting Resins: Epoxy, polyester, vinyl ester

- Thermoplastic Resins: Polyethylene, polypropylene, polyvinyl chloride

Pipe End Configurations

- Open ends

- Flanged

- Threaded

- Socket and spigot

- Butt-weld

Surface Treatments

- Smooth

- Textured

- Coatings: Epoxy or polyurethane

Certifications and Standards

- ASTM D3839: Standard specification for fiberglass pipe

- ASME B31.3: Process piping

- API 15LR: Fiberglass line pipe specification

- ISO 14692: Glass reinforced plastic piping in oil and gas industries

This detailed overview highlights the structural, material, and design parameters of filament wound FRP pipe, showcasing its versatility for diverse industrial applications.

FAQs about Filament Wound Frp Pipe

The life expectancy of FRP pipes can vary widely depending on several factors, including the quality of materials used, the manufacturing process, the operating conditions, and the level of maintenance provided. Under optimal conditions, FRP pipes can have a life expectancy of 30 to 50 years or more. Their inherent resistance to corrosion and chemical attack makes them particularly durable in environments where metal pipes would typically degrade, such as in chemical processing plants and wastewater treatment facilities. However, factors such as exposure to UV radiation, mechanical wear, and chemical compatibility can influence the longevity of FRP pipes. Proper installation, regular inspection, and maintenance can significantly extend the service life of FRP piping systems. By addressing potential issues early and ensuring that the pipes are used within their design parameters, users can maximize the lifespan of their FRP pipes, ensuring a reliable and cost-effective solution over the long term.

FRP pipes, while offering numerous advantages such as corrosion resistance and high strength-to-weight ratio, also come with certain challenges. One common issue is the potential for damage during handling and installation. Unlike metal pipes, FRP pipes can be more susceptible to surface scratches, cracks, or delamination if not properly managed. These damages can compromise the pipe’s structural integrity and reduce its performance. Another problem with FRP pipes is their sensitivity to UV radiation when used in outdoor applications. Prolonged exposure to sunlight can cause degradation of the pipe’s surface, leading to reduced mechanical properties over time. Additionally, FRP pipes can be affected by specific chemicals that may cause swelling, softening, or blistering of the resin matrix. While FRP pipes are designed to be resistant to many substances, it is essential to select the appropriate resin system for the intended application to avoid chemical compatibility issues. Regular inspection and maintenance are also necessary to ensure the long-term reliability of FRP piping systems.

The filament winding process in FRP manufacturing involves wrapping continuous strands of glass fibers, impregnated with resin, around a rotating mandrel. This process begins with the selection of fibers and resin that match the desired properties of the finished pipe. The fibers are coated with resin as they pass through a resin bath, ensuring complete saturation. They are then wound onto the mandrel in specific patterns, such as helical or hoop, to create layers that build up the pipe’s wall thickness. The winding angle and tension can be adjusted to optimize the pipe’s strength and stiffness for various applications. After winding, the pipe is cured, often with the application of heat, to solidify the resin and lock the fibers in place. Once cured, the pipe is removed from the mandrel and finished as required. The filament winding process is highly versatile and allows for the production of pipes with customized properties, making it suitable for a wide range of industrial uses.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.