FRP pipe MSDS (Material Safety Data Sheet) is an essential document that provides important safety and regulatory information for handling FRP (Fiberglass Reinforced Plastic) pipes. It outlines the composition of the materials used in FRP pipes, including resins, fiberglass reinforcement, and other additives. FRP pipe MSDS helps workers and engineers understand the potential hazards, such as dust inhalation during cutting or exposure to chemicals. It also provides guidelines for personal protective equipment (PPE), safe handling practices, fire safety, and first aid measures in case of accidents. By following FRP pipe MSDS, industries can ensure proper safety measures and compliance with regulations in their work environments. FRP pipe MSDS: Provides safety guidelines, handling, protective equipment, and potential health effects exposure to FRP material.

How about FRP Pipe MSDS

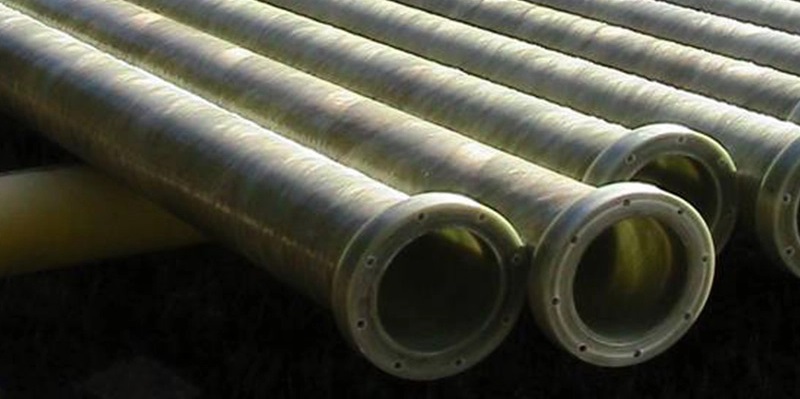

FRP pipe MSDS (Material Safety Data Sheet) is a critical document that provides essential information regarding the safe handling, use, and disposal of fiber-reinforced plastic (FRP) pipes. It outlines the potential hazards associated with FRP products, along with safety precautions, first aid measures, and proper storage guidelines. GangLong Fiberglass ensures that the FRP pipe MSDS is readily available to guide workers, safety officers, and emergency responders in the safe management of FRP products throughout their lifecycle. Understanding the content of an FRP pipe MSDS is crucial for maintaining a safe work environment and minimizing risks associated with the handling of FRP materials.

What is an MSDS?

MSDS, or Material Safety Data Sheet, is a document designed to provide comprehensive information about the hazards of a chemical or chemical mixture. Required by chemical manufacturers for all their products, MSDSs contain critical details such as the product’s identification, hazardous ingredients, physical and chemical properties, fire and explosion hazards, reactivity, toxicological effects, preventive measures, and first aid instructions.

These documents are intended to help employees and emergency responders safely handle hazardous substances. Employers must maintain accessible copies of MSDSs for each chemical in the workplace and ensure availability to employees during every shift.

Although MSDSs have now been replaced by Safety Data Sheets (SDSs), the purpose remains the same. SDSs follow a standardized 16-section format to ensure uniformity and improve usability, enhancing workplace safety and compliance with global standards.

What are the Hazard Identification Details in FRP Pipe MSDS?

FRP pipe MSDS contains a section dedicated to hazard identification, which outlines the potential health and safety hazards associated with FRP products. This section is vital for understanding the risks that workers may encounter when handling or processing FRP pipes.

- Potential Health Hazards

The primary health hazards associated with FRP pipes are related to dust and particulate matter generated during cutting, grinding, or machining processes. Inhalation of dust can cause respiratory irritation or discomfort, especially in individuals with pre-existing respiratory conditions. The MSDS will typically highlight these risks and recommend appropriate personal protective equipment (PPE) such as masks or respirators to minimize exposure. - Skin and Eye Irritation

FRP pipe MSDS may also indicate that direct contact with dust, fibers, or resin components can cause skin or eye irritation. Skin contact with fibers can lead to itching or redness, while eye contact with dust or particles can cause discomfort or inflammation. The MSDS emphasizes the importance of wearing protective gloves, clothing, and safety goggles to prevent such incidents. - Chemical Hazards

FRP pipes are made using various resins and additives that may pose chemical hazards, particularly during the manufacturing or processing stages. These hazards may include the potential for exposure to volatile organic compounds (VOCs) or other chemicals used in the production of FRP pipes. The MSDS will provide information on the nature of these chemical hazards and recommend safety measures to mitigate exposure risks.

First Aid Measures in FRP Pipe MSDS

The FRP pipe MSDS outlines specific first aid procedures to follow in case of exposure to potential hazards associated with fiberglass reinforced plastic (FRP) materials. These measures are vital for minimizing health risks and ensuring the safety of individuals working with or near FRP pipes. Whether the exposure occurs through inhalation, skin contact, eye contact, or ingestion, the MSDS provides clear, step-by-step instructions to reduce the severity of the effects and provide immediate relief.

Inhalation of Dust

Exposure to FRP dust generated during activities like cutting, grinding, or machining can lead to respiratory irritation. Inhalation of these particles may cause coughing, shortness of breath, or irritation of the throat. The first aid measures in the FRP pipe MSDS emphasize removing the affected individual from the source of exposure and moving them to a well-ventilated area or fresh air immediately. If the individual continues to have difficulty breathing, medical attention should be sought. To prevent inhalation of harmful dust, it is highly recommended to use appropriate respiratory protection, such as N95 masks or respirators, especially during operations that generate airborne particles. Installing proper ventilation systems or using dust extraction equipment can further reduce exposure risks.

Skin Irritation

FRP dust or fibers can cause skin irritation, including symptoms like itching, redness, or rashes. The first aid steps provided in the MSDS recommend removing any contaminated clothing and washing the affected skin thoroughly with soap and warm water. It is essential not to rub the skin, as this can worsen the irritation. For persistent symptoms, the MSDS advises seeking professional medical attention. Additionally, it is crucial to take preventative measures by wearing protective gloves, long sleeves, and long pants when handling FRP pipes or performing tasks that may produce dust or fibers. Skin creams or moisturizers may also help soothe mild irritation and prevent dryness. Proper hygiene practices and the use of personal protective equipment (PPE) are essential to avoid direct skin contact with FRP material.

Eye Contact

Exposure to FRP dust or particles in the eyes can result in symptoms such as redness, itching, or the sensation of a foreign body in the eye. The FRP pipe MSDS emphasizes the importance of immediate eye irrigation to flush out the particles. Individuals should flush their eyes with plenty of running water for at least 15 minutes, keeping their eyelids open to ensure complete rinsing. If irritation persists or vision problems occur, it is crucial to seek medical attention. Safety goggles or face shields should always be worn when working with FRP materials, particularly during cutting, grinding, or other processes that generate airborne particles. These protective measures are essential to prevent eye injuries and ensure worker safety.

Ingestion

Although the ingestion of FRP dust or particles is unlikely, accidental ingestion can still occur, especially if hands are not properly washed before eating or drinking. If ingestion happens, the MSDS advises rinsing the mouth thoroughly with water and seeking medical attention. It is important not to induce vomiting unless instructed by medical personnel. To reduce the risk of ingestion, workers should practice good hygiene, such as washing hands thoroughly before eating, drinking, or smoking, especially after handling FRP materials. Providing a clean, designated eating area separate from work areas can help minimize the chance of accidental ingestion.

Importance of Personal Protective Equipment (PPE)

In addition to first aid measures, the FRP pipe MSDS emphasizes the use of proper personal protective equipment (PPE) during all stages of handling and processing FRP materials. PPE, such as gloves, goggles, respirators, and protective clothing, plays a critical role in preventing exposure and reducing the likelihood of accidents or health issues. Ensuring that workers have access to the appropriate PPE and that they are trained in its correct use can significantly lower the risk of health complications associated with FRP pipes.

Firefighting Measures in FRP Pipe MSDS

FRP pipe MSDS includes information on firefighting measures due to the presence of resins and other organic materials that can contribute to combustion. This section outlines the appropriate methods and equipment for extinguishing fires involving FRP pipes.

- Suitable Extinguishing Media

The MSDS will specify the appropriate extinguishing media for fires involving FRP pipes. Common extinguishing agents include water spray, foam, dry chemical powder, or carbon dioxide (CO2). Using the correct extinguishing media is crucial for effectively suppressing the fire and preventing its spread. - Special Hazards Arising from the Material

In the event of a fire, FRP pipes may produce hazardous combustion products such as carbon monoxide, carbon dioxide, and other toxic gases. The MSDS will highlight these hazards and advise firefighters to wear self-contained breathing apparatus (SCBA) and full protective clothing to minimize exposure to smoke and toxic fumes. - Firefighting Instructions

The MSDS provides specific instructions for firefighting procedures, including the importance of maintaining a safe distance from the fire and using water spray to cool surrounding areas. It may also recommend evacuating personnel from the area if the fire poses a risk to human health or safety. Proper ventilation of the area after the fire is extinguished is essential to disperse any residual fumes or smoke.

Fire and Explosion Data in FRP Pipe MSDS

While FRP pipes are known for their fire resistance, certain conditions may still pose fire risks, particularly if they are exposed to high temperatures or open flames. The FRP pipe MSDS provides detailed information on fire safety and the precautions that should be taken in the event of a fire.

FRP pipes are generally resistant to ignition due to the nature of the polymer resin used in their construction. However, if exposed to extremely high temperatures, such as during a fire, the resin may begin to break down and release toxic gases like carbon monoxide (CO) or carbon dioxide (CO₂). For this reason, it is important to ensure that FRP pipes bridge are not installed near sources of open flame or extreme heat without appropriate fireproofing.

The FRP pipe MSDS recommends using suitable fire extinguishing methods, such as water, carbon dioxide (CO₂), or dry chemical extinguishers, in the event of a fire involving FRP pipes. Firefighters should also wear self-contained breathing apparatus (SCBA) to protect themselves from inhaling any harmful gases that may be released during combustion.

The Key of Fire Safety and Ventilation When Handling FRP Pipes

Fire safety and proper ventilation are crucial when working with FRP pipes. Although FRP itself is flame-resistant, the resins and materials used in its manufacturing can release toxic gases when exposed to heat or flames. These gases, including carbon monoxide and styrene vapors, pose significant health risks. Therefore, fire safety protocols and proper ventilation are essential to minimize these hazards during installation or handling, ensuring the safety of workers and compliance with safety regulations.

Fire Safety Measures for Handling FRP Pipes

Although FRP pipes are resistant to ignition, exposure to high temperatures can cause toxic gases to be released. Fire safety protocols should be followed, with fire extinguishers readily accessible in work areas. Workers should be trained in fire safety procedures, including how to use extinguishers and respond to emergencies. Implementing fire prevention measures, such as controlling the temperature and minimizing flame exposure, is essential to prevent combustion and ensure a safe working environment when dealing with FRP materials.

Importance of Proper Ventilation

Proper ventilation is key to ensuring the safety of workers when handling FRP pipes. Activities like cutting, drilling, or sanding FRP can generate harmful dust and fumes. Effective ventilation systems such as dust collection units or fume hoods should be used to remove airborne particles and maintain air quality. Personal protective equipment, including respirators, should also be used to prevent inhalation of fiberglass dust. By maintaining proper airflow, health risks from dust inhalation and exposure to fumes are reduced, ensuring a safer workplace.

Training and Awareness

Training workers on fire safety and ventilation protocols is vital for minimizing hazards when working with FRP pipes. Workers should be familiar with the MSDS guidelines that outline safe practices for handling FRP materials, including fire safety and ventilation requirements. Ensuring that workers understand how to operate fire extinguishers, use PPE, and maintain ventilation systems can reduce the likelihood of accidents. Regular training updates will reinforce safety awareness and ensure that employees are prepared to respond to potential hazards.

Fire and Explosion Data for FRP Pipe MSDS

FRP pipe MSDS provides crucial information on the fire and explosion risks associated with FRP pipes. While FRP pipes are generally resistant to combustion, the resins and other organic components can contribute to fire under certain conditions. This section guides emergency response teams on how to manage fire-related incidents involving FRP pipes.

- Flash Point

The flash point is the lowest temperature at which the vapors of a material can ignite in the presence of an ignition source. FRP pipes, specifically the resin component, can have varying flash points depending on the type of resin used. For instance, polyester resins typically have flash points in the range of 31-33°C (88-91°F). The FRP pipe MSDS provides specific flash point information, helping emergency responders understand the potential flammability of the material. - Fire and Explosion Hazards

Although FRP pipes are designed to be flame-retardant, they can still present fire hazards when exposed to open flames or high heat. The combustion of FRP pipes can produce hazardous gases such as carbon monoxide, carbon dioxide, and other toxic fumes. The MSDS highlights these potential hazards and stresses the importance of using proper firefighting equipment and procedures to handle fires involving FRP pipes safely. - Firefighting Measures

The FRP pipe MSDS outlines appropriate firefighting measures for extinguishing fires involving FRP pipes. Suitable extinguishing media include water spray, foam, dry chemical powder, and carbon dioxide (CO2). The MSDS advises using water spray to cool adjacent structures and materials to prevent the spread of fire. Firefighters should wear full protective clothing and self-contained breathing apparatus (SCBA) to protect themselves from heat, flames, and toxic fumes. The MSDS also emphasizes maintaining a safe distance and avoiding direct contact with burning material to minimize the risk of injury.

Handling and Storage Guidelines in FRP Pipe MSDS

Proper handling and storage of FRP pipes are crucial for maintaining safety in the workplace and ensuring the longevity of the products. The FRP pipe MSDS provides guidelines for safely handling and storing these materials.

- Safe Handling Practices

The MSDS advises on safe handling practices to minimize exposure to hazards associated with FRP pipes. This includes using appropriate PPE, such as gloves, masks, and safety glasses, when cutting, grinding, or performing other tasks that generate dust. Workers should be trained on the safe handling of FRP pipes and the importance of using tools and equipment designed for working with FRP materials to reduce the risk of injury. - Proper Storage Conditions

The MSDS outlines the ideal storage conditions for FRP pipes to prevent damage and degradation. FRP pipes should be stored in a cool, dry, and well-ventilated area, away from direct sunlight and sources of heat or ignition. Stacking should be done in a manner that prevents crushing or deformation of the pipes. Proper storage helps maintain the integrity and performance of the FRP pipes over time. - Spill and Leak Procedures

Although FRP pipes do not typically pose a risk of spills or leaks, the MSDS may include procedures for managing situations where dust or debris is released. This section advises on using dust control measures, such as wetting down the area to reduce airborne particles, and using appropriate cleaning equipment to collect and dispose of the material safely.

Exposure Controls and Personal Protection in FRP Pipe MSDS

The use of proper personal protective equipment (PPE) is one of the most critical safety measures outlined in the FRP pipe MSDS. To minimize the risk of exposure to fiberglass dust, workers must wear appropriate PPE during the installation, cutting, or sanding of FRP pipes.

Safety goggles or face shields are necessary to protect the eyes from dust and debris. Even small amounts of fiberglass dust can cause irritation or injury if they come into contact with the eyes. Respiratory protection is equally important, particularly in environments where dust concentrations are high or ventilation is limited. NIOSH-approved dust masks or respirators should be worn to prevent inhalation of fiberglass particles.

Gloves should be used to protect the skin from direct contact with fiberglass and resin, both of which can cause irritation. Additionally, workers should wear long sleeves and coveralls to limit skin exposure. Protective clothing can be especially important when working in confined spaces or during prolonged handling of FRP materials.

The FRP pipe data MSDS also recommends that workers regularly wash their hands and face after handling FRP materials, especially before eating or drinking. This helps to prevent the ingestion of any residual dust or particles that may have settled on the skin.

Engineering Controls

The MSDS recommends implementing engineering controls to reduce exposure to FRP dust and fumes. This may include using local exhaust ventilation (LEV) systems to capture dust at the source during cutting, grinding, or sanding operations. Proper ventilation helps maintain air quality in the work area and reduces the concentration of airborne particles.

Personal Protective Equipment (PPE)

The use of appropriate PPE is crucial for protecting workers from exposure to FRP dust, fibers, and chemicals. The MSDS specifies the types of PPE required, including:

- Respiratory Protection: N95 masks or respirators are recommended to prevent inhalation of dust and fibers.

- Eye Protection: Safety goggles or face shields protect the eyes from dust and particles.

- Skin Protection: Gloves and protective clothing prevent skin contact with fibers and dust. Workers should be trained on the proper use and maintenance of PPE to ensure effective protection.

Hygiene Measures

The MSDS emphasizes the importance of good hygiene practices when working with FRP pipes. Workers should wash their hands thoroughly after handling FRP materials, especially before eating, drinking, or smoking. Work areas should be kept clean, and contaminated clothing should be changed and washed to prevent skin irritation and reduce the risk of exposure.

Disposal Considerations in FRP Pipe MSDS

The FRP pipe MSDS provides guidance on the proper disposal of FRP materials to comply with environmental regulations. Following these guidelines helps minimize the environmental impact associated with FRP waste. Safe disposal practices ensure compliance with local, regional, and national standards, preventing environmental contamination.

Waste Disposal

The MSDS outlines procedures for safely disposing of FRP waste, including dust, offcuts, and damaged pipes. While FRP is generally non-hazardous, proper disposal practices are crucial to avoid contamination. Waste should be collected and disposed of according to regulations, ensuring no harm to the environment, especially in landfills or water systems.

Recycling and Reuse

The MSDS encourages recycling or reusing FRP materials when possible. Some FRP waste, like offcuts or scrap, can be repurposed into new products, reducing the need for raw materials. Recycling helps lower energy consumption, reduces waste, and minimizes the environmental footprint. Companies should seek recycling programs for proper disposal and reuse of FRP materials.

Avoiding Environmental Release

To prevent environmental release of FRP dust, the MSDS advises using dust control measures, such as air filtration or extraction systems, during the processing of FRP pipes. Proper containment and secure waste storage prevent particles from spreading, ensuring no contamination of surrounding areas. These practices protect both workers and the environment from harmful exposure.

Cutting FRP Pipe with Precision: Tools and Techniques to Use

Key Components of FRP Pipe MSDS

Key Components

An FRP pipe MSDS contains several critical sections that provide essential information about the product, its composition, and the safety measures needed when handling it. Each section is designed to ensure that workers and engineers understand the potential hazards associated with FRP pipes and take appropriate precautions to minimize risks. These sections include product identification, hazard information, composition, and handling instructions, all of which are necessary for maintaining a safe working environment.Understanding these components is crucial for ensuring that workers and engineers follow the proper safety protocols when working with fibercast FRP pipes.

Product Identification

The product identification section of the FRP pipe MSDS provides key details about the product, including its official name, trade names, and the chemical family it belongs to. It often includes information about the manufacturer’s name and contact details, as well as a description of the product’s intended use. For example, GangLong Fiberglass FRP pipe would be listed along with its specific composition (resins, fiberglass) and use cases in industrial applications such as water treatment, chemical transport, or construction. This information helps workers identify the correct FRP product, ensuring that proper safety measures are followed during installation, cutting, or handling.

Composition and Information on Ingredients

The composition section describes the materials used to manufacture the FRP pipe, including the types of resin (such as polyester or epoxy) and the fiberglass reinforcement. This information is critical for assessing the product’s properties and understanding the potential hazards that may arise. For example, resins can emit toxic fumes when exposed to heat, and certain types of fiberglass can produce fine dust particles that may pose respiratory risks. Understanding the chemical components allows workers to make informed decisions about necessary personal protective equipment and safety protocols.

Hazard Identification

The hazard identification section is one of the most important parts of the FRP pipe MSDS, as it outlines the risks associated with working with the product. This section includes information about the potential dangers, such as skin irritation or eye damage from exposure to fiberglass dust or resin fumes. FRP pipes can also cause respiratory issues if the dust is inhaled during cutting, grinding, or installation. By identifying these hazards, the MSDS ensures that workers can take the necessary precautions, such as using appropriate personal protective equipment, to avoid injury or long-term health effects from handling FRP materials.

Hazards and Precautions for Handling FRP Pipes

Handling FRP pipes, particularly during processes like cutting, drilling, or installation, can present several potential hazards. The production of fiberglass dust is a primary concern, as fine particles can become airborne during mechanical processes. If inhaled, these dust particles can cause respiratory irritation, leading to short-term discomfort or long-term health issues like chronic respiratory conditions. In addition, fiberglass dust can irritate the skin or eyes upon contact, leading to itching, redness, or more severe reactions if not properly managed.

Personal Protective Equipment (PPE)

To mitigate the risks associated with fiberglass exposure, the FRP pipe MSDS recommends several critical safety measures, starting with the use of proper personal protective equipment (PPE). Workers should wear safety goggles or protective eyewear to shield their eyes from fiberglass dust and debris. Gloves should be worn to prevent skin irritation from direct contact with dust or fibers. The MSDS also emphasizes the importance of using respiratory protection to prevent inhalation of harmful dust. NIOSH-approved dust masks or respirators are essential in areas where FRP dust is likely to accumulate, especially during tasks that generate airborne particles, such as cutting, sanding, or grinding.

Ventilation and Dust Control

In addition to personal protective equipment, the MSDS stresses the importance of adequate ventilation when working with FRP pipes. In enclosed spaces, fiberglass dust can accumulate quickly, increasing the risk of inhalation. Local exhaust ventilation systems, such as fume hoods or dust extraction units, should be used to remove particles from the air. Ensuring that the workspace is well-ventilated will help keep the air clean and minimize the concentration of airborne dust, reducing health risks for workers. Proper ventilation systems also reduce the overall fire risk by preventing the buildup of potentially flammable dust.

Careful Handling to Avoid Physical Damage

Another critical precaution outlined in the FRP pipe MSDS is the proper handling of FRP pipes to avoid physical damage. FRP pipes are strong, but they are also susceptible to cracking or chipping if dropped or struck. Any physical damage to the pipes may compromise their structural integrity, leading to potential failure. Workers should use appropriate lifting equipment and techniques to move FRP pipes, ensuring they are handled with care. Storing the pipes properly and protecting them from impact during transport can further reduce the risk of damage.

Environmental Impact and Disposal Guidelines for FRP Pipes

The FRP pipe MSDS addresses the environmental impact of FRP materials and provides guidance on safe disposal. While FRP is generally non-toxic once fully cured, incomplete curing can leave harmful residues like styrene and peroxides that pose environmental risks. Proper disposal practices are essential to avoid contamination. Adhering to local, regional, and national regulations helps ensure that FRP materials do not contribute to environmental pollution, making waste management a critical part of the overall safety and sustainability of using FRP pipes.

Recycling FRP Materials

Recycling FRP materials helps reduce the environmental footprint, but it is more complex than recycling traditional materials like steel. FRP consists of fiberglass and resin, which are difficult to separate and process. Not all recycling centers are equipped to handle FRP, so it is essential to consult local authorities for proper recycling procedures. Some FRP waste can be repurposed into new products, reducing the need for virgin materials. Encouraging recycling programs can help reduce waste generation, supporting the circular economy and making FRP more sustainable.

Environmental Contaminants and Hazardous Waste Management

FRP waste may contain hazardous substances such as styrene, which can harm the environment if not disposed of correctly. The MSDS emphasizes the importance of using sealed containers and specialized waste management services to handle such waste. Hazardous FRP waste must be treated as per local or federal laws, requiring specific handling, transportation, and disposal protocols. Ensuring that FRP materials are classified and managed properly protects public health and prevents contamination of soil, air, and water. Proper waste management helps mitigate potential risks to both human health and the environment.

Long-Term Sustainability and Waste Minimization

To promote sustainability, companies should focus on reducing FRP waste by optimizing manufacturing processes and minimizing scrap. Lean manufacturing principles can help in reducing the volume of waste generated. Designing FRP products with recyclability in mind can make the recycling process easier and more efficient. The MSDS encourages collaboration with sustainability initiatives, such as using eco-friendly resins or improving recycling methods. These practices contribute to the reduction of waste and the overall environmental footprint of FRP production, helping the industry align with sustainability goals while maintaining efficient resource use.

Deriving FRP Pipe Burst Pressure with Barlow’s Formula Explained

What are the Chemical Composition and Hazardous Ingredients in FRP Pipe MSDS?

The FRP pipe MSDS includes detailed information on the chemical composition of the FRP pipes, including the resins, fibers, and additives used in their production. This section helps identify any hazardous ingredients that may pose health or environmental risks.

Resin Matrix

FRP pipes are primarily made of a resin matrix, which acts as a binder for the reinforcing fibers. The resin is typically composed of polyester, vinyl ester, or epoxy, depending on the specific application and desired properties of the FRP pipe. The MSDS specifies the type of resin used and any associated hazards. For example, uncured resins can emit volatile organic compounds (VOCs) that may pose inhalation hazards. GangLong Fiberglass uses high-quality resins in the production of FRP pipes to minimize health and environmental risks.

Reinforcing Fibers

The reinforcing fibers in FRP pipes, usually glass fibers, provide structural strength and rigidity. While long glass fiber themselves is generally non-hazardous, the MSDS will indicate that dust generated from cutting, grinding, or sanding FRP pipes can cause respiratory irritation if inhaled. The document emphasizes the importance of using appropriate personal protective equipment (PPE) such as masks and respirators during such activities.

Additives and Fillers

Additives and fillers may be incorporated into the resin matrix to enhance the performance of FRP pipes. These substances can include pigments, flame retardants, and stabilizers. The FRP pipe MSDS lists these additives and highlights any potential hazards associated with their use. Safety measures, such as wearing gloves and using proper ventilation, are recommended to minimize exposure.

Essential FRP Pipe Code List for Engineers and Designers

FAQs about Frp Pipe Msds

FRP (Fiberglass Reinforced Plastic) is generally not considered hazardous in its finished form, as it is non-toxic, non-corrosive, and does not release harmful substances during normal use. However, there are some safety concerns related to the manufacturing and installation processes. During fabrication or cutting, FRP can release fine fiberglass particles, which may pose respiratory risks if inhaled. For this reason, it is important to wear proper personal protective equipment (PPE), such as masks, gloves, and eye protection, when handling FRP materials during installation or repairs.

Once installed, FRP is safe for use in a variety of applications, including industrial, marine, and public infrastructure. It is resistant to chemicals, fire, and extreme weather conditions, making it a preferred material for harsh environments. FRP also has the benefit of being non-conductive, which enhances safety in electrical applications. Proper handling during fabrication and adherence to safety guidelines ensures that FRP poses minimal health risks in its final application.

FRP pipe material refers to a composite made from fiberglass reinforced with a polymer resin. This material is created by combining strong glass fibers with a durable resin matrix, usually polyester, vinyl ester, or epoxy. The glass fibers provide the pipe with strength and rigidity, while the resin adds flexibility and resistance to environmental factors such as chemicals, UV light, and moisture. Together, these materials create a pipe that is lightweight, strong, and highly durable.

FRP pipes are known for their ability to withstand corrosion, making them suitable for use in industries like chemical processing, wastewater treatment, and marine environments. Unlike traditional metal pipes, FRP pipes do not rust or corrode when exposed to water or harsh chemicals, which significantly extends their lifespan. Additionally, FRP pipes are resistant to fire and have low thermal conductivity, making them useful in a wide range of applications where temperature fluctuations or fire safety is a concern.

While FRP pipes offer many advantages such as corrosion resistance, lightweight construction, and durability, they do have a few limitations. One of the primary issues with FRP pipes is their susceptibility to impact damage during installation or in environments with heavy mechanical loads. Although FRP pipes are strong, they can crack or chip if not handled carefully. Once damaged, repair can be more complex than with traditional materials.

Another concern is the cost of FRP pipes. They tend to be more expensive upfront compared to materials like PVC or metal, which may be a consideration for budget-conscious projects. However, the longer lifespan and lower maintenance costs of FRP pipes often balance out the higher initial investment. Additionally, FRP pipes can be sensitive to UV exposure over long periods, which can degrade the resin if not properly protected with UV inhibitors or coatings. Understanding these challenges allows for better planning and handling of FRP pipes during their lifecycle.

The ASME code relevant to FRP (Fiberglass Reinforced Plastic) piping is ASME B31.3, which covers the design, materials, fabrication, assembly, and testing of piping systems. FRP piping falls under the scope of non-metallic piping materials within the code, ensuring its safe use in chemical processing and other industries. MSDS for FRP pipes highlights handling procedures, emphasizing safe practices to prevent hazards such as dust inhalation during cutting or grinding. While FRP is non-corrosive and lightweight, its installation and maintenance must adhere to ASME standards to ensure mechanical integrity and compatibility with transported chemicals.

Fiberglass itself is not classified as a hazardous material under typical conditions, but its handling can pose health risks. FRP pipe MSDS highlights that dust generated during cutting, grinding, or sanding may irritate the skin, eyes, and respiratory tract. Prolonged or repeated exposure to fiberglass dust without protective measures may lead to discomfort or minor respiratory issues. MSDS recommends using personal protective equipment (PPE), such as gloves, safety glasses, and masks, to mitigate exposure risks. Proper cleanup and disposal procedures are also advised to reduce environmental impact, aligning with workplace safety regulations.

FRP pipe stands for Fiberglass Reinforced Plastic pipe, a composite material known for its strength, corrosion resistance, and lightweight properties. According to the FRP pipe MSDS, this material is commonly used in industries handling corrosive chemicals or harsh environments. The MSDS provides critical safety guidelines for managing potential risks during fabrication, installation, or maintenance, particularly concerning exposure to resin fumes or dust. These measures ensure that FRP pipes can be used safely in applications like chemical processing, water treatment, and oil and gas without adverse effects on health or the environment.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.