FRP pipe span chart for diameters (inches) and thicknesses with span in feet. Covers corrosion-resistant fiberglass piping for applications. The frp pipe span chart is crucial for determining the correct support spacing in FRP piping systems. Proper support placement is essential to prevent sagging, reduce stress, and maintain the integrity of the pipe under various loads and environmental conditions. By referencing the frp pipe span chart, engineers can ensure that pipes are adequately supported, reducing the risk of deformation or failure. GangLong Fiberglass provides detailed span charts for different pipe sizes and applications, ensuring that installation meets the necessary structural and operational requirements. Proper use of these charts ensures long-lasting and reliable FRP pipe installations, including those utilizing China FRP sand pipe, in industrial settings. The FRP pipe span chart helps prevent sagging, stress, and deformation by providing the maximum allowable spans for pipes and support configurations in feet.

Simplifying Your Life: Key Functionalities

| Attributes | Details |

|---|---|

| Place of Origin | Hebei, China |

| Brand Name | GangLong Fiberglass |

| Product Name | FRP Pipe |

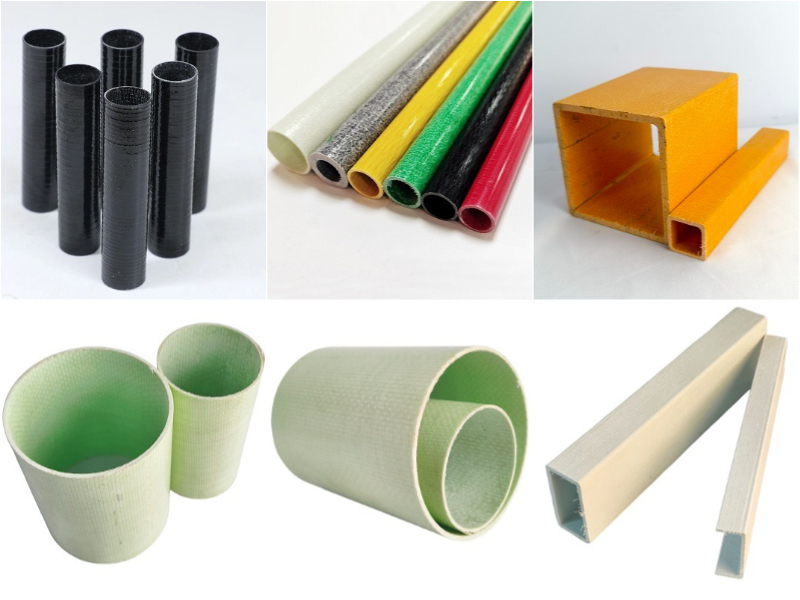

| Material | Fiberglass Reinforced Plastic |

| Technology | Pultrusion |

| Surface Treatment | Smooth Paint or Customer Requirement |

| Processing Services | Molding, Cutting |

| Color | Customized Color |

| Shape | Customized Shape |

| Size | Customized Size |

| Thickness | Customized Thickness |

| Length | Customized Length |

| OEM | OEM Accepted |

| Features | Lightweight, High Strength, Corrosion Resistant, High Dimensional Stability, Compression Resistant, Fireproof, Super Waterproof |

| Certificate | ISO9001 |

| Type | Manufacturer |

| Application | Wastewater Discharge, Exhaust, Cable Tray |

| Port | All Major Ports |

| Packing Details | As per Customer Requirement |

| Sales Unit | Single Item |

| Supply Capacity | 200 Pieces Per Day |

What is an FRP Pipe Span Chart?

An frp pipe span chart outlines the recommended maximum distances between supports for FRP piping systems based on various conditions. This chart takes into account factors such as the weight of the fluid being transported, the diameter of the pipe, and the operating temperature, all of which affect the structural integrity of the piping system. The primary purpose of the span chart is to prevent sagging and bending of the pipe due to gravitational forces or internal pressure, which could lead to failures, leaks, or other operational issues.

FRP pipes have a different flexibility and strength compared to metal pipes, making the use of a span chart essential to determine the appropriate support spacing. The span chart ensures that FRP pipes remain well-supported and can handle the operational loads and stresses without bending or causing excess strain at the joints.

What Is FRP Pipe Span Chart Importance in Industrial Applications

The frp pipe span chart is a crucial reference tool that provides guidance on the maximum allowable spacing between pipe supports for fiberglass-reinforced plastic (FRP) pipes. Properly determining the span length ensures that the pipe will not sag or deform under its own weight or the load of the fluids it carries. The frp pipe span chart considers several factors, including the pipe diameter, operating temperature, pressure, and the pipe’s material properties. Using this chart effectively allows engineers and contractors to design systems that are both safe and efficient for a wide range of industrial applications.

GangLong Fiberglass produces high-quality FRP pipes that adhere to the specific requirements laid out in the frp pipe span chart, ensuring optimal performance across various industries, such as water treatment, chemical processing, and oil and gas.

FRP Pipe Span Chart User Guide

Factors That Influence the FRP Pipe Span

Several factors affect the recommended spacing for FRP pipes, ensuring the support system is tailored to specific requirements. Understanding these elements allows engineers to design piping systems that will perform optimally in their environments. Below are the main factors that influence the span between supports in FRP pipes.

Pipe Diameter

Larger diameter FRP pipes require more frequent supports because they are heavier and prone to sagging under their own weight, especially when filled with fluid. For example, a 12-inch diameter pipe will require more support than a 6-inch diameter pipe. The span between supports needs to be shorter for larger pipes to prevent bending and deformation, ensuring stability and safety over time.

Operating Temperature

Temperature fluctuations cause FRP pipes to expand and contract, impacting their flexibility. As temperatures increase, the pipe becomes more flexible, reducing its load-bearing capacity. This needs to be accounted for in the span chart. Pipes operating in high-temperature environments require closer support intervals to prevent sagging and deformation, ensuring the structural integrity of the piping system is maintained, even under extreme heat conditions.

Internal Pressure and Fluid Load

Pipes carrying high-pressure fluids or dense liquids require more support to prevent strain on the pipe walls. The FRP pipe span chart takes these factors into account by recommending shorter spans for high-pressure systems. The increased internal load on the pipe requires more frequent supports to prevent sagging and material fatigue, ensuring the pipe can handle both the pressure and fluid weight without compromising performance.

Material Strength and Composition

The material properties of the FRP pipe, including its tensile strength and elasticity, impact the span recommendations. FRP pipes with higher tensile strength and stiffness can support longer spans without bending. Conversely, more flexible materials require closer support points to prevent deformation. GangLong Fiberglass ensures that their FRP pipes are manufactured with optimal material properties, balancing flexibility and strength, and meeting the specifications outlined in the span chart.

Environmental Factors

External factors, such as wind load, seismic activity, and vibration, can also influence the pipe span. For example, pipes in areas with high wind or seismic activity may require additional support points to maintain stability. The FRP pipe span chart accommodates these external forces, ensuring that the pipe remains secure and able to handle environmental challenges without failure. Properly accounting for these factors ensures the durability of the piping system.

Piping System Layout

The layout and configuration of the piping system also affect the recommended span between supports. Horizontal pipes, for example, often require more frequent supports than vertical pipes or those with frequent changes in direction. The FRP pipe span chart takes into account these layout factors, offering guidance for different pipe runs, ensuring the piping system remains structurally sound over time, regardless of the pipe’s orientation.

How to Use an FRP Pipe Span Chart

To effectively use the frp pipe span chart, engineers and contractors must carefully assess the specific conditions of their project. The chart typically provides recommended span lengths based on pipe size, temperature, and fluid load, which can then be applied to the design of the pipe support system.

Step 1: Determine the Pipe Size: Start by identifying the diameter of the FRP pipe being used in the system. This will narrow down the span recommendations specific to that pipe size.

Step 2: Assess Operating Conditions: Next, consider the operating temperature and the fluid load within the pipe. If the pipe will be subjected to high temperatures or heavy fluid loads, select the corresponding section of the span chart that accounts for these conditions.

Step 3: Apply Span Chart Recommendations: Once the operating conditions and pipe size have been identified, use the frp pipe span chart to determine the maximum allowable distance between supports. Ensure that this spacing is adhered to throughout the piping system to prevent sagging and structural failures.

GangLong Fiberglass provides detailed guidance on how to use the span chart in conjunction with their FRP pipes, ensuring that contractors and engineers can optimize support placement for reliable, long-lasting performance.

FRP Pipe Specifications for Industrial Applications

In addition to following the FRP pipe span chart, understanding key specifications of FRP pipes is essential for their use in industrial applications. These specifications include pressure ratings, temperature resistance, and material properties, which must be considered when designing a piping system to ensure its reliability and performance in demanding environments.

Pressure Ratings

FRP pipes are available in various pressure ratings, indicating the maximum internal pressure they can handle. Selecting the correct pressure rating ensures the pipe won’t rupture or fail. The pressure rating must align with the FRP pipe span chart to avoid placing unnecessary strain on the pipe. Proper selection is critical for maintaining safety and performance under operational conditions.

Temperature Resistance

FRP pipes are designed to withstand a wide range of temperatures. However, high temperatures can reduce their structural integrity over time. Pipes used in high-temperature environments must have specific heat resistance properties. Closer support spacing, as per the FRP pipe span chart, is necessary to prevent thermal expansion from compromising the pipe’s strength, ensuring reliable operation in extreme conditions.

Chemical Resistance

One major advantage of FRP pipes is their resistance to chemicals, which makes them ideal for industries such as chemical processing and wastewater treatment. The type of resin used determines chemical compatibility, so understanding the chemical environment is crucial for selecting the correct pipe material. Adhering to the span chart ensures that the pipe remains durable and resistant to degradation in chemically aggressive conditions.

Tensile Strength and Elasticity

Tensile strength and elasticity are critical in determining an FRP pipe’s suitability for industrial applications. FRP pipes are designed to withstand stress while maintaining flexibility. The tensile strength, combined with elasticity, allows FRP pipes to handle high mechanical loads, making them ideal for industries like mining or offshore drilling. The material properties ensure durability, even under demanding conditions.

Lightweight and Ease of Handling

Compared to traditional materials like steel, FRP pipes are much lighter. This feature makes them easier to handle during installation, reducing labor and transport costs. Despite being lightweight, they maintain strength and durability, making them ideal for large-scale industrial projects. The reduced weight not only lowers installation costs but also ensures efficient long-term performance in the system.

Durability and Longevity

FRP pipes are highly durable, offering long service life with minimal maintenance requirements. Their resistance to corrosion and high pressure ensures reliable performance even in harsh environments. This durability reduces the need for frequent repairs or replacements, making FRP pipes a cost-effective solution for industries like chemical processing, water distribution, and sewage systems. Their longevity adds significant value over time.

GangLong Fiberglass provides comprehensive FRP pipe solutions that meet all relevant specifications for industrial use, including adherence to the span chart for optimal performance. Among their offerings, PPR FRP Pipe stands out by combining polypropylene random (PPR) with FRP for increased strength and durability. This innovative pipe solution not only meets industry standards but also offers enhanced performance in demanding environments, making it an ideal choice for a wide range of industrial applications.

How Resin Types Impact FRP Pipe Tensile Strength

The Key of Proper Support in FRP Pipe Systems

Proper support is crucial for maintaining the integrity of FRP piping systems, particularly in industrial environments where pipes are subjected to significant loads and environmental stresses. The frp pipe span chart is an invaluable tool for ensuring that the pipes are adequately supported to prevent sagging, stress, and eventual failure.

By following the span chart recommendations and using high-quality FRP pipes, such as those produced by GangLong Fiberglass, contractors and engineers can design systems that offer long-term reliability, even in the most challenging conditions.

The Key Elements of the FRP Pipe Span Chart

The frp pipe span chart is an indispensable tool for engineers and designers working with fiberglass reinforced plastic (FRP) piping systems. This chart provides essential information on the maximum allowable distances between pipe supports, helping to ensure that FRP pipes maintain their structural integrity throughout their service life. Understanding the key elements of the frp pipe span chart is crucial for accurate installation and reliable performance.

Pipe Diameter and Wall Thickness

One of the primary factors considered in the frp pipe span chart is the pipe diameter and wall thickness. These dimensions directly influence the pipe’s ability to span between supports without excessive deflection. Larger diameter pipes or those with thinner walls are more prone to sagging and therefore require closer support spacing. For example, a 10-inch diameter FRP pipe with a thin wall may have different span recommendations compared to a 6-inch pipe with a thicker wall. The frp pipe span chart provides specific support spacing based on these parameters to ensure optimal performance.

Operating Conditions and Environmental Factors

The FRP pipe span chart also takes into account the operating conditions and environmental factors that affect the performance of FRP pipes, including the ID of FRP Pipe. This measurement is essential for determining load capacity and ensuring that the pipes can withstand various stresses during operation. Temperature, pressure, and the type of fluid being transported can significantly impact the pipe’s structural requirements. High temperatures may cause the pipe material to expand, while high pressure can increase the load on the pipe. Additionally, environmental factors such as exposure to chemicals or UV radiation can affect the durability and flexibility of FRP pipes. The frp pipe span chart provides guidelines to account for these conditions, ensuring that the support spacing is appropriate for the specific application.

Load and Weight Considerations

Load and weight considerations are another critical aspect covered by the frp pipe span chart. The weight of the pipe itself, along with the weight of the fluid it carries, must be factored into the support spacing calculations. Heavier pipes or those carrying dense fluids require more frequent supports to prevent sagging or bending. The frp pipe span chart includes different support spacing recommendations based on the load that the pipe will bear. This helps in designing a support system that can handle the operational demands and prevent potential issues such as pipe deformation or failure.

Material Properties and Construction Type

The material properties of FRP pipes and their construction type also influence the recommendations provided by the frp pipe span chart. FRP pipes can be made from various resin systems, such as polyester, vinyl ester, or epoxy, each with different mechanical properties. The construction method, whether filament-wound or contact-molded, also affects the pipe’s strength and flexibility. The frp pipe span chart takes these factors into account, offering support spacing guidelines tailored to the specific type of FRP pipe being used.

Safety and Compliance

Safety and compliance are crucial considerations in the use of fibercast FRP pipes. The frp pipe span chart helps ensure that the installed piping systems meet safety standards and regulatory requirements. By adhering to the recommended support spacing, engineers can avoid issues such as excessive deflection or pipe collapse, which could pose safety risks. The chart is often aligned with industry standards and codes, helping to ensure that the FRP piping system is compliant with relevant regulations.

Maintenance and Inspection

Maintenance and inspection requirements are also relevant when using the frp pipe span chart. Proper support spacing helps in minimizing stress on the pipes, which in turn reduces the likelihood of damage or wear over time. Regular inspections of the piping system are essential to identify any potential issues early on. The frp pipe span chart provides a framework for maintaining optimal support spacing, which can aid in the overall longevity and reliability of the FRP piping system.

Custom and Specialized Applications

In some cases, custom or specialized applications may require adjustments to the standard recommendations provided by the frp pipe span chart. For instance, pipes used in unique environments or under specific load conditions might need tailored support solutions. The frp pipe span chart serves as a baseline, but engineers may need to adjust the support spacing based on project-specific requirements. Consulting with manufacturers like GangLong Fiberglass or utilizing advanced design tools can help address these specialized needs.

Integration with Other Design Tools

The frp pipe span chart can be integrated with other design tools and software to enhance accuracy and efficiency in the design process. Many engineers use software that incorporates the frp pipe span chart data to model and analyze piping systems. This integration allows for real-time adjustments and simulations, ensuring that the support spacing recommendations are accurately applied in the design phase. By combining the frp pipe span chart with other design tools, engineers can create more robust and reliable piping systems.

Documentation and Record-Keeping

Proper documentation and record-keeping are important aspects of using the frp pipe span chart. Maintaining records of the support spacing calculations and the chart’s guidelines helps in tracking compliance and making informed decisions during maintenance or upgrades. It also provides a reference for future projects, ensuring consistency and adherence to best practices. Keeping detailed records can aid in troubleshooting and verifying that the installed piping systems meet the required standards.

Future Developments and Trends

The field of FRP piping is continually evolving, with advancements in materials and construction techniques impacting the recommendations provided by the frp pipe span chart. Staying informed about the latest developments and trends can help engineers make the most of new technologies and improve the performance of FRP piping systems. The frp pipe span chart may be updated periodically to reflect these advancements, providing engineers with the most current guidelines for support spacing and design.

Understanding the frp pipe span chart is essential for ensuring the proper installation and performance of FRP piping systems. By considering factors such as pipe diameter, operating conditions, load, and material properties, engineers can design effective support systems that meet safety standards and operational requirements. Regular maintenance, integration with design tools, and proper documentation further contribute to the reliability and longevity of FRP pipes. As technology advances, staying updated on new developments and trends will continue to enhance the effectiveness of the frp pipe span chart in the field of piping design.

Know FRP’s Coefficient of Thermal Expansion

FRP Pipe Span Chart: Essential Guidelines for Proper Support

An frp pipe span chart is an essential reference for determining the maximum allowable distance between supports for fiberglass-reinforced plastic (FRP) pipes. Properly spaced supports are crucial to prevent sagging, bending, or structural failure of the pipes due to their weight, the weight of the fluid they carry, and other external factors. The frp pipe span chart takes into consideration variables such as pipe diameter, operating temperature, fluid load, and material properties, ensuring that piping systems are designed to operate safely and efficiently over time.

GangLong Fiberglass manufactures high-quality FRP pipes designed to meet the specific span requirements laid out in the frp pipe span chart, offering solutions for a variety of industrial sectors, including chemical processing, water treatment, and oil and gas.

The Key of FRP Pipe Span Chart for System Integrity

The frp pipe span chart plays a critical role in maintaining the integrity and functionality of FRP piping systems. The span chart provides engineers and contractors with precise guidelines on how far apart pipe supports should be installed, based on factors such as the pipe’s size, weight, and the operational conditions it will face. Proper support placement ensures that FRP pipes remain level and free from excess stress, which could otherwise cause deformation or leaks at connection points.

FRP pipes differ significantly from metal pipes in terms of flexibility and strength. As a result, FRP pipes typically require shorter spans between supports to prevent sagging or overloading. When using a frp pipe span chart, it is crucial to account for all variables, including the weight of the transported fluids, as this impacts the overall load on the piping system.

FRP Pipe Fittings: What You Need to Know

In addition to following the frp pipe span chart, selecting the right FRP pipe fittings is crucial for ensuring system flexibility and efficiency. Fittings such as elbows, tees, and reducers allow the piping system to navigate complex layouts and connect to other components without compromising performance. The proper use of fittings also reduces stress on the system by allowing for controlled flow and distribution of fluids.

Elbows: Elbows are used to change the direction of the pipe, typically at 45 or 90 degrees. In FRP systems, elbows must be carefully designed to handle the specific pressure and load conditions of the system while maintaining smooth flow. Properly supported elbows, in line with the frp pipe span chart, prevent strain on joints and maintain system efficiency.

Tees: Tees allow for the connection of three different pipes, often in a “T” shape. These fittings are essential for branching systems and distributing fluids to multiple locations. Tees must be supported according to the span chart to avoid uneven stress and potential leaks.

Reducers: Reducers are used to connect pipes of different sizes, allowing for changes in pipe diameter within the system. By using reducers, engineers can adapt the system to meet varying flow rates and pressure demands. Supporting reducers according to the frp pipe span chart ensures that transitions between pipe sizes do not introduce unnecessary strain on the system.

GangLong Fiberglass offers a comprehensive range of FRP pipe fittings that are designed to complement their piping systems, ensuring that every component works together seamlessly for optimal performance.

Top Challenges Contractors Face in Securing FRP Pipes Tenders

Why It Is Necessary to Calculate FRP Pipe Span

Calculating the FRP pipe span is crucial to ensure the stability and longevity of industrial piping systems. Proper span calculations help prevent sagging, excessive deflection, or failure under load. In FRP pipes, which are known for their lightweight yet strong properties, incorrect span lengths can lead to structural issues such as stress, deformation, and even pipe breakage. By calculating the correct span, engineers can optimize the design of the system, ensuring it meets safety standards while maintaining performance and reducing maintenance costs. Proper span calculations also take into account environmental factors, such as temperature changes, seismic forces, or wind loads, which might affect the piping system over time.

How to Calculate FRP Pipe Span: Step-by-Step

Calculating the correct span for FRP pipes is essential to ensure that the system remains structurally sound and capable of handling the internal pressures, external loads, and environmental conditions it will encounter. Here’s a step-by-step guide to calculate the appropriate FRP pipe span, taking into account various critical factors such as pipe size, material specifications, load conditions, engineering factors, and safety factors.

Determine Pipe Diameter

The diameter of the FRP pipe plays a crucial role in determining the span between supports. Larger pipes are inherently heavier and experience greater stress, which means they require more frequent support to avoid sagging or bending under their own weight. On the other hand, smaller pipes, due to their lighter weight, can generally be supported over longer distances. The larger the diameter, the shorter the span needs to be to maintain structural integrity.

Check Material Specifications

Before calculating the span, it is essential to understand the properties of the specific FRP material used in the pipe. Key material specifications include the modulus of elasticity, ultimate tensile strength, and the type of resin and fibers used in the composition. These material properties dictate how much weight or pressure the pipe can withstand without failing. For example, carbon fiber-reinforced FRP pipes will have a higher strength and stiffness than glass fiber-reinforced pipes, allowing for longer spans.

Identify Load Conditions

The next step in calculating the span is identifying the load conditions the FRP pipe will face. These include internal pressure, which pushes outward on the pipe walls, and external loads such as wind, seismic forces, or weight from hanging equipment like valves and pumps. Temperature variations can also influence the stress on the pipe. As the temperature increases, FRP pipes expand, becoming more flexible and reducing their load-bearing capacity. These factors must be carefully considered when calculating the span to ensure the pipe does not deform under stress.

Select Allowable Deflection

Industry standards typically specify the maximum allowable deflection for piping systems, which is the amount a pipe can bend without compromising its performance or safety. The deflection is often limited to a fraction of the span, such as 1/120th of the span length. This ensures that the pipe maintains its structural integrity and does not suffer from excessive sagging, which could lead to operational issues or even failure. The allowable deflection limits are usually set by standards and engineering codes, and it is crucial to follow them during span calculations.

Engineering Factor – Dynamic Loads and Vibration Considerations

An important engineering factor to consider when calculating the FRP pipe span is the dynamic load and vibration that the pipe may experience during operation. In environments where pipes are exposed to mechanical vibrations, such as in power plants or industrial manufacturing facilities, the pipes are subjected to forces that can influence the span calculations. Vibration can induce oscillations that place additional stress on the pipe, requiring closer support intervals. For pipes that may experience dynamic forces, such as fluctuating pressures or moving equipment, engineers must take vibration and dynamic loading into account to ensure the proper support structure.

Use a Span Chart

Once you have the necessary data regarding pipe diameter, material specifications, and load conditions, you can refer to an FRP pipe span chart. These charts provide recommended span lengths based on pipe size, material strength, and expected load conditions. The span chart is derived from engineering calculations and industry standards, offering a quick and reliable method for determining safe support spacing for FRP pipes. Span charts simplify the process, ensuring that the pipe is properly supported for both short-term and long-term performance.

Apply Safety Factors

To account for unforeseen forces or environmental factors, it is important to apply a safety margin when calculating the FRP pipe span. Safety factors are typically added to the calculated load-bearing capacity of the pipe. A common safety margin is between 1.5 to 2 times the expected load, which ensures that the system remains reliable even in the event of unexpected pressure spikes or external disturbances. This step helps prevent structural failure and extends the lifespan of the piping system.

Verify Against Codes

Finally, after calculating the FRP pipe span and applying safety factors, it is essential to cross-check your results with relevant design codes and standards. Codes such as ASTM D2996 (Standard Specification for Filament-Wound Fiberglass (FRP) Pipe) or ASME B31.3 (Process Piping) provide additional guidelines for safe design and construction. Verifying the span calculations against these standards ensures that the piping system meets all legal and industry requirements, preventing future issues related to regulatory non-compliance.

FRP Pipe Span Chart and Essential Accessories for Proper Installation

In addition to the necessary FRP pipe span chart, several essential accessories are vital for proper installation and performance of FRP piping systems. These accessories ensure the system remains functional, efficient, and long-lasting under various operational conditions. They support, seal, and protect the pipes, improving the reliability and durability of the system throughout its service life.

Pipe Supports

Pipe supports are crucial for distributing the load of the piping system. They prevent excessive sagging or deflection by providing secure placement at appropriate intervals. Correctly spaced pipe supports, as indicated by the FRP pipe span chart, ensure the system stays stable, even under heavy loads. By avoiding pipe movement and stress, they maintain the integrity of the system over time, preventing misalignment and potential damage.

Brackets and Clamps

Brackets and clamps are essential for holding the FRP pipe securely in place. These accessories prevent the pipe from moving along its span, which could lead to misalignment or stress that damages the system. They are especially important in horizontal runs, where the risk of shifting or slippage is higher. Proper use of brackets and clamps ensures the correct alignment and positioning of the pipes, improving the system’s overall efficiency and safety.

Expansion Joints

Expansion joints are vital for accommodating the natural expansion and contraction of FRP pipes caused by temperature changes. They absorb movement without damaging the system, preventing stress fractures or pipe deformation. In environments where temperature fluctuations occur frequently, expansion joints are necessary to maintain system stability. They also help to manage pressure surges and shifts in ground, reducing the risk of failures while allowing flexibility in the piping system.

Gaskets and Seals

Gaskets and seals are critical for maintaining the integrity of the FRP pipe connections. They prevent leaks at joints and connections, ensuring the system is leak-proof even under high pressure. The proper sealing of the system is essential for preventing the escape of fluids and the ingress of contaminants, maintaining the safety and efficiency of the entire system. Quality gaskets and seals ensure a reliable and long-lasting performance for FRP pipes in demanding environments.

Elbows, Tees, and Flanges

Elbows, tees, and flanges are fittings that facilitate the proper configuration of the FRP pipe system. They allow for changes in direction, the joining of multiple pipes, and easy disassembly for maintenance. Selecting the appropriate fittings is essential for keeping the system operational and efficient. By choosing the right elbows, tees, and flanges, engineers can create a flexible and functional piping system that can be adapted for specific needs and future modifications.

Anchors

Anchors play a vital role in stabilizing the FRP pipe system. They prevent axial movement, ensuring the pipe stays in place under pressure. Anchors are especially important in systems subject to internal pressure, as they resist the forces that could otherwise cause misalignment or damage. These components contribute to the stability of the entire piping system, ensuring that it remains securely positioned and operates safely without failure.

Integration with FRP Pipe Span Chart

When combined with the FRP pipe span chart, these accessories ensure the proper support, protection, and efficiency of the system. The chart offers guidance for the appropriate spacing of supports, while the accessories like pipe supports, clamps, and expansion joints ensure that the system functions optimally under pressure and varying conditions. Proper integration of these components guarantees that the piping system is secure, reliable, and long-lasting.

Ensuring Longevity and Performance

By following the FRP pipe span chart and correctly utilizing accessories such as supports, expansion joints, and anchors, the longevity and performance of the system are greatly enhanced. These components work together to prevent damage, improve operational efficiency, and reduce the need for frequent maintenance. When properly installed, FRP pipes offer a reliable and durable solution for various industrial applications, ensuring a smooth and efficient operation for years to come.

FAQs about FRP Pipe Span Chart

FRP (Fiberglass Reinforced Plastic) pipes are available in a wide range of standard sizes to meet the diverse needs of industrial applications. The standard diameters for FRP pipes typically range from 1 inch to 144 inches (about 2.5 cm to 366 cm), depending on the specific requirements of the project. The wall thickness of the pipes varies based on the pressure rating and the type of fluid being conveyed. For example, FRP pipes used for high-pressure applications will have thicker walls compared to those used for low-pressure or gravity-flow systems.

In addition to standard sizes, FRP pipes can be customized to meet specific project requirements, including unique diameters, lengths, and pressure ratings. This flexibility makes FRP an ideal choice for a wide range of industries, including chemical processing, water treatment, and power generation. GangLong Fiberglass manufactures FRP pipes in standard and custom sizes, ensuring that clients receive the appropriate product for their specific application needs. Proper sizing of FRP pipes is essential for ensuring optimal flow rates, pressure handling, and system efficiency.

The life expectancy of FRP (Fiberglass Reinforced Plastic) pipes is typically 50 years or more, depending on the operating conditions, the quality of the materials used, and the installation procedures. One of the key advantages of FRP pipes is their resistance to corrosion, which contributes to their long service life in environments that would degrade traditional metal pipes. FRP pipes are highly durable in applications where they are exposed to chemicals, UV radiation, and varying temperatures, making them ideal for industries such as chemical processing, water treatment, and oil and gas.

The actual lifespan of FRP pipes can be influenced by several factors, including the type of resin and fiberglass used, the temperature and pressure conditions, and the quality of the installation. Regular maintenance and inspections can also help to maximize the service life of the piping system. GangLong Fiberglass offers high-quality FRP pipes designed for longevity, ensuring that they meet or exceed the expected life expectancy in demanding industrial applications.

The American Society of Mechanical Engineers (ASME) provides standards for FRP piping in its ASME B31.3 code, titled “Process Piping.” This code covers the design, materials, fabrication, installation, and testing of piping systems, including those made from fiberglass-reinforced plastic (FRP). Specifically, the ASME B31.3 code addresses the use of FRP in industrial applications such as chemical plants, petroleum refineries, and power plants, where corrosion resistance and lightweight piping materials are critical.

In addition to ASME B31.3, the design and installation of FRP piping systems can be governed by other codes, such as ASTM standards, which provide more specific guidance for materials and performance. ASME B31.3 ensures that FRP piping systems meet rigorous safety and performance standards in high-stress industrial environments. Engineers and contractors use these codes to ensure that FRP piping installations are durable, safe, and compliant with regulatory requirements. GangLong Fiberglass produces FRP pipes that adhere to these codes, ensuring their suitability for use in critical industrial applications.

To calculate the pipe span for fiberglass reinforced plastic (FRP) pipes, several factors must be considered, including the pipe’s diameter, material properties, operating conditions, and load requirements. The span refers to the distance between two support points where the pipe is allowed to rest without excessive deflection or bending.

Pipe Diameter: Larger pipes will require more support due to increased weight.

Material Strength: FRP materials are strong but flexible; the modulus of elasticity of the fiberglass will influence deflection.

Load and Pressure: The internal pressure, as well as external loads like wind or seismic forces, must be considered.

Deflection Limits: Typically, deflection should not exceed a certain percentage of the span (commonly 1/120th of the span).

Once these factors are known, engineers can use pipe span charts or design formulas specific to FRP pipes, which account for material properties, to determine the safe span length for different pipe sizes and conditions.

The pressure design for FRP (fiberglass reinforced plastic) pipes depends on both the internal fluid pressure and the pipe’s structural properties. FRP pipes are designed to withstand internal pressure, external loads, and various environmental factors while maintaining long-term performance.

Pressure Class: The design pressure is based on the pipe’s wall thickness, the type of resin used, and the reinforcement materials (glass fibers). A pressure class is determined based on the maximum operating pressure the pipe can safely handle.

Hoop Stress Calculation: The internal pressure creates hoop stress, and the design must ensure that the pipe’s walls are thick enough to resist this stress without failure.

Safety Factor: A safety factor is typically applied to account for unknowns or unexpected operational conditions, often ranging from 1.5 to 2.0.

Design codes, like ASTM D2996 and ASME B31.3, offer guidelines for calculating the appropriate wall thickness and pressure class based on these factors.

FRP stands for Fiberglass Reinforced Plastic, which refers to a composite material made by embedding glass fibers in a plastic resin matrix. The glass fibers provide strength and stiffness, while the resin holds the fibers in place and offers resistance to corrosion, chemical attacks, and high temperatures.

FRP pipes are commonly used in industries where corrosion-resistant materials are required, such as in chemical processing, wastewater treatment, and oil and gas applications. These pipes are lightweight, durable, and easy to install, offering significant advantages over traditional materials like steel or concrete. FRP pipes are also more flexible, which can help reduce the likelihood of failure due to ground movement or temperature changes. The resin can be tailored for specific applications, making FRP a versatile option for various piping systems.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.