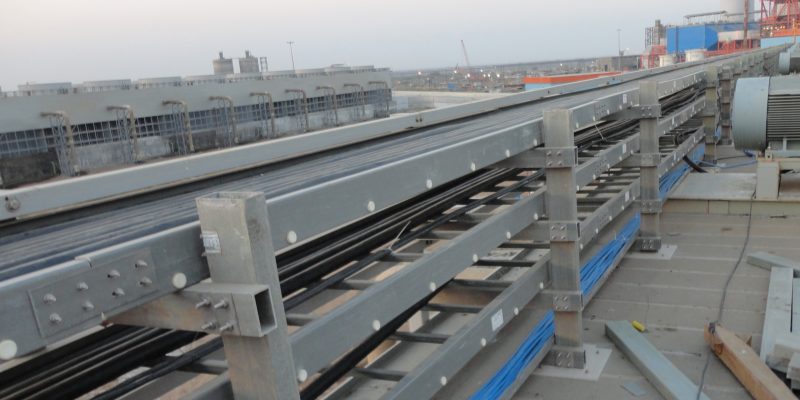

An inverted cable tray is a specialized type of cable tray designed to support and organize cables with an inverted layout. This unique configuration can optimize space and improve cable accessibility, especially in industrial and commercial environments. The inverted cable tray is often used when traditional cable trays cannot provide the required organization or safety.Choosing an inverted cable tray system offers several benefits. By positioning the tray upside down, better cable protection is achieved, particularly from dust and debris. Additionally, this setup reduces the risk of accidental cable dislodgment, ensuring secure installations. Inverted cable tray systems are also adaptable for various installation conditions, making them suitable for complex or high-traffic cable management needs. These systems can contribute to efficient, organized, and protected cabling arrangements.

Inverted Cable Tray Installation

Installing an inverted cable tray requires careful planning to ensure secure, efficient cable management. A well-organized layout that incorporates elements like a flat cable tray can help streamline the process, providing a stable foundation for cables to be routed safely and efficiently. By following the proper steps and avoiding common mistakes, you can achieve a robust setup that supports both safety and functionality.

Preparing for Inverted Cable Tray Installation

Cable Layout Needs

Begin by assessing the types, sizes, and routing requirements of the cables to be installed. Understanding the number of cables, their purpose, and their specific needs will help you determine the appropriate cable tray size, spacing, and layout. This step ensures that the cable tray can accommodate all cables without overcrowding, allowing for efficient cable management and preventing potential cable damage.

Environmental Conditions

Take into account the environmental factors that might affect the installation and the longevity of the system. Factors such as dust, moisture, or airborne debris can cause interference during the installation process, and may even lead to future maintenance issues. Ensure that the work area is clean, dry, and protected from contaminants, especially if the installation is in a high-humidity or dusty environment.

Load Capacity Requirements

It is crucial to select an inverted cable tray that meets the load-bearing capacity needed to support the cables. The tray must be strong enough to handle the weight of all cables, ensuring that they are supported properly over time without risk of sagging or failure. Check the manufacturer’s specifications to confirm the tray’s load capacity and ensure it aligns with the total weight of the installed cables.

Support Structure

The support structure for the cable tray is essential to ensure stability and safety. Adequate supports must be in place, especially when installing the tray in elevated spaces. The supports should be placed at proper intervals to prevent any bowing or sagging of the tray. Additionally, ensure that the support structure can withstand the load and environmental factors to avoid future instability.

Safety Equipment

Since inverted cable tray installations often require working at heights or in challenging environments, using appropriate safety equipment is essential. This includes personal protective equipment (PPE) such as helmets, gloves, harnesses, and safety shoes. Proper training on working at elevated spaces is also necessary to minimize the risk of accidents and injuries during installation.

Long-Term Maintenance

Taking time to properly plan and execute the installation will pay off in the long run. Proper preparation can prevent common maintenance issues such as cable damage, tray misalignment, and poor cable management. A well-installed cable tray system will be more durable, easier to maintain, and will help ensure the overall stability of the cable management setup over its lifespan.

Steps for Installing Inverted Cable Trays

Following the right steps ensures an efficient inverted cable tray installation process. Here is a step-by-step guide:

- Plan the Tray Path: Map out the exact route for the inverted cable tray.

- Secure Tray Supports: Install support structures where the tray will be mounted.

- Position and Attach the Tray: Attach the inverted cable tray to the supports, ensuring it’s firmly in place.

- Route the Cables: Place cables within the tray, securing them at regular intervals.

- Double-Check Connections: Verify all connections and stability of the installed tray.

- Conduct a Final Inspection: Ensure all components are secure, and no cables are loose.

Each step is essential to prevent future issues with the inverted cable tray, supporting reliability and safety.

Common Mistakes to Avoid During Installation

During installation, some mistakes may lead to operational challenges or compromise safety. Avoid these common errors:

- Overloading the Tray: An overloaded inverted cable tray can bend or break, so follow load guidelines.

- Skipping Support Structures: Failing to install adequate support can cause the tray to sag or detach.

- Improper Cable Securing: Loose cables can lead to disorganization and even safety hazards.

- Ignoring Environmental Factors: Exposure to moisture or dust without protection can reduce tray durability.

- Inadequate Inspection: Lack of a final inspection might leave weak points that can lead to failures.

By addressing these potential pitfalls, you can improve the durability and safety of the inverted cable tray system, ensuring it performs effectively for its intended purpose.

Cable Tray Partition: Organize and Secure Cables Effectively

Inverted Cable Tray Wiring Techniques

Wiring within an inverted cable tray requires careful planning and attention to detail. Proper routing, secure placements, and safety precautions contribute to a stable and effective cable management system. For residential settings, a residential cable tray offers a streamlined solution, ensuring that cables are neatly organized and safely routed through walls or ceilings without compromising accessibility or aesthetics.

How to Route Wiring in an Inverted Cable Tray

Routing wiring in an inverted cable tray requires strategic planning to maintain organization and functionality. To ensure efficiency, consider the following aspects:

- Route Planning: Map out the entire cable path before installation to minimize crossing and interference.

- Segmentation: Separate different types of cables, such as data and power, to reduce electromagnetic interference.

- Cable Bends: Avoid sharp bends that can strain cables; use gradual curves where necessary.

- Future Access: Leave space for easy access to cables for future maintenance or upgrades.

- Cable Labels: Label each cable to identify its function, which simplifies troubleshooting and repairs.

Effective routing can prevent signal interference and make it easier to maintain the inverted cable tray system over time.

Tips for Securing Wires within an Inverted Tray

Securing wires properly within an inverted cable tray is essential for maintaining cable integrity, preventing wear from movement, and ensuring long-term system reliability. Since cables in inverted trays are more prone to shifting due to gravity and environmental factors, careful fastening is critical. Here are several effective techniques and best practices to keep cables firmly in place:

Cable Ties

Use high-quality, UV-resistant cable ties to bundle and secure cables at regular intervals along the tray. These ties should be spaced consistently to avoid drooping and cable displacement. When working outdoors or in areas with strong UV exposure, UV-stabilized nylon ties are essential to prevent deterioration over time. Avoid over-tightening, as excessive pressure can damage cable insulation.

Fasteners

Fasteners, such as saddles, brackets, or wire retainers, provide fixed points of support that anchor cables directly to the tray structure. These are particularly important for long cable runs or when the tray is installed overhead. Fasteners help distribute cable weight evenly and prevent cables from sagging or slipping out of position during operation or maintenance activities.

Clamps and Clips

Clamps and clips offer additional stability by holding individual cables or cable bundles securely in place. They are especially useful in installations subject to vibrations, such as near machinery or in industrial environments. Choose insulated or cushioned clamps when necessary to protect cables from abrasion and mechanical stress, extending their operational life.

Organizers

Cable organizers, such as dividers or cable ducts, can help separate different types of cables and maintain a neat, organized layout. This is particularly important in trays carrying power and data cables together, where separation reduces the risk of electromagnetic interference. Organizers also simplify troubleshooting and maintenance by clearly defining cable paths.

Testing for Security

Once all cables are secured, gently test for stability by lightly tugging or moving cable bundles to ensure they stay in place. This final step helps confirm that no ties or fasteners are loose, and that cables will remain secure during normal operation or vibration. Regular inspections after installation are recommended to maintain cable integrity.

Safety Considerations for Wiring in Inverted Trays

Wiring safety is crucial in inverted cable trays, as improper handling can lead to hazards and system failures. Follow these safety practices to maintain a secure environment:

- Load Capacity: Ensure that the inverted cable tray does not exceed its rated load to avoid structural strain.

- Protective Insulation: Use cables with protective insulation suitable for the environment, especially in high-temperature or moisture-prone areas.

- Grounding Requirements: Verify that the cable tray meets grounding requirements to reduce electrical hazards.

- Regular Inspections: Conduct periodic inspections to check for signs of wear, corrosion, or loose wiring.

- Proper PPE: Use appropriate personal protective equipment (PPE) when handling wiring in elevated or hazardous areas.

Safety precautions help protect both the inverted cable tray system and personnel, ensuring the longevity and integrity of the installation.

Types and Sizes of Inverted Cable Trays

Understanding the types and sizes available for an inverted cable tray is essential for selecting the right system for your needs. Size, depth, and load capacity all play a role in optimizing performance and meeting specific installation requirements.

Standard Sizes of Inverted Cable Trays

Inverted cable trays come in various standard sizes to accommodate different installation and cable management needs. Selecting the appropriate size can enhance efficiency and organization.

- Width Options: Inverted cable trays are available in widths typically ranging from 4 to 24 inches to hold varying cable volumes.

- Length Variations: Standard lengths usually start from 5 feet and can extend to 10 feet or more, depending on the layout.

- Height Specifications: Heights often range from 1 to 4 inches, affecting both cable capacity and structural needs.

- Application Suitability: Standard sizes are suitable for most general applications, including industrial and commercial setups.

Choosing a standard size allows for easier installation, as these options are widely available and compatible with most support systems.

Choosing the Right Depth for Your Inverted Cable Tray

The depth of an inverted cable tray is crucial, as it determines cable volume capacity and system stability. Selecting the right depth depends on several factors:

- Cable Quantity: Greater depth is needed for installations with large cable bundles or thicker cables.

- Environmental Protection: Deeper trays can offer better protection against dust and debris, especially in open environments.

- Structural Integrity: Depth impacts structural strength, with deeper trays often being more rigid and stable.

- Future Expansion: If additional cables may be added, consider a deeper tray to accommodate growth.

A deeper inverted cable tray provides advantages for installations requiring durability and adaptability to environmental challenges.

Heavy Duty Inverted Cable Tray Options for High Load Capacity

Heavy duty inverted cable trays are designed to support significant loads, making them ideal for demanding applications. These trays offer high load capacities for complex, large-scale setups.

- Increased Support Strength: Heavy duty trays are reinforced to handle substantial weight, ensuring structural integrity over time.

- Corrosion Resistance: Many heavy duty trays come with protective coatings, making them suitable for corrosive or outdoor environments.

- High Traffic Applications: They are commonly used in settings where cables need to support high traffic, such as in industrial facilities.

- Extended Durability: The reinforced design helps heavy duty inverted cable trays withstand wear, even in rigorous conditions.

- Examples of Usage: Often used in heavy industrial settings, large data centers, and areas with high vibration.

Choosing a heavy duty inverted cable tray with high load capacity ensures that the tray can accommodate demanding setups without compromising stability or performance.

Cable Tray Heat Shield | Protect Wiring from Heat

Inverted Cable Tray Hangers and Supports

Hangers and supports play a vital role in ensuring the stability and durability of an inverted cable tray system. Proper selection and installation techniques help secure the system while promoting safety and longevity.

Selecting the Right Cable Tray Hanger for Inverted Trays

Choosing the correct hanger for an inverted cable tray is essential to maintain structural stability and meet load requirements. Key considerations include:

- Load Capacity: Hangers should support the full weight of the cables and tray, especially in heavy-duty setups.

- Material Compatibility: Select hangers made from corrosion-resistant materials for long-lasting durability, especially in outdoor or humid environments.

- Mounting Position: Different hangers suit specific mounting positions, such as wall-mounted, ceiling-suspended, or floor-mounted configurations.

- Vibration Resistance: In settings with machinery or movement, hangers designed for vibration resistance are recommended to prevent loosening.

- Ease of Installation: Some hangers offer easier installation or adjustability, which can save time and reduce labor costs.

Selecting the right hanger ensures that the inverted cable tray remains securely mounted, enhancing safety and reliability.

Installation Tips for Cable Tray Hangers

Proper installation of cable tray hangers helps distribute weight evenly and prevents strain on the inverted cable tray system. When planning the setup, it’s important to consider the cable tray structure to ensure it supports the system’s load and maintains stability. Here are some helpful tips:

- Spacing of Hangers: Place hangers at regular intervals, typically every 5 feet, to evenly distribute the weight along the tray.

- Tighten Connections: Ensure that all bolts and connections are firmly tightened to avoid any loosening over time.

- Level Alignment: Use a level to ensure the tray is aligned correctly, preventing unwanted strain on cables or tray components.

- Allow for Adjustment: Install hangers that allow for height and position adjustments, which can be useful for accommodating future changes.

- Avoid Overloading: Do not place more weight than each hanger’s load rating, as this could lead to structural failures.

These installation practices help maximize the effectiveness of the inverted cable tray hangers, contributing to a stable and organized system.

Benefits of Using Deep and Heavy Duty Inverted Cable Trays

Selecting deep and heavy duty inverted cable trays can enhance the durability and efficiency of cable management systems. These trays are designed to support complex installations, providing extra capacity, strength, and cost-effective solutions.

Advantages of Deep Cable Trays for Large Cable Volumes

Deep inverted cable trays are a smart choice for managing large and complex cable systems, particularly in industrial, commercial, and data-heavy environments. Their increased depth offers both functional and structural advantages, making them ideal for installations where cable density, organization, and future scalability are key considerations. Here’s a closer look at the benefits of using deep cable trays:

Increased Capacity

One of the primary advantages of deep cable trays is their ability to hold a greater volume of cables. This makes them especially valuable in facilities with extensive wiring needs, such as data centers, manufacturing plants, or large commercial buildings. The added vertical space allows for the installation of multiple cable layers without overcrowding, ensuring safe and efficient cable distribution.

Organized Layout

With more depth available, cables can be arranged in a more structured and segmented manner. This helps prevent tangling and minimizes electromagnetic interference between different types of cables, such as power and communication lines. Deep trays allow for clear separation and routing, promoting better airflow and reducing the risk of overheating or signal degradation.

Enhanced Cable Protection

Deeper trays provide an added layer of protection for cables from external elements. The increased depth helps shield cables from dust, debris, and accidental contact, especially in industrial or construction environments. This protective feature contributes to longer cable lifespan and fewer maintenance issues caused by environmental exposure.

Simplified Maintenance

The additional space in deep cable trays makes it easier to identify, access, and work on individual cables when maintenance is needed. Technicians can more easily trace cable paths, perform repairs, or replace damaged sections without disrupting adjacent cables. This improves maintenance efficiency and reduces downtime during system servicing.

Future Expansion

Deep cable trays are designed with scalability in mind. As infrastructure needs grow and more cables are required, the existing tray can accommodate new additions without requiring a complete overhaul. This flexibility makes deep trays a cost-effective long-term solution, especially in environments where upgrades and expansions are expected.

When to Use Heavy Duty Inverted Cable Trays for Durability

Heavy duty inverted cable trays are ideal for applications where strength and durability are top priorities. They are designed to withstand demanding conditions.

- High Load Capacity: Heavy duty trays support significant weight, making them essential for installations with thick cables or bundled wiring.

- Environmental Resistance: Many heavy duty trays are coated to resist corrosion, allowing use in harsh or outdoor environments.

- Structural Integrity: Reinforced design minimizes bending or sagging, even when subjected to heavy loads or high traffic areas.

- Industrial Applications: These trays are widely used in industrial settings where machinery or movement can impact cable systems.

- Long-Term Reliability: Heavy duty trays provide durable, long-lasting solutions, reducing the need for frequent replacements or repairs.

Heavy duty inverted cable trays are especially beneficial in challenging environments, as they offer both stability and resilience.

Cost and Efficiency Benefits of Inverted Cable Tray Systems

Inverted cable tray systems, particularly deep and heavy duty options, contribute to cost savings and operational efficiency.

- Reduced Maintenance Costs: High-quality inverted cable trays require minimal maintenance, lowering long-term expenses. With reliable cable tray products, you can be assured of a durable system that reduces the need for frequent repairs or replacements.

- Efficient Cable Management: The organized layout helps prevent tangled or damaged cables, minimizing disruptions and maintenance needs.

- Streamlined Installation: Standardized tray designs make installation faster, reducing labor costs and setup time.

- Space Optimization: Inverted tray systems maximize space by allowing cables to be arranged compactly, making them ideal for confined spaces. Accurate cable tray measurement is essential in this process, ensuring that the tray fits perfectly within the available area while maintaining efficiency in cable organization.

- Extended System Lifespan: The durability of heavy duty trays ensures that the system remains functional over long periods, minimizing replacement costs.

By choosing deep or heavy duty inverted cable trays, businesses can benefit from enhanced efficiency and reduced operational costs, making these systems a valuable investment.

Essential Cable Tray Tools for Efficient Installation

Best Practices for Maintaining an Inverted Cable Tray System

At GangLong Fiberglass, we understand the importance of proper maintenance for an inverted cable tray system. Regular maintenance helps extend the lifespan of the tray, ensuring safety and stability in any environment. Following these best practices will help keep your cable management system efficient and reliable.

Routine Maintenance for Inverted Cable Trays

Routine maintenance is essential to preserve the structural integrity and performance of inverted cable trays over time. These systems often operate in challenging environments—overhead, in industrial zones, or outdoors—where exposure to dust, moisture, and vibration can gradually impact reliability. A proactive maintenance routine helps minimize downtime, prevent safety hazards, and extend the lifespan of the entire cable management system. Here’s how to maintain your inverted cable trays effectively:

Cleaning and Dust Removal

Dust and debris accumulation can interfere with airflow and lead to cable overheating or insulation wear. Schedule periodic cleaning to remove any build-up inside and around the tray. Use a vacuum or soft brush for general cleaning and, if necessary, compressed air to reach narrow spaces. In sensitive environments, follow any regulatory cleaning guidelines to prevent contamination or equipment failure.

Lubrication of Movable Parts

In installations where the tray includes adjustable joints, hinges, or support brackets, applying a suitable lubricant helps prevent metal fatigue, reduce friction, and ensure smooth operation. Regular lubrication protects moving parts from rust and premature wear, especially in environments with fluctuating temperatures or exposure to chemicals.

Checking for Corrosion

Corrosion is a serious concern, particularly in humid, coastal, or industrial environments. During inspections, look for signs of rust, pitting, or discoloration on the tray or its supports. If corrosion is found, clean the affected area and apply anti-corrosion coatings or replace damaged sections. FRP trays are corrosion-resistant, but even they should be inspected for surface degradation or UV damage.

Reviewing Support Structures

The stability of an inverted cable tray system depends heavily on its support structure. Over time, vibrations, building shifts, or thermal expansion can loosen support brackets or anchor points. Check that all supports are firmly secured and free of stress or damage. Reinforce or replace any weak components to prevent tray sagging or structural failure.

Updating Cable Labels

Clear and accurate cable labeling simplifies future maintenance, troubleshooting, and upgrades. As cables are added, removed, or rerouted, it’s essential to keep all labels up to date. Use durable, legible labels that can withstand environmental conditions. Color-coding or QR-coded tags can further streamline identification during inspections or emergency repairs.

Inspecting Wiring and Tray Stability

Regular inspections are key to identifying potential issues before they become serious problems. At GangLong Fiberglass, we suggest the following inspection practices for your inverted cable tray:

- Cable Condition Checks: Examine cables for any signs of wear, including frayed wires, insulation cracks, or other damage.

- Structural Integrity: Inspect the tray structure for bending, sagging, or signs of strain that could compromise stability.

- Connector Security: Ensure all connectors and clamps holding the cables are tight and not showing signs of wear.

- Support Reinforcements: Verify that all support brackets are holding securely, especially in high-vibration environments.

- Environmental Impact Assessment: Consider any environmental changes that might impact the tray, like temperature fluctuations or increased moisture.

Routine inspections will allow you to maintain a stable, safe, and effective inverted cable tray system, preventing long-term damage.

Troubleshooting Common Issues

At GangLong Fiberglass, we understand that even well-maintained systems can experience occasional issues. Here’s how to address some common problems with inverted cable trays:

- Sagging Trays: This can occur if the load exceeds capacity. Check load ratings and add additional supports if needed.

- Loose Cables: If cables become loose, secure them with additional ties or clamps to prevent disorganization.

- Corrosion: Apply a protective coating or replace damaged sections if corrosion is found, especially in outdoor settings.

- Electrical Interference: If interference is detected, rearrange cables to separate power and data lines, reducing signal disruption.

- Physical Damage: Replace any damaged components or cables immediately to prevent further issues or safety risks.

With these troubleshooting steps, maintaining the efficiency and stability of your inverted cable tray system is straightforward, allowing for a well-functioning setup tailored to your needs.

FAQs about Inverted Cable Tray

Yes, cable trays can be installed upside down, creating what’s known as an inverted cable tray. This installation method can be useful in situations where cables need added protection from dust or physical interference. An inverted cable tray keeps cables secure and accessible, making it an effective solution in industrial and commercial environments. However, before installing a cable tray upside down, consider the load requirements and ensure the tray and support systems are rated for the intended orientation. Proper planning and adherence to safety guidelines are essential for maintaining system integrity and durability.

Cable trunking and cable trays are both used for organizing and protecting cables, but they have distinct functions. Cable trays are open structures, often used for routing and supporting heavy cables. They allow airflow, reducing heat buildup around cables, and are commonly seen in industrial or commercial settings. In contrast, cable trunking is a closed, rigid structure that fully encloses cables. Trunking provides extra protection against dust, moisture, and physical contact, making it useful in environments where cables need complete shielding. The choice between the two depends on the specific protection and organization needs of the installation.

The three main types of cable trays are ladder, perforated, and solid-bottom trays. Ladder trays are ideal for heavy cables and high ventilation, with open rungs that reduce heat buildup. Perforated trays feature small holes along the tray’s bottom, providing support while also allowing some ventilation and cable cooling. Solid-bottom trays offer maximum cable protection and support, making them suitable for environments requiring dust or moisture protection. Each type serves a distinct purpose, so choose the one that best fits your project’s requirements based on load, ventilation, and environmental protection needs.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.