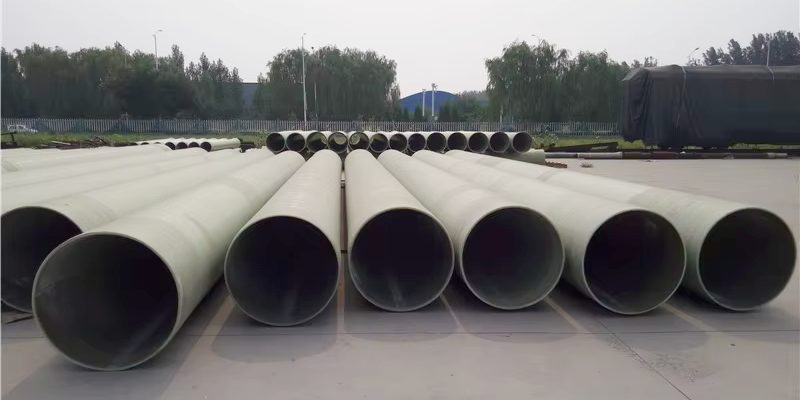

Large diameter fiberglass tubes are increasingly essential in both industrial and commercial applications, particularly opaque & translucent large diameter fiberglass tubes for fluid levels, power systems, and telescoping sets. Their demand is growing due to their superior performance in harsh environments. Industries such as water treatment, chemical processing, and marine engineering highly value these tubes for their durability and reliability. The unique fiberglass tube properties, such as resistance to corrosion and excellent strength-to-weight ratio, make them the preferred choice over traditional materials. They are resistant to corrosion, ensuring longevity in environments exposed to moisture or chemicals. Additionally, these tubes are lightweight, making transportation and installation easier, while maintaining impressive strength for structural integrity. For industries requiring custom solutions, large diameter fiberglass tubes provide flexibility in design and performance, further enhancing their widespread use.

Key Features of Large Diameter Fiberglass Tube

Large‑diameter fiberglass tubes, characterized by their round cross‑sections, combine lightweight yet high‑strength construction with excellent corrosion resistance, non‑conductivity, and non‑magnetic properties. Their dimensional stability under temperature and pressure variations, coupled with low maintenance requirements, makes them a cost‑effective, durable solution for demanding industrial and construction applications.

Corrosion-Resistant Properties

Large diameter fiberglass tubes exhibit outstanding corrosion resistance, remaining unaffected by moisture, chemicals, and saline solutions that would damage metal pipes. Their composite prevents rust and degradation, ensuring structural integrity over long periods. This longevity minimizes the need for replacements or repairs in harsh industrial environments such as water treatment plants, chemical processing facilities, and marine applications, reducing operational costs.

Non-Conductive Properties

Large diameter fiberglass tubes offer excellent electrical insulation, making them ideal for environments where conductivity must be avoided. Their non-conductive composite prevents interference with high-voltage lines, sensitive equipment, and systems. This property ensures safety by eliminating risks of short circuits or unintended currents. Fiberglass provides electrical isolation from ambient electromagnetic fields, supporting reliable operation in power plants, laboratories, manufacturing facilities.

Non-Magnetic Features

Large diameter fiberglass tubes are inherently non-magnetic, making them suitable for applications where magnetic interference must be minimized. Unlike metal pipes, fiberglass does not interact with magnetic fields, ensuring accurate performance of sensitive equipment in aerospace and medical environments. This neutrality prevents distortion in instruments and sensors. Utilizing non-magnetic tubes enhances operational stability and integrity in settings requiring electromagnetic compliance.

Lightweight Construction

Large diameter fiberglass tubes feature lightweight construction that reduces handling, transportation, and installation effort compared to metal counterparts. Their low-density composite simplifies shipping logistics and decreases labor requirements with long pipe runs. This weight also lowers stress on supporting structures, facilitating deployment in extensive industrial and infrastructure projects. Despite lightness, these tubes deliver reliable strength and durability for demanding applications.

High Strength and Durability

Large diameter fiberglass tubes boast exceptional tensile strength, enabling them to withstand high pressures, temperature variations, and impact without cracking or deforming. The fiber-reinforced composite resists fatigue and maintains integrity under mechanical loads, providing reliable performance over extended service intervals. This durability minimizes maintenance and replacement needs in heavy-duty industrial sectors such as oil and gas, engineering, and infrastructure construction.

Stable Dimensions

Large diameter fiberglass tubes exhibit excellent dimensional stability, maintaining consistent size and shape despite fluctuations in temperature, pressure, or humidity. Unlike metal pipes, which may expand or contract and cause leaks or misalignments, fiberglass resists environmental stresses. This reliability preserves secure connections and reduces fitting adjustments. Engineers benefit from performance and integrity in installations requiring precise tolerances and reduced maintenance.

Low Maintenance Costs

Large diameter fiberglass tubes require minimal maintenance because their corrosion resistance and strength prevent leaks and cracks. The composite construction removes the need for frequent inspections or treatments required by metal pipes. Reduced failure risks lead to fewer repairs and lower labor expenses the tube’s lifetime. This cost-effectiveness makes fiberglass an attractive option for industries seeking durable, low-overhead piping solutions.

Large Diameter Fiberglass Tube Price: Key Factors and Cost Comparison

Understanding the price of large diameter fiberglass tubes requires examining several key factors that influence their cost. These tubes are valued for their performance, but the final price can vary based on material composition, manufacturing processes, customization, and compliance with industry standards. Let’s explore each of these aspects to gain a clearer picture of the cost structure.

Material Composition

One of the most important factors affecting the price of large diameter fiberglass tubes is the type of materials used. These tubes are typically made from a combination of resins and reinforcement materials, such as fiberglass. The choice of resin, such as polyester or vinyl ester, can significantly impact the final cost. Higher-quality resins offer better corrosion resistance and durability but are often more expensive. Additionally, the amount and type of reinforcement fibers, which provide strength, also play a crucial role in determining the price.

Manufacturing Process

The method used to manufacture large diameter fiberglass tubes is another critical factor. Two common processes are filament winding and contact molding. Filament winding involves winding continuous fibers around a mandrel, creating strong, lightweight tubes with precise wall thickness. This process is often more cost-effective for producing high volumes. In contrast, contact molding uses hand lay-up techniques and typically results in a thicker wall with higher resin content. Though contact molding can be more expensive, it is ideal for custom or small-batch orders where high strength is needed.

Customization Options

Large diameter fiberglass tubes can be customized in terms of size, shape, and fittings to meet specific project requirements. Customization increases the overall price due to additional labor and specialized materials. However, many industries require specific tube dimensions, flanges, or couplings, which must be considered during production. While standard tubes may offer lower prices, customized solutions provide added value for unique applications, ensuring the tubes meet exact performance criteria.

Industry Standards and Certifications

Compliance with industry standards and certifications also plays a role in determining the price of large diameter fiberglass tubes. These standards, such as ASTM or AWWA certifications, guarantee that the tubes meet specific performance and safety requirements. While tubes adhering to these standards may cost more, they ensure reliability and longevity in demanding environments, making them a smart long-term investment.

Price Range and Cost-Effectiveness

The price of large diameter fiberglass tubes can vary widely depending on the factors mentioned above. Small diameter fiberglass tubes, such as those with diameters of 6 to 12 inches, may be more affordable, while larger tubes, like those exceeding 72 inches in diameter, will be more expensive. However, innovations in small diameter fiberglass tube production have led to more efficient manufacturing processes, making these tubes even more cost-effective. Small diameter fiberglass tubes are often a more budget-friendly option, making them an attractive choice for projects with cost constraints. Custom orders and higher-quality materials will also drive up costs. Despite the higher initial investment, fiberglass tubes are more cost-effective over time compared to traditional materials like steel or PVC. They offer low maintenance, long lifespan, and resistance to corrosion, reducing repair and replacement costs.

Flexible Fiberglass Tube: Lightweight and Durable Options

Large Diameter Fiberglass Tubes for Sale: Sizes, Specifications, and Applications

When it comes to purchasing large diameter fiberglass tubes, understanding the available sizes and specifications is key. These tubes are designed for a variety of industrial applications, each requiring specific dimensions and features to meet performance standards. Below, we explore the common sizes on the market, their applications, and how to choose the right tube for your project.

Common Sizes and Specifications of Large Diameter Fiberglass Tubes

Large diameter fiberglass tubes come in a range of sizes to accommodate different project requirements. Standard diameters for these tubes typically range from 6 inches to 162 inches, providing flexibility for both small and large-scale projects. The most common lengths available are 20 feet and 40 feet, though custom lengths and diameters can be requested for specialized applications. Many manufacturers, including those producing high-quality large diameter fiberglass tubes, also offer custom options, allowing clients to specify particular wall thicknesses, shapes, or additional fittings to meet specific needs.

Custom Sizes and Features Available

For projects requiring non-standard sizes, custom large diameter fiberglass tubes are often the best solution. These custom orders can include unique diameter measurements, special coatings for enhanced durability, and the integration of specific features like couplings, flanges, or reinforced sections. Customization ensures that the tubes perform optimally in their intended application, providing enhanced longevity and structural integrity.

Applications of Large Diameter Fiberglass Tubes

Large diameter fiberglass tubes are widely used in industries where durability, corrosion resistance, and lightweight materials are essential.

- Wastewater Treatment Plants: Fiberglass tubes are resistant to chemical corrosion and moisture, making them ideal for water treatment facilities.

- Industrial Pipelines: Desalination plants and power utilities rely on these tubes for the safe and efficient transport of water, steam, and chemicals.

- Marine Applications: Dock and pier construction projects benefit from the non-corrosive properties of fiberglass, especially in saltwater environments.

These industries value the high strength-to-weight ratio and long service life of large diameter fiberglass tubes, which perform reliably even in harsh conditions.

Best Practices for Evaluating and Selecting Fiberglass Tubes

When selecting large diameter fiberglass tubes for a specific project, it’s important to evaluate several factors:

- Application Requirements: Consider the environmental conditions the tube will face, such as exposure to chemicals, water, or extreme temperatures.

- Size and Wall Thickness: Ensure that the chosen diameter and wall thickness match the structural demands of the project.

- Customization Needs: Determine whether standard tubes are sufficient, or if custom features like specialized fittings are required.

By carefully evaluating these factors, you can ensure that your large diameter fiberglass tube selection provides optimal performance for your specific application.

Finding Large Diameter Fiberglass Tubes Near You: A Complete Guide

When searching for large diameter fiberglass tubes, it’s important to know where to look and what factors to consider. Whether you’re looking for a fiberglass tube near me or sourcing from online vendors, understanding your options can save time and money. Let’s explore how you can find the right large diameter fiberglass tube, with a special focus on availability, popular brands like GangLong Fiberglass, and the advantages of local purchasing versus distant suppliers.

Sourcing Large Diameter Fiberglass Tubes Locally and Online

One of the first things to consider when looking for a large diameter fiberglass tube is whether you want to purchase it locally or from an online vendor. Local suppliers may offer faster delivery times and more personalized customer service, making them ideal for urgent projects or when specific advice is needed. Many industrial hubs feature specialized suppliers that stock a range of fiberglass tubes in various sizes.

If local options are limited, online vendors can provide access to a wider selection. Websites from established manufacturers like GangLong Fiberglass make it easy to browse available products, specifications, and pricing. Some online platforms also offer customization options, allowing you to order tubes tailored to your specific requirements.

Availability in Industrial Hubs and Specialized Suppliers

Large diameter fiberglass tubes are widely available in major industrial hubs, where infrastructure projects and industrial applications drive demand. These hubs often have specialized suppliers that can meet the needs of local industries. For instance, regions with a strong presence in water treatment, marine engineering, or chemical processing are likely to have a greater number of suppliers offering these tubes.

Well-known brands like GangLong Fiberglass have established networks of distributors and retailers that supply large diameter fiberglass tubes across various regions. This ensures that even if you’re not located in an industrial hub, you can still source high-quality tubes without difficulty.

Popular Manufacturers and Distributors of Large Diameter Fiberglass Tubes

At GangLong Fiberglass, we take pride in our expertise in producing durable, high-performance fiberglass tubes. Our products are widely used across various industries, including wastewater treatment, power plants, and marine applications. As the manufacturer, we offer a broad range of large diameter fiberglass tubes, ensuring that we can meet the specific size and specifications required for your project. We are committed to providing high-quality, reliable solutions for all your fiberglass tube needs.

Local vs. Distant Suppliers: What’s Best?

When deciding between local and distant suppliers, consider the trade-offs.

- Purchasing large diameter fiberglass tubes locally offers several benefits:

- Faster delivery times: You can receive your order quickly, reducing project delays.

- Personalized customer service: Local suppliers may provide more direct communication and faster responses to inquiries.

- Easy returns and exchanges: Dealing with nearby suppliers makes logistics simpler if issues arise.

On the other hand, buying from distant suppliers or online vendors like GangLong Fiberglass can offer a wider variety of products and potential cost savings:

- Wider selection: Distant suppliers may offer a larger inventory and customization options.

- Bulk discounts: If you need a large quantity of tubes, buying from online suppliers can often lead to significant savings.

Thick Wall Fiberglass Tube: A Comprehensive Applications

Support and Purchasing Assistance for Large Diameter Fiberglass Tubes

When purchasing large diameter fiberglass tubes, having access to expert support can make the process much smoother and more efficient. Professional assistance is available from sales and engineering teams to guide you through the selection and purchasing process, ensuring that the products meet your specific requirements. Whether you are dealing with a complex installation or need customized solutions, the right support can help avoid potential challenges.

Professional Assistance for Large Diameter Fiberglass Tubes

Experienced sales and engineering teams offer comprehensive selection support. They help determine optimal tube size, wall thickness, and compatible fittings across applications—from water treatment and industrial pipelines to chemical processing. Leveraging industry‑standard expertise, these professionals validate that your chosen tubes meet both performance requirements and regulatory criteria, streamlining procurement while minimizing risks linked to incorrect specifications.

Custom Solutions, Pricing, and Availability

Sales teams can provide tailored large‑diameter fiberglass tube solutions to match your project’s unique specifications. Custom options include varied diameters, wall thicknesses, lengths, and specialized reinforcements or fittings. Pricing reflects these customizations, bulk order discounts, and production lead times. Engaging early with the supplier yields accurate availability estimates, allowing you to plan delivery schedules and budgets for cost‑effective procurement.

Additional Resources for Detailed Planning

Manufacturers and distributors offer technical bulletins, case studies, and product specifications to support planning and design. Technical bulletins detail material properties, performance standards, and installation guidelines. Case studies illustrate successful large‑diameter fiberglass tube applications, revealing best practices and innovative solutions. Reviewing these resources enhances understanding of tube capabilities and real‑world performance, helping you anticipate challenges and optimize system integration.

Key Considerations When Purchasing Large Diameter Fiberglass Tube

When purchasing large diameter fiberglass tubes, consider more than just size. Key factors—material composition and resin type, pressure and temperature ratings, mechanical strength, environmental and chemical resistance, and customization options—determine their performance, durability, and suitability. Evaluating these ensures optimal selection tailored to your project’s specific requirements.

Material Composition and Resin Type

The resin and fiber makeup of a large‑diameter fiberglass tube directly impact its durability, chemical resistance, and thermal performance. Common resins include epoxy (excellent chemical and temperature resistance), vinyl ester (balanced corrosion protection), and polyester (cost‑effective for general use). Selecting the right resin ensures the tube withstands exposure to acids, alkalis, and extreme temperatures without compromising structural integrity or service life.

Pressure and Temperature Ratings

Verify that the fiberglass tube’s rated pressure and temperature limits match your system’s demands. Tubes designed for high‑pressure service often feature thicker walls and optimized winding patterns. Temperature ratings, typically from –40 °C to over 150 °C, determine suitability for steam, hot water, or cryogenic applications. Installing tubes beyond their specified ratings increases risk of deformation, cracking, or catastrophic failure under load.

Strength and Load‑Bearing Capacity

Large‑diameter fiberglass tubes offer a superior strength‑to‑weight ratio, making them ideal for heavy‑duty piping and structural supports. Their tensile and impact strengths depend on fiber orientation, resin quality, and wall thickness. Fiber‑wound construction provides uniform strength distribution around the circumference, resisting crushing and bending forces. Always choose tubes whose published load‑bearing specifications exceed your maximum expected mechanical or fluid pressures.

Corrosion Resistance and Environmental Compatibility

Fiberglass inherently resists rust and many chemical attacks, unlike metal alternatives. In addition, filament wound tubes—where continuous fibers are wound under tension—offer even greater mechanical strength and durability alongside chemical resistance. However, resin formulation and gel coat additives further enhance resistance against specific media—marine saltwater, acids, or alkalis. Confirm compatibility with fluids and gases in your process, as aggressive chemicals (e.g., strong oxidizers) may require specialty resins. Properly selected tubes maintain integrity and avoid leaching or degradation even in the harshest environments.

Customization and Fabrication Options

Sourcing large‑diameter fiberglass tubes that can be tailored to length, wall thickness, and end‑fitting requirements streamlines installation and reduces on‑site labor. Suppliers often offer custom cutting, flange bonding, and shape modifications (oval or square profiles) to match complex layouts. Early engagement with fabricators ensures tubes integrate seamlessly with joints, supports, and adjacent materials, minimizing field adjustments and potential alignment issues.

Advantages and Disadvantages of Large Diameter Fiberglass Tube Compared to Other Sizes

Large diameter fiberglass tubes play a crucial role in various industries, including construction, infrastructure, and industrial fluid transport. Compared to smaller-diameter fiberglass tubes, they offer unique benefits such as increased load-bearing capacity, efficient material transport, and structural stability. However, they also come with specific challenges, including higher costs, complex installation, and transportation difficulties. To better understand the strengths and weaknesses of large-diameter fiberglass tubes relative to smaller sizes, we will analyze them from multiple perspectives, including structural performance, cost-effectiveness, installation and transportation, application range, and maintenance requirements.

| Dimension | Large‑Diameter Advantages | Large‑Diameter Disadvantages | Small‑Diameter Advantages | Small‑Diameter Disadvantages |

|---|---|---|---|---|

| Structural Performance | High strength‑to‑weight ratio; minimal bending; pressure resistant | Heavy; low flexibility | Lightweight; highly flexible | Low load capacity; deforms under pressure |

| Cost & Efficiency | Fewer sections and joints; extended service life | High unit cost; costly repairs | Low material cost; inexpensive section replacement | Multiple joints increase maintenance |

| Transport & Installation | Simplified layout with fewer pieces | Requires wide‑load transport and cranes | Manoeuvrable by crew or standard vehicles | Many pieces lengthen installation time |

| Applications | Suits high‑volume fluids and structural uses; corrosion‑resistant | Over‑engineered for small or low‑pressure tasks | Ideal for compact or modular systems | Unsuitable for large‑scale or heavy‑duty |

| Maintenance & Durability | Thick walls; few leak points | Difficult access for repair; special tools required | Easy inspection and swap‑out; low spare cost | Thin walls; higher leak potential |

How to Choose the Right Tapered Fiberglass Tube Size

How to Cut Large Diameter Fiberglass Tube into Suitable Lengths

Cutting a large diameter fiberglass tube into precise lengths requires careful planning, the right tools, and proper safety measures. Unlike cutting traditional materials such as metal or PVC, fiberglass requires special handling to prevent splintering, ensure clean edges, and maintain structural integrity. The process involves selecting the appropriate cutting tools, following specific cutting techniques, and implementing safety measures to protect both the worker and the material. Additionally, post-cut finishing and surface treatment are crucial to achieving a smooth and reliable final product. Below, we will explore the process in detail through different aspects, including tool selection, cutting techniques, safety precautions, and post-cut finishing.

Selecting the Right Cutting Tools

Choosing the appropriate cutting tool is essential for achieving a clean and precise cut without damaging the fiberglass tube. Since fiberglass is a composite material made of glass fibers and resin, traditional cutting tools may not be effective and could result in frayed edges or excessive dust production.

- Diamond Blade Saw – Ideal for high-precision cuts, a diamond-tipped blade minimizes fiber fraying and delivers a smooth edge. It is commonly used for industrial applications.

- Carbide-Tipped Circular Saw – A more accessible option that provides good cutting efficiency, especially when working with thicker fiberglass tubes.

- Angle Grinder with Cutting Disc – Useful for on-site modifications, though it may require extra finishing due to rougher edges.

- Band Saw with Fine-Tooth Blade – Works well for controlled, low-vibration cutting, reducing material stress and ensuring cleaner cuts.

Effective Cutting Techniques for Large Diameter Tubes

Once the appropriate tool is selected, using the right cutting technique is crucial to prevent cracking, delamination, or uneven cuts. The method chosen depends on the tube thickness, diameter, and project requirements.

- Marking the Cut Line – Use a measuring tape and chalk line to ensure straight and accurate cuts. Applying masking tape along the cut line can help reduce splintering.

- Slow and Steady Cutting – Avoid applying excessive force when cutting. Instead, let the tool gradually slice through the material to prevent cracks or fiber unraveling.

- Rotational Cutting (For Large Tubes) – For extra-large diameter tubes, rotating the tube while keeping the saw in place can ensure a more even and consistent cut.

- Cooling and Dust Control – Using a wet cutting technique (such as spraying water) can minimize dust and heat buildup, preserving both the cutting blade and the fiberglass integrity.

Safety Precautions When Cutting Fiberglass

Fiberglass cutting generates fine particles that can irritate the skin, eyes, and respiratory system. Proper safety measures should always be followed to protect workers and maintain a safe work environment.

- Personal Protective Equipment (PPE):

- Respirator or Dust Mask – Prevents inhalation of fiberglass dust, which can be hazardous to lung health.

- Safety Glasses or Face Shield – Protects the eyes from airborne particles.

- Gloves and Long-Sleeved Clothing – Reduces skin irritation caused by fiberglass dust.

- Ventilation: Cutting fiberglass in a well-ventilated area or using an extraction system helps reduce airborne dust concentration.

- Tool Safety: Ensure all cutting tools are properly secured and operated according to manufacturer guidelines to prevent kickbacks or blade damage.

Post-Cut Finishing and Surface Treatment

After cutting, the edges of the fiberglass tube may have sharp or frayed fibers, requiring finishing to ensure smooth surfaces and prevent injuries.

- Edge Smoothing – Use sandpaper, a file, or a deburring tool to remove rough edges and create a clean finish.

- Sealing the Cut End – Applying resin, epoxy, or protective tape helps prevent future fiber exposure and strengthens the tube’s cut edge.

- Cleaning the Tube – Wipe down the tube with a damp cloth or compressed air to remove residual dust and debris before installation or further processing.

Cutting a large diameter fiberglass tube requires careful planning, the right tools, and proper execution to ensure precision and durability. Using specialized cutting equipment, following controlled cutting techniques, prioritizing safety precautions, and performing post-cut finishing all contribute to a successful cutting process. Whether the tube is being prepared for industrial piping, structural applications, or electrical conduit systems, adhering to these best practices will result in high-quality and reliable cuts.

FAQs about Large Diameter Fiberglass Tube

Fiberglass tubing is incredibly strong, especially considering its lightweight composition. The strength-to-weight ratio is one of its most significant benefits. Fiberglass tubing can withstand high pressure, extreme temperatures, and harsh environments without losing its integrity. Its durability makes it an excellent choice for industries that require both strength and corrosion resistance, such as chemical processing and marine applications. Typically, fiberglass tubing can support significant structural loads while being much lighter than steel or aluminum. The strength depends on factors such as wall thickness, diameter, and the specific resin used in production, but it remains one of the most reliable materials for industrial use.

Cutting a fiberglass tube is a straightforward process but requires some specific tools and safety precautions. First, always wear protective gear like gloves, goggles, and a mask to avoid inhaling fiberglass dust. A fine-tooth saw, such as a hacksaw or a circular saw with a carbide-tipped blade, works best for cutting fiberglass tubing. You should mark the cutting line clearly before starting, and make sure to cut slowly and evenly to prevent splintering. It’s important to use low pressure while cutting, allowing the saw to do the work. After cutting, edges can be smoothed with sandpaper to remove roughness.

Fiberglass tubes are versatile and used across various industries due to their strength, corrosion resistance, and lightweight properties. They are commonly found in municipal water systems, industrial pipelines, and chemical processing plants. Fiberglass tubes are also used in marine construction, such as docks and piers, because of their resistance to saltwater corrosion. Additionally, they are favored in infrastructure projects that require durable yet lightweight materials, like bridges or wastewater treatment facilities. Their non-conductive nature makes them ideal for electrical applications, while their ability to withstand high pressures makes them useful in ammonia processing and desalination systems.

Fiberglass pipes come in a wide range of sizes to suit various applications. The diameters typically start from as small as 2 inches (50 mm) and can go up to 144 inches (3.6 meters) or more. Large diameter fiberglass pipes are often used in industrial settings, water treatment, and chemical processing. Standard sizes include 4-inch (100 mm), 6-inch (150 mm), 8-inch (200 mm), and upwards. However, larger diameters, ranging from 10 inches (250 mm) to 72 inches (1.8 meters) or beyond, are commonly used for larger infrastructure projects. The size of the pipe required depends on factors like flow rate, pressure rating, and the specific requirements of the project. When selecting a fiberglass pipe, it is essential to consult with a supplier or engineer to determine the correct size based on the needs of the application and local regulations.

Fiberglass pipes are known for their longevity and durability. Under proper conditions, large diameter fiberglass pipes can last 50 years or more. Their resistance to corrosion, chemical degradation, and environmental factors contributes significantly to their extended lifespan. Unlike metal pipes, fiberglass does not rust, making it ideal for use in aggressive environments, such as water treatment facilities or chemical plants. Additionally, the strength of fiberglass can withstand extreme temperatures and pressures. However, the actual lifespan may depend on factors like installation quality, maintenance, exposure to UV light, and specific environmental conditions. Regular inspections and maintenance are essential to ensure that fiberglass pipes perform optimally over their extended service life. Their low maintenance requirements are another reason fiberglass is often chosen for infrastructure projects.

Fiberglass pipes are typically associated with insulation, rather than foam. The insulation is often applied to fiberglass pipes to improve thermal efficiency, reduce heat loss, and prevent condensation. Fiberglass insulation is made from spun glass fibers and is commonly used for both residential and industrial applications. It is designed to be placed around the pipe to protect against extreme temperatures and enhance energy conservation. In some cases, the fiberglass pipe itself may have an outer layer of foam or resin for added strength and insulation properties, but the primary material for insulation is fiberglass. Foam may also be used for insulation around other types of pipes, but fiberglass pipe insulation is more effective for high-temperature environments and areas where energy efficiency is a concern.

Fiberglass pipes offer numerous advantages, especially in large diameter applications. One of the key benefits is their resistance to corrosion, which makes them ideal for transporting chemicals, water, or wastewater. Unlike metal pipes, fiberglass pipes are not susceptible to rust or degradation from aggressive chemicals, ensuring a longer lifespan. Fiberglass is also lightweight, making installation easier and more cost-effective, especially for large diameter pipes. It can handle high temperatures and pressure without compromising structural integrity, making it suitable for both hot and cold water systems. Additionally, fiberglass pipes are environmentally friendly since they are made from non-toxic materials and are recyclable. Overall, their durability, low maintenance, and cost-effectiveness in the long run make fiberglass pipes a preferred choice in many industries, including oil and gas, mining, and water treatment.

Determining the correct size for a fiberglass pipe involves several factors, including the flow rate, pressure requirements, and the specific purpose of the pipe. First, calculate the required flow rate in gallons per minute (GPM) or liters per second (L/s) for the system. The pipe size will need to accommodate this flow while maintaining adequate pressure levels. It’s important to consider the pipe’s pressure rating, as larger pipes are often used for higher pressure systems. Additionally, consider factors like the type of fluid being transported, temperature, and the distance the pipe will cover. Consulting with a professional or using engineering software can help you select the right diameter. It’s essential to ensure the pipe is neither too small (which would restrict flow) nor too large (which could increase costs unnecessarily).

The thickness of fiberglass pipe insulation depends on various factors such as the pipe’s temperature, the surrounding environment, and the level of energy efficiency desired. For large diameter fiberglass pipes, insulation thickness typically ranges from 1 inch (25 mm) to 3 inches (75 mm), though it may go thicker in extreme conditions. If the pipe is carrying hot water or steam, a thicker insulation layer will be required to prevent heat loss. In cold environments or for pipes carrying cold water, insulation thickness helps prevent freezing. Building codes or standards may also provide guidelines for required insulation thickness. For energy-efficient systems, a thicker layer of fiberglass insulation will reduce energy consumption, while also offering protection against condensation and improving system performance.

Glass Reinforced Plastic (GRP) pipes, which are often used as large diameter fiberglass pipes, typically come in standard lengths of 20 feet (6 meters). However, the length can vary depending on the manufacturer and the specific project requirements. Custom lengths can also be fabricated to meet the specific needs of the installation. Longer sections are advantageous for large infrastructure projects, as fewer joints are needed, reducing the potential for leaks or failure. When installing GRP pipes, it is important to consider factors like transportation, handling, and installation logistics. The length of the pipes chosen will depend on the installation site’s space and the contractor’s preference for minimizing the number of joints. Longer lengths are typically used for projects like water supply systems, sewage networks, and industrial piping.

Large-diameter fiberglass mortar tubes have a long lifespan due to their durability and resistance to environmental factors. When properly maintained, they can last anywhere from 5 to 15 years, depending on the frequency of use, exposure to UV rays, and storage conditions. Unlike cardboard or PVC alternatives, fiberglass mortar tubes do not degrade quickly from moisture or temperature fluctuations. However, repeated exposure to high-velocity projectiles or explosive forces can gradually weaken the internal structure, necessitating regular inspections for cracks, delamination, or fiber wear. To extend their lifespan, users should store them in a dry, shaded area and inspect them for signs of damage after each use. Over time, fiberglass materials may become brittle if subjected to extreme conditions, but their longevity makes them a preferred choice for heavy-duty applications such as pyrotechnics, industrial launching systems, and military-grade mortars.

Yes, large-diameter fiberglass mortar tubes are designed to be reusable, making them a cost-effective and durable solution for repeated applications. Their high-strength composite construction allows them to withstand multiple firings without significant wear or deformation. Unlike single-use materials such as cardboard, fiberglass mortar tubes maintain their structural integrity even after exposure to high-pressure launches. However, their reusability depends on proper care and maintenance. Users should conduct routine inspections for internal and external damage, such as cracks, resin breakdown, or fiber exposure. Any signs of structural weakening could pose safety risks and should be addressed before reuse. Additionally, cleaning and proper storage help prolong their lifespan. Industries such as fireworks displays and military operations rely on fiberglass mortar tubes for their ability to handle repeated stress while maintaining consistent performance.

Glass tubes are widely used across various industries, but when considering large-diameter fiberglass tubes, their applications differ significantly from traditional glass tubes. Fiberglass-reinforced plastic (FRP) tubes are commonly used in structural, industrial, and utility applications due to their lightweight strength and resistance to corrosion. They are frequently employed in chemical processing, wastewater management, electrical conduit systems, marine applications, and aerospace engineering. In construction, fiberglass tubes serve as support columns, protective casings, and lightweight structural components. Their non-conductive nature makes them an ideal choice for electrical and communication infrastructure. Unlike standard glass tubes, which are fragile and primarily used in laboratory settings, fiberglass tubes provide high durability, impact resistance, and thermal insulation, making them a preferred alternative to traditional materials like steel or aluminum in large-scale projects.

Large-diameter fiberglass conduits offer numerous advantages, making them an essential choice in industries requiring durable and non-corrosive piping systems. Some key benefits include:

Corrosion Resistance – Unlike metal conduits, fiberglass does not rust or deteriorate when exposed to moisture, chemicals, or extreme temperatures, making it ideal for underground and marine applications.

Lightweight Strength – Despite its high strength-to-weight ratio, fiberglass is significantly lighter than steel or concrete, reducing transportation and installation costs.

Non-Conductivity – Fiberglass is an excellent insulator, eliminating the risk of electrical conductivity, which is crucial for power and communication infrastructure.

Durability – It resists environmental stress, impact, and UV degradation, providing a long lifespan with minimal maintenance.

Customizability – Available in various diameters and thicknesses, fiberglass conduits can be tailored for specific industrial needs, ensuring efficiency and reliability in large-scale projects.

Large-diameter fiberglass pipes exhibit exceptional strength, often outperforming traditional materials like PVC, concrete, or even steel in certain applications. Their strength primarily comes from the fiberglass-reinforced polymer (FRP) composite structure, which allows for high tensile strength, impact resistance, and pressure tolerance. Fiberglass pipes can withstand pressures ranging from 150 to 450 psi (pounds per square inch) or more, depending on the manufacturing process and intended application. They are also resistant to thermal expansion and contraction, which helps maintain structural integrity in fluctuating temperatures. Compared to metal pipes, fiberglass pipes are less prone to deformation, cracking, or corrosion, making them ideal for industrial fluid transport, oil and gas pipelines, water treatment plants, and underground utilities. Despite their lightweight construction, their load-bearing capacity is substantial, allowing them to function effectively in high-stress environments.

While Glass Reinforced Plastic (GRP) pipes offer numerous benefits, they also come with some drawbacks that must be considered:

Initial Cost – GRP pipes tend to have a higher upfront cost compared to materials like PVC or standard steel, which can be a limiting factor for budget-conscious projects.

Impact Sensitivity – While strong, GRP pipes can be brittle under excessive impact, leading to potential cracking or delamination if not handled properly.

Complex Installation – Specialized tools and trained personnel are often required for proper joining and installation, increasing labor costs.

Temperature Limitations – Though resistant to many environmental factors, GRP pipes may not perform well in extreme high-temperature conditions, potentially leading to resin degradation.

Limited Load-Bearing Capacity – While effective for many applications, GRP pipes might not be suitable for extremely high-pressure loads compared to traditional steel pipes in certain heavy-duty industries.

Despite these disadvantages, GRP pipes remain a preferred choice for industries requiring corrosion-resistant, lightweight, and durable solutions in large-diameter pipeline systems.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.