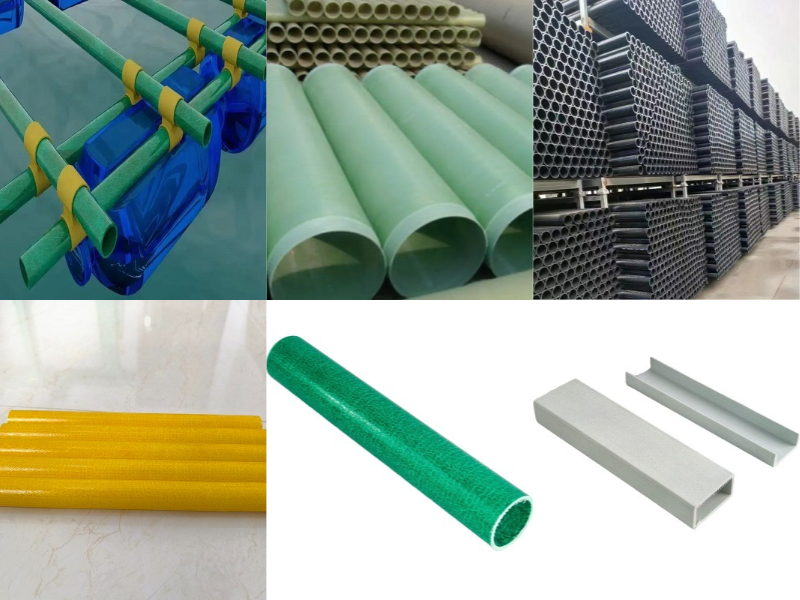

Marine fiberglass pipes are widely used in marine applications due to their durability, lightweight nature, and corrosion resistance. These pipes are available in various standard sizes, which can be customized based on specific marine requirements. Common sizes of marine fiberglass pipes are designed to meet the diverse needs of ships, offshore platforms, and marine infrastructure. Choosing the right size is crucial for efficient operation, as it affects fluid flow, pressure management, and installation processes. Marine fiberglass pipes provide flexibility in both size and configuration, making them suitable for a wide range of marine and offshore applications. Marine fiberglass pipes resist CO₂, H₂S, saltwater corrosion, 1½-36in sizes, 150-4000psi pressure for low- to medium-pressure applications.

Simplifying Your Life: Key Functionalities

| Attributes | Details |

|---|---|

| Place of Origin | Hebei, China |

| Brand Name | Ganglong Fiberglass |

| Product Name | Marine Fiberglass Pipes |

| Material | Glass Fiber Reinforced Plastic |

| Technology | Pultrusion |

| Surface Treatment | As per Customer Requirements |

| Processing Services | Molding, Cutting |

| Color | Customized Color |

| Shape | Customized Shape |

| Size | Customized Size |

| Thickness | Customized Thickness |

| Length | Customized Length |

| OEM | OEM Accepted |

| Features | Lightweight, High Strength, Corrosion Resistant, High Dimensional Stability, Compression Resistant, Fireproof, Super Waterproof |

| Certificate | ISO9001 |

| Type | Manufacturer |

| Port | All Major Ports |

| Packing Details | As per Customer Requirements |

| Sales Unit | Single Item |

| Supply Capacity | 200 Pieces per Day |

What Are Marine Fiberglass Pipes?

Marine fiberglass pipes are essential components in various marine applications, providing excellent durability, resistance to corrosion, and lightweight construction. They are manufactured using a combination of high-strength hollow glass fibers and epoxy resin, making them ideal for harsh marine environments where traditional materials may not hold up as effectively. Similar to fiberglass drill pipe, marine fiberglass pipes are often preferred over steel or metal alternatives due to their long lifespan and minimal maintenance requirements, which reduce operational costs in the long run. The demand for marine fiberglass pipes continues to grow, driven by their versatility and reliability in different marine settings, including offshore platforms, shipbuilding, and coastal infrastructure projects.

Marine fiberglass pipes are essential components in various marine and offshore applications, offering exceptional durability, corrosion resistance, and a lightweight structure. These pipes are crafted using reinforced long glass fibers combined with resin, making them well-suited to the harsh environments commonly found in the marine industry. Marine fiberglass pipes are often preferred over traditional steel or metal pipes due to their ability to withstand the challenging conditions in saltwater environments, including exposure to moisture, chemicals, and extreme temperatures.

These pipes have become a popular choice for marine platforms, ships, and coastal installations, where long-term performance and low maintenance requirements are critical. Marine fiberglass pipes, such as those offered by GangLong Fiberglass, are built to meet rigorous industry standards, providing dependable solutions for various fluid transport, structural, and protective applications.

The Key of Marine Fiberglass Pipe Sizes

Selecting the right size for marine fiberglass pipes is crucial for ensuring efficiency and optimal performance. Marine fiberglass pipes come in various sizes, typically ranging from 1 inch to over 100 inches in diameter. The size selection depends on the specific application, fluid type, and required flow rates. Proper sizing ensures reliable operation, minimizes operational issues, and optimizes fluid flow in marine environments.

Standard Pipe Sizes and Their Applications

Small-diameter marine fiberglass pipes (1 to 6 inches) are used in compact systems, such as shipboard water supply and offshore chemical transfer. Medium-diameter pipes (6 to 24 inches) are ideal for moderate fluid transport needs, including wastewater management. Large diameter fiberglass pipe (24 inches to 100 inches+) are used in high-capacity systems, such as seawater intake and cooling water lines, handling larger flow rates and pressures.

Customization for Specific Projects

Customization allows marine fiberglass pipes to meet unique project requirements, ensuring proper integration with existing systems. Tailored pipes can be adjusted in diameter, wall thickness, and resistance to chemicals or temperature. Custom sizing is crucial for shipbuilding, oil and gas platforms, and water management systems, ensuring optimal performance under specific operational conditions and fluid characteristics.

Impact of Pipe Size on System Efficiency

Choosing the correct pipe size impacts system efficiency and performance. Smaller pipes can restrict fluid flow, causing higher pressure drops and operational challenges. Oversized pipes may increase costs and installation difficulties. The right size optimizes flow, minimizes pressure issues, and ensures smooth system operation, contributing to cost savings and enhanced long-term performance.

Consulting Experts for Optimal Size Selection

Selecting the correct pipe size requires expert guidance. GangLong Fiberglass offers specialized knowledge to help assess the unique needs of each project. By evaluating flow rates, pressure levels, and environmental conditions, the team ensures that the right pipe size is chosen, optimizing system performance and reducing operational costs.

How to Purchase Marine Fiberglass Pipes Suitable for Ships and Offshore Operations

Marine fiberglass pipes are essential components for ships and offshore applications, valued for their durability, corrosion resistance, and lightweight properties. Selecting the right pipes involves evaluating their specifications, certifications, compatibility with marine environments, and supplier reputation. This guide explores the factors you need to consider when purchasing marine fiberglass pipes for maritime and offshore operations.

Assessing Application Requirements

Understanding your operational needs is the first step in selecting suitable marine fiberglass pipes.

- Pipe Usage: Determine whether the pipes will handle water transport, fuel systems, exhaust systems, or other functions.

- Pressure and Temperature: Evaluate the pressure levels and temperature ranges the pipes will be exposed to in their applications. Ensure the selected pipes meet or exceed these operational thresholds.

- Chemical Compatibility: For offshore use, confirm the pipes can resist exposure to seawater, fuels, and other chemicals without degrading.

Checking Material Specifications

The material properties of marine fiberglass pipes significantly impact their performance in maritime settings.

- Corrosion Resistance: Marine environments demand pipes resistant to corrosion caused by saltwater and harsh weather conditions.

- Strength and Durability: Ensure the pipes are strong enough to withstand mechanical stresses, including vibrations and impacts, while maintaining longevity.

- Weight: Lightweight pipes are easier to handle and install, especially in confined or elevated areas.

Ensuring Compliance with Certifications

Certifications verify that marine fiberglass pipes meet industry standards for safety and performance.

- Marine Certifications: Look for compliance with certifications like ISO, ABS, or DNV, which validate the pipes’ suitability for marine applications.

- Fire Resistance: Inquire about compliance with fire safety standards, especially for pipes used in fuel or exhaust systems.

Selecting a Reliable Manufacturer

Choosing a trusted manufacturer ensures the quality and availability of your marine fiberglass pipes.

- Experience and Expertise: Manufacturers like GangLong Fiberglass specialize in composite piping solutions for marine and offshore industries, offering reliable products backed by years of experience.

- Product Range: Ensure the manufacturer provides pipes and fittings compatible with your system requirements, including customized solutions for unique applications.

- Support Services: Opt for a supplier offering installation guidance, after-sales support, and maintenance advice.

Evaluating Cost-Effectiveness

Balancing quality and budget is critical when purchasing marine fiberglass pipes.

- Long-Term Savings: Invest in high-quality pipes to minimize maintenance and replacement costs over time.

- Bulk Discounts: For large projects, inquire about discounts on bulk purchases and cost-effective shipping options.

GangLong Fiberglass: Your Trusted Partner for Marine Fiberglass Pipes

Wide Range of Flow-Efficient Piping Solutions

At GangLong Fiberglass, we understand that different industries require different piping solutions. Our extensive product range ensures that we have the right fiberglass pipes for every application. Whether you’re looking for pipes for water transport, industrial chemicals, or other specialized uses, we offer efficient, cost-effective, and highly durable solutions that ensure smooth flow and reliable performance.

Certified for ASTM D2992 and API 15HR Standards

Quality is a cornerstone of our products. All of our fiberglass pipes are rigorously tested and certified to meet the ASTM D2992 and API 15HR standards. These certifications validate our pipes’ ability to withstand extreme conditions, such as high pressures, corrosion, and temperature fluctuations, ensuring they are safe, durable, and perform at the highest industry standards. With us, you get products that guarantee long-term reliability.

Durable, Temperature-Resistant Pipe Systems

Our fiberglass piping systems are built to endure harsh conditions, including extreme temperatures. Made from advanced materials, our pipes offer exceptional resistance to corrosion, abrasion, and chemical damage, providing longevity and minimal maintenance costs over time. This durability makes them ideal for industries like oil and gas, where the piping system needs to withstand extreme operational environments.

Tailored Solutions for Oil and Gas Pipeline Materials

We recognize that every project is unique, especially in the oil and gas sector. Our team at GangLong Fiberglass works closely with clients to develop custom piping systems that are perfectly suited to your project’s specific requirements. Whether it’s special diameter sizes, pressure handling, or corrosion resistance, we provide tailored fiberglass pipes that ensure optimal performance and meet your precise technical needs. We don’t just sell pipes – we provide solutions that make your project more efficient and cost-effective.

Marine Fiberglass Pipes for Sale: Choosing the Right Supplier

Finding marine fiberglass pipes for sale can be a straightforward process if you know what to look for in a supplier. A reputable supplier, such as GangLong Fiberglass, will offer a wide variety of marine fiberglass pipes, ensuring that you can find the ideal pipe for your project, whether you are involved in shipbuilding, offshore oil exploration, or coastal infrastructure development.

When evaluating potential suppliers, it’s important to consider several factors. First, the quality of the pipes should meet industry standards, such as IMO (International Maritime Organization) and CCS (China Classification Society) certifications. These certifications ensure that the pipes are built to withstand the rigorous demands of marine environments.

Price is another key consideration when sourcing marine fiberglass pipes. While it can be tempting to opt for cheaper alternatives, it’s crucial to prioritize quality and longevity. High-quality pipes, like those from GangLong Fiberglass, offer long-term durability and reduced maintenance, ultimately saving costs over time. Additionally, consider the supplier’s customer support and ability to provide custom solutions to meet your project’s specific requirements.

Marine Fiberglass Pipes Near Me: Finding Local Suppliers

For those searching for “marine fiberglass pipes near me,” it’s often beneficial to find a local supplier that can provide quick and efficient service. Proximity to a supplier like GangLong Fiberglass can significantly reduce delivery times and ensure you have access to necessary support and maintenance services.

Local suppliers often have a better understanding of regional regulations and environmental conditions, allowing them to recommend the most suitable marine fiberglass pipes for your project. Moreover, working with a nearby supplier can help minimize shipping costs and logistical delays, which are critical for large-scale marine projects where timelines are tight.

To find the right supplier, check local directories or marine industry listings, and always verify the supplier’s certifications and reviews to ensure they provide high-quality products. By partnering with a trusted local supplier, you can ensure smooth and timely project execution.

Marine Fiberglass Pipes for Sale: Evaluating Suppliers

Marine fiberglass pipes for sale can be found through a variety of suppliers, but it’s important to evaluate them based on quality, pricing, and product selection. A trusted supplier like GangLong Fiberglass offers a diverse range of marine fiberglass pipes designed to meet the needs of various marine applications, including fluid transport, drainage systems, and structural reinforcement.

When evaluating suppliers, prioritize those who adhere to global industry standards, such as IMO and CCS certifications. These certifications guarantee that the products are designed to withstand the demanding marine environment and comply with safety and durability standards.

Price is another critical consideration. While lower-priced options may seem appealing, it’s essential to prioritize long-term performance and maintenance requirements. High-quality marine fiberglass pipes from suppliers like GangLong Fiberglass often result in reduced maintenance costs, extended lifespan, and improved operational efficiency, ultimately saving money over time.

Exploring the Role of GangLong Fiberglass in Marine Applications

GangLong Fiberglass has been a key player in the development of fiberglass pipes for marine applications, driving innovation in the sector. By investing in research and development, GangLong Fiberglass has been able to improve the strength, reliability, and longevity of marine fiberglass pipes, allowing them to meet the ever-increasing demands of the marine industry.

In addition to marine fiberglass pipes, GangLong Fiberglass has also developed high-quality fiberglass access doors, providing durable and reliable solutions for access points in marine environments. The company’s commitment to innovation has extended to creating customized piping solutions and access doors for various offshore projects. These innovations have led to the widespread adoption of fiberglass pipes and access doors in marine environments, where their corrosion resistance and ease of maintenance are essential.

Key projects have included the installation of marine fiberglass pipes in offshore platforms and marine vessels, where they have proven to be a cost-effective and efficient solution for transporting fluids, gases, and chemicals. By leveraging the expertise of GangLong Fiberglass, marine operators can access the latest advancements in fiberglass pipe technology and ensure their operations meet the highest performance and safety standards.

Fiberglass Pipes in the Oil and Gas Industry

The oil and gas industry is one of the primary sectors that benefit from marine fiberglass pipes. Offshore platforms and oil rigs are exposed to some of the harshest environmental conditions, including saltwater, high pressures, and extreme temperatures. Marine fiberglass pipes are an ideal solution for these environments because they resist corrosion, require minimal maintenance, and offer a long operational lifespan.

Fiberglass pipes are commonly used in applications such as seawater cooling systems, chemical transportation, and firewater systems on oil rigs. Due to their lightweight nature, they are easier to install than traditional steel pipes, reducing labor costs and installation time. The flexibility of marine fiberglass pipes also makes them adaptable to various pipeline configurations and layouts, ensuring that they can meet the complex needs of the oil and gas sector.

In addition to their corrosion resistance, fiberglass pipes can withstand high pressures and temperatures, making them suitable for transporting oil, gas, and other hydrocarbons. The pipes’ durability reduces the risk of leaks and pipe failures, which can have catastrophic consequences in offshore oil production. By choosing GangLong Fiberglass products, oil and gas companies can ensure that their operations remain safe and efficient, even in the most challenging conditions.

Fiberglass Tubing in Oilfield Applications

Fiberglass tubing is widely used in oilfield operations, particularly in drilling and extraction processes. The unique properties of fiberglass, such as its resistance to corrosion and ability to withstand high pressures, make it an excellent choice for transporting water, chemicals, and hydrocarbons in oilfields.

In oilfield applications, fiberglass tubing is often preferred over traditional materials like steel because it is lightweight, easier to handle, and reduces transportation and installation costs. Additionally, fiberglass tubing is highly resistant to chemical reactions, which is crucial in oil extraction where the pipes come into contact with corrosive substances.

GangLong Fiberglass offers fiberglass tubing solutions that are specifically designed for use in oilfield environments. Their products are built to withstand the harsh conditions typically found in oil and gas extraction, ensuring durability and longevity in even the most demanding applications.

Maintenance and Longevity of Marine Fiberglass Pipes in Oilfield Applications

In the oilfield, maintaining equipment is crucial to avoid costly downtime and ensure the smooth operation of drilling and extraction processes. Marine fiberglass pipes are known for their low-maintenance requirements, making them an ideal choice for oilfield operations.

GangLong Fiberglass marine fiberglass pipes offer a long service life, even in harsh conditions. Their resistance to chemicals and corrosion means they require less frequent maintenance, reducing the risk of equipment failure and operational interruptions. This longevity makes them a cost-effective solution for oilfield operations, where downtime can be incredibly expensive.

How About GRE Pipe Joint Types?

Glass Reinforced Epoxy (GRE) pipes are commonly used in marine applications, and selecting the appropriate joint type is essential for ensuring the integrity of the piping system. GRE pipes, such as those offered by GangLong Fiberglass, come with several joint options, each suited to different operational needs and installation environments.

The most common types of GRE pipe joints include:

- Bell and Spigot Joints: These are easy to install and provide a tight seal, making them ideal for high-pressure systems.

- Adhesive Bonded Joints: These offer a strong, permanent connection between pipe segments, suitable for long-term installations.

- Mechanical Joints: Often used in systems where flexibility is required, mechanical joints allow for easy disassembly and reassembly of pipes during maintenance or repair.

Choosing the correct joint type depends on several factors, including the specific application, pressure requirements, and the environmental conditions in which the pipes will operate. The right joint can prevent leaks and ensure the long-term reliability of the marine fiberglass piping system.

How About Fiberglass Pipe Applications in Marine Environments?

Marine environments are harsh and demanding, making the selection of the right materials for piping systems crucial. Marine fiberglass pipes have become the material of choice for a wide range of applications in marine environments due to their resilience and resistance to corrosion. These pipes are often used in seawater cooling systems, firewater pipelines, and ballast systems, where exposure to saltwater and chemicals can quickly degrade other materials.

The key advantage of marine fiberglass pipes is their long-term durability in harsh environments, which significantly reduces the risk of failure and ensures that systems continue to operate smoothly. Their non-corrosive properties also make them ideal for wastewater and drainage systems on marine platforms and ships, where reliability is critical to the overall safety and efficiency of operations.

GangLong Fiberglass provides specialized marine fiberglass pipes that meet the highest industry standards, ensuring they perform optimally even in the toughest marine conditions. This makes them an excellent investment for long-term marine infrastructure projects.

Applications of Marine Fiberglass Pipes in Offshore Environments

Marine fiberglass pipes are designed to provide superior performance in various offshore applications, offering unmatched resistance to corrosion and high-pressure environments. Below are specific uses of marine fiberglass pipes in offshore installations:

Disposal or Injection Tubing

Marine fiberglass pipes are commonly used in offshore oil and gas operations for disposal and injection tubing. These pipes safely transport produced water, chemicals, or waste fluids from the well to disposal sites or injection points. Their high resistance to corrosion, particularly from salty seawater, ensures a long service life and minimal maintenance, even under harsh offshore conditions.

Production Tubing – ESP, Gas Lift, Rod Pumping, PCP

In production wells, marine fiberglass pipes are used for a variety of pumping methods, including Electrical Submersible Pumps (ESP), Gas Lift, Rod Pumping, and Progressive Cavity Pumps (PCP). These pipes withstand the high-pressure and corrosive fluids commonly encountered in production systems. Their lightweight nature makes them easier to handle, while their strength ensures the pipes perform reliably in demanding environments like offshore rigs.

Casing Liners

Fiberglass pipes are also used as casing liners in offshore wells. They provide an effective solution for protecting the wellbore from contamination or collapse due to their corrosion resistance. The ability of marine fiberglass pipes to resist rust and other forms of corrosion ensures that the integrity of the well is maintained, even in aggressive marine environments.

Chemical Waste Disposal

Offshore installations often deal with hazardous chemicals and waste products. Marine fiberglass pipes are ideal for safely transporting chemical waste from offshore platforms to designated disposal sites. These pipes offer excellent chemical resistance, ensuring that corrosive substances do not compromise the integrity of the piping system, reducing the risk of leaks and failures.

Geothermal

Marine fiberglass pipes are increasingly being used in geothermal applications in offshore settings. They are highly resistant to extreme temperatures and aggressive geothermal fluids, making them ideal for transporting hot fluids in geothermal energy systems. Their durability helps reduce operational downtime and maintenance costs while providing reliable performance over time.

Slotted Production Liners and Prepacked Screens

Marine fiberglass pipes are widely used in slotted production liners and prepacked screens. These systems allow for the controlled flow of fluids and gases into the well while preventing the entry of unwanted particles or debris. The corrosion resistance and strength of fiberglass pipes ensure long-term reliability and reduced maintenance in these critical applications.

Observation Well Casing

In offshore exploration, marine fiberglass pipes are commonly used as casing for observation wells. These wells are used to monitor reservoir conditions and collect data on the fluid composition and pressure levels within the well. Marine fiberglass pipes provide the necessary structural integrity while being resistant to the corrosive environment of the marine setting.

Open Hole Casing, Zone to Surface

Marine fiberglass pipes are also used in open hole casing applications, providing essential support in wellbores that lack a pre-formed casing. These pipes ensure the well is stable and secure, even in areas where traditional metal pipes would quickly corrode. The fiberglass pipes can extend from the reservoir zone all the way to the surface, offering a robust solution for offshore wells.

Cement Tail Pipe

In offshore drilling, marine fiberglass pipes are used as cement tail pipes during cementing operations. These pipes are designed to carry cement from the surface to the wellbore to seal and protect the casing. Their resistance to corrosion and wear ensures that cementing operations are completed efficiently, without the risk of pipe degradation that could compromise the cement job.

Deviated Wells

Deviated wells, which are drilled at angles to reach specific targets, often require specialized piping. Marine fiberglass pipes are ideal for these types of wells due to their flexibility and resistance to the physical stresses encountered in deviated drilling. Their corrosion resistance and lightweight design ensure that they provide a reliable and cost-effective solution for transporting fluids in offshore deviated wells.

Centrifugally Cast Fiberglass Pipe: A Comprehensive Guide

Benefits of Marine Fiberglass Pipes in Corrosive Environments

Marine fiberglass pipes are essential for industries operating in corrosive environments, particularly in the marine and offshore sectors. These pipes are engineered to resist the harsh effects of saltwater, chemicals, and extreme conditions that would degrade traditional materials like metal. Their unique properties make them a reliable and safe choice for transporting fluids and chemicals in demanding applications. This guide explores the key benefits of marine fiberglass pipes in corrosive environments, emphasizing their durability, chemical resistance, and additional safety features.

Exceptional Corrosion Resistance

The primary advantage of marine fiberglass pipes is their resistance to corrosion in harsh marine environments.

Marine settings expose materials to constant moisture, salt, and other corrosive elements, which can rapidly deteriorate metal pipes. Marine fiberglass pipes, however, are inherently resistant to these conditions. This durability ensures a longer lifespan and reduces maintenance costs, making them ideal for applications such as seawater transport, desalination plants, and cooling systems on ships or offshore platforms. Their non-reactive surface further prevents rust formation and structural degradation.

Superior Chemical Resistance

Marine fiberglass pipes are designed to withstand exposure to a wide range of chemicals, making them versatile for industrial use.

In offshore and marine industries, pipes often transport hazardous or reactive chemicals. Fiberglass materials are engineered to resist degradation when exposed to these substances, maintaining their integrity and performance. For instance, in oil and gas operations, marine fiberglass pipes are used to safely handle drilling fluids, chemical solutions, and wastewater, ensuring operational efficiency without the risk of leaks or corrosion-related failures.

Non-Conductive and Electrically Safe

Another significant benefit of marine fiberglass pipes is their non-conductive nature, which enhances safety in environments with electrical hazards.

Unlike metal pipes, fiberglass pipes do not conduct electricity, reducing the risk of sparks or accidental electrical discharge. This property is particularly valuable in marine applications where flammable materials or volatile environments are common. The non-conductive characteristic of fiberglass pipes ensures safe operations on oil platforms, chemical transport systems, and other sensitive installations.

Lightweight and Easy to Handle

The lightweight nature of marine fiberglass pipes provides operational advantages, particularly in large-scale installations.

Fiberglass pipes are easier to transport, handle, and install compared to metal alternatives, reducing labor and logistical costs. In offshore operations where space and resources are limited, this feature simplifies the installation process and allows for quicker deployment of systems. Despite their lightweight design, fiberglass pipes maintain high structural integrity and can withstand the rigors of marine environments.

Cost-Effective and Long-Lasting

The combination of durability and low maintenance needs makes marine fiberglass pipes a cost-effective choice.

Their resistance to corrosion and chemicals means fewer repairs and replacements over time, resulting in lower lifecycle costs. For industries requiring long-term solutions in challenging environments, marine fiberglass pipes deliver significant savings without compromising on reliability or safety.

Maintenance and Longevity of Marine Fiberglass Pipes

Marine fiberglass pipes are recognized for their exceptional durability and minimal maintenance requirements, making them an ideal choice for marine and offshore operations. Their resistance to corrosion, lightweight design, and cost-effective maintenance solutions contribute to their long service life, ensuring reliable performance even in harsh marine environments. This section explores the key aspects of maintaining and maximizing the longevity of marine fiberglass pipes, including their resistance to wear, ease of maintenance, and operational cost benefits.

Resistance to Corrosion and Wear

Marine fiberglass pipes are designed to withstand the corrosive nature of marine environments, reducing the need for frequent maintenance.

Unlike metal pipes, which are susceptible to rust and corrosion due to constant exposure to saltwater and harsh weather, fiberglass pipes resist these challenges effortlessly. This property ensures a longer operational life with minimal intervention. Additionally, the non-reactive nature of fiberglass eliminates the need for protective coatings or corrosion inhibitors, simplifying maintenance processes and reducing associated costs.

Low-Maintenance Requirements

The smooth internal surface of marine fiberglass pipes minimizes the accumulation of debris, leading to reduced cleaning and maintenance.

GangLong Fiberglass pipes feature a non-porous surface that ensures efficient fluid flow by preventing blockages or buildups over time. This smooth design reduces the frequency of inspections and cleaning, saving both time and resources. Furthermore, the durability of fiberglass eliminates concerns about cracking or structural degradation, further reducing maintenance demands compared to traditional materials like steel or PVC.

Longevity and Operational Efficiency

Marine fiberglass pipes are engineered to last for decades, offering a long-term solution for marine and offshore applications.

Their robust construction ensures that they can handle extreme environmental conditions, including fluctuating temperatures, high-pressure applications, and exposure to chemicals. This longevity translates to fewer replacements and lower lifecycle costs. Fiberglass pipes also maintain their structural integrity over time, ensuring consistent performance without degradation, which is vital for critical operations such as transporting seawater, fuel, or chemicals.

Lightweight Design for Easy Handling

The lightweight nature of marine fiberglass pipes simplifies installation and reduces labor costs, contributing to overall efficiency.

Fiberglass pipes require less heavy machinery during installation, making them easier to transport and position, especially in offshore environments where resources may be limited. This ease of handling not only reduces upfront installation costs but also ensures quicker deployment and less downtime for operational systems.

Cost-Effective Over the Long Term

The combination of minimal maintenance and extended lifespan makes marine fiberglass pipes a highly economical choice for marine industries.

Reduced maintenance costs, fewer replacements, and enhanced operational efficiency contribute to significant savings over the lifespan of these pipes. Their durability in harsh conditions ensures reliable performance, minimizing the risk of costly interruptions or repairs.

How about Marine Fiberglass Pipes vs. Traditional Materials

Marine fiberglass pipes stand out as an advanced alternative to traditional materials like steel, iron, and PVC, particularly in marine and offshore applications. While traditional materials have been commonly used due to their strength and availability, they are often plagued by issues such as corrosion, weight, and high maintenance costs. Marine fiberglass pipes, on the other hand, excel in areas such as durability, corrosion resistance, lightweight design, and long-term cost-effectiveness.

| Factor | Marine Fiberglass Pipes | Traditional Materials (Steel/Iron/PVC) |

|---|---|---|

| Corrosion Resistance | Superior corrosion resistance, inherently non-reactive, no need for protective coatings | Highly susceptible to corrosion, requires protective coatings and frequent maintenance |

| Lightweight Design and Ease of Installation | Much lighter, reduces need for heavy equipment, easy and fast installation | Heavy, requiring specialized equipment for transportation and installation, increases costs |

| Longevity and Maintenance Requirements | Longer lifespan, minimal maintenance, resistant to degradation even in harsh conditions | Shorter lifespan, frequent inspections, anti-corrosion treatments, and repairs needed |

| Chemical Resistance and Versatility | Highly resistant to acids, solvents, hydrocarbons, suitable for diverse fluid transport | Reacts negatively to certain chemicals, leading to wear, leaks, or damage |

| Cost-Effectiveness Over Time | Higher initial cost, but lower long-term costs due to reduced maintenance and replacements | Lower initial cost, but higher total cost over time due to frequent maintenance and replacements |

Thick Wall Fiberglass Tube: A Comprehensive Applications

Global Shipping Considerations for Marine Fiberglass Pipes

Shipping marine fiberglass pipes internationally involves multiple factors that must be carefully managed to ensure timely delivery and compliance with global trade regulations. Companies sourcing these materials need to account for shipping costs, customs requirements, and logistics coordination to avoid project delays or increased expenses. Selecting a supplier experienced in global shipping can streamline the process, minimize risks, and guarantee that materials are delivered efficiently. This section explores the key considerations for global shipping of marine fiberglass pipes and how companies like GangLong Fiberglass facilitate smooth international logistics.

Shipping Costs and Weight Considerations

Shipping costs are a critical factor in global logistics, influenced by the size, weight, and shipping method of marine fiberglass pipes.

Marine fiberglass pipes are lightweight compared to traditional materials, which reduces shipping expenses. However, their length and volume can still lead to higher freight costs. Companies should work closely with suppliers to optimize packaging and transportation methods, such as consolidating shipments, to reduce costs. Partnering with a supplier like GangLong Fiberglass, which has experience in international logistics, can help manage these factors effectively.

Delivery Timelines and Project Scheduling

Timely delivery is essential for large-scale projects that rely on marine fiberglass pipes. Delays in shipping can disrupt project timelines and increase costs.

Companies need to plan for shipping lead times, which may vary depending on the supplier’s location, the mode of transport, and global shipping conditions. Air freight may offer faster delivery but at a higher cost, while sea freight is more economical for large shipments but slower. GangLong Fiberglass ensures accurate scheduling and tracking to help clients meet their project deadlines without unexpected delays.

Customs Regulations and Compliance

Navigating customs requirements is crucial when shipping marine fiberglass pipes across international borders.

Each country has specific import regulations, duties, and documentation requirements. Failure to comply with these rules can result in delays, fines, or seized shipments. Suppliers like GangLong Fiberglass are experienced in handling customs paperwork and ensuring that shipments meet all regulatory requirements, helping clients avoid potential issues.

Packaging and Handling to Prevent Damage

Proper packaging is essential to protect marine fiberglass pipes during international transit.

Fiberglass pipes require secure, durable packaging to prevent damage from handling, stacking, or environmental conditions. High-quality suppliers like GangLong Fiberglass use advanced packaging solutions that ensure the pipes arrive in perfect condition, even after long journeys.

Supplier Expertise in Global Shipping

Choosing a supplier with global shipping expertise is critical to the success of international projects.

GangLong Fiberglass provides end-to-end shipping solutions, managing everything from freight arrangements to customs clearance. With a proven track record in global logistics, GangLong ensures reliable delivery of marine fiberglass pipes, including specialized options like red thread fiberglass pipe, which is known for its corrosion resistance and durability. This allows clients to focus on their projects without worrying about supply chain complications.

Global shipping for marine fiberglass pipes requires careful planning, cost management, and compliance with international regulations. By partnering with experienced suppliers like GangLong Fiberglass, companies can ensure seamless logistics, timely delivery, and the success of their projects.

FAQs about Marine Fiberglass Pipes

Fiberglass pipes are ideal for marine applications due to their corrosion resistance, lightweight structure, and durability. Unlike metal pipes, they resist damage from saltwater, ensuring a longer lifespan in harsh marine environments. Additionally, fiberglass pipes have high strength-to-weight ratios, making them easy to handle and install on boats or marine structures. Their non-conductive nature minimizes electrochemical reactions, further preventing deterioration. Fiberglass pipes are also customizable, allowing precise engineering for unique marine needs like fluid transfer, ventilation, or structural support.

Marine-grade fiberglass pipes typically handle temperatures from -100°F to 300°F, depending on their resin composition. This makes them suitable for a variety of marine applications, such as hot water systems, exhausts, or chemical pipelines. Selecting the appropriate resin system, like epoxy or vinyl ester, can extend their thermal capacity and durability under fluctuating marine temperatures.

Fiberglass pipes have a lifespan of 50 years or more when used in marine environments, provided they are properly maintained. Their resistance to UV radiation, corrosion, and chemical damage ensures longevity. In harsh conditions, such as constant exposure to saltwater, the material remains reliable with minimal degradation, making it a preferred choice for long-term marine applications.

Fiberglass insulation is water-resistant but not entirely waterproof. In marine environments, prolonged exposure to water can reduce its thermal efficiency. To address this, fiberglass insulation is often coated with a moisture-resistant layer to protect it from saturation. Regular inspection is necessary to maintain its integrity and effectiveness.

Fiberglass pipes boast high tensile strength, typically ranging from 18,000 to 30,000 psi, making them durable enough for marine applications. This strength ensures they can withstand significant pressure and stress without breaking, even under the challenging conditions of marine environments like rough seas or high-pressure fluid systems.

Fiberglass outperforms plastic in marine settings due to its superior strength, heat resistance, and durability. While plastic can deform or degrade under high temperatures or UV exposure, fiberglass maintains its structural integrity. Its enhanced corrosion resistance also makes it ideal for long-term use in saltwater environments.

The thickness of marine fiberglass pipes varies based on application, typically ranging from 3 mm to 25 mm. Thicker pipes are used in high-pressure or structural applications, while thinner pipes suffice for ventilation or low-pressure systems. Custom thicknesses can be manufactured to meet specific marine requirements.

Fiberglass piping inherently resists corrosion, especially in marine environments where saltwater exposure is constant. This eliminates the need for additional corrosion protection, such as coatings or linings, reducing maintenance costs. However, regular inspections ensure optimal performance over its lifespan.

Fiberglass pipe insulation is a fibrous material designed to retain heat or protect against extreme temperatures. Unlike foam, it offers superior resistance to high temperatures, making it better suited for marine applications where heat retention and fire resistance are critical.

Fiberglass Reinforced Plastic (FRP) pipes in marine settings can typically withstand temperatures up to 300°F, depending on the resin type used. High-temperature resins, such as phenolic or epoxy, can further increase this threshold for specialized applications like exhaust systems.

PVC pipes are not ideal for marine applications involving high temperatures, as they typically handle water temperatures up to 140°F. Fiberglass pipes, with their higher temperature resistance, are better suited for hot water systems on boats or marine installations.

Fiberglass pipe insulation is fire-resistant but not entirely fireproof. It can withstand high temperatures without igniting, making it ideal for marine applications requiring fire safety. For enhanced protection, it can be combined with fire-retardant coatings.

Yes, fiberglass insulation can safely touch hot water pipes in marine environments. Its high heat resistance ensures it remains effective without melting or degrading. This makes it a reliable choice for insulating hot water systems aboard ships or in marine installations.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.