A yellow fiberglass tube is a lightweight, durable material made from glass fibers reinforced with a polymer. Lightweight, durable yellow fiberglass tube: corrosion-resistant, insulating, self‑extinguishing—ideal for cooling tower replacements. It is known for its strength, flexibility, and resistance to corrosion and weathering. The vibrant yellow color enhances visibility, making it suitable for a variety of industrial applications. Commonly used in construction, electrical insulation, and automotive components, yellow fiberglass tube offers superior performance in harsh environments. Its ability to withstand extreme temperatures and moisture makes it ideal for both indoor and outdoor use. In industries requiring high strength and low weight, yellow fiberglass tube has become a reliable solution for structural support and protection against environmental factors.

What is Yellow Fiberglass Tube

Yellow fiberglass tube is a non‑metallic structural composite formed by embedding fine glass fibers in a polymer resin matrix. The result is a smooth, hollow cylinder that combines the following key attributes:

- Lightweight yet strong: Offers a high strength‑to‑weight ratio, making it easier to handle, transport, and install than steel or aluminum tubing.

- Corrosion‑ and chemical‑resistant: Impervious to rust, acids, alkalis and many solvents, so it’s ideal for harsh or wet environments.

- Weather‑ and UV‑resistant: Retains mechanical properties and color stability even after prolonged outdoor exposure.

- Thermally insulative: Low thermal conductivity helps reduce heat transfer, making it useful for insulating hot or cold piping.

- Self‑extinguishing: Meets many fire‑safety standards by resisting ignition and preventing flame propagation.

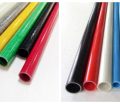

- Customizable: Available in a wide range of diameters, lengths, wall thicknesses and colors—though yellow is often chosen for enhanced visibility in industrial settings.

Why Choose Yellow Fiberglass Tube?

Due to its exceptional durability, outstanding corrosion resistance, high strength-to-weight ratio, and superior weather resistance—along with unique advantages in fire retardancy, self-extinguishing properties, high visibility, and versatile customization—yellow fiberglass tubing has become the preferred choice across industries such as construction, chemical processing, marine equipment, and power utilities, replacing traditional metal and plastic materials.

Durability

Yellow fiberglass tube is renowned for its long-lasting performance even in the harshest conditions. Unlike materials like wood or metal that may degrade over time, fiberglass maintains its structural integrity due to its composition of reinforced glass fibers and polymers. This combination provides excellent resistance to wear and tear, making it ideal for applications where reliability over decades is critical. Its durability minimizes replacement and maintenance costs, providing a dependable solution for industries such as construction, automotive, and infrastructure.

Corrosion Resistance

One of the standout features of yellow fiberglass tube is its exceptional resistance to corrosion. When exposed to moisture, saltwater, or chemicals, traditional materials like steel may rust or degrade. Fiberglass, on the other hand, remains unaffected due to its non-metallic composition. This makes yellow fiberglass tube perfect for applications in marine environments, chemical plants, or outdoor installations where prolonged exposure to corrosive agents is inevitable. This resistance ensures that the material maintains both its appearance and functionality for extended periods.

Lightweight

Compared to steel or aluminum, yellow fiberglass tube is significantly lighter, making it easier to handle, transport, and install. This reduction in weight translates to faster construction times and lower labor costs. Despite being lightweight, it does not compromise on strength, providing a high strength-to-weight ratio. Its ease of handling is particularly valuable in applications requiring frequent adjustments or installations in hard-to-reach areas. Industries that prioritize portability and efficiency greatly benefit from the lightweight nature of fiberglass tubes.

Flexibility

Unlike rigid materials such as steel or wood, yellow fiberglass tube offers superior flexibility. This allows it to bend or absorb impacts without cracking or losing its structural integrity. This characteristic is critical in applications subject to dynamic stresses, such as bridges, industrial piping systems, or earthquake-prone areas. Fiberglass’s flexibility also provides resilience during transportation and handling, reducing the risk of damage. It ensures that the material adapts to changing loads or stress conditions without compromising performance.

Weather Resistance

Yellow fiberglass tube excels in resisting extreme weather conditions, including intense heat, freezing temperatures, heavy rain, and prolonged sunlight. While materials like wood warp and metals corrode in harsh climates, fiberglass retains its strength and shape. Its ability to withstand UV radiation prevents degradation or discoloration, making it an excellent choice for outdoor applications such as cooling tower columns, pipelines, and utility poles. This weather resistance ensures long-term performance in environments that challenge traditional materials.

Chemical Resistance

In environments where exposure to harsh chemicals is common, yellow fiberglass tube provides unmatched reliability. It resists damage from acids, alkalis, solvents, and other corrosive agents that can compromise the integrity of materials like steel or aluminum. This feature makes it indispensable in industries like chemical processing, wastewater treatment, and laboratories, where maintaining structural strength in corrosive conditions is crucial.

Self-Extinguishing Properties

Safety is a top priority in industrial and construction settings, and the self‑extinguishing, Polyester-Fire Rated nature of yellow fiberglass tube adds an extra layer of protection. While it is not completely fireproof, it resists burning and does not contribute to the spread of flames. This makes it a safer alternative to wood and certain plastics, especially in environments where fire hazards are present. Its fire‑rated polyester resin formulation also ensures compliance with stringent safety regulations, making it an ideal choice for projects requiring enhanced flame resistance.

High Visibility

The vibrant yellow color of fiberglass tubes is not just aesthetic—it serves a functional purpose as well. In industrial settings, high visibility enhances safety by making the material easier to identify, especially in low-light conditions or high-traffic areas. This reduces the risk of accidents during construction, maintenance, or operation. Additionally, the color remains vibrant over time due to UV resistance, ensuring the material continues to serve as a visual aid throughout its lifespan.

Versatility

Yellow fiberglass tubes are incredibly versatile and can be customized to meet the specific requirements of various industries. Whether used as structural supports, electrical insulators, cooling tower columns, or protective barriers, their adaptability makes them suitable for a wide range of applications. Their ability to perform well in both indoor and outdoor environments makes them a go-to material for engineers and designers looking for reliable and innovative solutions.

Cost-Effectiveness

While the initial cost of yellow fiberglass tube may be higher than some traditional materials, its long-term cost savings make it an economical choice. The combination of low maintenance, extended service life, and reduced labor costs offsets the upfront investment. Additionally, its lightweight nature reduces transportation expenses, while its durability minimizes the need for frequent replacements. Over time, this makes fiberglass tubes a cost-effective solution for projects that demand reliability and efficiency.

Applications of Yellow Fiberglass Tube

Construction Frameworks

Yellow fiberglass tube is widely used in the construction industry for frameworks, handrails, and ladders. Its lightweight design simplifies handling and installation, while its corrosion resistance ensures longevity in environments exposed to moisture or chemicals, such as bridges, marine structures, and water treatment facilities. Unlike steel or wood, fiberglass requires minimal maintenance, making it an economical and reliable choice for structural support. Its ability to withstand extreme weather further enhances its utility in outdoor construction projects.

Marine and Water Treatment Facilities

In environments where materials are constantly exposed to moisture and saltwater, such as bridges, docks, and water treatment facilities, yellow fiberglass tube offers superior corrosion resistance. Traditional materials like steel corrode over time in these conditions, whereas fiberglass remains unaffected, maintaining structural integrity for years. This makes it ideal for applications like guardrails, structural supports, and pipelines in marine or wet environments.

Automotive Components

The automotive industry leverages yellow fiberglass tube for creating lightweight yet strong components. Its reduced weight helps improve fuel efficiency without compromising durability. Common uses include heat shields, exhaust system components, and lightweight structural parts. Additionally, its excellent insulating properties make it a suitable protective casing for electrical wiring and components, improving vehicle safety by reducing the risk of electrical hazards or thermal damage.

Electrical Insulation and Cable Protection

Due to its non-conductive nature, yellow fiberglass tube is a critical component in electrical and engineering applications. It serves as insulation for high-voltage cables and protective coverings for wires, safeguarding against electrical hazards. The material’s resistance to temperature fluctuations and harsh environmental conditions ensures reliable performance in both residential and industrial settings. This makes it indispensable in power plants, substations, and other installations where electrical safety is a priority.

Industrial Safety Barriers and Equipment

Yellow fiberglass tubes are often used to construct safety barriers, guardrails, and equipment in industrial settings. The material’s bright yellow color enhances visibility, ensuring worker safety in high-traffic or low-light environments. Its impact resistance and ability to self-extinguish in case of fire make it a reliable option for industrial safety systems.

Cooling Towers and HVAC Systems

Fiberglass tubes are extensively used in cooling towers to replace traditional wooden structural columns. Their lightweight and durable properties make them ideal for HVAC systems, where corrosion resistance and thermal insulation are crucial. They also ensure longevity and consistent performance, reducing maintenance and replacement costs in high-moisture environments.

Urban and Rural Structural Projects

Yellow fiberglass tubes are a cost-effective solution for reinforcing building structures in urban and rural areas. Their strength, flexibility, and affordability make them an excellent choice for applications like fencing, scaffolding, and temporary structures. They are particularly useful in projects requiring materials that can withstand harsh weather conditions while maintaining long-term reliability.

Protective Casings for Sensitive Equipment

Fiberglass tubes are also used to house and protect sensitive equipment in harsh environments. For example, they can be used to encase pipelines, electrical equipment, or delicate machinery exposed to chemicals, UV radiation, or extreme temperatures. Their chemical resistance and insulating properties ensure the safety and durability of the encased materials.

By excelling in these diverse applications, yellow fiberglass tube has become a go-to material for industries that demand strength, durability, and long-term reliability in challenging conditions.

DIY Project: How to Make Scaffolding Out of Fiberglass Tube

Factors That Affect the Price of Yellow Fiberglass Tube

The price of yellow fiberglass tube is influenced by several key factors that buyers need to consider.

Size of the Tube

One of the primary factors is the size of the tube. Large diameter fiberglass tubes typically require more material and manufacturing effort, which can increase the overall cost. For applications that require specific dimensions, it’s important to match the size with your project needs to avoid unnecessary expenses.

Thickness

Thickness also plays a significant role in determining the price. Thicker rigid fiberglass tubes offer increased durability and strength but are more expensive due to the additional materials used. Projects requiring greater load-bearing capacity or impact resistance often demand thicker yellow fiberglass tubes, which may raise the price. However, if your application does not require extreme durability, opting for a standard thickness of rigid fiberglass tube can reduce costs.

Length of the Tube

Another factor to consider is the length of the tube. Longer lengths of yellow fiberglass tube are generally more cost-effective for large projects since they reduce the need for multiple joints and connections. However, handling and transportation may add to the total cost, particularly for bulk orders. Shorter lengths might be preferable for smaller, more precise applications but could end up being more expensive on a per-unit basis.

Special Customization Options

Additionally, special customization options such as specific color treatments, chemical resistance, or fire retardant properties can influence the price. Customizing yellow fiberglass tube to meet unique project requirements often incurs higher costs, but these modifications can be essential for specialized applications.

Source of the Raw Materials and the Manufacturing Process

The source of the raw materials and the manufacturing process impact pricing. Tubes made from higher-quality fiberglass or produced using advanced techniques may come at a premium. However, this often results in a more reliable and long-lasting product.

How to Find a Yellow Fiberglass Tube Supplier

When sourcing yellow fiberglass tube, it’s crucial to choose a reliable supplier that meets your specific project needs. Below are five important tips for selecting the right supplier:

Check Product Specifications

Begin by confirming your supplier provides details on tube diameter, wall thickness, length options, resin and fiber composition, and tolerances. Matching these specifications to your project requirements prevents overspending on features and ensures proper performance. Request data sheets, material certifications, and manufacturing process documentation to validate that the yellow fiberglass tubing aligns with your application’s structural, chemical, and environmental demands.

Assess Material Quality

Prioritize suppliers who implement rigorous quality control measures throughout production, including raw material inspection, fiber wet-out consistency checks, and post-curing strength testing. Ask for evidence such as certification reports, traceability records, and UV exposure test results. High-grade resin formulations with proven chemical resistance and UV stabilizers will ensure your yellow fiberglass tubing maintains consistent integrity under industrial and outdoor conditions.

Consider Availability and Delivery Options

Investigate each supplier’s inventory levels, typical lead times to ensure they can fulfill your project schedule. Inquire about expedited production or shipping services for urgent needs. Evaluate their logistics network and partnerships with carriers to confirm reliable, on-time delivery. Large-volume purchases may qualify for bulk discounts or favorable terms, so discuss pricing tiers and return policies before placing an order.

Evaluate Cost Transparency

Ensure prospective suppliers furnish detailed quotations that break down material costs, taxes, shipping fees, handling expenses, and any additional surcharges. Request line-item pricing for raw tubes and custom fabrication to identify potential hidden charges. Compare multiple bids side by side to ensure bulk order discounts and payment terms are stated. Clear cost transparency prevents budget overruns and facilitates accurate project planning.

Check for Customer Support and After-Sales Service

Assess the supplier’s commitment to customer satisfaction by evaluating their comprehensive technical assistance, warranty terms, and responsiveness to inquiries. Confirm after-sales support such as detailed replacement policies and spare parts availability. Reliable communication channels—phone or email—ensure efficient, prompt issue resolution. Proactive customer service and clear escalation processes minimize downtime and protect your investment throughout the yellow fiberglass tubing’s operational lifespan.

GangLong Fiberglass Yellow Square Tubing

At GangLong Fiberglass, we take pride in offering high-quality yellow fiberglass tubes that cater to various industries, including construction and industrial projects. One of our standout products is fiberglass square tubing, a durable and versatile solution widely used for structural support. Made from hollow glass fiber reinforced with a resin matrix, this tubing offers superior strength and flexibility compared to traditional materials like steel or aluminum.

What is Fiberglass Square Tubing?

Fiberglass square tubing provides excellent resistance to corrosion, moisture, and extreme temperatures, making it ideal for both indoor and outdoor applications. Additionally, its lightweight nature simplifies installation, reducing the time and labor costs required for complex structural projects. In areas exposed to harsh environments or chemicals, fiberglass tubing remains a preferred choice due to its long-lasting durability.

Local Availability of Square Tube 50x50x5

Locally, the square tube 50x50x5 is commonly used in construction projects where high strength and low weight are required. It is particularly suited for frameworks, handrails, and safety barriers, providing a stable and safe structure. The square tube 50x50x5 offers precise dimensions that make it easy to integrate into various architectural designs. Whether it’s a residential building or an industrial facility, this type of tubing enhances both the safety and longevity of structural components.

Applications of Square Tube 50x50x5 in Construction

At GangLong Fiberglass, we are committed to ensuring our products are locally available and tailored to meet the needs of your specific project. The versatility of fiberglass square tubing means it can be used for everything from support columns to ladder systems, offering unparalleled performance in a variety of settings. We take great care in selecting the best materials to ensure that each piece of tubing meets the highest standards of quality and performance.

Fiberglass Antenna Tube: Ideal Choice for Outdoor Antennas

Customizing Yellow Fiberglass Tubes for Specific Needs

When it comes to yellow fiberglass tube, customization plays a key role in ensuring that the product meets the exact requirements of different projects. Each project is unique, and having the ability to modify dimensions such as length and thickness makes the yellow fiberglass tube a versatile option for a wide range of applications.

Length

Yellow fiberglass tubes can be customized in length to suit specific applications. Longer tubes are ideal for large frameworks, structural supports, or extended pipelines, while shorter tubes work well for compact installations or smaller-scale projects. Adjusting the length ensures that the tube fits seamlessly into the design, minimizing the need for cutting and reducing material waste.

Thickness

The thickness of the tube can be modified to achieve the desired strength and resilience. Thicker tubes are recommended for heavy-duty applications, such as those involving high loads or exposure to extreme environmental conditions. For lighter applications, thinner tubes may be sufficient, providing cost savings without compromising performance.

Diameter and Wall Thickness

Selecting the appropriate diameter and wall thickness is critical for specific uses. Larger diameters are often used in frameworks and structural supports to provide greater load-bearing capacity, while smaller diameters are suitable for lightweight or compact installations. Wall thickness can also be adjusted to enhance thermal insulation or withstand higher pressure in demanding environments.

Finish

The surface finish of yellow fiberglass tubes can be tailored to meet project needs. Smooth finishes are often used for aesthetic or ergonomic purposes, while textured finishes may enhance grip for handrails or safety barriers. Additionally, protective coatings can be applied to increase resistance to UV rays, chemicals, or abrasions, extending the lifespan of the tube in harsh environments.

Shape and Size

Yellow fiberglass tubes are available in various shapes, including round, square, or rectangular profiles. For example, square tubes like 50x50x5 are commonly used in construction for their balance of strength and flexibility, making them suitable for frameworks, handrails, and safety barriers. Customizing the shape and size ensures the tube fits the exact structural and safety requirements of a project.

Color

While the default vibrant yellow enhances visibility and safety in industrial settings, additional color options can be selected for specific applications or branding purposes. The bright yellow also remains a preferred choice for hazardous environments due to its ability to improve visibility.

Load-Bearing Capacity

Customization allows yellow fiberglass tubes to be tailored to handle specific load requirements. By selecting the right combination of thickness, diameter, and wall strength, the tube can be optimized for applications requiring varying degrees of load-bearing capacity, from lightweight installations to heavy industrial frameworks.

Thermal and Insulation Properties

For projects requiring insulation, such as HVAC systems or electrical enclosures, thicker walls can be added to improve thermal resistance. This customization ensures optimal performance in applications where temperature control or energy efficiency is a priority.

Industry-Specific Needs

Yellow fiberglass tubes can be tailored for specialized applications across industries. For example, square profiles like 50x50x5 are favored in construction, while round profiles with thick walls may be ideal for chemical plants or marine environments. Selecting the right dimensions and features ensures compliance with industry standards and improves project efficiency.

Comparison of Yellow Fiberglass Tubes with Other Materials

Below is a detailed comparison of yellow fiberglass tube against traditional materials—steel and aluminum—across ten critical performance and economic factors. Use this table to quickly assess which material best suits your application requirements.

| Property | Yellow Fiberglass | Steel | Aluminum |

|---|---|---|---|

| Strength & Durability | High strength; corrosion‑proof | Very strong; rusts without coating | Good strength; oxidizes |

| Corrosion Resistance | Inherent resistance | Coating required | Natural oxide layer |

| Weight | Very light | Heavy | Moderate |

| Thermal Insulation | Excellent | Poor | Poor |

| Electrical Conductivity | Non‑conductive | Conductive | Conductive |

| Weather Resistance | UV‑stable, waterproof | Prone to rust in wet/salt air | UV‑stable; needs coating |

| Cost Efficiency | Higher upfront; low upkeep | Low upfront; high upkeep | Mid upfront; mid upkeep |

| Marine/Chemical Use | No coating needed | Special coatings needed | Anodizing/painting needed |

| Versatility | Custom sizes/colors | Fabrication cost | Standard profiles |

| Environmental Impact | Long life; limited recycling | Recyclable; energy‑intensive | Recyclable; moderate energy |

Installing and Maintenance of Yellow Fiberglass Tube

Proper preparation, handling, installation environment, and post‑installation inspection are essential for yellow fiberglass tubes. Regular cleaning, avoidance of harsh chemicals, UV protection, routine damage inspections, and safe handling extend their lifespan and ensure reliable performance. Following these practices maximizes durability and safety in any application.

Installing Practices

Preparation

Inspect the tubes for any signs of damage, such as cracks or defects, and discard any compromised pieces to prevent failures. Clean the mounting surface thoroughly, removing dust, oil, and debris. A contaminant‑free substrate promotes strong adhesion, ensures precise fit, and reduces the risk of damage during installation, safeguarding long‑term performance.

Handling Precautions

Wear appropriate personal protective equipment, including gloves and safety glasses, to guard against fiberglass irritation. Handle the tubes gently, avoiding bending, dropping, or applying excessive pressure. Treat fiberglass as strong yet brittle, and use padded tools when necessary to minimize the risk of cracks during handling.

Installation Environment

Install the fiberglass tubes only in dry, moderate conditions, avoiding high humidity, freezing temperatures, or direct precipitation. Verify that ambient temperature supports proper adhesive curing and fastener tightening. Confirm compatibility between the fiberglass and surrounding materials, ensuring chosen adhesives, sealants, or mechanical fasteners are rated for fiberglass to prevent chemical attack or slippage.

Post-Installation Inspection

After installation, verify all tubes are properly aligned, plumb, and securely fastened. Check for gaps, loose fittings, or misaligned joints that could compromise structural integrity. Tighten connections to manufacturer specifications and seal joints properly. Conduct a final visual inspection to confirm every joint and support meets quality standards before use.

Maintenance and Care

Regular Cleaning

Use non‑abrasive, pH‑neutral cleaners to lift dirt and stains without harming the resin. Wipe tubes gently with a soft cloth or sponge—avoid steel wool, brushes with stiff bristles, or scrubbing pads. Rinse thoroughly with clean water afterward to remove any residue and prevent streaking or buildup on the surface.

Avoid Harsh Chemicals

Do not use strong solvents, bleach, or acidic cleaners on fiberglass tubes. These substances can attack the resin matrix, causing dulling, micro‑cracks, or discoloration over time. If you must remove stubborn deposits, choose a fiberglass‑safe cleaner and follow the manufacturer’s dilution and contact‑time guidelines precisely.

Protect from UV Exposure

Install UV‑resistant coatings or clear varnishes on tubes exposed to direct sunlight. Alternatively, position shading devices—awnings, covers, or canopies—to block peak UV hours. Regularly inspect coated surfaces for chalking or wear, and reapply protective layers as needed to maintain color stability and prevent resin degradation.

Inspect for Damage

Perform visual inspections at least twice a year, or more frequently in harsh environments. Look for surface cracks, delamination, or fading. Check for loose fittings, gasket wear, or sealant gaps. Early detection of minor issues lets you tighten connections, re‑seal joints, or replace affected sections before larger failures occur.

Proper Handling

Whenever moving or adjusting installed tubes, wear gloves to protect against fiberglass splinters and to maintain a secure grip. Use padded supports or cradles to distribute weight evenly and avoid point loading. Do not drag tubes across rough surfaces—lift and carry them to prevent abrasion and surface damage.

Essential Guide for Fiberglass Tube Near Me Suppliers

FAQs About Yellow Fiberglass Tube

Yellow fiberglass is a composite material made from glass fibers reinforced with a polymer resin, giving it a strong yet lightweight structure. The yellow color is often added to enhance visibility, especially in industrial applications where safety is critical. Fiberglass itself is known for its durability, corrosion resistance, and flexibility, making it ideal for various environments, including construction, automotive, and marine industries. The yellow fiberglass tube is commonly used in applications requiring high strength and low weight, such as structural supports, electrical insulation, and handrails. Its ability to withstand extreme temperatures and resist chemical damage further enhances its versatility across multiple industries. Additionally, the vibrant yellow color is particularly useful in situations where the material needs to stand out for safety or aesthetic reasons.

Restoring yellow fiberglass to a white color typically involves cleaning and applying specialized products. First, you should clean the surface using a gentle detergent or soap solution to remove dirt and stains. For tougher discoloration, a mild abrasive cleaner or fiberglass-specific cleaner may be needed. Rinse thoroughly to avoid residue. After cleaning, applying a fiberglass restorer or polish can help bring back the original white color. These products are designed to remove oxidation and restore the surface finish. In cases where the yellowing is severe due to UV exposure, sanding and reapplying a clear protective coat or gel coat may be necessary. It’s essential to avoid harsh chemicals that could further damage the fiberglass material.

Fiberglass tubes are used across various industries due to their strength, flexibility, and resistance to environmental factors. In construction, they serve as structural supports, safety railings, and ladder components. Their non-conductive nature makes them ideal for electrical insulation in high-voltage applications. Fiberglass tubes are also commonly found in the automotive industry, used for components like exhaust systems, heat shields, and protective casings for electrical wiring. Additionally, they are used in marine environments due to their corrosion resistance, ensuring longevity even in harsh, salty conditions. Beyond these industrial uses, fiberglass tubes are also popular in recreational applications, such as in fishing rods and sports equipment.

Fiberglass tubing is incredibly strong, with a high strength-to-weight ratio that makes it suitable for demanding applications. It can withstand significant loads without bending or breaking, making it ideal for structural support in buildings, bridges, and industrial frameworks. While lighter than steel or aluminum, fiberglass tubing offers comparable tensile strength, which allows it to endure both heavy weights and impacts. The material is also resistant to corrosion and environmental factors, such as UV light and moisture, enhancing its durability. Its combination of strength and flexibility makes fiberglass tubing a top choice for applications requiring lightweight materials that maintain structural integrity over time.

The R-value of yellow fiberglass insulation depends on its thickness and density. Typically, fiberglass insulation has an R-value ranging from 2.9 to 4.3 per inch of thickness. For instance, a 3.5-inch thick fiberglass batt commonly found in walls might have an R-value of around R-11 to R-15, while thicker insulation for attics can achieve higher R-values. Yellow fiberglass tubes used in industrial or HVAC applications often have R-values optimized for thermal resistance, with exact specifications varying by manufacturer. These tubes are particularly effective for insulating pipes or ducts, minimizing heat loss and improving energy efficiency. The R-value you require depends on the intended application—whether for residential walls, attics, or specialized uses in heating and cooling systems. Always check the product’s technical datasheet for precise R-values to ensure it meets your insulation needs effectively.

Touching fiberglass insulation, including yellow fiberglass tubes, is not recommended without proper protection. Fiberglass is made of tiny glass fibers that can irritate the skin, eyes, and respiratory system. Direct contact can cause itching or rash, and inhaling fibers may lead to throat or lung irritation. If you must handle yellow fiberglass insulation, wear protective clothing, gloves, goggles, and a dust mask to minimize exposure.

For yellow fiberglass tubes used in HVAC or pipe insulation, these often come with a protective outer coating or foil, reducing the risk of direct contact. However, cutting or modifying them may still release fibers into the air. When working with fiberglass insulation, ensure proper ventilation and clean up any residue using a vacuum equipped with a HEPA filter. Taking these precautions will help you avoid discomfort or health risks associated with fiberglass exposure.

Fiberglass mortar tubes, often used in pyrotechnics, are durable and can last many years with proper care. Their longevity depends on factors like the frequency of use, storage conditions, and exposure to the elements. Typically, high-quality fiberglass tubes can last 5-10 years or more if they are stored in a dry, cool environment and not subjected to physical damage or excessive heat.

For yellow fiberglass tubes specifically, their durability stems from fiberglass’s inherent resistance to weathering, corrosion, and impact. However, repeated exposure to high heat from fireworks or constant moisture can degrade the resin binding the fibers, leading to cracking or weakening. Regularly inspect your mortar tubes for signs of wear, such as chips, cracks, or discoloration, to ensure safety. Replacing damaged tubes is essential to avoid risks, as compromised fiberglass can fail during use.

Yellow fiberglass insulation is generally non-flammable and is considered a fire-resistant material. The glass fibers used in its construction have a high melting point, typically above 1,000°F (540°C), making them resistant to ignition. However, the binder materials or facings (such as kraft paper or foil) attached to some insulation products may be combustible. When used in yellow fiberglass tubes, the outer layer often incorporates fire-resistant coatings or coverings for added safety in applications like HVAC insulation.

It’s important to note that while fiberglass insulation itself does not burn, it can degrade or emit smoke if exposed to extreme heat. Always follow local building codes and safety guidelines to ensure proper installation and fire protection. In high-temperature environments, consider using insulation specifically rated for those conditions to maintain safety and performance.

When looking for thin insulation with a high R-value, aerogel insulation is one of the best options. Aerogels have an R-value of 10 to 30 per inch, far exceeding that of fiberglass, including yellow fiberglass tubes. While fiberglass insulation typically provides an R-value of 2.9 to 4.3 per inch, aerogels achieve excellent thermal resistance in a fraction of the thickness.

Yellow fiberglass tubes are often chosen for their balance of affordability, ease of installation, and decent thermal performance. However, in situations where space is limited and higher R-values are required, aerogel blankets or panels may be preferred despite their higher cost. Hybrid solutions can also involve combining fiberglass with other materials to enhance performance. Always choose insulation based on your project’s specific requirements, including space constraints, thermal efficiency, and budget.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.