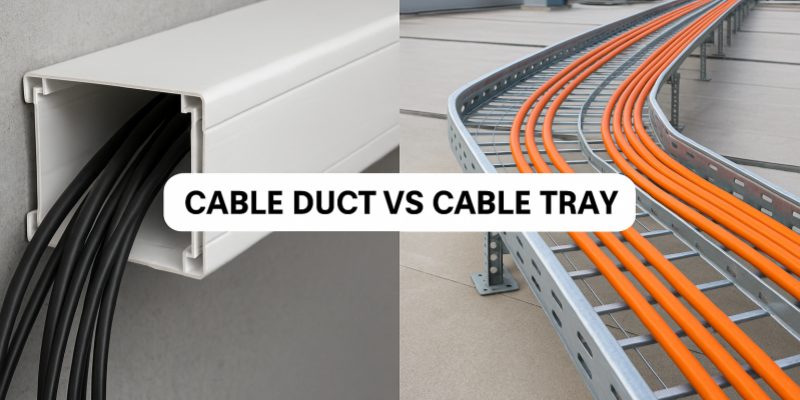

Cable duct vs cable tray: trays offer less protection and require fire-resistant cables for exposure to environmental hazards. When comparing cable duct vs cable tray, it’s essential to understand the role each system plays in wiring and cable management. Cable trays are typically used to support and organize cables in open environments, providing easy access for maintenance and changes. They are ideal for large installations, as they allow for a high degree of flexibility. On the other hand, cable ducts are closed systems designed to protect cables from mechanical damage, dust, and other external factors. They are often used in areas where a more secure and protected environment is needed, such as in residential buildings or areas with harsh conditions. The choice between cable duct vs cable tray, in terms of bus duct vs cable tray, depends on the installation environment, required protection, and ease of access.

Cable Duct vs Cable Tray: Overall Overview

When it comes to organizing and protecting cables in both industrial and commercial settings, the debate of cable duct vs cable tray often arises. Both of these systems are designed to provide efficient pathways for cables, ensuring safety, accessibility, and neat organization. However, there are significant differences between the two that can affect installation, performance, and long-term maintenance. In this article, we will explore the key differences, benefits, and applications of cable duct vs cable tray systems to help you choose the best solution for your needs.

What Are Cable Ducts?

Cable ducts are a type of enclosed pathway designed to house and protect cables. They provide a fully covered environment, offering protection from external factors such as dust, moisture, and physical damage. Cable ducts can be installed on walls, floors, or ceilings, depending on the needs of the installation. Cable duct vs cable tray are available in various materials, including PVC, fiberglass, and metal, each providing different levels of protection and durability.

The main advantage of using a cable duct system is that it offers a completely enclosed space for cables, which is essential in environments where cables need to be fully shielded from the elements. Additionally, cable ducts allow for the secure routing of cables over long distances, minimizing the risk of damage from external factors. This makes cable ducts a popular choice in settings like data centers, factories, and locations where cables may be exposed to harsh conditions.

What Are Cable Trays?

Cable trays, on the other hand, are open systems that provide support for cables without fully enclosing them. These trays are typically used to organize and route large numbers of cables, particularly in commercial and industrial settings. Cable trays come in various designs, including ladder-type trays, perforated trays, and solid-bottom trays, each offering unique advantages depending on the environment and type of cables being used.

Unlike cable ducts, cable trays are designed with an open structure, allowing for easy access to cables for maintenance or modification. The open nature of cable trays provides greater flexibility in managing cable systems, especially when it comes to adding or removing cables. Additionally, cable trays are often easier and faster to install, as they do not require the enclosed pathways that cable ducts do. They are often used in applications where air circulation and easy access to cables are important, such as in server rooms, factories, and electrical installations.

The Role of Cable Duct vs Cable Tray in High-Traffic Environments

In high cable density environments, choosing between cable duct vs cable tray is critical. Cable trays are ideal for frequent access and changes, offering open designs that support airflow and reduce overheating risks. Cable ducts, however, provide greater protection against mechanical impact, making them suitable for high-traffic or hazardous areas. Each system serves different needs—trays for accessibility and cooling, ducts for security and durability. GangLong Fiberglass offers both options to support varied commercial and industrial applications.

Environmental Considerations for Cable Duct vs Cable Tray

The installation environment greatly influences the choice between cable duct vs cable tray. Cable ducts are ideal for harsh conditions—such as underground, outdoor, or chemical-exposed areas—where protection from moisture, dust, and physical damage is essential. Cable trays, with their open design, are better suited for dry indoor spaces like data centers or offices, where airflow and easy access for maintenance are priorities.

How About the Safety Features of Cable Duct vs Cable Tray

Safety is always a primary concern when designing and installing any cable management system. Cable ducts provide a higher level of security, offering full protection from external elements such as physical damage, moisture, or corrosive substances. This makes them the ideal choice for installations in hazardous environments, such as chemical plants or areas with extreme temperatures.

Cable trays, while offering less protection from external forces, are still designed with safety in mind. Their open structure provides ample airflow, reducing the risk of overheating, while their robust materials ensure the cables are securely held in place. At GangLong Fiberglass, we ensure that all our cable trays meet the highest safety standards, providing reliable support for both indoor and outdoor installations.

Cope Cable Tray Address and Key Product Offerings Explained

Key Differences Between Cable Duct and Cable Tray Systems

When comparing cable duct vs cable tray systems, there are several factors to consider. The two systems serve different purposes and are suitable for different environments. Below are some key differences to keep in mind:

Enclosure vs. Open Design

The most obvious difference between cable ducts and cable trays is the level of enclosure. Cable ducts are fully enclosed, providing maximum protection for cables. This makes them ideal for environments where cables need to be shielded from external elements such as moisture, dust, or physical impact. Duct cable trays, which combine the features of both duct and tray systems, offer a middle ground. They provide some protection while still allowing for easy access, making them useful in environments where a balance of security and flexibility is needed. In contrast, traditional cable trays are open systems that allow for easy access to cables. This design is beneficial when flexibility and maintenance accessibility are important, as cables can be easily added, removed, or adjusted without needing to dismantle the entire system.

Protection vs. Accessibility

Cable ducts offer superior protection compared to cable trays, making them the better choice for harsh environments. The enclosed design of cable ducts prevents exposure to external elements, which helps to protect sensitive cables, such as fiber optics or power cables, from damage. On the other hand, cable trays offer less protection but more accessibility, making them an ideal solution when cable systems need to be regularly adjusted or maintained. Cable trays are also a good option for systems that require ample airflow, as the open design allows for better ventilation around cables.

Cost and Installation

One key difference between cable duct vs cable tray systems is the cost and installation complexity. Cable ducts, often installed via direct burial, underground channels, or sealed surface mounts, are more expensive and time-consuming due to their enclosed, protective design. In contrast, cable trays are mounted above ground on walls or ceilings using brackets and supports. Their open structure allows for faster installation, easier routing, and future access, making them a more cost-effective choice in many commercial or industrial settings.

Materials Used

Material selection for cable ducts vs cable trays is key to ensuring performance and durability in different environments. Cable ducts are typically made from PVC, aluminum, or galvanized steel, offering good protection in humid, outdoor, or corrosive conditions. Cable trays are often made from stainless steel, galvanized steel, or aluminum, allowing strong support and better airflow for heat-sensitive installations. Each material suits specific needs based on environmental exposure, load capacity, and maintenance requirements.

Flexibility and Customization

A key difference between cable duct vs cable tray lies in flexibility. Cable trays are modular and easily adaptable, allowing for quick changes or expansion as cabling needs grow, making them ideal for evolving systems. Cable ducts, while less flexible once installed due to their enclosed design, offer better protection for high-value or hazard-exposed cables. Both systems can be customized in size and configuration to suit specific project needs, balancing flexibility with protection based on the environment.

Cable Duct vs Cable Tray: Pros and Cons

Choosing between cable duct vs cable tray involves weighing the unique pros and cons each system offers. Cable ducts provide superior protection, making them ideal for environments where security, moisture resistance, and complete enclosure are critical. However, they can be more expensive and harder to maintain. In contrast, cable trays excel in accessibility, airflow, and cost-efficiency, but offer less physical protection. Understanding these trade-offs is key to selecting the right solution for your installation.

| Aspect | Cable Duct | Cable Tray |

|---|---|---|

| Cable Protection | Fully enclosed; excellent protection from physical, chemical, and environmental damage | Partial protection; cables are exposed to dust, moisture, and other hazards |

| Fire & Heat Resistance | Superior fire resistance; protects cables from heat and fire risks | Requires fire-rated cables; open design aids cooling but less fire-resistant |

| Security | Provides tamper protection; ideal for public or high-security areas | Less secure due to open design |

| EMI Shielding & Grounding | Metal ducts shield EMI and support grounding | Offers limited EMI protection; separation required for power/data cables |

| Cooling & Airflow | Limited airflow; potential for heat buildup | Excellent ventilation; promotes airflow and reduces overheating |

| Access & Maintenance | Harder to access; disassembly needed for changes | Easy cable access for maintenance, upgrades, and inspection |

| Installation & Cost | More complex and costly; longer install time | Easier and cheaper to install; lower labor and material costs |

| Flexibility & Scalability | Rigid; difficult to modify once installed | Highly adaptable; supports future changes and expansions |

| Aesthetics | Concealed; better suited for finished or visible areas | Exposed; may appear cluttered in visible installations |

| Burial & Outdoor Suitability | Suitable for underground or harsh outdoor environments | Not recommended for underground use |

| Best Use Cases | Industrial plants, hazardous zones, outdoors, secured environments | Data centers, commercial buildings, rooftops, areas needing frequent changes |

Common Applications for Cable Duct vs Cable Tray

When planning a cable management system, understanding the specific applications of cable duct vs cable trays is essential. These two systems serve different purposes depending on environmental conditions, maintenance needs, safety requirements, and flexibility. Choosing the right one for the right use case ensures system performance, safety, and cost-efficiency across various industries.

Cable Duct Applications

Data Center Applications

In data centers, cable ducts are used to enclose and protect sensitive data and power cables. The enclosed design prevents dust accumulation, reduces electromagnetic interference, and ensures cables are safe from physical damage. This setup supports uninterrupted operation and simplifies cable management in high-density environments where reliability is critical.

Chemical and Hazardous Environment Applications

Cable ducts are well-suited for chemical plants and hazardous environments where cables must be shielded from corrosive vapors, moisture, and chemicals. Their enclosed structure helps maintain cable integrity and reduce fire risks. These ducts offer a durable solution in safety-sensitive installations where environmental exposure is a constant concern.

Outdoor Installation Applications

For outdoor applications, cable ducts protect cables from rain, UV rays, debris, and temperature fluctuations. They are commonly used on rooftops or exterior walls in public infrastructure, offering long-term durability and preventing accidental contact. Their enclosed design also helps resist tampering and mechanical wear caused by external forces.

Public and Security-Sensitive Area Applications

In public buildings or high-security areas, cable ducts provide a safe and concealed path for important wiring. The enclosed structure protects cables from tampering, accidental disconnection, and vandalism. This makes them suitable for use in transportation hubs, schools, and public venues where safety and order are priorities.

Cable Tray Applications

Industrial Facility Applications

Cable trays are widely used in industrial facilities to support and organize large volumes of power and control cables. Their open structure allows for ventilation, reducing heat buildup around heavy-load wiring. Trays also enable easy access for maintenance, making them ideal for fast-paced industrial environments with evolving system demands.

Commercial Building Applications

In commercial spaces such as offices and retail buildings, cable trays provide an accessible and flexible cable routing solution. They simplify maintenance and allow for easy cable upgrades or replacements. The open design helps technicians quickly locate and manage cabling without disrupting building operations or damaging walls.

Telecommunications and Network Applications

Cable trays are ideal for telecom and network applications where structured cabling and expansion flexibility are essential. They allow for organized separation of power and signal cables and simplify cable identification. Their layout flexibility supports fast upgrades, making them a common choice in network hubs and server rooms.

Cable Duct vs Cable Tray:Factors in Choosing the Best Cable Management

Selecting between cable duct vs cable tray systems is more than a matter of budget or preference—it’s a strategic decision that impacts long-term cable performance, safety, and maintenance. Wires and cables are essential for powering real-time operations, but managing them requires planning for the future. A well-designed cable management system ensures not only efficiency today but also adaptability and reliability over time.Several critical factors should guide your decision between cable ducts and cable trays:

Cable Size and Scalability

When selecting a cable management system, start by assessing the size of individual cables and the entire bundle. Your system must accommodate the current cable load without overcrowding, which could lead to overheating or signal interference. Also consider future scalability—leave space for additional cables as your infrastructure grows. Cable trays are easier to expand, while cable ducts may require more planning upfront to handle future needs without major modifications.

Support Strength

Your cable management system must support the total cable weight without sagging or structural failure. Cable trays, often made of metal or fiberglass, offer strong, modular support ideal for larger runs. Cable ducts provide a more rigid structure but may be less adaptable to added weight. In either case, strength matters—especially when planning for long-term reliability and the potential addition of future cable loads to the same support system.

Cost and Lifecycle Value

While cable trays usually cost less upfront due to lower material and labor needs, cable ducts may offer better protection in harsh conditions, reducing long-term maintenance costs. Consider total cost of ownership, not just installation expenses. If frequent cable access or changes are expected, trays may save time and labor. For secure, static environments, ducts offer durability and reduce the chance of damage, saving replacement costs in the long run.

Environmental Conditions

Harsh environments can shorten cable life if the right management system isn’t used. Cable ducts are better for areas with exposure to chemicals, moisture, dust, or extreme temperatures, providing full enclosure and shielding. In dry, climate-controlled interiors, cable trays allow better airflow, helping dissipate heat from high-power cables. Match material and structure to your environment to ensure safe, long-lasting performance for your cabling infrastructure.

Flexibility and Routing

Cable trays offer greater flexibility, adapting to directional changes, elevation shifts, and layout modifications with ease. Their modular structure supports system changes without replacing the entire route. Cable ducts are more rigid and harder to reconfigure once installed, but provide consistent protection and cable separation. If your project requires frequent layout changes or expansion, cable trays are usually the more efficient and flexible solution.

Regulatory Compliance

Compliance with electrical codes like NEC Article 392 is non-negotiable. Cable trays can only support certain types of cables, while ducts may be required in classified or hazardous environments. Choosing a system that meets relevant codes ensures safety, avoids penalties, and prevents costly rework. Always verify installation and cable types against applicable regulations to ensure your system is both legal and safe.

Installation and Maintenance Access

Cable trays are easier and quicker to install, especially in open or overhead spaces. Their open design allows for fast routing and cable replacement, reducing labor costs during future maintenance. In contrast, cable ducts require more precise installation and sealing, but protect cables from tampering or external damage. If your setup demands frequent access or modifications, trays are typically more efficient over time.

Color Coding and Identification

Color may seem minor, but it’s important for serviceability. Cable trays and ducts should support clear identification through labels or color-coded routing. This helps maintenance teams quickly identify cable types, reducing errors during troubleshooting or upgrades. Planning your color scheme and labeling system in advance improves safety and efficiency, especially in complex environments like data centers or industrial facilities where dozens of cable runs may exist.

Choosing Clamps for Effective B Line Cable Tray Grounding

The Cost Implications of Cable Duct vs Cable Tray

When evaluating cable duct vs cable tray systems, understanding the cost implications is essential for making an informed decision. These two cable management solutions differ not only in structure and functionality but also in how they impact project budgets—both initially and over time. From material and installation expenses to maintenance and long-term scalability, each system carries unique cost considerations that should align with your project’s technical needs, environmental conditions, and future growth plans.

Upfront Material Costs

Cable ducts typically incur higher initial material costs due to their enclosed design. They require more raw material—such as PVC, aluminum, or galvanized steel—to fully encapsulate and protect the cables. This added protection makes them ideal for harsh environments, but it also increases the price compared to open systems like cable trays, which require less material and offer a simpler structural profile.

Installation Labor Costs

Installing cable ducts usually demands more time and skilled labor. Their sealed construction means installers must carefully align and fasten each section, often incorporating gaskets, joints, and weatherproofing. In contrast, cable trays are easier and faster to install. Their open structure allows technicians to lay out and mount trays using brackets and supports with minimal effort, significantly lowering installation labor costs.

Maintenance and Accessibility Costs

Cable trays offer easier access for maintenance, saving time and labor in the long run. Since they are open, cables can be quickly inspected, replaced, or upgraded. Cable ducts, however, may require full or partial disassembly to access enclosed cables, which adds to maintenance costs over time. If your system requires frequent adjustments, trays are a more cost-efficient choice.

Long-Term Scalability and Upgrade Costs

The modular nature of cable trays makes them highly adaptable to system expansions. Adding or rerouting cables is simple, with minimal disruption or added expense. Cable ducts are less flexible—modifying them after installation may involve cutting, resealing, or even replacing sections, leading to higher upgrade costs. For growing facilities, trays generally provide better long-term value.

Total Cost of Ownership

While cable ducts may offer better protection, their higher upfront and maintenance costs must be considered in the context of the project’s environment and requirements. Cable trays tend to offer a lower total cost of ownership, especially in environments where cable access, modification, and expansion are expected. The cost-effectiveness of trays makes them a practical choice for many modern commercial and industrial applications.

How to Determine Cable Tray Coupler Price Accurately

FAQs about Cable Duct Vs Cable Tray

Cable tray and cable channel are both used for supporting electrical cables, but they differ in design and application. A cable tray is typically a larger, open metal structure used to organize and support cables, often used in larger facilities or industrial settings. It provides ample space for cables, allows easy installation, and is designed to support heavy cable loads. Cable channel, on the other hand, is narrower and typically used in smaller applications or areas with limited space. It often features a cover to protect the cables from external damage or environmental factors. Cable channels are ideal for low-capacity cable systems or where aesthetic concerns are important, offering a more discreet option. While both serve the same purpose, the choice between cable tray and cable channel depends on the scale of the installation and the specific needs of the environment.

Cable tray and cable trench both provide routes for electrical cables, but they are used in different scenarios. A cable tray is a metal or plastic structure installed above ground to support cables, allowing for easy access, flexibility, and ventilation. It is commonly found in commercial and industrial environments where the cables need to be routed along walls or ceilings. Cable trays are installed on supports and are generally above ground or elevated.

In contrast, a cable trench is a physical trench or excavation in the ground where cables are laid directly in the soil or within concrete or metal ducts. Trench installations are used for underground cable systems, often when cables need to be routed over long distances or in areas without overhead space. While cable trays provide easier access and maintenance, cable trenches are often used when above-ground routing is not feasible.

There are three main types of cable tray systems used for cable management:

Ladder Cable Tray: Ladder trays are characterized by their “ladder” design, with two parallel side rails connected by rungs. They are ideal for supporting heavy cables and providing easy access for maintenance. The open structure allows for better ventilation, which reduces the risk of cable overheating.

Solid Bottom Cable Tray: This type of tray has a solid base, providing additional protection for cables from environmental elements and debris. Solid bottom trays are ideal for routing cables in environments where protection from dust or chemicals is needed. They also provide a more secure cable pathway in certain industrial applications.

Perforated Cable Tray: Perforated trays have small holes or slots along the base, providing ventilation while also supporting cables. These trays are lighter than solid bottom trays and offer flexibility for use in different environments. The perforated design is often preferred for its balance of protection and airflow.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.