Cable trays play a crucial role in modern infrastructure by providing an efficient and organized system for cable management. They are widely used in various industries, including commercial, industrial, and residential settings, to securely support and route electrical wiring. As the demand for cost-effective solutions grows, there is a need for cheap cable tray options that do not compromise on durability or safety. Affordable cable trays allow businesses to manage installation costs while maintaining the integrity and reliability of their electrical systems. Cheap cable tray supports and routes cable bundles along ceilings, walls, and workstations with a sleek, compact surface-mounted design. There are several types of cable trays, including ladder, perforated, and solid-bottom trays, each suited for different applications depending on the environment and cable requirements. Whether used in power distribution, control, or communication systems, selecting the right cheap cable tray ensures both safety and long-term performance.

What Are Cheap Cable Trays?

Definition and Purpose in Industrial and Residential Setups

A cable tray is an essential component used in electrical installations to support and manage cables, providing a safe and organized route for wiring. In both industrial and residential setups, cable trays offer a cost-effective solution for organizing power, data, and control cables. They are commonly used in environments where flexibility, safety, and easy maintenance are required. The primary purpose of a cable tray is to support cables, prevent tangling or damage, and provide easy access for future modifications or repairs. A cheap cable tray option allows businesses and homeowners to install effective cable management systems without breaking the budget while still ensuring safe, efficient performance.

Common Materials Used (e.g., Steel, Aluminum, Plastic)

Choosing the right cable tray material is crucial, as cable trays are manufactured from diverse materials based on installation requirements such as strength, environment, and cost.

- Steel: This is one of the most common materials used for cable trays due to its strength and durability. Steel trays are perfect for heavy-duty applications where large amounts of power cables need to be supported. They are often galvanized or coated to prevent corrosion, making them suitable for industrial and commercial installations.

- Aluminum: Aluminum trays are lighter than steel but still offer great strength and resistance to corrosion. These trays are commonly used in environments where weight is a concern, such as for ceiling-mounted cable trays in commercial buildings or residential settings.

- Plastic: Plastic cable trays are ideal for light-duty applications and are often used in environments with minimal mechanical stress. They offer corrosion resistance, are lightweight, and are easy to install, making them a good option for residential or small commercial setups.

When choosing a cheap cable tray, material selection is important. It ensures that the tray will meet the specific needs of the installation without compromising safety or durability.

Overview of Benefits: Safety, Organization, and Efficiency

The use of cable trays offers numerous benefits, particularly in terms of safety, organization, and operational efficiency:

- Safety: Properly installed cable trays reduce the risk of electrical fires, overheating, and short circuits by preventing cables from becoming tangled or damaged. They also make it easier to maintain grounding and bonding connections, which are vital for preventing electrical hazards.

- Organization: Cable trays help to keep cables neatly organized, making it easier to identify and access them for maintenance or upgrades. This organization is especially important in large installations where many cables of different sizes and types are involved.

- Efficiency: By using a cable tray, the installation process becomes quicker and more cost-effective. The trays provide a clear, easy-to-follow route for cables, simplifying the layout and reducing the time spent on installation. They also provide an accessible path for future modifications, making it easy to add or remove cables without disrupting the system.

Whether you’re looking for a cheap cable trays for a small residential project or a more robust solution for industrial applications, these trays provide essential benefits that enhance the safety, organization, and efficiency of your electrical systems. By choosing the right materials and installation method, you can achieve long-lasting results while maintaining cost-effectiveness.

Cable Duct vs Cable Tray: Which Is Right for Your Installation?

Popular Types of Cheap Cable Trays

Cheap Cable Tray solutions come in various types to suit different applications. From heavy-duty industrial ladder and perforated trays to lightweight wire mesh options, under-desk racks, and wall-mounted systems, each design offers cost-effective cable management tailored to specific settings. Understanding these types ensures optimal performance and organized installs.

Industrial Cable Tray

Industrial cable trays offer a cost-effective solution for large-scale cable management without sacrificing durability or safety. Made from galvanized steel or aluminum, they support heavy-duty power runs across factories, warehouses, and commercial buildings. Available in ladder, perforated, and solid-bottom styles, these trays balance airflow and protection to prevent cable overheating. Their modular design allows easy customization and scalability, enabling installers to configure long-distance supports quickly and adapt layouts as facility needs evolve.

Wire Mesh Cable Tray

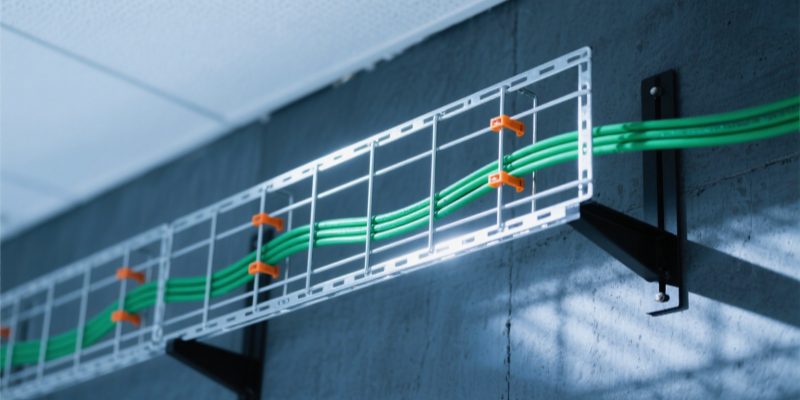

Wire mesh cable trays provide an economical, lightweight option ideal for light-duty installations such as offices, retail spaces, or small industrial sites. Constructed from galvanized wire mesh, they allow excellent airflow and simplify cable routing, reducing the risk of heat buildup. Their open framework makes installation and handling fast while cutting labor costs. Versatile mounting options—under desks, along walls, or within ceiling plenums—ensure cables remain accessible and well-organized.

Under Desk Cable Tray

Under-desk cable trays, including DIY cable management tray, deliver an affordable, practical solution for managing computer and accessory wiring in office workstations. Compact and easy to install, these trays tuck neatly beneath desks, concealing cables to create a cleaner workspace. By grouping power cords, data cables, and peripherals out of sight, they reduce trip hazards and streamline troubleshooting. Their unobtrusive design fits most desk frames without additional support, making them a popular choice for improving both aesthetics and safety.

Wall-Mounted Cable Management Tray

Wall-mounted cable trays offer a budget-friendly way to utilize vertical space for cable routing in areas with limited floor room. Mounted along walls or in narrow corridors, they keep cables off the ground, minimizing clutter and trip risks. These trays suit residential, commercial, and light industrial applications, especially for low-voltage or data wiring. Easy installation and minimal building modifications make them an attractive option for projects that require neat, accessible cable runs without extensive infrastructure changes.

How Innerduct in Cable Tray Enhances Cable Organization

Applications of Cheap Cable Trays

In modern wiring applications, affordable cable trays are popular for their low cost and easy installation. They neatly conceal cluttered cables in home and office settings, support medium-duty wiring in light industrial environments, and offer flexible, cost-effective routing solutions for temporary or DIY projects alike.

Home and Office Cable Management

In home and office settings, cheap cable trays provide an affordable, organized solution for managing power cords, data cables, and charging wires. Under-desk trays mount discreetly beneath desktops to conceal bundles of cables, reduce clutter, and protect wires from damage. Wall-mounted trays offer similar benefits along vertical surfaces, keeping cables out of sight and preventing tripping hazards. These cost-effective trays improve workspace aesthetics, enhance safety, while remaining cost-effective and efficient.

Small-Scale Industrial Applications

Wire mesh cable trays are ideal for small-scale industrial settings requiring moderate-duty cable management. Their open-grid design supports power and control cables in factories, warehouses, and light manufacturing facilities. Mesh trays allow easy customization and expansion while providing ventilation to prevent cable overheating. Lightweight and quick to install, these trays reduce material and labor costs. This cost-effective solution delivers organized, safe cable routing without the need for heavy-duty infrastructure support.

DIY and Temporary Installations

Cheap cable trays in DIY and temporary setups provide modular, reusable solutions for organizing cables during short-term projects. These lightweight trays allow tool-free assembly and removal, ideal for construction sites, events, or renovations. Configurable sections adapt to changing layouts and can be reused across jobs, maximizing cost efficiency. By keeping power and data cables protected and neat, these trays improve safety, reduce tripping hazards, and streamline setup and dismantling processes.

Best Practices for Cable Tray Risk Assessment During Installation

Tips for Choosing the Right Cheap Cable Tray

In selecting an affordable cable tray, balance project scope, budget, and environmental demands. Consider material longevity, installation ease, maintenance, and compliance with relevant standards. By carefully assessing these factors, you can choose a cost-effective tray solution that delivers reliable, safe cable management and long-term performance.

Evaluate Project Requirements and Budget Constraints

Assess the project scope and budget before selecting a cheap cable tray. Determine cable volume, installation complexity, and load requirements. For small residential or office settings, lightweight trays such as plastic or aluminum may suffice. Larger industrial applications demand durable options like galvanized steel or heavy-duty wire mesh. Balance cost against future needs. Insufficient load capacity or corrosion resistance can increase maintenance expenses. Align tray selection with functional requirements, lifespan.

Consider Material Longevity and Environmental Factors

When selecting a cheap cable tray, it’s important to consider the material longevity and the environmental factors that may impact the tray’s performance over time. Cable trays come in various materials, including plastic, aluminum, galvanized steel, and stainless steel. Each material offers different levels of strength, corrosion resistance, and durability, depending on the environment in which they will be used.

- Galvanized Steel: For industrial or outdoor environments where trays will be exposed to moisture, humidity, or harsh chemicals, galvanized steel is often the most cost-effective and durable choice. It offers a good balance of strength, corrosion resistance, and affordability, making it a popular option for industrial settings.

- Aluminum: If the installation requires a lightweight option, aluminum trays are often a good choice. They are rust-resistant and durable, but may not offer the same load-bearing capabilities as galvanized steel. Aluminum trays are ideal for indoor settings where weight is a concern, and the environmental impact is minimal.

- Plastic: For applications in dry, low-risk environments, cheap cable trays made from plastic can be a cost-effective option. They are lightweight, easy to install, and resistant to corrosion, but they may not provide the durability needed for heavy-duty or outdoor use.

- Wire Mesh: Wire mesh trays are ideal for environments where flexibility, airflow, and cost-efficiency are key considerations. These trays are commonly used in small-scale or light-duty applications, offering versatility and easy installation. However, they may not provide the level of protection required for cables exposed to extreme temperatures or physical impact.

Assess Installation and Maintenance Requirements

Evaluate installation complexity and maintenance needs before choosing a cheap cable tray. Consider mounting methods, accessibility for cable additions, and cleaning ease. Modular trays simplify reconfiguration and reduce labor when adding or removing cables. Open designs allow visual inspections, while smooth surfaces ease cleaning. Verify required tools and hardware. Selecting trays that balance simple installation with straightforward routine future maintenance guarantees effective cable management over the system’s lifespan and inspections.

Ensure Compliance with Standards and Certifications

Choose cable trays that comply with industry standards and certifications to ensure safety and reliability. Look for UL, CSA, or CE marks confirming adherence to electrical and fire guidelines. For outdoor or hazardous locations, verify NEMA or IP ratings suit environmental exposure. Proper certification simplifies inspections, future maintenance, and reduces liability. Compliant trays guarantee regulatory conformity and provide dependable efficient cable support and peace of mind for installers and operators.

FAQs about Cheap Cable Tray

Yes, in many cases, cable trays are cheaper than conduit, both in terms of material costs and installation expenses. Cable trays are generally more cost-effective for large-scale installations because they are easier to install and require less labor. Unlike conduit, which often requires individual sections to be connected and sealed, cable trays typically feature a modular design that allows for quicker assembly and easier access to cables. This can significantly reduce installation time and labor costs, making them a more affordable choice for cable management, especially in larger commercial or industrial projects.Additionally, cable trays offer more flexibility. In installations where cables may need to be added or adjusted in the future, cable trays make it easier to manage changes without extensive rework or new materials. Conduit, on the other hand, may require more costly modifications to accommodate additional cables.

While cable trays are not strictly necessary in every installation, they are highly beneficial and often essential in larger or more complex electrical systems. They provide a safe and organized way to manage electrical cables, especially in commercial, industrial, and high-traffic areas. Cable trays offer several advantages, including ease of installation, better accessibility for maintenance, and a clear pathway for cables, which helps prevent tangling, damage, and overheating.

In installations where many cables need to be run over long distances, cable trays are almost always necessary because they provide an efficient method of supporting, organizing, and protecting cables. In residential setups, where cable management requirements are often less complex, cable trays may not be as necessary. However, in industrial or commercial environments where the safety of cables is critical, cable trays ensure that cables are properly secured, routed, and protected, making them a vital component for large-scale or high-demand electrical systems.

Cable trays and ladder trays are both used for managing and supporting cables, but they differ primarily in their design and application.

Cable Tray: A cable tray is a broad term that refers to a system of trays designed to hold electrical cables and organize wiring. Cable trays come in various designs, such as solid-bottom, perforated, and wire mesh trays. The tray type selected depends on the specific application, load requirements, and environmental conditions. Cable trays are ideal for accommodating both power cables and communication cables in commercial and industrial settings.

Ladder Tray: A ladder tray, also known as a ladder cable tray, is a specific type of cable tray that consists of two side rails connected by rungs, resembling a ladder. The design allows for better airflow around cables, which is especially important in environments where high currents may generate heat. Ladder trays are typically used for larger or more complex installations where multiple cables need to be supported with maximum ventilation.

While both types of trays perform similar functions, the ladder tray is often the preferred choice for larger installations that require additional airflow, while cable trays can be used for a wider range of applications, depending on the type chosen.

The most common cable management solution is the cable tray system, particularly in commercial, industrial, and high-traffic areas. Cable trays provide an organized, safe, and easily accessible way to manage and support electrical cables. Their modular design allows for flexible installation, making them suitable for both large and small projects. Cable trays help keep cables organized, prevent overheating, and provide easy access for maintenance and future upgrades.

Other common cable management solutions include conduits, raceways, and cable ties. Conduits provide additional protection for cables, especially in areas where cables are exposed to physical damage, moisture, or chemicals. Raceways are enclosed systems similar to conduits, but they are often used in smaller installations. Cable ties are used for bundling and securing cables in place, often within a tray or raceway system.

While all of these solutions have their applications, cable trays remain the most widely used for managing large volumes of cables in complex electrical systems, particularly in commercial and industrial settings.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.