The density of FRP pipes, lightweight benefits are crucial factors in choosing the right density of FRP pipe. FRP (Fiber Reinforced Plastic) pipes are composite materials made from a combination of thermoset resin and fiberglass reinforcement. These pipes are widely used in industries such as chemical processing, oil and gas, and water treatment due to their corrosion resistance, strength, and lightweight properties. When considering FRP vs Steel Pipe, FRP offers notable advantages in terms of weight, as it is significantly lighter than steel, making it easier to transport and install. Additionally, FRP pipes are more resistant to corrosion, offering a longer service life, especially in harsh environments, whereas steel pipes are more susceptible to rust and deterioration. The density of FRP pipe plays a crucial role in its overall performance, influencing factors like strength, durability, and ease of installation. Lower density typically makes the pipes easier to transport and install, while still providing the necessary structural integrity for industrial applications. Density of FRP pipe (1.8 g/cm³), thermal properties, and standards guide for DIN-compliant piping systems. The density of FRP pipe is a key consideration for engineers when selecting the right pipe for specific environments and pressure conditions.

What is the Density of FRP Pipe

The density of FRP pipe is a critical factor when selecting materials for industrial applications. FRP, or fiberglass-reinforced plastic, combines the strength of glass fibers with the lightweight nature of plastic, creating a highly durable and corrosion-resistant pipe solution. Understanding the density of FRP pipe helps engineers and technicians select the right type of pipe for specific applications, ensuring that performance standards are met while reducing the overall weight and cost of the project. GangLong Fiberglass offers a wide range of FRP pipe designed to meet the specific density and performance requirements of various industries.

The Composition and Structure of FRP Pipe

FRP pipes are composed of a matrix of fiberglass and resin, typically using polyester, vinyl ester, or epoxy resins. The density of FRP pipe is directly related to the ratio of these materials used during the manufacturing process. A higher concentration of fiberglass results in increased strength and rigidity, while the resin provides the necessary bonding and corrosion resistance. The overall density of FRP pipe can vary depending on the thickness of the pipe walls and the specific type of resin and fiberglass combination used.

At GangLong Fiberglass, FRP pipes are manufactured to offer the perfect balance of density, strength, and weight for demanding applications. These pipes are often used in environments where weight savings are essential, such as in offshore platforms or large-scale chemical plants. The density of the pipe is a significant factor in determining its load-bearing capabilities and resistance to environmental stressors.

How the Density of FRP Pipe Affects Performance

The density of FRP pipe has a direct impact on its performance in industrial and commercial applications. In general, a higher-density pipe will offer greater strength and durability, making it ideal for high-pressure or heavy-duty applications. However, this increase in density also results in a heavier pipe, which can influence installation and handling costs. Lower-density FRP pipes are lighter, making them easier to transport and install, but they may not offer the same level of strength as higher-density options.

GangLong Fiberglass manufactures pipes with a range of densities, allowing for flexibility in applications. For instance, in chemical processing plants, where exposure to aggressive chemicals is common, higher-density FRP pipes provide the necessary protection and durability. Conversely, in water treatment systems, where weight reduction and ease of installation are prioritized, a lower-density FRP pipe may be preferred.

The ability to customize the density of FRP pipes ensures that engineers can select the right pipe for the job, balancing weight, strength, and cost. At GangLong Fiberglass, every FRP pipe is designed with these considerations in mind, ensuring maximum performance under specific conditions.

The key factors influencing frp pipe life expectancy

Factors Influencing the Density of FRP Pipe

Key Factors

Type of Resin Matrix

The type of resin used in the matrix significantly affects the density of FRP pipes. Polyester resins, typically used for general applications, have lower density compared to vinyl ester and epoxy resins. Vinyl ester resins offer superior resistance to chemicals, heat, and corrosion, resulting in slightly higher density. Epoxy resins, known for their excellent mechanical properties, have the highest density among common resins and are used for high-performance FRP pipes in demanding applications.

Type of Reinforcement Material

The reinforcement material used in FRP pipes directly influences their density. Glass fiber, the most common reinforcement, is denser than other fibers, providing strength and durability. Carbon fiber, used in specialized applications, has lower density but is more expensive. Aramid fibers have a high strength-to-weight ratio and a density lower than glass fiber but higher than carbon fiber. The fiber-to-resin ratio also affects density: a higher fiber content generally increases the density of the pipe.

Manufacturing Process

The manufacturing process plays a crucial role in determining the density of FRP pipes. Methods such as filament winding and pultrusion provide precise control over fiber orientation and density. Pultruded pipes tend to have uniform density and higher fiber content. In contrast, hand lay-up and spray-up processes may result in lower fiber-to-resin ratios, reducing the overall density. The method used can impact the material composition and density of the finished product.

Additives and Fillers

Additives and fillers can slightly alter the density of FRP pipes. Fire retardants increase the material’s density by enhancing fire resistance. Mineral fillers, like silica or calcium carbonate, improve mechanical properties but can also raise the density. Pigments and colorants typically have a minor effect on the density. The type and quantity of additives or fillers used will influence the final density and performance characteristics of the pipes.

Curing Process

The curing process, which involves hardening the resin, also affects the density of FRP pipes. Proper curing ensures maximum strength and dimensional stability. Incomplete curing can result in a lower-density material, while over-curing may cause brittleness and alter the density. The curing process must be carefully controlled to achieve the desired properties of the FRP pipe.

Environmental Factors

Temperature and humidity can cause slight changes in the density of FRP pipes over time. FRP materials may expand or contract with temperature fluctuations, leading to minor density variations. While water absorption can increase the density slightly in humid environments, most FRP materials are resistant to water absorption, making this a minor factor in most applications.

Pipe Diameter and Wall Thickness

The diameter and wall thickness of FRP pipes also affect their overall density. Larger diameter pipes or those with thicker walls have a higher apparent density, even if the material density remains unchanged. The ratio of the pipe’s volume to surface area influences its weight and overall density, with thicker walls increasing the mass and strength of the pipe, making it more resistant to internal pressure and external forces.

How the Density of FRP Pipe Affects Installation

The density of FRP pipe not only influences its performance but also impacts the installation process. Higher-density pipes are typically heavier and may require additional support during installation, particularly in long runs or elevated installations. However, due to their strength and durability, higher-density pipes may reduce the need for frequent maintenance or replacement, offering long-term cost savings.

On the other hand, lower-density FRP pipes are much lighter, making them easier to handle and install. This reduces labor costs and the need for heavy machinery during installation. In environments where quick installation is essential, such as emergency repairs or large-scale projects, lower-density FRP pipes from GangLong Fiberglass provide a practical and efficient solution. Despite their lower weight, these pipes maintain the necessary strength to function effectively in many industrial applications.

FRP Pipe Size Chart and Density Impact

FRP pipe sizes are categorized based on outer diameter (O.D.), which is one of the key factors in determining pipe performance. The larger the outer diameter, the thicker the walls, and the denser the pipe. Understanding how pipe size and density work together helps engineers make informed decisions about the type of pipe needed for specific projects.

For example, pipes with a smaller O.D. and lower density are ideal for applications where flexibility and ease of installation are paramount, such as in HVAC systems or small-scale water distribution networks. Conversely, pipes with a larger O.D. and higher density are suitable for high-pressure environments, such as chemical transport lines or oil pipelines.

GangLong Fiberglass offers a variety of FRP pipe sizes, ensuring that each application can be matched with the appropriate pipe. For specific needs, such as using ppr frp pipe in applications requiring enhanced strength and chemical resistance, GangLong provides tailored solutions to meet industry demands.When selecting FRP pipes, it is essential to consider both the size and the density to ensure that the pipe will perform as expected under the specific conditions it will face.

Choosing the Right Density of FRP Pipe for Your Application

Choosing the right density of FRP pipe is crucial for ensuring optimal performance, durability, and cost-effectiveness. Several factors influence this decision, including the type of fluid being transported, the operating temperature and pressure, and the environmental conditions. Below is a guide to help determine the appropriate FRP pipe density for different applications.

Mechanical and Structural Requirements

Higher-density FRP pipes are ideal for high-pressure and heavy-duty applications due to their increased strength and rigidity. These pipes, reinforced with more fiberglass or carbon fiber, resist deformation and damage under stress. In contrast, lower-density pipes are better for moderate pressure and applications requiring more flexibility. Higher-density pipes excel in oil and gas pipelines, chemical processing, and heavy industrial environments where mechanical loads are significant.

Weight Considerations

Lightweight FRP pipes are crucial in industries like transportation, aerospace, and marine, where reducing system weight lowers transportation costs and simplifies installation. Lower-density pipes are easier to handle and install, reducing labor costs. However, higher-density pipes, while heavier, provide more strength and rigidity, making them ideal for heavy industrial applications where a solid, durable structure is necessary.

Chemical and Environmental Resistance

The density of FRP pipes impacts their resistance to environmental factors such as chemical corrosion and UV degradation. Higher-density pipes, made from resins like vinyl ester or epoxy, offer superior protection against harsh chemicals and environmental degradation. These pipes are suitable for chemical processing or marine environments, ensuring long-term durability. Lower-density pipes may be sufficient for less aggressive conditions but may need more maintenance in harsh environments.

Cost Efficiency and Budget Constraints

Higher-density FRP pipes are more expensive due to additional resin and fiber reinforcement. Lower-density pipes, made with polyester resin and glass fibers, are more affordable and suitable for applications with less demanding strength requirements. However, higher-density pipes offer long-term savings by providing superior performance, lower maintenance, and extended service life, especially for critical infrastructure where reliability is crucial.

Specific Application Requirements

Different industries require specific FRP pipe densities. Water and wastewater systems benefit from medium-density pipes with glass fiber for strength and corrosion resistance. The oil and gas industry needs high-density, carbon fiber-reinforced pipes to withstand high pressures and chemicals. Marine applications require pipes that resist saltwater corrosion, while agriculture uses lower-density pipes for cost-effective, durable irrigation solutions.

Temperature and Thermal Properties

High-density FRP pipes are better for high-temperature applications due to their improved thermal stability. For systems dealing with elevated temperatures, such as geothermal or industrial processes, pipes made with high-density resins like epoxy or aramid provide superior heat resistance. These pipes also experience less thermal expansion, ensuring stability in environments with significant temperature fluctuations, enhancing long-term performance.

Importance of FRP Pipe Span Charts in Industrial Piping

Density of High Temperature Resistant FRP Pipe

The density of high-temperature resistant FRP (Fiber Reinforced Polymer) pipes is influenced by the materials chosen for both the resin matrix and the reinforcement fibers. These pipes are specifically designed to withstand elevated temperatures without losing their structural integrity, mechanical properties, or resistance to environmental degradation. Below is a detailed overview of the factors that influence the density of high-temperature resistant FRP pipes:

Resin Matrix for High-Temperature Applications

The choice of resin in high-temperature resistant FRP pipes is a critical factor in determining their density. The resin matrix not only provides the structural framework for the pipe but also defines its thermal stability and chemical resistance at elevated temperatures.

- Epoxy Resin: Epoxy resins are commonly used for high-temperature applications because they offer superior thermal stability, resistance to chemicals, and low shrinkage. Epoxy-based FRP pipes typically have higher densities compared to polyester or vinyl ester pipes, due to the resin’s inherent chemical structure. The density of epoxy resin is typically around 1.1 to 1.2 g/cm³.

- Vinyl Ester Resin: Vinyl ester resins offer good thermal resistance and chemical stability, making them suitable for applications in moderately high-temperature environments (up to approximately 150°C or 300°F). While vinyl ester resins have a slightly lower density compared to epoxy resins, they are still denser than polyester. Vinyl ester resins typically have a density of about 1.1 to 1.3 g/cm³.

- Phenolic Resin: For extremely high-temperature applications (above 200°C or 392°F), phenolic resins can be used. These resins are known for their excellent thermal stability and resistance to heat degradation. Phenolic resin-based FRP pipes tend to have a density in the range of 1.3 to 1.4 g/cm³.

Reinforcement Materials

The type of reinforcement material used in FRP pipes significantly affects the density, as the reinforcement fibers make up a large portion of the pipe’s composition. For high-temperature applications, the choice of reinforcement material is often based on both mechanical strength and thermal properties.

- Carbon Fiber: Carbon fiber is commonly used in high-temperature FRP pipes because it can withstand very high temperatures (up to approximately 300°C or 572°F) without losing its strength. It also has a lower density than glass fiber. The density of carbon fiber is typically around 1.6 to 1.8 g/cm³, which is lower than that of glass fibers. Using carbon fiber in FRP pipes can reduce the overall density while maintaining strength at high temperatures.

- Glass Fiber: Glass fiber is the most common reinforcement used in FRP pipes. The density of glass fiber itself is approximately 2.5 g/cm³, and while it is denser than carbon fiber, it is still relatively lightweight compared to metal materials. Glass fiber reinforcement is suitable for high temperatures, but its upper temperature tolerance is generally lower than carbon fiber, often around 120°C to 180°C (248°F to 356°F).

- Aramid Fiber : Aramid fibers offer excellent thermal stability and resistance to impact and fatigue, though they are less commonly used in high-temperature FRP pipes. The density of aramid fiber is typically 1.44 g/cm³, making it lighter than glass fiber and suitable for applications that require a combination of strength and lightweight properties.

Pipe Wall Thickness

The density of an FRP pipe is also affected by its wall thickness, as thicker pipes require more material (both resin and reinforcement fibers). A thicker pipe wall will naturally increase the overall mass and density of the pipe, regardless of the resin or reinforcement type used. In high-temperature applications, thicker walls may be required for pipes to withstand greater internal pressure and mechanical stresses at elevated temperatures, which can lead to an increase in the overall density of the pipe.

Additives and Fillers

In high-temperature resistant FRP pipes, specific additives and fillers are often incorporated to enhance performance at elevated temperatures. These may include:

- Fire Retardants: High-temperature resistant FRP pipes often contain fire retardants to improve safety and prevent combustion. These fire retardants can increase the pipe’s density, but they also improve its fire resistance. Common fire retardants might include halogenated compounds or aluminum hydroxide.

- Thermal Stabilizers: Additives that improve thermal stability can also be included in high-temperature FRP pipes. These stabilizers typically do not significantly alter the density but ensure the resin matrix maintains its properties at elevated temperatures.

For example, silica or calcium carbonate can be added as fillers to increase the material’s heat resistance or improve its mechanical properties. However, these fillers often result in an increase in the overall density of the pipe.

Temperature Resistance and Pipe Density

High-temperature resistant FRP pipes are designed to perform well under elevated temperatures, typically ranging from 150°C to 250°C (300°F to 482°F), depending on the resin and reinforcement materials used. The density of these pipes plays an essential role in ensuring they can maintain their structural integrity under such conditions. Generally:

- Higher-Density Pipes: Higher-density pipes made with epoxy or phenolic resins and reinforced with glass or carbon fibers tend to offer superior thermal stability. They are more capable of withstanding high temperatures, ensuring the pipe does not warp, crack, or degrade over time.

- Lower-Density Pipes: While still offering resistance to heat, lower-density pipes may not perform as well in extreme high-temperature applications. These pipes are usually better suited for lower temperature ranges or applications where weight reduction is a priority over maximum heat resistance.

Typical Density Range for High-Temperature Resistant FRP Pipes

For high-temperature resistant FRP pipes, the density range generally falls between 1.2 g/cm³ and 1.6 g/cm³, depending on the specific materials used:

- Epoxy-based FRP Pipes: Around 1.2 to 1.4 g/cm³.

- Vinyl Ester-based FRP Pipes: Around 1.1 to 1.3 g/cm³.

- Phenolic Resin-based FRP Pipes: Around 1.3 to 1.4 g/cm³.

- Carbon Fiber Reinforced FRP Pipes: Around 1.6 to 1.8 g/cm³.

In high-temperature applications, the density of FRP pipes is primarily determined by the choice of resin matrix, reinforcement fibers, and any additives or fillers included to enhance thermal resistance. Higher-density FRP pipes, typically made with epoxy or phenolic resins and reinforced with glass or carbon fibers, are ideal for extreme temperature environments. When selecting high-temperature resistant FRP pipes, it is important to balance the desired thermal performance, mechanical strength, weight considerations, and cost. By carefully choosing the right materials and pipe specifications, you can ensure that the FRP pipe meets both the temperature requirements and the overall performance needs of the application.

Calculating Density of FRP Pipe

Calculating the density of a Fiber Reinforced Polymer (FRP) pipe involves understanding the individual densities of the components that make up the pipe — primarily the resin matrix and the reinforcement fibers — as well as their respective proportions within the pipe. Here’s a step-by-step guide on how to calculate the density of an FRP pipe:

Understand the Components of the FRP Pipe

An FRP pipe is typically composed of:

- Resin Matrix: This is the polymer material that binds the fibers together. Common resins include polyester, vinyl ester, and epoxy.

- Reinforcement Fibers: These are the materials that provide strength and stiffness to the pipe. The most common fibers are glass fibers, carbon fibers, and aramid fibers.

The overall density of the FRP pipe depends on the volume fraction of the resin and fiber, as well as their individual densities.

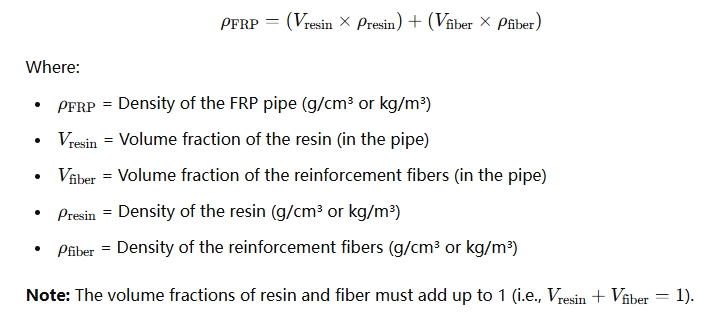

Formula for Density of the FRP Pipe

The density of the FRP pipe is the weighted average of the densities of the resin and reinforcement fibers, based on their volume fractions in the pipe. The formula can be expressed as:

Step-by-Step Calculation Process

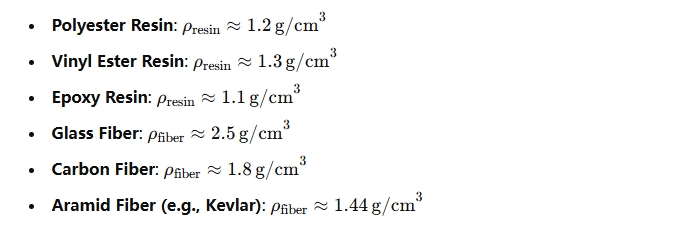

Step 1: Identify the Densities of the Components

You need the density values of the resin and the reinforcement fibers. For example:

Step 2: Determine the Volume Fractions of the Resin and Fiber

The volume fractions (Vresin and Vfiber) depend on the fiber-to-resin ratio in the FRP pipe. This is usually specified by the manufacturer or determined through the pipe’s design specifications. For example:

- Fiber Volume Fraction: Vfiber=0.30 (meaning 30% of the pipe’s volume is made up of fiber).

- Resin Volume Fraction: Vresin=0.70 (meaning 70% of the pipe’s volume is made up of resin).

Step 3: Apply the Formula

Now you can apply the formula for the density of the FRP pipe. Let’s use the following example:

- Resin: Epoxy resin with a density of 1.1 g/cm3

- Fiber: Glass fiber with a density of 2.5 g/cm3

- Volume Fractions: Vresin=0.70, Vfiber=0.30

The calculation for the density of the FRP pipe would be:

ρFRP=(0.70×1.1)+(0.30×2.5)

ρFRP=0.77+0.75=1.52 g/cm3

So, the density of this FRP pipe would be 1.52 g/cm³.

Considerations for Accurate Calculation

- Fiber-to-Resin Ratio: The fiber-to-resin ratio can vary depending on the pipe’s design and intended use. Higher fiber content generally results in a stronger but denser pipe.

- Material Type: The type of resin and fiber affects both the performance and the density. Epoxy and carbon fibers typically provide better mechanical properties but result in a higher density.

- Wall Thickness: The thickness of the FRP pipe walls will influence the total volume of material, affecting the mass and density. However, the density calculation itself is primarily concerned with the material composition rather than geometry.

Density of FRP Pipes with Multiple Layers

In some cases, FRP pipes may be made with multiple layers, such as a combination of internal and external resin layers with different fiber reinforcements. For these cases, you would calculate the density for each layer separately, taking into account the specific fiber-to-resin ratio in each layer, and then find the overall density of the pipe as a weighted average based on the volume of each layer.

For example:

- Layer 1 (Outer Layer): Epoxy resin with glass fiber reinforcement

- Layer 2 (Inner Layer): Polyester resin with carbon fiber reinforcement

You would calculate the density of each layer individually and then combine them using the same weighted average formula based on their respective volumes.

To calculate the density of an FRP pipe, you need to know the densities of the resin and fiber materials, as well as their respective volume fractions in the pipe. The formula involves a weighted average calculation based on the relative proportions of resin and fiber. This calculation allows you to determine the overall density of the FRP pipe, which is crucial for understanding its strength, weight, and suitability for various applications.

Characteristics of FRP Pipe

FRP (Fiber Reinforced Plastic) pipes are a versatile and high-performance solution widely used in industries ranging from aerospace to chemical processing. One of the key features of FRP pipes is their low density of FRP pipe, typically ranging from 1.5 to 2.0, making them significantly lighter than traditional materials like carbon steel. Despite their lightweight nature, FRP pipes offer impressive strength properties, making them a superior choice for applications that require both durability and weight reduction. Their excellent corrosion resistance, electrical and thermal properties, and design flexibility further enhance their appeal, making them ideal for a variety of demanding applications.

Light Weight and High Strength

FRP pipes are lightweight, with a relative density of 1.5 to 2.0, making them 1/4 to 1/5 the weight of carbon steel. Despite being lighter, they match or even exceed carbon steel’s tensile strength. This high specific strength makes FRP pipes ideal for applications in aerospace, rockets, spacecraft, and high-pressure vessels where weight reduction is critical. Epoxy FRPs can achieve tensile and compressive strengths over 400 MPa, demonstrating their high-performance capability.

Good Corrosion Resistance

FRP pipes are highly resistant to corrosion, outperforming traditional materials such as carbon steel, stainless steel, and wood. They can withstand exposure to various aggressive substances like acids, bases, salts, oils, and solvents. This makes them ideal for environments where corrosion resistance is essential, particularly in chemical processing plants. The material’s durability under harsh conditions ensures a longer lifespan, reducing maintenance costs and enhancing reliability in many industries, from chemical processing to water treatment.

Good Electrical Properties

FRP pipes are excellent electrical insulators, making them suitable for use in electrical applications. Their dielectric properties remain stable even at high frequencies, which is essential for high-frequency systems such as radar antennas. This makes FRP pipes a popular choice in electronics and telecommunications industries where reliable insulation is crucial. They help prevent electrical losses and interference, offering secure and efficient transmission, particularly in microwave and high-frequency communication systems.

Good Thermal Performance

FRP pipes have low thermal conductivity, making them highly efficient as thermal insulators. With thermal conductivity values of 1.5 to 1.67 kJ/(m·h·K) at room temperature, they are significantly better insulators than metals. FRP pipes also perform well in high-temperature environments, making them suitable for thermal protection in aerospace applications. They can withstand extreme temperatures up to 2000°C, providing essential protection for spacecraft during re-entry and resisting the effects of high-speed air scouring.

Flexible Design Options

FRP pipes offer exceptional design flexibility, allowing manufacturers to meet a wide range of structural and performance requirements. They can be tailored to specific needs, such as high strength in certain directions, excellent dielectric properties, or resistance to high temperatures and corrosive environments. This versatility ensures that FRP pipes are suitable for various applications, from industrial processes to specialized aerospace projects. Customizing FRP pipes for performance and durability enables their use in unique and demanding environments.

Excellent Workmanship

FRP pipes can be easily molded into complex shapes, making them an ideal choice for applications that require intricate designs. The molding process is flexible, allowing manufacturers to choose the most suitable method based on the product’s shape, technical requirements, and production volume. FRP pipes can be molded in one step, offering economic advantages, especially for small production runs. This capability allows for cost-effective manufacturing of high-performance pipes with complex geometries, providing significant technological advantages in various industries.

Applicable Standards for FRP Pipes, Fittings, and Joints

Fiberglass-reinforced plastic (FRP) pipes are widely used in industrial applications due to their high strength-to-weight ratio, corrosion resistance, and durability. The density of FRP pipe typically ranges from 1.5 to 2.0 g/cm³, making it significantly lighter than traditional metal piping systems while maintaining comparable structural performance. To ensure reliability, international standards such as BS 6464, ASTM D2996, ASTM D3517, and others establish rigorous requirements for design, materials, and testing. These standards specifically account for the density of FRP pipe and its implications on pressure ratings, installation methods, and long-term performance in various operating environments. Below is a detailed overview of the key standards governing FRP piping systems.

BS 6464

BS 6464 is a British Standard that specifies the requirements for reinforced plastic pipes, fittings, and joints used in process plants. This standard addresses the design, installation, and maintenance of these systems to ensure that they are reliable and meet safety requirements. It focuses on the material properties, performance under pressure, and durability of FRP piping systems. The standard provides detailed guidelines on testing and certification processes to ensure that FRP pipes and fittings maintain their structural integrity in various industrial environments.

41-GP-22

41-GP-22 is a Canadian standard that applies to reinforced polyester process equipment, including fiberglass-reinforced thermosetting resin pipes and fittings. It provides a framework for ensuring that these components are suitable for use in demanding process plant environments. The standard emphasizes performance criteria such as resistance to chemical corrosion, strength under high pressure, and thermal stability. It also outlines testing methods to verify the suitability of the materials for process applications, ensuring that FRP components comply with industry regulations and safety standards.

ASTM D2996

ASTM D2996 is an important standard that outlines the specifications for filament-wound fiberglass pipes. These pipes are commonly used in applications that require high strength, chemical resistance, and durability. This standard provides requirements for the design, materials, and construction methods used in manufacturing filament-wound FRP pipes. It includes specific guidelines on the allowable stress, pressure ratings, and environmental performance of these pipes. The standard also addresses the required testing procedures to ensure the pipes meet industry needs, particularly in terms of long-term reliability and safety under various operating conditions.

ASTM D2997

ASTM D2997 provides specifications for centrifugally cast fiberglass pipes, which are manufactured by using centrifugal forces to form uniform, high-strength pipes. This method of production ensures that the pipes have excellent mechanical properties and structural integrity. The standard covers all aspects of centrifugally cast FRP pipe construction, including the materials used, the manufacturing process, and the performance characteristics. It includes requirements for pressure ratings, durability, and testing methods to verify the strength and stability of these pipes in demanding industrial settings.

ASTM D1599

ASTM D1599 is a standard test method for determining the resistance of plastic pipes, tubing, and fittings to short-time hydraulic failure pressure. This test is crucial for ensuring that FRP pipes and related components can withstand high-pressure conditions without failure. The standard provides detailed procedures for performing the test and specifies the conditions under which the tests should be conducted. It also includes performance criteria to help manufacturers verify the durability and safety of FRP pipes in applications where pressure fluctuations or high-pressure environments are expected.

ASTM D5421

ASTM D5421 specifies the requirements for contact-molded fiberglass flanges, which are commonly used in industrial piping systems. This standard ensures that the flanges are manufactured to withstand harsh environments, including high temperatures, corrosive substances, and mechanical stresses. The specification covers the materials, design, and performance of these flanges, including pressure ratings and dimensional tolerances. Additionally, the standard outlines the testing methods used to evaluate the mechanical strength and durability of the flanges, ensuring they provide secure and reliable connections within FRP piping systems.

ASTM D3517

ASTM D3517 is the standard specification for fiberglass pressure pipes. It focuses on the performance and specifications of pipes that are designed to withstand high-pressure environments. The standard covers the materials used, the construction methods, and the performance criteria for these pipes, which are essential for industries such as oil and gas, water treatment, and chemical processing. It includes requirements for pressure ratings, tensile strength, and resistance to environmental factors. The standard also specifies the required testing procedures to ensure that the pipes can handle the demands of high-pressure applications.

ASTM D5685

ASTM D5685 provides specifications for fiberglass pressure pipe fittings, which are integral components in any FRP piping system. This standard ensures that the fittings are manufactured to meet the same performance and durability criteria as the pipes themselves. The specification outlines the materials, dimensions, and pressure ratings of these fittings, as well as the methods used to test their strength and integrity. It ensures that the fittings can maintain a secure and leak-free connection in high-pressure systems, making them suitable for a wide range of industrial applications.

ASTM D4024

ASTM D4024 outlines the specifications for machine-made fiberglass flanges. These flanges are critical components in connecting various sections of FRP piping systems. The standard includes detailed requirements for the materials, design, and manufacturing process of machine-made flanges, ensuring that they can withstand the pressures and stresses common in industrial environments. It also covers the testing procedures used to verify the strength and durability of the flanges, ensuring that they provide reliable connections in piping systems exposed to mechanical stress, temperature fluctuations, and corrosive environments.

The Key of Density of FRP Pipe in Engineering Applications

Fiber Reinforced Plastic (FRP) pipes are widely recognized for their strength, corrosion resistance, and versatility in various industries. A key factor that contributes to the performance of these pipes is the density of FRP pipe, which directly impacts several critical aspects of its application, such as strength, flexibility, and resistance to environmental factors. The understanding of how density interacts with the material properties of FRP pipes is crucial for engineers designing systems where these pipes are used, including chemical processing, water treatment, and oil and gas industries. The density of FRP pipe is not only a measure of its physical weight but also plays a vital role in determining its durability and long-term performance under different operational conditions.

The Importance of Density in FRP Pipe Performance

The density of FRP pipe is a critical factor in determining its performance across various applications. It directly impacts several key characteristics, including strength, durability, weight, and flexibility. While lower-density pipes provide advantages in terms of ease of handling and transportation, the density must be carefully optimized to ensure the pipe can withstand operational pressures and environmental conditions.

Strength and Durability

The density of an FRP pipe is closely linked to its strength and durability. Higher-density FRP pipes typically contain a greater proportion of fiberglass reinforcement, increasing their ability to withstand higher pressures and mechanical stress. These pipes are more suited to applications that require high strength, such as industrial settings with demanding conditions. Conversely, lower-density pipes, though still strong, are better suited to applications with moderate pressure demands and less mechanical stress. Additionally, the density influences how well the pipes resist aggressive environmental factors like corrosive chemicals.

Flexibility and Weight

FRP pipes are known for their lightweight nature compared to traditional metal pipes. The density of FRP pipe directly affects this characteristic, making it easier to transport and install. While weight reduction provides handling benefits, it must be balanced with the need for flexibility. Lower-density pipes generally offer increased flexibility, making them ideal for applications requiring movement or vibration accommodation. On the other hand, higher-density pipes tend to be stiffer, making them more suitable for applications that demand a more rigid structure.

Pressure Handling and Resistance

The density of FRP pipe is crucial in determining its ability to handle internal and external pressures. Higher-density FRP pipes are better equipped to withstand high-pressure environments, such as those found in oil and gas pipelines or chemical processing systems. Their increased density provides added resistance to leaks, ruptures, and deformation under pressure. Lower-density pipes, while still capable of handling moderate pressures, are better suited for applications like drainage systems or low-pressure water transport, where the demands on the pipes are less severe.

Environmental Resistance

FRP pipes are known for their excellent resistance to environmental factors such as corrosion, UV exposure, and chemical degradation. The density of FRP pipe plays a role in enhancing its resistance to these environmental stressors. Higher-density pipes often include additional protective layers, such as thicker resin coatings or more densely packed fiberglass, which provide superior protection against external damage. Lower-density pipes, while still offering some environmental resistance, may not be as durable in harsh conditions and may require more frequent maintenance or replacement.

FRP Pipe Specifications and Density

The specifications of an FRP pipe, such as its diameter, wall thickness, and pressure rating, are all influenced by its density. Engineers and designers must carefully select the right specifications to ensure the pipe performs optimally in its intended environment. The density of FRP pipe affects the wall thickness and the overall strength of the pipe, which in turn determines its ability to handle pressure and external forces.

Resin and Fiber Selection

The selection of resin and fiberglass used in manufacturing FRP pipes directly impacts their density. Different types of resin, such as epoxy or vinyl ester, have varying densities and offer different levels of chemical resistance and flexibility. Similarly, the type and arrangement of fiberglass reinforcement, whether it’s continuous roving, woven fabrics, or chopped strand mat, will influence the pipe’s density and strength. Engineers must consider the specific requirements of the application, such as chemical exposure and temperature fluctuations, when determining the appropriate combination of resin and fiber.

Customizable Density for Specific Applications

One of the advantages of FRP pipes is that their density can be customized to meet the needs of specific applications. For instance, pipes designed for high-pressure environments, such as oil pipelines, will typically have a higher density to ensure they can withstand the operational stresses. Conversely, pipes used in less demanding environments, such as water treatment plants, may have a lower density to reduce weight and installation costs while still providing adequate performance.

FRP Pipe Dimensions and Weight

The dimensions of FRP pipes, including their outer diameter (O.D.), wall thickness, and length, are essential factors in determining their weight. The density of FRP pipe is a key element in calculating its weight per meter, which is critical when considering transportation, handling, and installation.

Weight per Meter

The weight of an FRP pipe is typically measured per meter, and the density of the material is the main factor influencing this calculation. Lower-density pipes will weigh less per meter, making them easier to install and reducing the overall cost of transportation. However, engineers must ensure that the reduced weight does not compromise the pipe’s ability to handle operational pressures.

Installation Considerations

When installing FRP pipes, the weight of the material plays a significant role in determining the methods and equipment required. Lightweight pipes can often be installed manually or with minimal equipment, reducing labor costs and speeding up the installation process. Heavier pipes, on the other hand, may require specialized equipment or additional labor, especially in high-pressure systems or in installations that require precise alignment.

FRP Pipe Pressure Rating and Density

The pressure rating of an FRP pipe is a measure of how much internal pressure the pipe can withstand without failing. Understanding the frp pipe pressure rating is crucial for ensuring that the selected pipe can handle the operational demands of the system, particularly in high-pressure environments.The density of FRP pipe directly influences its pressure rating, with higher-density pipes generally being able to handle greater pressures.

Internal and External Pressures

FRP pipes must be designed to handle both internal and external pressures. Internal pressures come from the fluids or gases being transported through the pipe, while external pressures may be exerted by the surrounding environment. Higher-density FRP pipes, due to their greater structural integrity, are better equipped to manage these pressures without deforming or failing. In applications like oil and gas pipelines, where pressure fluctuations can be significant, selecting the appropriate pipe density is critical to ensuring long-term performance.

Pressure Testing and Safety Factors

Before installation, FRP pipes undergo pressure testing to determine their maximum pressure capacity. The results of these tests are heavily influenced by the density of the pipe, which dictates its overall strength. Engineers also incorporate safety factors when selecting the appropriate pressure rating for a specific application. These safety factors account for variations in material density and the potential for degradation over time due to environmental factors.

How Resin Types Impact FRP Pipe Tensile Strength

FAQs about Density of Frp Pipe

The density of FRP (Fiber Reinforced Plastic) typically ranges between 1.5 to 2.0 grams per cubic centimeter (g/cm³), depending on the specific resin and fiberglass reinforcement used. This relatively low density, compared to traditional materials like steel or concrete, makes FRP an ideal material for applications where weight is a significant factor. Despite its lightweight nature, FRP maintains high strength and durability, which allows it to perform well in environments that are prone to corrosion, chemical exposure, or high stress. The combination of low density and high performance is one of the key reasons FRP is used extensively in industries such as oil and gas, water treatment, and chemical processing, where lightweight, strong materials are necessary to improve operational efficiency and reduce maintenance costs.

GRP (Glass Reinforced Plastic) pipe typically has a density in the range of 1.8 to 2.1 grams per cubic centimeter (g/cm³). The density of GRP pipes can vary slightly depending on the resin type and the ratio of glass fibers to resin in the composite structure. GRP is valued for its lightweight properties combined with high strength, making it a popular choice for industries that require corrosion-resistant and durable piping systems. The relatively low density of GRP pipes also helps in reducing transportation and installation costs, as they are easier to handle than traditional materials like metal or concrete. GRP pipes are commonly used in chemical processing, water treatment, and marine applications, where resistance to harsh environments is crucial. This makes GRP an effective solution in projects where reducing weight without sacrificing performance is essential.

The weight of FRP (Fiber Reinforced Plastic) material varies depending on the specific type of resin and the proportion of fiberglass used in the composite. On average, FRP materials have a weight range of 1.5 to 2.0 kilograms per cubic meter. This makes FRP significantly lighter than many traditional materials such as steel, which weighs around 7.8 kilograms per cubic meter, or aluminum, which weighs about 2.7 kilograms per cubic meter. Despite its lighter weight, FRP offers superior strength and resilience, which makes it highly suitable for applications in industries where weight reduction is important, such as aerospace, automotive, marine, and construction. FRP’s lightweight nature also makes transportation and installation easier, reducing overall project costs while maintaining high performance in demanding environments.

The density of a fiberglass pipe typically ranges from 1.5 to 2.0 g/cm³ (1500 to 2000 kg/m³). This can vary depending on the specific type of fiberglass used and the resin matrix. Fiberglass-reinforced plastic (FRP) pipes are made by embedding glass fibers in a polymer resin, which makes them strong yet relatively lightweight compared to metal pipes. The density of fiberglass pipes is generally lower than that of steel or concrete, which makes them ideal for applications where corrosion resistance and lightweight properties are important.

The weight of Fiberglass Reinforced Plastic (FRP) per cubic foot typically ranges from 90 to 120 pounds per cubic foot (lb/ft³). This is based on the density of FRP, which can vary depending on the specific fiberglass type and resin matrix used. FRP is significantly lighter than metals like steel or aluminum, making it an attractive choice for applications where weight reduction is important, such as in automotive, aerospace, and marine industries.

The mass density of Glass Fiber Reinforced Polymer (GFRP) typically ranges from 1.5 to 2.0 g/cm³ (1500 to 2000 kg/m³). GFRP is composed of glass fibers embedded in a polymer resin matrix. The density can vary based on the fiber content, the type of glass fibers, and the resin used in the composite. This mass density is lower than metals like steel or aluminum, making GFRP a popular material for applications requiring a good balance of strength and lightness, such as structural components in construction, marine, and automotive sectors.

No, FRP (Fiberglass Reinforced Plastic) is generally heavier than carbon fiber. The density of FRP typically ranges from 1.5 to 2.0 g/cm³, while carbon fiber’s density is much lower, around 1.6 to 1.8 g/cm³. While both materials are lightweight compared to metals, carbon fiber is stronger and lighter than fiberglass in most applications, offering higher specific strength and stiffness. However, carbon fiber is more expensive than FRP, making fiberglass a more cost-effective alternative for less demanding applications.

FRP (Fiberglass Reinforced Plastic) is generally lighter than aluminum in terms of weight per volume. Aluminum has a density of around 2.7 g/cm³, while FRP typically ranges from 1.5 to 2.0 g/cm³. This means that FRP can be approximately 40-50% lighter than aluminum by volume. While aluminum is more commonly used in structural and load-bearing applications due to its higher strength, FRP is a good choice for corrosion-resistant, lightweight applications such as marine, automotive, and construction, where lower weight is essential.

No, FRP (Fiberglass Reinforced Plastic) is not lighter than carbon fiber. Carbon fiber is a stronger and lighter material with a lower density, typically ranging from 1.6 to 1.8 g/cm³, whereas FRP typically has a density of 1.5 to 2.0 g/cm³. While FRP offers excellent strength-to-weight ratio at a lower cost than carbon fiber, carbon fiber is superior in performance due to its significantly lower density and higher tensile strength. However, carbon fiber’s higher cost makes FRP a more affordable option for many industrial applications.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.