Splice plate for cable tray: easy-install, 4-bolt design, joins tray sections, multiple variations for secure system connections. A splice plate for cable tray is a key component used to connect two tray sections, ensuring a continuous and stable path for electrical cables. It plays a vital role in maintaining the structural integrity of the system, which is essential for both safety and reliable performance. Typically made from durable materials like steel or aluminum, splice plates are built to withstand mechanical stress and environmental challenges. In some installations, an insert plate for cable tray may also be used to assist with alignment or added support. Splice plates are especially important in industrial, commercial, and residential projects with long cable runs, where they help secure tray joints, prevent cable damage, and ensure smooth cable routing.

Types of Splice Plate for Cable Tray

When selecting the appropriate splice plate for cable tray, especially in ladder systems, it’s crucial to consider the specific requirements of the installation. The right splice plate ensures the stability, safety, and functionality of the cable tray system. Here are the most common types of splice plates, each designed for specific installation needs:

Straight Splice Plates

Straight splice plates are designed to connect two straight sections of a cable tray, providing a seamless, smooth connection. These plates are essential for creating a continuous, uninterrupted pathway for cables. They help ensure that the tray system remains structurally intact and supports cable routing without gaps or misalignments. Straight splice plates are available in a variety of materials, such as steel, aluminum, and stainless steel, allowing for customization based on the installation environment and load requirements. For example, stainless steel plates are commonly used in corrosive environments, while aluminum plates may be selected for lighter-duty applications.

Expansion Splice Plates

Expansion splice plates are specifically designed to accommodate thermal expansion and contraction due to temperature fluctuations. These plates allow for the natural expansion or contraction of the cable tray system, helping to prevent stress and maintain the system’s integrity over time. Expansion splice plates are particularly beneficial in environments with significant temperature changes, such as outdoor installations or industrial settings, where thermal movements could lead to system misalignment or even structural damage. By using expansion splice plates, the cable tray system can adapt to temperature shifts without compromising its function.

Fixed Angle Splice Plates

Fixed angle splice plates are used to connect cable tray sections at predetermined angles, either horizontally or vertically. These plates are perfect for installations that require cables to follow specific routes, such as along walls, ceilings, or around obstacles. When used with the appropriate cable tray cross section, fixed angle splice plates provide a stable and reliable connection between tray sections, ensuring that the cable tray system remains aligned and secure. They are ideal for structured installations where precise direction changes are required, providing a rigid support to maintain the system’s layout and reduce the risk of disconnections or misalignments.

Adjustable Angle Splice Plates

Adjustable angle splice plates offer increased flexibility by allowing the tray sections to be connected at varying angles. This type of splice plate is ideal for complex setups where the routing of cables requires multiple directional changes. Adjustable angle splice plates provide versatility in installations, allowing cable trays to be routed through intricate or tight spaces with ease. These plates are particularly useful in custom cable management layouts, ensuring that the cable tray system can be adapted to fit specific installation challenges without compromising on stability or safety.

Each type of splice plate for cable tray plays a critical role in ensuring the safety, durability, and efficiency of the cable management system. Whether you’re dealing with thermal expansion, tight spaces, or complex routing needs, selecting the right splice plate will ensure that your cable tray system remains functional and reliable throughout its lifespan.

Materials Used for Splice Plate for Cable Tray

The splice plate for cable tray plays a pivotal role in ensuring the structural integrity and safety of the entire cable tray system, particularly in ladder systems, where mechanical strength and stability are critical. The material chosen for the splice plate directly affects its durability, resistance to environmental factors, and ability to handle the stresses imposed on the cable tray system. Below are the most commonly used materials in the construction of splice plates:

Steel

Steel is widely used for splice plates due to its high strength and durability. It’s ideal for industrial environments with heavy cable loads, offering strong resistance to mechanical stress. Steel is cost-effective and reliable in high-wear settings, ensuring long-lasting support for cable trays under significant physical demands.

Stainless Steel

Stainless steel is perfect for corrosive or harsh environments. It provides excellent resistance to moisture, chemicals, and extreme weather. Commonly used in marine, chemical, and outdoor applications, stainless steel ensures a strong and corrosion-resistant connection, maintaining cable tray performance in tough environmental conditions.

Aluminum

Aluminum splice plates are lightweight, affordable, and easy to handle, making them suitable for residential or light commercial use. Though not as strong as steel, aluminum offers reliable support in dry, indoor, or low-stress environments. Its natural corrosion resistance adds to its appeal for simpler installations.

Fiberglass

Fiberglass splice plates are non-conductive and corrosion-resistant, ideal for electrical or hazardous installations. They ensure electrical insulation and long-term durability where exposure to chemicals or moisture is a concern. Commonly used in power plants or chemical facilities, they meet high safety and performance standards.

Features of Splice Plate for Cable Tray

A splice plate for cable tray is designed with several key features to ensure its effectiveness in connecting cable tray sections securely and safely. These features contribute to the overall functionality, ease of installation, and durability of the system. Below are some of the most important features:

Durability

Splice plates offer excellent durability, capable of withstanding vibrations, impacts, and mechanical loads across industrial, commercial, and outdoor settings. They resist temperature fluctuations, moisture, and corrosive chemicals, making them ideal for harsh environments. This resilience ensures long-term structural integrity and dependable function of the performance cable tray system, even in harsh physical and environmental conditions, thereby minimizing maintenance needs over time.

Ease of Installation

Most splice plates come with pre-drilled holes, allowing for quick alignment and secure attachment using standard fasteners such as bolts, screws, or nuts. This feature simplifies the installation process, significantly reducing labor time and associated costs. Whether for a new installation or maintenance work, the ease of handling and straightforward design of the splice plate make it highly efficient and user-friendly for electricians and installers.

Flexibility

Splice plates are available in a wide range of sizes, materials, and configurations, including flat and angled types. This allows them to accommodate various cable tray designs, including horizontal runs, vertical drops, or bends. They can be selected to suit different load requirements and environmental conditions, such as high heat or corrosive exposure, providing a tailored and effective solution for almost any cable management layout.

Safety and Compliance

High-quality splice plates are engineered to meet rigorous industry safety standards and electrical codes, including the National Electrical Code (NEC). Their robust construction minimizes the risk of electrical faults, short circuits, or physical damage to cables. When properly installed, they help ensure safe, efficient cable tray performance while protecting personnel and equipment, and ensuring compliance with all relevant regulations and workplace safety requirements.

What is Expansion Joint Cable Tray Installation

How to Install a Splice Plate for Cable Tray

Installing a splice plate for cable tray is an essential task to ensure the integrity and safety of the cable management system. Proper installation guarantees that the cable tray sections are securely connected, providing a stable pathway for electrical cables. A well-installed splice plate allows for smooth and uninterrupted cable routing, which is crucial for maintaining safety and performance. Below is a detailed step-by-step guide for installing a cable tray connector plate effectively:

Step-by-Step Guide

Preparation

Gather essential tools: a screwdriver or power drill, a wrench, fasteners (bolts, screws, or nuts), and the splice plate. Confirm that the splice plate matches the cable tray’s size and material. For special environments, use suitable materials (e.g., stainless steel for corrosive settings). Double-check all dimensions to ensure a proper fit before beginning the installation.

Aligning Sections

Position the two cable tray sections to be connected. Place the splice plate between them, aligning all edges precisely. Accurate alignment is crucial to prevent issues like cable misrouting or mechanical stress. Adjust the tray sections as needed to ensure the connection is secure and well-balanced before fastening.

Securing the Splice

Use the correct fasteners to attach the splice plate to both tray sections. Tighten them evenly without overtightening to avoid damaging the components. Follow the manufacturer’s guidelines for fastener type and size based on tray material, dimensions, and load requirements. A secure fit ensures a durable and stable tray connection.

Testing

After securing the splice, gently pull on the tray sections to check for stability. The connection should feel firm, without wobble or gaps. If movement occurs, inspect and retighten all fasteners. Testing is vital to ensure the safety and long-term reliability of the cable tray system.

Considerations

Cable Movement and Airflow

When installing the splice plate for cable tray, make sure that the location does not obstruct the free movement of cables or block airflow, especially if your system involves large quantities of cables or requires good ventilation. Adequate airflow helps to prevent overheating, particularly in systems carrying high-voltage or high-current cables.

Space for Expansion

Keep in mind that cable tray systems are often subject to future expansion. When installing the splice plate, leave some space for easy access in case additional tray sections are needed. Position the splice plate in a way that allows flexibility for future modifications or cable expansions.

Environmental Conditions

Consider the installation environment when positioning the splice plate. In environments with fluctuating temperatures, moisture, or harsh chemicals, you may need to use corrosion-resistant materials (such as stainless steel) to ensure long-term reliability.

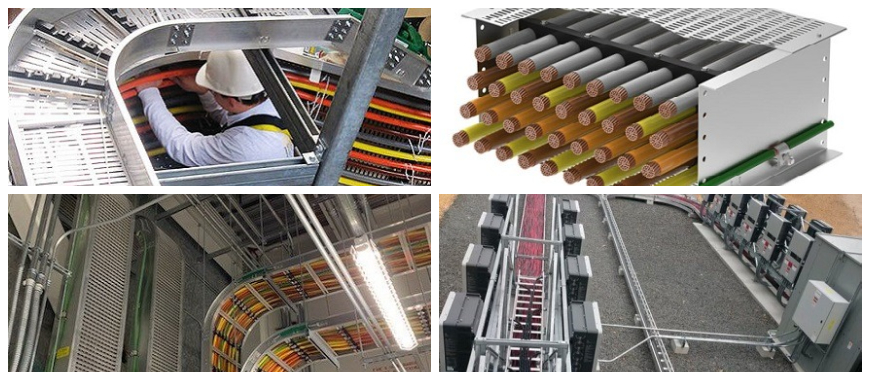

Applications of Splice Plate for Cable Tray Systems

A splice plate for cable tray plays an essential role in connecting different sections of cable trays, ensuring that the cable management system remains secure, stable, and efficient. These splice plates are versatile and widely used across various industries and environments, providing a seamless pathway for electrical cables while maintaining the integrity of the system. Below are some of the key areas where splice plates for cable tray are commonly applied:

Manufacturing and Industrial Facilities

In industrial settings like factories, data centers, and power stations, splice plates for cable tray are essential for connecting tray sections and maintaining system stability. These environments involve complex, large-scale cabling for machinery, control systems, and IT infrastructure. Splice plates prevent tray misalignment, cable sagging, and physical damage. Their high-strength materials withstand temperature changes, mechanical stress, and chemical exposure, ensuring safe and reliable cable routing even in harsh, high-demand operating conditions.

Commercial Buildings and Public Infrastructure

Splice plates for cable tray are widely used in commercial buildings such as offices, malls, hospitals, airports, and schools. These spaces rely on efficient cable routing to support lighting, power, HVAC, security, and communication systems. Splice plates ensure safe, stable connections between tray sections, improving organization and compliance with safety codes. In healthcare environments especially, they help maintain uninterrupted connections for medical equipment and power-critical systems, reducing risks and enhancing system maintainability and reliability.

High-Tech Residential Installations

In larger homes with smart systems, solar panels, or extensive wiring, splice plates for cable tray help manage power, security, and data cables. For example, dedicated cable trays for solar installations (cable tray for solar) ensure that photovoltaic wiring is neatly routed and protected alongside other electrical runs. Though less common in small-scale housing, they are valuable for residential projects involving home automation, multi-room audio, and advanced networking. Splice plates offer expandability, allowing systems to evolve with future electrical needs. Their use helps maintain clean, organized installations and supports safe routing as homeowners upgrade or expand their technology infrastructure over time.

Discover the Latest Cable Tray Splice Plate Price Trends

Benefits of Using Splice Plate for Cable Tray Systems

Integrating a splice plate for cable tray into a cable management system provides multiple advantages. These include improved organization, enhanced safety, cost savings, durability, and future-ready adaptability. Below are the key benefits explained in concise detail.

Organization and Efficiency

A splice plate for cable tray helps keep cable layouts organized by securely joining tray sections. This reduces cable tangling, misrouting, and physical damage. It also simplifies identification, maintenance, and replacement work. For large-scale systems, improved organization means faster troubleshooting and fewer delays, leading to better operational efficiency and time savings.

Safety

Splice plates strengthen the structural integrity of cable trays, preventing misalignments that could lead to loose cables or hazards. By minimizing cable movement and supporting a stable layout, they reduce the risk of short circuits, sparks, and fires. Proper installation also helps meet safety codes and protect cables from mechanical or environmental damage, enhancing workplace safety.

Cost-Effective

Compared to custom fittings, splice plates are a low-cost solution for connecting tray sections. They require minimal tools, lowering installation time and labor costs. When systems expand, splice plates allow for quick reconfiguration without replacing entire trays. This adaptability supports long-term savings and avoids costly structural overhauls in dynamic facilities.

Future-Proofing

As technology advances, cable tray systems must adapt. Splice plates enable easy expansion and rearrangement of tray layouts, reducing the need for system-wide redesigns. Whether adding circuits or upgrading equipment, they support change without disruption. This flexibility ensures the system can grow with evolving demands, delivering ongoing value and scalability.

Enhanced Durability

Splice plates are made from strong materials like steel or aluminum, offering excellent resistance to stress, corrosion, and harsh environments. They maintain tray stability even in areas exposed to temperature extremes or moisture. By reinforcing tray connections, they reduce wear and tear, extend system lifespan, and minimize the need for frequent repairs.

Comprehensive Overview of Cable Tray Splice Plates and Components

In modern cable management systems, maintaining stability, safety, and flexibility is essential. A splice plate for cable tray plays a key role by securely joining tray sections, supporting structural integrity, and enabling system expansion or reconfiguration. Whether used in industrial plants, data centers, or commercial buildings, the right splice plate enhances overall performance and simplifies maintenance. The table below outlines the key features and benefits of various commonly used splice plate types.

| Component | Key Features | Benefits |

|---|---|---|

| Splice Plate for Cable Tray | Secure connections, simple installation, standard materials (steel/aluminum) | Improves organization, enhances safety, cost-effective, durable, future-proof |

| Cable Tray Expansion Splice Plate | Accommodates thermal expansion, durable materials, seamless integration, adjustable design | Prevents thermal damage, flexible in temperature variations, extends system life |

| Cable Tray Adjustable Splice Plate | Angle flexibility, high-strength materials, easy to install, corrosion resistance (optional) | Customizable layouts, cost-effective, enhances safety, supports future upgrades |

| Cable Tray Hinged Splice Plate | Hinged design, secure locking, durable construction, corrosion-resistant options | Quick access for maintenance, reduces downtime, simplifies installation, ensures safety |

| Exterior Non-Metallic Cable Tray | Non-metallic material, UV-stable, impact and corrosion resistant, lightweight | Ideal for harsh environments, low maintenance, long-lasting, easy handling |

Benefits of Using B Line Cable Tray Splice Plate

FAQs about Splice Plate for Cable Tray

A splice plate for cable tray is a vital accessory used to connect two sections of a cable tray, ensuring a continuous and stable pathway for electrical cables. It is typically made from durable materials such as steel, stainless steel, or aluminum. The splice plate plays an important role in maintaining the structural integrity of the cable tray system by securing the individual tray sections together. This allows for a secure and organized method of routing cables in industrial, commercial, or residential environments. A splice plate for cable tray typically has pre-drilled holes to facilitate easy attachment with screws or bolts, ensuring a tight and stable connection between the sections. These plates come in different sizes and materials to suit different cable tray systems, making them adaptable for various installation needs. In addition to their primary function, splice plates help protect the cables from external forces, reducing the risk of damage due to tray movement or shifting.

While cable trays are designed to route and support electrical wiring, it is not recommended to splice wires directly within the tray. Splicing wires typically involves joining two or more electrical conductors together, which requires proper techniques and the use of specific junction boxes, connectors, or other approved methods. Cable trays, including splice plates for cable tray, are primarily intended to protect and support cables while maintaining their organized layout, not to serve as a point for electrical connections or splicing. When splicing wires, it is essential to follow safety codes and regulations that apply to your specific location. These codes are designed to minimize the risk of short circuits, fire hazards, or electrical failures. If splicing is necessary, always use appropriate tools and enclosures designed for the purpose. Installing a splice box, for example, allows the spliced wires to be housed safely while keeping them separated from the other cables in the tray.

A splice plate is a hardware component used to connect two sections of cable trays, ensuring a stable and continuous pathway for cables. It is typically made of materials such as steel, stainless steel, aluminum, or fiberglass, depending on the installation environment and specific needs. The primary purpose of a splice plate is to join different sections of a cable tray together securely, preventing disconnection and maintaining the structural integrity of the system. These plates are especially crucial in large-scale installations where multiple tray sections are required to form an expansive system. Splice plates often feature pre-drilled holes that allow for easy installation with fasteners such as bolts or screws. Some splice plates are designed for flexibility, allowing for adjustments in angles or lengths. Depending on the system requirements, they come in different types, including straight, adjustable, or hinged splice plates, each serving different purposes in complex cable tray installations.

Yes, cable trays need to be bonded to ensure electrical safety and prevent hazards such as electric shocks or fires. Bonding refers to the process of connecting the metallic parts of the tray system to the building’s grounding system, creating a safe path for stray electrical currents or faults to travel to the ground. This is especially important in industrial or commercial settings where large electrical systems are used, and the cable tray could potentially carry live electrical cables. Proper bonding helps to eliminate any potential differences in electrical potential between the cable tray and the surrounding environment, which could lead to dangerous electrical faults. Electrical codes, such as the National Electrical Code (NEC) in the U.S., require cable trays to be bonded in specific ways, depending on their location, purpose, and the types of cables being supported. Failure to properly bond a cable tray could lead to dangerous situations like electrical shock or fire risks. Bonding should be done by professionals who understand the specific requirements of the electrical system in place.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.