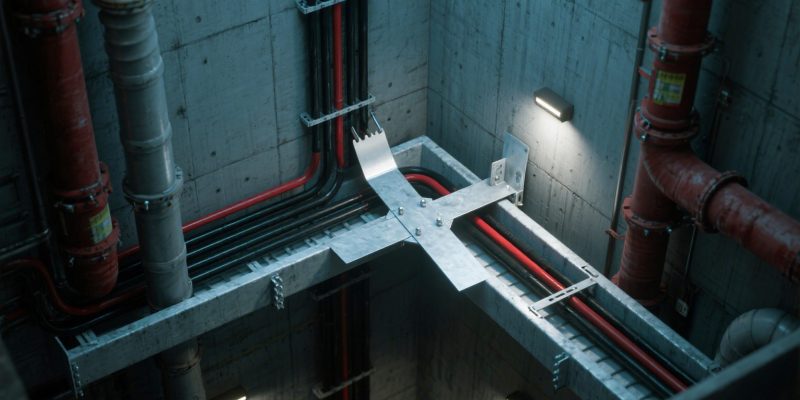

Bonding jumpers for cable tray are essential electrical conductors that create a secure, continuous grounding path between different sections of a cable tray system. They help protect against electrical hazards such as shocks and equipment damage by allowing fault currents to safely flow to ground. Aluminum bonding jumper for cable tray ensures secure electrical bonds between sections, available in steel or stainless steel finishes. In industrial and commercial settings—such as power plants, data centers, and manufacturing facilities—these jumpers are critical for maintaining electrical continuity, reducing electromagnetic interference (EMI), and complying with grounding standards. They play a vital role in stabilizing voltage levels and enhancing the overall safety and performance of complex electrical networks.

What is Bonding Jumper for Cable Tray

A bonding jumper for cable tray is a length of conductive material—typically tinned copper, aluminum, or stainless steel—used to electrically connect separate sections of a cable tray system to the facility’s grounding network. Its main purposes are to:

- Maintain electrical continuity between tray sections and any connected metal components (e.g., conduits or racks).

- Provide a low-resistance path for fault currents to safely return to ground, reducing the risk of shock, fire, or equipment damage.

- Prevent ground loops and suppress electromagnetic interference (EMI) by keeping all tray parts at the same electrical potential.

Key Features of Bonding Jumpers for Cable Tray

Bonding jumper for cable tray combine electrical performance, durability, and compliance. Supplied on reels for fast deployment, they simplify installation and maintenance while ensuring continuous grounding and EMI suppression under harsh conditions.

High Conductivity Materials

Constructed from tinned copper, aluminum, or stainless steel, these bonding jumpers offer excellent electrical conductivity and minimal voltage drop. By providing a low-resistance path, they enable rapid dissipation of fault currents and prevent arc faults. Installers can select appropriate conductor gauges to match expected fault-current capacity, ensuring compliance with NEC and IEC requirements and improving overall personnel and equipment safety.

Corrosion Resistance

Corrosion resistance is achieved through tin plating, passivation, or stainless steel construction, protecting bonding jumpers against moisture, chemicals, and salt spray. These finishes prevent oxidation at terminations and maintain reliable electrical contact. Extended service life results from resisting environmental degradation in outdoor, and coastal installations, reducing maintenance frequency and ensuring consistent grounding performance under harsh conditions in heavy industrial environments.

Mechanical Durability

Braided or stranded constructions resist vibration and thermal cycling without cracking or fatigue. Reinforced lugs and heavy-duty terminations maintain secure connections under dynamic loads. These durable bonding jumpers ensure grounding integrity in seismic zones, machinery rooms, and environments. Their robust design prevents loosening or breakage that could compromise safety, minimizing maintenance and supporting uninterrupted electrical continuity across cable tray systems.

Flexibility and Vibration Tolerance

Flexible braid and stranded-wire designs accommodate structural movement, thermal expansion, and constant vibration without fatigue or failure. Supplied on reels, they can be cut to precise lengths for custom installations. This elasticity prevents stress concentrations, maintaining conductor integrity and secure connections. Ideal for mobile equipment, conveyor systems, and aircraft applications, these jumpers ensure uninterrupted grounding even under dynamic operational conditions.

EMI Mitigation

By providing a continuous low-impedance path, bonding jumpers suppress electromagnetic interference in cable trays and enclosures. This shielding effect prevents loops that radiate or pick up noise, protecting sensitive electronics and communication systems. Reduced EMI leads to clearer signals, fewer data errors, and improved equipment performance. Effective interference suppression minimizes troubleshooting time and enhances reliability in high-frequency or high-power installations.

Standardized Sizing and Mounting

Available in various conductor gauges and lengths, bonding jumpers on reels meet NEC and IEC fault-current requirements. Universal mounting hardware—clamps, lugs, and busbar adapters—ensures code-compliant installation across diverse cable tray profile and conduit sizes. Clearly marked gauge, length, and material simplify selection and reduce errors. This standardization speeds deployment, streamlines inspections, and guarantees reliable grounding performance in heavy-duty applications and settings.

Bonding Jumper for Cable Tray Size

Factors Influencing Jumper Size

Selecting the right bonding jumper for cable tray is a critical decision to ensure the safe and reliable operation of an electrical system. Several key factors influence the size of the jumper, starting with the current rating of the system. The jumper must be able to handle the fault current expected in the system without overheating or becoming a weak point that could cause failure. Another important consideration is the number of cables running through the tray. More cables or larger cables increase the need for a larger jumper to maintain electrical continuity and grounding.

Environmental conditions also play a significant role in determining jumper size. For example, in locations where high humidity or corrosive elements like saltwater are present, the jumper material might need to be upgraded to a corrosion-resistant alloy, such as tinned copper or stainless steel. Temperature extremes can affect the performance of the bonding jumper, requiring the use of materials that can withstand heat or cold without compromising their effectiveness. Additionally, the physical dimensions of the tray, such as length and the number of tray sections, also influence jumper size—longer trays or those with multiple sections will require a jumper that can span these distances without excessive voltage drop. This is particularly important when you build cable trays, as proper jumper selection ensures safe and efficient operation for the entire system.

Common Cable Tray Bonding Jumper Sizes

The most common bonding jumper for cable tray sizes are 2 AWG and 4 AWG, typically used in medium- to low-voltage systems. These sizes are suitable for most general applications, providing enough current-carrying capacity while remaining flexible for installation. However, in systems that handle high electrical loads, such as those found in data centers, power plants, or industrial manufacturing facilities, larger jumpers like 6 AWG or even 8 AWG may be required. These larger sizes are designed to handle increased fault currents, ensuring the system remains stable and that jumpers do not overheat.

In high-power applications, tinned copper or aluminum conductors may be used for jumpers, depending on the system’s needs. Tinned copper is often preferred for its corrosion resistance, making it ideal for outdoor or harsh environments, while aluminum is a more cost-effective alternative, particularly for larger-scale systems. As the power demand increases, so does the need for larger jumpers, ensuring they can safely carry the fault currents without degradation.

Bonding Jumper Size Chart

A cable tray bonding jumper size chart typically provides detailed recommendations based on the system’s electrical rating and tray dimensions. For example, a 2 AWG jumper is typically suitable for lower-current applications or shorter distances between trays and ground points. For systems with higher fault currents or where the jumper must span longer distances, 4 AWG or even 6 AWG jumpers are recommended.

- 2 AWG: Suitable for small to medium-scale systems where fault currents are moderate and the tray is not excessively large.

- 4 AWG: Ideal for medium to large systems, particularly in industrial or commercial environments where fault currents are higher or tray lengths are longer.

- 6 AWG: Recommended for high-power systems, such as data centers and power plants, that require a larger jumper to handle significant fault currents and larger trays.

- 8 AWG and above: Typically used for systems with extremely high fault current potential or very long cable tray runs.

The size chart would also take into account the material of the jumper (whether copper or aluminum) and environmental conditions, such as whether the tray is located indoors or outdoors, in dry or corrosive environments, or exposed to extreme temperatures. Selecting the proper jumper size and material is essential for system safety, grounding efficiency, and maintaining electrical integrity throughout the cable tray system.

Key Steps for Regular Cable Tray Inspection Success

Applications of Bonding Jumper for Cable Tray in Industrial Settings

Bonding jumper for cable tray systems ensure consistent grounding and electrical continuity in critical industrial environments. In settings like power plants, data centers, telecommunications facilities, and manufacturing plants, they mitigate fault currents, prevent hazards, and support reliable, uninterrupted operations.

Power Plants

In power plants, bonding jumpers ensure uniform electrical potential across high-voltage cable tray and conduit, preventing harmful voltage differentials that could trigger sparks, fires, or equipment failure. By maintaining consistent grounding, these jumpers protect critical power generation infrastructure, safeguard personnel, and sustain uninterrupted energy transmission. Their design and installation according to code requirements underpin the stability and safety of plant operations.

Data Centers

In data centers, bonding jumpers preserve electrical integrity for sensitive IT systems. Grounding server racks, network switches, and cable trays prevents static buildup, electrical faults, and electromagnetic interference. Consistent grounding reduces downtime, protects hardware from damage, and ensures reliable data processing and transmission. Proper installation and maintenance of jumpers support uninterrupted operations and regulatory compliance.

Telecommunications Facilities

Telecommunications facilities demand uninterrupted service, making bonding jumpers indispensable for grounding cable trays and equipment. Proper bonding prevents electrical surges and faults from disrupting communication lines or damaging hardware. By providing a continuous low-resistance path to ground, jumpers enhance signal integrity, reduce downtime, and protect against transient events. Regular inspection and adherence to grounding standards ensure stable operation and safeguard both infrastructure and personnel.

Manufacturing Plants

In manufacturing plants, complex electrical networks feed power to heavy machinery and automated systems via cable trays. Bonding jumpers provide essential grounding, maintaining uniform potential across tray sections and conduits. This prevents equipment malfunctions, electrical shocks, and potential fires. Consistent grounding also minimizes electromagnetic interference, improving production quality. Routine testing and maintenance of bonding jumpers ensure long-term safety, equipment reliability, and smooth manufacturing operations.

Requirements for Bonding Jumper in Cable Tray

NEC (National Electrical Code) Standards

The bonding jumper for cable tray is essential for the safe and reliable operation of electrical systems, as it ensures a continuous grounding path in the event of a fault. According to the National Electrical Code (NEC), particularly Article 250, bonding jumper installations must meet specific standards covering conductor sizing, grounding electrode connections, and secure installation methods. These requirements help properly ground the entire cable tray system, allowing fault currents to safely dissipate. Adhering to NEC guidelines is critical for preventing electrical shock hazards, equipment failure, and fires, ultimately protecting both systems and personnel.

Grounding Conductors in Cable Trays

The type of cable tray being used—whether ladder trays, wire mesh trays, or solid-bottom trays—dictates the specific requirements for bonding jumpers. Each type of tray has unique physical characteristics and electrical needs, and these must be accounted for when selecting the appropriate bonding jumper for cable tray systems.

Ladder trays

These trays are typically used for larger, more complex installations, often carrying high-voltage or multi-phase cables. As a result, the cable tray grounding bonding jumper in ladder tray installations typically needs to have a higher current-carrying capacity to handle the increased fault current. The larger cables and open spaces in ladder trays may require heavier-duty bonding jumpers to maintain safe grounding and ensure electrical continuity.

Wire mesh trays

These trays are often used in environments where flexibility is important, and they tend to carry smaller cables. Bonding jumpers for wire mesh trays need to be more flexible, allowing for easy modifications and adjustments during installation. Their lower current demands generally mean that smaller gauge jumpers are sufficient for most applications.

Solid-bottom trays

Solid-bottom trays are used in situations where cable protection and heat dissipation are critical. They often require more robust bonding connections to avoid overheating, especially in high-power applications. A solid, continuous connection between the tray sections is necessary to maintain electrical continuity and reduce the risk of electromagnetic interference (EMI) or grounding faults.

Safety Considerations

The primary purpose of cable tray grounding jumpers is to ensure the safety of electrical systems, personnel, and equipment by providing a reliable path for fault currents. Improperly sized or poorly installed jumpers can lead to high-resistance connections, increasing the risk of overheating, system malfunctions, or fire. In sensitive environments like data centers, inadequate bonding can also result in electromagnetic interference (EMI), disrupting electronic equipment. To prevent these risks, bonding jumpers must be made from corrosion-resistant materials such as tinned copper or stainless steel and installed with secure, durable connections. Following NEC standards and proper grounding practices ensures a continuous, effective grounding path across all cable tray sections, enhancing both safety and system reliability.

Bonding Jumper for Cable Tray Electrical: Ensuring Effective Grounding

Function of Electrical Bonding Jumpers

The bonding jumper for cable tray ensures electrical continuity and grounding by connecting tray sections and components like metal conduits. This prevents voltage differences and provides a low-resistance path for fault currents, reducing risks such as shock, fire, or equipment damage. It also eliminates ground loops that can disrupt sensitive equipment. By meeting safety standards, bonding jumpers improve overall system reliability and electrical performance.

Preventing Grounding Errors

Improper installation or sizing of the bonding jumper for cable tray can cause grounding issues, leading to overheating, shock hazards, or equipment failure. Common problems include high resistance or incomplete grounding across tray sections. To prevent this, follow NEC standards and manufacturer guidelines, ensure proper jumper sizing, and perform regular inspections to keep connections secure and corrosion-free.

Cable Tray Bonding Jumper Price Breakdown for Different Sizes

Bonding Jumper for Cable Tray Aircraft: Special Considerations

Bonding in Sensitive Environments

In aircraft—where extreme EMI, fluctuating temperatures, and constant vibrations can undermine electrical integrity—the bonding jumper for cable tray must be engineered to endure these harsh conditions. A robust aircraft cable tray earthing jumper ensures uninterrupted electrical continuity and grounding throughout every phase of flight, from takeoff to landing, protecting against EMI-induced faults and vibration- or temperature-related disconnections. This reliable bonding system is critical to prevent electrical failures, safeguard onboard systems, and maintain overall flight safety.

Standards for Aircraft Bonding

Aviation standards like those of the FAA require aircraft cable tray bonding jumpers to endure extreme conditions without losing conductivity or durability. Tinned copper and aluminum are chosen for their corrosion resistance, thermal conductivity, and strength, keeping jumpers intact under temperature swings and vibration. Engineered to flex with structural movement while maintaining electrical continuity, these jumpers prevent grounding failures during flight. This combination of regulatory compliance, material choice, and design flexibility ensures reliable long-term grounding performance in aviation.

Importance of Grounding in Aircraft Electrical Systems

Proper grounding is critical to aircraft safety and performance. The bonding jumper for cable tray ensures that every tray section remains tied to the aircraft’s main ground, directing fault currents safely away from sensitive components. This unified grounding network minimizes electrical hazards and upholds the integrity of avionics, communications, and power systems throughout flight.

Safety Through Fault Current Management

By providing a low-resistance path to ground, bonding jumpers redirect fault currents away from critical circuitry and structure. This prevents overheating, sparks, and potential fires, protecting both passengers and equipment. In the event of a short circuit or insulation failure, the grounding system ensures that dangerous currents do not damage vital systems or compromise flight safety.

EMI Prevention for Avionics

Effective grounding suppresses electromagnetic interference (EMI) by keeping equipment at the same electrical potential. Bonding jumpers link cable trays and conduits to the aircraft’s ground, reducing noise and signal distortion in navigation, communication, and flight-control electronics. This EMI mitigation is essential for maintaining accurate sensor readings and uninterrupted data links.

Static Charge Mitigation

Aircraft accumulate static charge during flight, especially in turbulent or high-altitude conditions. Bonding jumpers safely bleed off static electricity through the grounding network, preventing voltage buildup that could lead to harmful discharges. This static control safeguards fuel systems, sensors, and personnel from unexpected shocks or ignition risks.

Enhanced System Reliability

A robust grounding scheme with properly sized and installed bonding jumpers ensures continuous electrical continuity, even under vibration and temperature fluctuations. Regular inspection and corrosion-resistant materials maintain long-term performance, reducing maintenance requirements and downtime. Reliable grounding underpins the overall stability of the aircraft’s electrical infrastructure.

Supply Side Bonding Jumper for Cable Tray

What is a Supply Side Bonding Jumper?

A supply side bonding jumper for cable tray is an essential component in electrical systems, designed to create a secure connection between the grounding electrode conductor (GEC) and the neutral or ground busbar. This jumper helps ensure that the cable tray system remains properly grounded, providing an efficient and safe path for fault currents to dissipate into the earth. By connecting the electrical system’s power source directly to the cable tray, the bonding jumper prevents dangerous ground loops, which could lead to electrical hazards or erratic behavior in electrical equipment.

In addition to ensuring safety, the supply side bonding jumper is also crucial for maintaining the overall stability of the electrical system. It ensures that the electrical tray system, and any cables running through it, are uniformly grounded, thus promoting a consistent electrical potential throughout the installation. This connection is especially vital in large-scale electrical systems such as power plants, commercial buildings, and data centers, where safe and reliable electrical grounding is imperative to system function and personnel safety.

Installation in Cable Tray Systems

When installing a supply side bonding jumper for cable tray, it is critical to follow National Electrical Code (NEC) guidelines to ensure the installation is safe, effective, and compliant. The NEC outlines specific requirements for conductor sizing, grounding electrode connections, and bonding conductor installation that must be adhered to when connecting the bonding jumper.

The jumper must be installed securely between the grounding system and the cable tray system to guarantee continuous electrical continuity and an effective fault current path. Proper installation involves selecting the correct wire gauge, securing the jumper at each point where grounding connections are made, and ensuring that all joints and connections are tight and corrosion-free. Additionally, the grounding electrode conductor should be installed in a manner that minimizes the possibility of high-resistance paths, which could impair the effectiveness of the grounding system.

Benefits of Proper Supply Side Bonding

Compliance with Safety Codes and Regulations

The bonding jumper for cable trays is essential for meeting NEC, IEC, and FAA grounding standards. It provides a low-impedance path for fault currents, satisfying conductor sizing, connection, and material requirements. Proper installation and sizing facilitate inspections and certifications, ensure uninterrupted operations in regulated industries like aerospace and healthcare, where compliance is critical for safety and uptime.

Prevents Dangerous Electrical Faults

A correctly installed supply-side bonding jumper directs fault currents safely to ground before they can cause harm. This rapid dissipation stops arc flashes, voltage surges, and ground faults by eliminating high-voltage differentials between tray sections or equipment. The result is a lower probability of fires, explosions, or catastrophic failures during both normal operation and fault conditions.

Protects Personnel and Equipment

Bonding jumpers safeguard personnel and sensitive electronics by providing a controlled path for fault currents. Personnel face lower shock risk under fault conditions, while sensitive devices—PLCs, sensors, and servers—are shielded from voltage spikes and stray currents that could corrupt data or damage components. This measure extends equipment lifespan, reduces maintenance costs, and ensures workplace safety compliance.

Ensures Proper Grounding and System Stability

Bonding jumpers tie all cable tray sections and metallic components into a unified grounding network, maintaining a consistent electrical reference for connected equipment. This uniform potential prevents floating conductors and stray currents that can disrupt power delivery or instrument accuracy. Stable grounding promotes balanced load sharing, accurate sensors, and reliable power distribution. As a result, installations experience fewer outages.

Reduces Electromagnetic Interference (EMI)

A robust bonding jumper arrangement keeps tray assemblies and enclosures at equal potential, preventing electromagnetic loops that radiate or pick up noise. This shielding effect protects communication, control, and data systems—minimizing bit-errors, signal distortion, and system malfunctions. In high-speed or high-power environments, effective EMI mitigation maintains uptime and performance, reduces troubleshooting requirements, and supports compliance with electromagnetic compatibility industry regulations.

Improves Long-Term Reliability

Well-designed bonding jumpers with corrosion-resistant materials and secure fasteners maintain grounding integrity over decades. Regular inspections detect wear, loosening, or damage before failures occur. Consistent grounding limits conductor fatigue under cyclic loads and protects insulation integrity. These practices extend service life, lower repair frequency, and support sustainable, cost-effective operations, ensuring electrical systems remain reliable and safe throughout their lifespan.

Key Applications of Bonding Jumper Cable Tray in Industry

Bonding Jumper for Cable Tray: Conduit to Cable Tray Bonding

Conduit and Cable Tray Bonding

Bonding conduit to a cable tray is crucial in electrical installations where the conduit carries power or control cables alongside the cable tray. This bonding ensures that both systems—the conduit and the cable tray—are electrically continuous. It prevents potential electrical faults from developing between the two systems, thus reducing the risk of electric shock, fire, or equipment damage. When conduit and tray systems are properly bonded, they form a unified grounding network, ensuring that all electrical components are grounded correctly. This enhances safety by maintaining a common ground potential, improving the overall reliability and operational integrity of the electrical installation.

Methods of Bonding Conduit to Tray

There are several methods available for bonding conduit to a cable tray, with the most common being the use of bonding jumpers, strap kits, and conduit clamps. A bonding jumper for cable tray is typically used to ensure both the conduit and tray share the same ground potential, thereby preventing grounding issues that could lead to electrical faults. Strap kits are flexible, easy-to-use solutions that secure the bonding jumper to both the conduit and tray. Conduit clamps, often made from metal, are another popular option to create a strong, secure connection between the conduit and the tray, enhancing the grounding system’s effectiveness. The choice of bonding method depends on various factors, including the type of tray, voltage requirements, and environmental conditions such as moisture or corrosive elements. In sensitive or high-power installations, using a combination of methods may be necessary to meet safety and performance standards.

NEC Requirements for Conduit-to-Tray Bonding

The National Electrical Code (NEC) outlines clear guidelines for bonding conduit to cable trays to ensure safety and proper grounding. According to NEC Article 250, bonding conductors must be of the correct size based on the system’s electrical load and the type of materials used. The NEC also provides specific instructions in Article 318 for installing cable trays and bonding methods that must be followed to ensure safe operation. NEC Table 250.95 specifies the conductor size for bonding, ensuring that it can handle fault currents effectively. By adhering to these standards, electrical installations can ensure that both the conduit and cable tray systems remain safely grounded and that any fault currents can be safely dissipated. Proper bonding not only ensures compliance with electrical safety codes but also protects the system from electrical failures and enhances the longevity and stability of the installation.

Inspection and Maintenance of Bonding Jumper for Cable Tray

Regular inspection and maintenance of the bonding jumper for cable tray are critical to preserving the integrity and safety of the grounding system. Environmental stressors like moisture, temperature swings, and vibration can degrade materials and connections over time. A structured program of visual checks, electrical tests, corrective maintenance, and thorough record-keeping ensures reliable grounding, minimizes downtime, and upholds compliance with industry standards.

Visual Inspections

Conduct routine visual checks for signs of wear, corrosion, or loosened terminations on bonding jumpers and attachment hardware. Focus on areas exposed to moisture, chemical splash zones, or high-vibration equipment. Early detection of physical defects—such as frayed conductors, rust, or missing fasteners—allows for prompt corrective action before resistance increases or connections fail.

Electrical Testing

Schedule periodic continuity and ground-resistance measurements using a micro-ohmmeter or earth-ground tester. Compare readings against manufacturer specifications and code requirements (e.g., NEC). Abnormally high resistance values indicate compromised conductivity, necessitating immediate repair or replacement. Consistent testing validates the low-impedance path essential for safe fault current dissipation.

Maintenance and Repairs

Follow approved procedures for cleaning, tightening, or replacing bonding jumpers and connectors. Remove surface corrosion with contact cleaners, then apply anti-corrosion compounds to protect bare metal. Replace any jumper showing material fatigue or damage, ensuring the new conductor is correctly sized and torqued per manufacturer guidelines. Proper upkeep extends service life and reduces unexpected outages.

Documentation and Record-Keeping

Maintain detailed records of all inspections, test results, repairs, and replacements. Include dates, personnel, equipment used, and measured values. A comprehensive log supports trend analysis, helps predict component lifespan, and demonstrates compliance during audits. Accurate documentation ensures accountability and aids in planning future maintenance to preserve grounding system performance.

FAQs about Bonding Jumper for Cable Tray

Yes, cable trays must be bonded to ensure proper grounding and electrical continuity throughout the system. Bonding is a critical step in any cable tray installation, as it ensures that all metallic parts of the cable tray are electrically connected and provide a path for fault currents to flow safely to the ground. This is particularly important in preventing electrical hazards, such as shock or fire, and maintaining the overall integrity of the electrical system.

The National Electrical Code (NEC) mandates that cable trays be bonded to electrical grounding systems to maintain system stability. Without proper bonding, there is a risk that the cable tray could become energized during a fault, leading to serious safety issues for personnel and equipment. Additionally, bonding helps prevent electromagnetic interference (EMI) and ensures that the electrical system operates at its optimal performance.

Bonding is typically achieved using bonding jumpers or other bonding devices that connect different tray sections together. Ensuring that all tray components are bonded correctly is a safety measure that cannot be overlooked in any electrical installation.

A bonding jumper cable is an essential component used to provide electrical continuity and a safe path for fault current between different parts of an electrical system, such as a cable tray, electrical panel, or grounding electrode. The purpose of the bonding jumper cable is to create an effective electrical connection between various metallic parts that could potentially become energized during a fault, ensuring that the entire system remains safely grounded.

Typically made from materials like copper or aluminum, bonding jumper cables are specifically designed to handle fault currents and maintain low resistance to ensure proper grounding. They are often installed in cable tray systems to connect tray sections, thus creating a continuous grounding path from one tray to the next. The bonding jumper cable must meet specific National Electrical Code (NEC) standards, which dictate its size, material, and installation methods to ensure safety.

In installations where electromagnetic interference (EMI) or ground loops might be a concern, bonding jumper cables are particularly crucial in maintaining system performance and safety. Proper installation of bonding jumper cables is essential to avoid grounding errors, electrical shocks, and equipment malfunction.

The National Electrical Code (NEC) provides comprehensive guidelines for the proper grounding and bonding of electrical systems, including cable trays. Specifically, NEC Article 250 outlines the requirements for grounding, which includes the grounding of metallic cable trays. According to NEC guidelines, cable trays need to be properly bonded and grounded to ensure that fault currents can safely flow to the ground, preventing electrical hazards such as shocks, fires, or system failures.

NEC Section 318-3 specifies that cable trays are considered part of the equipment grounding conductor (EGC) system, meaning they must be used to carry fault current. Furthermore, NEC 318-7 mandates that cable tray sections should be bonded together using bonding jumpers to maintain electrical continuity. The code also requires that cable trays be properly connected to a grounding electrode conductor (GEC).

The NEC also provides specific requirements for ground conductor sizing and ensures that the material used for bonding jumpers (typically copper or aluminum) meets certain conductivity standards. Additionally, any splices or connections within the cable tray system must be designed to maintain grounding integrity. Compliance with these standards is essential for the safe operation of electrical systems and to prevent potential hazards caused by improper grounding.

Yes, conduit needs to be bonded to cable tray systems to ensure a continuous, effective grounding path across the entire electrical installation. The purpose of bonding the conduit to the cable tray is to create a low-resistance path for fault currents, ensuring that any electrical fault in the system is safely directed to ground, which reduces the risk of electrical shock, fire, and other hazards.

According to the NEC, conduit and cable trays that are part of the same electrical system should be bonded together. This can be achieved through the use of bonding jumpers, bonding straps, or grounding clamps, which create an electrical connection between the tray and the conduit. The bonding ensures that, in the event of a fault, the electrical current can flow safely through the tray and conduit to the ground, preventing potentially dangerous situations where electrical components could become energized.

For specific moisture-laden environments or areas with corrosive conditions, special considerations might be required to ensure that the bonding remains intact and effective over time. The NEC provides guidelines for different bonding methods based on environmental factors and installation conditions. Therefore, bonding both conduit and cable trays is essential for maintaining system safety and meeting code requirements.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.